Professional Documents

Culture Documents

Consolidated Punchlist - OM - r3 - 5feb19

Consolidated Punchlist - OM - r3 - 5feb19

Uploaded by

Billy Talaugon0 ratings0% found this document useful (0 votes)

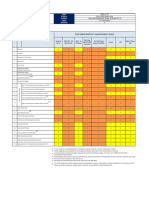

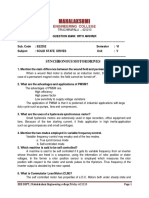

9 views2 pagesThe document contains a list of 36 items requiring action or resolution regarding a water treatment plant project. The items include providing as-built drawings, connecting equipment, supplying documentation and manuals, adding access points, developing operating procedures, and addressing issues like leaks. Most items are marked as ongoing, with a few noted as not yet addressed. Resolution steps proposed include supplying nameplates, manhole covers, spare parts, and developing maintenance plans for inclusion in operating manuals.

Original Description:

Consolidated Punchlist_OM_r3_5Feb19

Original Title

Consolidated Punchlist_OM_r3_5Feb19

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document contains a list of 36 items requiring action or resolution regarding a water treatment plant project. The items include providing as-built drawings, connecting equipment, supplying documentation and manuals, adding access points, developing operating procedures, and addressing issues like leaks. Most items are marked as ongoing, with a few noted as not yet addressed. Resolution steps proposed include supplying nameplates, manhole covers, spare parts, and developing maintenance plans for inclusion in operating manuals.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

9 views2 pagesConsolidated Punchlist - OM - r3 - 5feb19

Consolidated Punchlist - OM - r3 - 5feb19

Uploaded by

Billy TalaugonThe document contains a list of 36 items requiring action or resolution regarding a water treatment plant project. The items include providing as-built drawings, connecting equipment, supplying documentation and manuals, adding access points, developing operating procedures, and addressing issues like leaks. Most items are marked as ongoing, with a few noted as not yet addressed. Resolution steps proposed include supplying nameplates, manhole covers, spare parts, and developing maintenance plans for inclusion in operating manuals.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

Item Action Taken

Observations Classification Date Rectified Status

# Area Resolution

-On going

Item # 15 - -list of items (for Intake Gallery and Clarifier) to be

1 -As-Built Drawings B on going

Intake Gallery submitted.

-Progressive submittal

-This MCC is actually connected already to the genset

line, only the 24V supply line for ATS is not yet

Item # 16 -

2 -MCC not connected to Genset A connected. on going

Intake Gallery

NC to get supply from GenSet 24V battery Supply

Item # 30 - Provide nameplate for local control panel which On going installation. Balance for Panels not yet

3 B on going

Intake Gallery includes the description and KKS code. available

To furnish the license software for the A/B PLC and

Item # 31 -

4 workstation/HMI. Likewise, the corresponding logic and B To be provided with OM Manuals on going

Intake Gallery

graphic drawings.

Item # 34 - To furnish data/specs sheet and internal control

5 B To be provided with OM Manuals on going

Intake Gallery diagram of the MOV (motor operated valve).

To provide nameplate and complete description on

Item # 36 -

6 each instrumentation and lamp at the Control Panel B To be provided by NC on going

Intake Gallery

(Control Building) and local panel.

To provide additional LAMP test button of the Control

Item # 37 -

7 Panel (Control Building) and local panel to be able to B To be provided by NC on going

Intake Gallery

verify that LAMPS are healthy at any given time.

Item # 94 - Provide nameplate for local control panel which nameplate are provided, KKS tags are not yet

8 B on going

Clarifier includes the description and KKS code. available

Open channel suction waterways access ways /

Item # 4 -

9 manholes are not easily removed for maintenance or de- B Manhole cover will be provided per conduit not yet

Commg

silting activities

Sequence of Cleaning? Decision factor when to decide

Item # 12 -

10 cleaning. And acceptance criteria to stop when it can be B to be included in the Manual not yet

Commg

considered clean enough.

3. Manholes

a. Conduits (add easy access for each conduit)

Common Manholes will be provided:

b. Well Pits (add easy access for each 3 wells groups,

a) one per conduit

gratings are heavy to be operated by OM personnel)

Item # 15 - b) one per conduit

11 c. Water Discharge Pits (add easy access for each 3 B not yet

Commg c) no need, going down is not frequent and overhead

wells groups, gratings are heavy to be operated by OM

crane is avaialable

personnel)

d) no need.

d. FCV and Flowmeter Valve Vaults (gratings too heavy

for OM personnel to open)

Item # 16 - 4. Access for each MOVs, and manual valves, grating are

12 B manholes will be provided not yet

Commg too heavy for OM personnel to open

Item # 17 -

13 5. Manual Operation of Mud Removal system MOVs B MOVs can be operated with Allen Wrench not yet

Commg

Item # 19 - tote bin shall be provided. mud cake can be used as

14 7. Clarifier Cake Disposal B not yet

Commg backfill material for Siguil Area

initial documents shall be sent to OM based on

Item # 20 -

15 8. Send Available Documents to OM B availability. All documents shall be transmitted to OM on going

Commg

during turnover

Item # 21 - 9. Chemical Dosing Flowrate vs River Quality and Flow will be developed during commissioning and will be

16 B on going

Commg Rate Chart (Table) included in the Manual

10. Frequency of following:

a. Dredging for Intake Gallery Mouth -will be developed during commissioning and will be

Item # 22 -

17 b. Filter Press Operation B included in the Manual on going

Commg

c. Mechanical Screen Operation -item A will be provided on weather/site condition

d. Mud Removal Operation

Item # 24 - - spare nozzle will be provided by NC

18 1. Spare parts and spare parts list B on going

Commg - We need list of spares and applicable consumables

- as a compromise, we (SEC)can make the naming

Item # 25 -

19 2. KKS numbering B while NC should make nameplate and install not yet

Commg

immediately

Item # 31 - On going repair, found leak after testing, increase

20 FeCl3 Tank Leaking A on going

Commg lining and redo leak testing

Item # 34 - Chemical Mixing Bund Wall Drain and Eyewash/Shower

21 B To be done by NC not yet

Commg Drain reroute to the chemical bundwall

Item # 37 -

22 Clarifier chemical Spillage A NC to clean not yet

Commg

Item # 36 -

23 TCLP for mud cake B SEC-PMT Action not yet

Commg

Item # 38 -

24 drum pump (drum to tote bine) B SEC-PMT Action not yet

Commg

Item # 40 - canopy will be retained but separate portable A-

25 A-beam for valve vaults, remove canopy B not yet

Commg Frame will be provided

Item # 41 -

26 Repair wall penetration at Well Pit Area Partition Wall B To be done by NC not yet

Commg

Mechanical Screen Area:

Item # 42 -

27 -trash bin B not yet

Commg

-flat bin surface (or make dike)

Item # 43 - Public Safety, enclosure / fence for the mechanical screen

28 B Fence/Protection will be provided separately not yet

Commg area

Mechanical Screen Area Opening:

-cover with gratings

Item # 44 - -manhole

29 B Gratings cover will be provided not yet

Commg -ladder going down

-maintenance access for sluice gate motors and screen

motors

Junction Box at Mechanical Screen:

Item # 45 - -seal gland

30 B To be done by NC not yet

Commg -put plug on box openings

-gasket on box cover

Item # 46 -

31 Access to River Gate B Gates will be provided separately not yet

Commg

Item # 47 - Power Box (beside Intake Gallery) should be watertight,

32 B To be done by NC not yet

Commg access manhole to be provided, for housekeeping

Item # 48 -

33 PLC Tools, tag, and Name plates for the Panels B To be done by NC not yet

Commg

Item # 49 -

34 Housekeeping for intake gallery and clarifier areas A To be done by NC not yet

Commg

Item # 50 - Bund Wall below chemical transfer pump to catch spillage

35 B To be done by NC not yet

Commg below pump

Item # 51 -

36 Movable step for Bund Wall to access tote bins B To be done by NC not yet

Commg

Item # 52 -

37 FeCl3 injection port leaking A To be done by NC not yet

Commg

Item # 53 -

38 2F floor corroded. Should be cleaned and repainted B To be done by NC not yet

Commg

Item # 54 -

39 Leaking dosing line, cracks observed on PSV B To be done by NC not yet

Commg

Item # 55 - Chemical Mixing tank with many patched up holes. Not Additional lining will be done, separate plastic tank

40 A not yet

Commg Acceptable to OM will be provided as spare

Item # 56 -

41 Overhead Crane B To be done by NC not yet

Commg

Item # 57 - Bund Wall Primary Containment, not enough, should be

42 B Additional wall will be checked if can be added not yet

Commg wall. This might be reported by Govt Authorities

Item # 58 -

43 Containment for Mud Cake regardless of TCLP Results A See # 14 not yet

Commg

Item # 59 -

44 rectify corroded floors, ladders, expanded metal on clarifier B To be done by NC not yet

Commg

Item # 60 - A-Polymer tank corroded external wall due to spillage of

45 B To be done by NC not yet

Commg FeCl3

Eyeshowers:

Item # 61 -

46 -2F make it shorter, too high B To be done by NC not yet

Commg

-GF shower too far from valve

Item # 62 -

47 Sluice Gate leak testing to be demonstrated to OM A To be done by NC Done

Commg

Item # 63 - Emergency Lights for Clarifier Building, and Mud Removal

48 B To be done by NC not yet

Commg Control Room

Item # 64 -

49 FE on Mud removal bldg B To be done by NC not yet

Commg

You might also like

- TFM228N - 428 - ON - OFF - v2 - NEW - TFM228 (428) SERIES - 18 MEI 2022Document2 pagesTFM228N - 428 - ON - OFF - v2 - NEW - TFM228 (428) SERIES - 18 MEI 2022Hans MuntheNo ratings yet

- Attachment 12.7 - QA - QC Checklist - MCC & CBDocument6 pagesAttachment 12.7 - QA - QC Checklist - MCC & CBehteshamNo ratings yet

- Project Scope of WorkDocument20 pagesProject Scope of WorkAbu Muhammed KhwajaNo ratings yet

- Inca Price List 2016Document13 pagesInca Price List 2016Billy Talaugon100% (1)

- 11kV SWGR EP-MS-P4-S2-082 2013Document86 pages11kV SWGR EP-MS-P4-S2-082 2013dimaomar89% (9)

- MDB Testing & Commissioning Procedure - Method Statement HQDocument3 pagesMDB Testing & Commissioning Procedure - Method Statement HQHansika RajapakshaNo ratings yet

- ITP C 006 Concrete SlipformDocument7 pagesITP C 006 Concrete SlipformAnil Pottekkat100% (1)

- SCC PIW SD PE Taman Salmon SG BulohDocument4 pagesSCC PIW SD PE Taman Salmon SG BulohJohan RamliNo ratings yet

- QA/QC CHECKLIST: Installation of M.V SwitchgearDocument2 pagesQA/QC CHECKLIST: Installation of M.V SwitchgearehteshamNo ratings yet

- PMT Document Review Comments Sheet: Revised Relocation Plan... 21-4428-12033101, PCD-ON-PSIA-SS-0238-21Document2 pagesPMT Document Review Comments Sheet: Revised Relocation Plan... 21-4428-12033101, PCD-ON-PSIA-SS-0238-21Asif HussainNo ratings yet

- Serial No Vendor Tasks Discription Work StatusDocument1 pageSerial No Vendor Tasks Discription Work Statusashish sahaNo ratings yet

- Indra: Cabinet NameDocument1 pageIndra: Cabinet NameBoualem AisNo ratings yet

- Inspection Test PlanDocument36 pagesInspection Test PlanShahid IqbalNo ratings yet

- Alpimatic Automatic Capacitor BanksDocument14 pagesAlpimatic Automatic Capacitor BanksamdatiNo ratings yet

- BDX CGK2 Brownfield - Design Responsibility Matrix DC1D (MEP)Document1 pageBDX CGK2 Brownfield - Design Responsibility Matrix DC1D (MEP)ignasius desky p sNo ratings yet

- QA/QC CHECKLIST: Installation of Access Control SystemDocument2 pagesQA/QC CHECKLIST: Installation of Access Control SystemehteshamNo ratings yet

- Annexure-1H - I&C Scope MatrixDocument2 pagesAnnexure-1H - I&C Scope MatrixSridhar VedulaNo ratings yet

- Drawings Issued To Woongnam On Sept.13, 2012Document193 pagesDrawings Issued To Woongnam On Sept.13, 2012manoj 2011No ratings yet

- 110VAC, 120VAC,: E. or or OnDocument1 page110VAC, 120VAC,: E. or or OnnitinrajuNo ratings yet

- Dehradun NCR 1.0Document22 pagesDehradun NCR 1.0Kiran BathiniNo ratings yet

- 3.5 Network CabinetDocument1 page3.5 Network CabinetBoualem AisNo ratings yet

- QA/QC Checklist - Installation of MDB Panel BoardsDocument6 pagesQA/QC Checklist - Installation of MDB Panel Boardsehtesham100% (1)

- MS 220kVLCCPanelBCFDRD07 PDFDocument12 pagesMS 220kVLCCPanelBCFDRD07 PDFSuprodip DasNo ratings yet

- 3.1 System CabinetDocument1 page3.1 System CabinetBoualem AisNo ratings yet

- Attachment 12.4 - QA - QC Checklist - FDBDocument3 pagesAttachment 12.4 - QA - QC Checklist - FDBehteshamNo ratings yet

- Human Perfomance Enhancement System - For RCADocument4 pagesHuman Perfomance Enhancement System - For RCARagvendra BistNo ratings yet

- ProLion Presentation enDocument20 pagesProLion Presentation enSuresh KumarNo ratings yet

- BH06 Corrigendum 2 Terms Conditions-38Document1 pageBH06 Corrigendum 2 Terms Conditions-38GreenNo ratings yet

- Electrical Work Status CommissioningDocument2 pagesElectrical Work Status CommissioningManish KaushikNo ratings yet

- Baa-3 30 07 2020Document2 pagesBaa-3 30 07 2020elitebaluNo ratings yet

- Baa-3 30 07 2020Document2 pagesBaa-3 30 07 2020elitebaluNo ratings yet

- Description of Problem Action Owner Action Owner Status Closed Date Remarks Defect List ReferenceDocument2 pagesDescription of Problem Action Owner Action Owner Status Closed Date Remarks Defect List ReferenceelitebaluNo ratings yet

- 20-Apr-2022 Parcel 1 Acs Submittal Rev02Document64 pages20-Apr-2022 Parcel 1 Acs Submittal Rev02mdabdulhadi88No ratings yet

- Bulk Carrier Internal AuditDocument7 pagesBulk Carrier Internal AuditAnurag JhaNo ratings yet

- ELECT-TIC-4.2-Low Voltage Distribution Panel & Accessories - Installation & Identification Final Visual InspectionDocument2 pagesELECT-TIC-4.2-Low Voltage Distribution Panel & Accessories - Installation & Identification Final Visual InspectionMuhammad IrfanNo ratings yet

- PV Genset Controller RFQ-Abbott Lab Phase IVDocument1 pagePV Genset Controller RFQ-Abbott Lab Phase IVadnan551978No ratings yet

- Scope Matrix For 230kv Hybrid SubstationDocument2 pagesScope Matrix For 230kv Hybrid SubstationDe Selva ArokiarajNo ratings yet

- Reinstating of Sea Water Cooling Phase Ii: Manpower LoadingDocument10 pagesReinstating of Sea Water Cooling Phase Ii: Manpower LoadingShams TabrezNo ratings yet

- Process Piping Upgradation: Line Areas Criticality Oct Nov Dec Jan Feb Status B B A A B B B A A B B B ADocument5 pagesProcess Piping Upgradation: Line Areas Criticality Oct Nov Dec Jan Feb Status B B A A B B B A A B B B Abilal haiderNo ratings yet

- Modification Procedure of PV Inverter Enersolis Series V1.2Document8 pagesModification Procedure of PV Inverter Enersolis Series V1.2Valdas GaidysNo ratings yet

- Book 2Document11 pagesBook 2akmal sorryNo ratings yet

- CAAB Findings (Need To Solve Before Commissioning)Document1 pageCAAB Findings (Need To Solve Before Commissioning)Mehedi HasanNo ratings yet

- Robonet Eng V2Document12 pagesRobonet Eng V2EstebanNo ratings yet

- Addendum 5f645ea2c19fdDocument7 pagesAddendum 5f645ea2c19fdsaadNo ratings yet

- M7635C - 7608 - 7612 QigDocument2 pagesM7635C - 7608 - 7612 QigVictor BitarNo ratings yet

- Design Requirements Drawing Following Major: StageDocument1 pageDesign Requirements Drawing Following Major: StagenitinrajuNo ratings yet

- Attachment 12.5 - QA - QC Checklist - SMDBDocument6 pagesAttachment 12.5 - QA - QC Checklist - SMDBehteshamNo ratings yet

- CRS Rev.0ADocument1 pageCRS Rev.0ANob Odyk NowsNo ratings yet

- Comments Sheet ENC BLD ACIDSDocument4 pagesComments Sheet ENC BLD ACIDSajay booraNo ratings yet

- Project: Cgk-064 Electrical Power Discrimination Study by Using Etap SoftwareDocument2,948 pagesProject: Cgk-064 Electrical Power Discrimination Study by Using Etap SoftwareDanang Tri PermadiNo ratings yet

- Construction Electrical Boq NewDocument7 pagesConstruction Electrical Boq Newmudassir mNo ratings yet

- MC34152, MC33152, NCV33152 High Speed Dual MOSFET Drivers: PDIP 8 P Suffix CASE 626Document12 pagesMC34152, MC33152, NCV33152 High Speed Dual MOSFET Drivers: PDIP 8 P Suffix CASE 626Diego AlejandroNo ratings yet

- Lapsefedi-ClarificationNo2 PDFDocument62 pagesLapsefedi-ClarificationNo2 PDFrojeshNo ratings yet

- T309 JHZH Let PWD Qua 0453 PDFDocument559 pagesT309 JHZH Let PWD Qua 0453 PDFMark Anthony MaulitNo ratings yet

- Installation Manual DPC-411 CabinetsDocument16 pagesInstallation Manual DPC-411 CabinetsalternativblueNo ratings yet

- Columbia Basin Trust - SheltersDocument4 pagesColumbia Basin Trust - Sheltersgrantday2000No ratings yet

- CHP Area WorksDocument9 pagesCHP Area Worksmani sharmaNo ratings yet

- Ghazni Substation NotesDocument1 pageGhazni Substation NotesYahya DarNo ratings yet

- Weekly HSSE Protect Status Report - October 13 2019-1Document1 pageWeekly HSSE Protect Status Report - October 13 2019-1richard.nclex2022No ratings yet

- Qic-Qsp-Uni-Tdr-Cl-0417 (B) (3) Rev001Document3 pagesQic-Qsp-Uni-Tdr-Cl-0417 (B) (3) Rev001Ragab EisaNo ratings yet

- BST-GEN-CRR-DTL-AIP-10018-10015-00 - K01 - General Arrangement and Installation Drawing - CP Controller (24V15A) & Solar Panel Power SystemDocument5 pagesBST-GEN-CRR-DTL-AIP-10018-10015-00 - K01 - General Arrangement and Installation Drawing - CP Controller (24V15A) & Solar Panel Power SystemRao DharmaNo ratings yet

- Token Ring Technology ReportFrom EverandToken Ring Technology ReportNo ratings yet

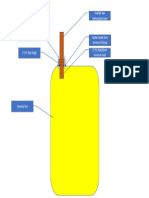

- Pipe Penetration To TankDocument1 pagePipe Penetration To TankBilly TalaugonNo ratings yet

- Car Plan AssignmentDocument4 pagesCar Plan AssignmentBilly TalaugonNo ratings yet

- Building Condition Assessment A Comprehensive Approach in Energy and Facility ManagementDocument56 pagesBuilding Condition Assessment A Comprehensive Approach in Energy and Facility ManagementBilly TalaugonNo ratings yet

- Job Hazard Analysis: Task or Step Hazards Controls Personal Protective Equipment (PPE)Document2 pagesJob Hazard Analysis: Task or Step Hazards Controls Personal Protective Equipment (PPE)Billy TalaugonNo ratings yet

- Job Hazard Analysis: Job/Activity: Installation/ Department or Location: FACDocument2 pagesJob Hazard Analysis: Job/Activity: Installation/ Department or Location: FACBilly TalaugonNo ratings yet

- Job Hazard Analysis: Job/Activity: Pest Control Application Department or Location: FAC/PLANT WIDEDocument2 pagesJob Hazard Analysis: Job/Activity: Pest Control Application Department or Location: FAC/PLANT WIDEBilly TalaugonNo ratings yet

- Design Parameters For 20cumDocument2 pagesDesign Parameters For 20cumBilly TalaugonNo ratings yet

- Job Hazard Analysis: Task or Step Hazards Controls Personal Protective Equipment (PPE)Document2 pagesJob Hazard Analysis: Task or Step Hazards Controls Personal Protective Equipment (PPE)Billy TalaugonNo ratings yet

- HttpsDocument2 pagesHttpsBilly TalaugonNo ratings yet

- M.T. Ang: This SiteDocument44 pagesM.T. Ang: This SiteBilly Talaugon100% (1)

- 20m3 Polythene Vertical White Water Tank Details - ProductDocument1 page20m3 Polythene Vertical White Water Tank Details - ProductBilly TalaugonNo ratings yet

- Sikad Polomolok: Bike PartsDocument17 pagesSikad Polomolok: Bike PartsBilly TalaugonNo ratings yet

- Front-Loading Automatic Washer: Product Model Numbers Overall Dimensions WFW9550WDocument1 pageFront-Loading Automatic Washer: Product Model Numbers Overall Dimensions WFW9550WBilly TalaugonNo ratings yet

- Design Inputs: Tank ParameterDocument10 pagesDesign Inputs: Tank ParameterBilly TalaugonNo ratings yet

- 10m3 Polythene Vertical Water Tank DetailsDocument1 page10m3 Polythene Vertical Water Tank DetailsBilly TalaugonNo ratings yet

- Signages For Port Operations - Rev 3Document6 pagesSignages For Port Operations - Rev 3Billy TalaugonNo ratings yet

- FAC Maintenance Log 2022 - GMDocument7 pagesFAC Maintenance Log 2022 - GMBilly TalaugonNo ratings yet

- E.traverse ProcedureDocument5 pagesE.traverse ProcedureBilly TalaugonNo ratings yet

- FG Ec en LSZH v1.4.1Document2 pagesFG Ec en LSZH v1.4.1Hadi Aja Panggil GueNo ratings yet

- FILE - 20220221 - 070144 - TBHK & DĐB - Lesson 1Document13 pagesFILE - 20220221 - 070144 - TBHK & DĐB - Lesson 1LONG HUYNH HOANGNo ratings yet

- Using Petrol-Driven Chainsaws: FISA Safety Guide 301Document2 pagesUsing Petrol-Driven Chainsaws: FISA Safety Guide 301Garden GrillNo ratings yet

- Assembly Instruction Safe Click enDocument8 pagesAssembly Instruction Safe Click enTr3mbl3No ratings yet

- Soeg RT m18 Ps K GBDocument5 pagesSoeg RT m18 Ps K GBabrap_dNo ratings yet

- Comparacion Entre MultimetrosDocument1 pageComparacion Entre MultimetrosEnrique GalindoNo ratings yet

- Terminal Blocks: KasugaDocument6 pagesTerminal Blocks: KasugaKs MuraliNo ratings yet

- Diagrama Electrico C-12 (9SM)Document2 pagesDiagrama Electrico C-12 (9SM)luis alberto100% (1)

- EN Operating Instructions TLS - v1Document9 pagesEN Operating Instructions TLS - v1martinNo ratings yet

- RENR81310001Document11 pagesRENR81310001Guido VillafuerteNo ratings yet

- 30 AWG Cable DATA SheetDocument2 pages30 AWG Cable DATA SheetTuýp Phờ NờNo ratings yet

- CH-SW240/2030S/D200AS: Product Data SheetDocument4 pagesCH-SW240/2030S/D200AS: Product Data Sheeticaro89No ratings yet

- Quick Guide Erbecryo 2: Necessary Operating StepsDocument2 pagesQuick Guide Erbecryo 2: Necessary Operating StepsVu HieuNo ratings yet

- OptimusDocument53 pagesOptimusMahmoud TabakhNo ratings yet

- System Unit-The Main Part of A Microcomputer, Sometimes Called The Chassis. ItDocument15 pagesSystem Unit-The Main Part of A Microcomputer, Sometimes Called The Chassis. ItJay Ann GonzagaNo ratings yet

- CelLink 16x2 (34) ManualDocument264 pagesCelLink 16x2 (34) ManualRecios Eca CerenNo ratings yet

- Pop-Up SystemDocument4 pagesPop-Up Systemkothat82No ratings yet

- Assembling 4WD Transfer CaseDocument10 pagesAssembling 4WD Transfer CaseTheKillerlvl900No ratings yet

- SpecificationsDocument3 pagesSpecificationsvenkat0236No ratings yet

- Relay Device No.Document6 pagesRelay Device No.Omid TajikNo ratings yet

- UNIT 5 Synchronous MotorDocument17 pagesUNIT 5 Synchronous Motorruchita dahadNo ratings yet

- Ritter m9 UltraclaveDocument1 pageRitter m9 Ultraclaveelectronico1000No ratings yet

- Design Features Puffer Interrupters: Contact PartingDocument1 pageDesign Features Puffer Interrupters: Contact PartingDoan Anh TuanNo ratings yet

- Mankenberg VV34,35,36Document2 pagesMankenberg VV34,35,36satphoenixNo ratings yet

- PhoenexDocument8 pagesPhoenexSebastián LagosNo ratings yet

- Flow Control Valves: 1 DescriptionDocument6 pagesFlow Control Valves: 1 Descriptionnotitle91No ratings yet

- t80931 Datasheet - enDocument8 pagest80931 Datasheet - enait oubella marouaneNo ratings yet

- Wheel Load Data R1Document1 pageWheel Load Data R1Jebin JacobNo ratings yet

- CAT - SIEMENS - LV-Power Distribution and Electrical Installation TechnologyDocument1,108 pagesCAT - SIEMENS - LV-Power Distribution and Electrical Installation TechnologymarcosNo ratings yet