Professional Documents

Culture Documents

Filter Media & Back Fill

Filter Media & Back Fill

Uploaded by

Murthy BabuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Filter Media & Back Fill

Filter Media & Back Fill

Uploaded by

Murthy BabuCopyright:

Available Formats

METHODOLOGY FOR CONSTRUCTION OF

FILTER MEDIA & BACK FILLING BEHIND

THE STRUCTURES.

-1- Filter Media & Back Fill Methodology

Methodology for Construction of Filter Media & Backfilling

behind the Structures.

1.1 General

1.1.1 Purpose / aim of the Method Statement submission:

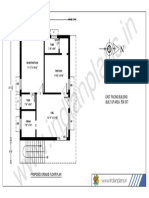

Construction of Filter Media and Backfilling behind the Abutments, Wing Walls, Retaining

Walls and Return Walls as shown in the drawing.

1.1.2 Scope of the Method of Statement:

This work consists of covering the Filter Media and Backfilling beyond the structures.

1.1.3 Reference to other controlling documents where appropriate:

As per the contract drawings and technical specification Clause No: 2500 and Clause

No:300,

1.2 Temporary Works

Safety works i.e. traffic regulation will be taken where ever necessary while unloading of

filter material and Backfilling material.

1.3 Surveys

The slope of the embankment will be checked as per drawing by supervision staff before

laying of filter media and Backfilling material.

1.4 Traffic Arrangements

Required manpower and display boards will be placed to regulate the flow of traffic with

out causing any congestion or stagnation.

1.5 Materials

1.5.1 Filter Media Material: The Filter Media materials will coarse sand and it will prevent

escape of the embankment material through the voids of the Filter Media and as well as

to allow free movement of water without creating any uplift head. The material should

fulfill the requirements as per MOSRTH, Clause No: 309.3.2.

Our Filter Media Material fulfill the requirements with the blending of 40mm Aggregates

– 30%, 20mm Aggregates – 30%, 10mm Aggregates – 40%

(Design Blend enclosed).

1.5.2 Backfill Material: The backfill material will be done with approved borrow material as

per IRC:78-2000, Appendix-6, Table-1.

-2- Filter Media & Back Fill Methodology

1.5.3 Acceptance Criteria: The gradation of the Filter Media Material will be satisfy the

following requirements.

a) D15 (Filter) < 5

D85 (Base)

b) 4 < D15 (Filter) < 20

D15 (Base)

c) D50 (Filter) < 25

D50 (Base)

1.6 Work Sequence Programme

Checking of embankment slope as per drawing

Transport and unloading of Filter Material & Boulders / Stones

Removal of unwanted material from the slopes of Embankment (if any)

Laying of Filter media as per drawing

Backfilling Behind the filter media (Max. 200mm compacted thick)

Compaction of Filter media & Backfill in single operation

1.7 Plants & Equipments

Tippers, water tanker, Vibratory roller / Mechanical tamper / Plate vibrator

-3- Filter Media & Back Fill Methodology

1.8 Work Methodology

The extent of backfill to be provided behind the abutment as in the drawing.

Laying of Filter Media Material and Backfill material will starts from the sill level

simultaneously with the 600 mm thickness as per the following manner.

1.8.1 Provide the wire mesh / Geotextile membrane at the weep holes location and then place

the Bigger size material i.e. more than 100 mm boulders packed to a thickness of 300

mm towards the wall and balance 300 mm thickness will be packed with blended filter

media material as per the design and laid the backfill material behind the filter media

material simultaneously. The entire operation will be done with single operation with the

compacted thickness of 150mm (Maximum) with 95% compaction.

1.9 Measurement for Payment

The Backfill and filter media will be measured separately in cum.

-4- Filter Media & Back Fill Methodology

You might also like

- PM IS 458-April 2021Document10 pagesPM IS 458-April 2021sandiip.patilNo ratings yet

- Foam 12 BUILDING COMPLETION NOTICEDocument3 pagesFoam 12 BUILDING COMPLETION NOTICEMurthy BabuNo ratings yet

- Test Certificate: Chettinad Cement Corporation PVT LTDDocument1 pageTest Certificate: Chettinad Cement Corporation PVT LTDChander BauraNo ratings yet

- QAP For Bitumen JobDocument2 pagesQAP For Bitumen JobSasanka SekharNo ratings yet

- Method StatementDocument3 pagesMethod StatementmemekenyaNo ratings yet

- Partnership Formation Activity 2Document4 pagesPartnership Formation Activity 2Shaira Untalan100% (1)

- Final Project Report On Investment BankingDocument26 pagesFinal Project Report On Investment BankingSophia Ali78% (9)

- License KeyDocument1 pageLicense KeyLolobau50% (10)

- Sec 400 (Most Version)Document37 pagesSec 400 (Most Version)abhijit_xpNo ratings yet

- Brick Test FormateDocument3 pagesBrick Test FormateVarun SharmaNo ratings yet

- Amendment No. 3 March 2017 TO Is 1786: 2008 High Strength Deformed Bars and Wires For Concrete Reinforcement - SpecificationDocument3 pagesAmendment No. 3 March 2017 TO Is 1786: 2008 High Strength Deformed Bars and Wires For Concrete Reinforcement - Specificationraviteja036No ratings yet

- Granular Sub-Base: Salient Features 2.1 MethodologyDocument2 pagesGranular Sub-Base: Salient Features 2.1 Methodologyvijay kumarNo ratings yet

- Filter Media SpecificationsDocument1 pageFilter Media SpecificationsVarshil Parikh100% (1)

- Specific Gravity of Filler: Determination Trial No AverageDocument1 pageSpecific Gravity of Filler: Determination Trial No AveragePrasanna S KulkarniNo ratings yet

- Letter To Highway Colleagues in India On Use of "Third Class" Bitumen Emulsion For Prime CoatDocument4 pagesLetter To Highway Colleagues in India On Use of "Third Class" Bitumen Emulsion For Prime CoatProf. Prithvi Singh Kandhal100% (1)

- Is 1195-1978 Specification For Bitumen Mastic For FlooringDocument20 pagesIs 1195-1978 Specification For Bitumen Mastic For FlooringVijayakrishna Singamsetti100% (1)

- Irc 097-1987Document10 pagesIrc 097-1987kruttika_apNo ratings yet

- Is 15388 (2003) - Specification For Silica FumeDocument13 pagesIs 15388 (2003) - Specification For Silica FumeN GANESAMOORTHYNo ratings yet

- Is 16651-2017Document18 pagesIs 16651-2017Assistant Coordinator Business DevelopmentNo ratings yet

- Is 6006Document19 pagesIs 6006Sathish KumarNo ratings yet

- Ultratech Cement LTD.: Concrete Mix Design Data For M-10Document2 pagesUltratech Cement LTD.: Concrete Mix Design Data For M-10Laxmi Kant PradhanNo ratings yet

- TDS - Polyalk CP 293+Document1 pageTDS - Polyalk CP 293+Anonymous ouZFaSBRNo ratings yet

- MBIU Report Gorakhpur BypassDocument167 pagesMBIU Report Gorakhpur BypassRaghav SharmaNo ratings yet

- Is 3117Document17 pagesIs 3117Amit Prasad100% (1)

- Bridge Design Format For Rural Road NQM Project AssamDocument35 pagesBridge Design Format For Rural Road NQM Project Assamarif ahmedNo ratings yet

- Is 4990 2011 PDFDocument20 pagesIs 4990 2011 PDFPratik DiyoraNo ratings yet

- 2721 Chain LinkDocument8 pages2721 Chain LinkPankaj GargNo ratings yet

- Texture Depth Measurement: National Highways Authority of IndiaDocument1 pageTexture Depth Measurement: National Highways Authority of IndiaQuality JamNo ratings yet

- Is 2547Document11 pagesIs 2547Vivek GosaviNo ratings yet

- WMM Plant CalibrationDocument13 pagesWMM Plant CalibrationDeepakNo ratings yet

- Binding Wire Consumption As Per Is CodeDocument1 pageBinding Wire Consumption As Per Is CodeSyed ZamanNo ratings yet

- Morth DLCDocument9 pagesMorth DLCAmit AbhangNo ratings yet

- Schedule K (EPC) PDFDocument2 pagesSchedule K (EPC) PDFAkshay PendurkarNo ratings yet

- SR No Description of Material & Test Specifications Charges M.E Testing PNC Existing Rates CementDocument3 pagesSR No Description of Material & Test Specifications Charges M.E Testing PNC Existing Rates CementAtulNo ratings yet

- CC Road PDFDocument222 pagesCC Road PDFPhani PitchikaNo ratings yet

- HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH EkudDocument16 pagesHKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH EkudRajesh GangwalNo ratings yet

- Retro-Reflectivity TestDocument8 pagesRetro-Reflectivity Testjitendra100% (1)

- Pmgsy Circular About Rural Road GeometryDocument16 pagesPmgsy Circular About Rural Road Geometryprasadnn2001100% (1)

- 2386 (Part-V) PDFDocument11 pages2386 (Part-V) PDFSoundar PachiappanNo ratings yet

- GSB Trial Patch-3Document2 pagesGSB Trial Patch-3Md YasinNo ratings yet

- MTC Fosroc Auramix 400Document2 pagesMTC Fosroc Auramix 400manish upadhyay0% (1)

- 02 - Part A - Earth WorkDocument28 pages02 - Part A - Earth WorkpvsvprasadcivilNo ratings yet

- BS 1881-116-1983 - Testing Concrete Part 116 - Method For Determination of Compressive Strength of Concrete CubesDocument10 pagesBS 1881-116-1983 - Testing Concrete Part 116 - Method For Determination of Compressive Strength of Concrete CubesSarifNo ratings yet

- CALIBRATION OF HM PlantDocument3 pagesCALIBRATION OF HM PlantDeven PatleNo ratings yet

- PQC Cracks Repair 1Document3 pagesPQC Cracks Repair 1Deven PatleNo ratings yet

- Review of IS 9012:1978 Recommended Practice For Shotcreting: Recommendations For Inclusion and AmendmentDocument8 pagesReview of IS 9012:1978 Recommended Practice For Shotcreting: Recommendations For Inclusion and Amendmentgayathry100% (1)

- PQC Methodology - Nagpur MumbaiDocument14 pagesPQC Methodology - Nagpur MumbaiGanesh Kumar TulabandulaNo ratings yet

- Is 16720 Product Manual Fuel AshDocument7 pagesIs 16720 Product Manual Fuel AshKolkata PIUNo ratings yet

- IRC 8-1980 dESIGN OF KM STONE PDFDocument24 pagesIRC 8-1980 dESIGN OF KM STONE PDFvishal gupta50% (2)

- Is.2720. (CBR Field Det) PDFDocument12 pagesIs.2720. (CBR Field Det) PDFAmeen SyedNo ratings yet

- BC Gradation Test SheetDocument1 pageBC Gradation Test SheetNithin Khandesh50% (2)

- Eiffic/Efuf (T:, RFRDT (FrrtfuDocument17 pagesEiffic/Efuf (T:, RFRDT (FrrtfuRamasubba RajuNo ratings yet

- GEOTRAN FWD AnalysisDocument19 pagesGEOTRAN FWD Analysisdigvijay singhNo ratings yet

- TDS of CAC-Hyperfluid R100 PDFDocument2 pagesTDS of CAC-Hyperfluid R100 PDFPrashant MankarNo ratings yet

- Section 400 - (Granular-Sub-Base) - Finally CorrectedDocument16 pagesSection 400 - (Granular-Sub-Base) - Finally CorrectedTousifAnwar MundaragiNo ratings yet

- Is 9640 1980 SPT Sampler PDFDocument15 pagesIs 9640 1980 SPT Sampler PDFmitnathNo ratings yet

- Sector Project-Package A:Mahua-Chuwahi RoadDocument6 pagesSector Project-Package A:Mahua-Chuwahi RoadVIMAL TIWARINo ratings yet

- QAP Test Frequency CONCRETEDocument17 pagesQAP Test Frequency CONCRETEfevahe756No ratings yet

- Method of Statement Road WorkDocument10 pagesMethod of Statement Road WorkAbu NijamNo ratings yet

- 1001Document6 pages1001enterlogNo ratings yet

- Method Statement For Embankment FillingDocument9 pagesMethod Statement For Embankment Fillingdamith50% (2)

- Mos GSBDocument5 pagesMos GSBJITHESH K G GVRNo ratings yet

- Method Statement For Earth Works For A Road ProjectDocument17 pagesMethod Statement For Earth Works For A Road ProjectMkmKamilNo ratings yet

- Sieve Size in MM: Grain Size Analysis ChartDocument17 pagesSieve Size in MM: Grain Size Analysis ChartMurthy BabuNo ratings yet

- Concrete Repair-SikaDocument72 pagesConcrete Repair-SikaMurthy BabuNo ratings yet

- Material and Components, Design and Workmanship5628-3Document132 pagesMaterial and Components, Design and Workmanship5628-3Murthy BabuNo ratings yet

- FOSROC WaterproofingDocument20 pagesFOSROC WaterproofingMurthy BabuNo ratings yet

- Inaugural AddrssDocument67 pagesInaugural AddrssMurthy BabuNo ratings yet

- East 934Document1 pageEast 934Murthy BabuNo ratings yet

- Cracks and Leakages in BuildingsDocument131 pagesCracks and Leakages in BuildingsMurthy BabuNo ratings yet

- Condition MonitoringDocument30 pagesCondition MonitoringMurthy BabuNo ratings yet

- East 1224Document1 pageEast 1224Murthy BabuNo ratings yet

- 7029 - East 874Document1 page7029 - East 874Murthy BabuNo ratings yet

- GO 119 Amandment 2018MAUD - MS223Document7 pagesGO 119 Amandment 2018MAUD - MS223Murthy BabuNo ratings yet

- ZONING REGULATIONS G.O.Ms. No. 690Document12 pagesZONING REGULATIONS G.O.Ms. No. 690Murthy BabuNo ratings yet

- Rules To Be Followed As Per NBCDocument3 pagesRules To Be Followed As Per NBCMurthy BabuNo ratings yet

- IBBI Examination QuestionsDocument2 pagesIBBI Examination QuestionsMurthy BabuNo ratings yet

- School Building Valuation in Rural AreasDocument66 pagesSchool Building Valuation in Rural AreasMurthy BabuNo ratings yet

- Mort H.5TH Rev.Document903 pagesMort H.5TH Rev.Murthy Babu90% (20)

- Lecture Notes 4 Conductors: Surface Forces and CapacitanceDocument6 pagesLecture Notes 4 Conductors: Surface Forces and CapacitanceJefersonNo ratings yet

- Presidential Decree No. 603 (Child and Youth Welfare Code)Document3 pagesPresidential Decree No. 603 (Child and Youth Welfare Code)Love Bordamonte93% (14)

- 7 Depreciation, Deplbtion, Amortization, and Cash FlowDocument52 pages7 Depreciation, Deplbtion, Amortization, and Cash FlowRiswan Riswan100% (1)

- ICSE IX Maths LogarithmsDocument2 pagesICSE IX Maths LogarithmsBarnali DuttaNo ratings yet

- Tanium FedCyber Exchange 2024 Program & SpeakersDocument5 pagesTanium FedCyber Exchange 2024 Program & Speakersandrew.scottNo ratings yet

- Cyberbullying: Mark Anthony P. Poblet E Bped Ep2-1 Edjieboy Romuoldo Bped EP2-1Document16 pagesCyberbullying: Mark Anthony P. Poblet E Bped Ep2-1 Edjieboy Romuoldo Bped EP2-1Vicai GarnaceNo ratings yet

- Power Up MocoDocument7 pagesPower Up MocoParents' Coalition of Montgomery County, MarylandNo ratings yet

- Four Types of Vocation: Follow HimDocument15 pagesFour Types of Vocation: Follow HimJeanette FormenteraNo ratings yet

- Government Finance: Taxation in The United States United States Federal BudgetDocument7 pagesGovernment Finance: Taxation in The United States United States Federal BudgetKatt RinaNo ratings yet

- Table of ContentDocument14 pagesTable of ContentSaroj adityaNo ratings yet

- Accounting Research Part 1Document2 pagesAccounting Research Part 1Leonard CañamoNo ratings yet

- Terms & Conditions - Insta Jumbo Loan: Please Note ThatDocument3 pagesTerms & Conditions - Insta Jumbo Loan: Please Note ThatZaed QasmiNo ratings yet

- Business Ethics: Dr. Rajinder KaurDocument24 pagesBusiness Ethics: Dr. Rajinder KaurDeepak SarojNo ratings yet

- Barut Vs CabacunganDocument7 pagesBarut Vs CabacunganCharm Divina LascotaNo ratings yet

- NotesDocument72 pagesNotesSandeep Singh MaharNo ratings yet

- UnitedHealthCare Fillable Reconsideration FormDocument1 pageUnitedHealthCare Fillable Reconsideration FormDavid R. GonzálezNo ratings yet

- Islamic Religious StudiesDocument10 pagesIslamic Religious StudiesBockarie MarahNo ratings yet

- DR Mouli ChandraDocument1 pageDR Mouli ChandraPerumalMarimuthuNo ratings yet

- Aqa 1121 Accn1 W MS Jan 12Document11 pagesAqa 1121 Accn1 W MS Jan 12NinjehPandehNo ratings yet

- Representative Assessee - An Overview and Future OutlookDocument63 pagesRepresentative Assessee - An Overview and Future Outlookjoseph davidNo ratings yet

- Solutions 2nd Edition Advanced Classroom Activity 2dDocument4 pagesSolutions 2nd Edition Advanced Classroom Activity 2dMirkoiNo ratings yet

- The Reform Branch of The ReformationDocument2 pagesThe Reform Branch of The Reformationcristina ignacioNo ratings yet

- Jeff Pippenger - Seven Times in LeviticusDocument16 pagesJeff Pippenger - Seven Times in LeviticusKelly K.R. RossNo ratings yet

- APS Student Calendar 2022-2023: (Approved by The ABOE, 2/7/2022)Document1 pageAPS Student Calendar 2022-2023: (Approved by The ABOE, 2/7/2022)api-615878402No ratings yet

- Amc 600 Installation Instructions 4189341325 UkDocument43 pagesAmc 600 Installation Instructions 4189341325 UkSebastian VasquezNo ratings yet

- Little WingDocument1 pageLittle Wingeric.mouricNo ratings yet

- FAR Quiz 3 Biological Assets and Investments With AnswersDocument6 pagesFAR Quiz 3 Biological Assets and Investments With AnswersRezzan Joy Camara MejiaNo ratings yet