Professional Documents

Culture Documents

GT-1033-Speed Pickups & #1 Bearing Seismic Probes, Disconnection and Removal

GT-1033-Speed Pickups & #1 Bearing Seismic Probes, Disconnection and Removal

Uploaded by

Madih ElghannamCopyright:

Available Formats

You might also like

- Dry Low Nox 2.0+ System Operation: Ge Power SystemsDocument10 pagesDry Low Nox 2.0+ System Operation: Ge Power SystemsFernando Piaggio100% (2)

- GT Hot Gas Path Inspection PDFDocument1 pageGT Hot Gas Path Inspection PDFNagarajakumar D100% (1)

- IGV Commissioning For AddFem POCO+ LogicDocument17 pagesIGV Commissioning For AddFem POCO+ LogicHankar Aravins100% (4)

- Generator VOL 8ADocument18 pagesGenerator VOL 8AEmadAlhosien Alhosien100% (1)

- C7 5-16-2010 Rev-01 Commented Trips, Alarms, Events, HoldsDocument34 pagesC7 5-16-2010 Rev-01 Commented Trips, Alarms, Events, Holdsbalumuriashok100% (1)

- Ia Caterpillar Specifications 3304 VehicularEngine TextDocument100 pagesIa Caterpillar Specifications 3304 VehicularEngine Textkatarkivos94% (16)

- GT-1065 - Disconnection and Removal, #2 Bearing Area Probes and TCPLsDocument14 pagesGT-1065 - Disconnection and Removal, #2 Bearing Area Probes and TCPLsMadih ElghannamNo ratings yet

- GT-1041-Wheelspace TCPLS, Disconnection and RemovalDocument12 pagesGT-1041-Wheelspace TCPLS, Disconnection and RemovalMadih ElghannamNo ratings yet

- GT-1002-Flame Detectors and Spark Plugs, Disconnection and RemovalDocument12 pagesGT-1002-Flame Detectors and Spark Plugs, Disconnection and RemovalMadih ElghannamNo ratings yet

- 07 Uch GT 9001e - PMDocument6 pages07 Uch GT 9001e - PMHassan Mahmood100% (1)

- SGC - GT Gas Turbine HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHDocument3 pagesSGC - GT Gas Turbine HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHjeromejoe100% (2)

- Bleed Valve FunctionDocument2 pagesBleed Valve FunctionajaysapruNo ratings yet

- Why Is DLN Tuning Done in GE Gas Turbines - What Is The Purpose To Do So - QuoraDocument2 pagesWhy Is DLN Tuning Done in GE Gas Turbines - What Is The Purpose To Do So - Quoraajo zinzoNo ratings yet

- The 9F Platform - A History of Refinement - Power Engineering InternationalDocument7 pagesThe 9F Platform - A History of Refinement - Power Engineering InternationalSujeet KumarNo ratings yet

- Gek 106852aDocument10 pagesGek 106852awednetoxNo ratings yet

- POTS - 27022021 - CI and MI Scope of WorkDocument10 pagesPOTS - 27022021 - CI and MI Scope of WorkPhong leNo ratings yet

- 07 Gas Turbine Valves - 0Document14 pages07 Gas Turbine Valves - 0VILAS VIJAYAN100% (2)

- Ge Gas Turbine Frame (9fa)Document7 pagesGe Gas Turbine Frame (9fa)ajo zinzoNo ratings yet

- GE Power Systems: Description 7FH2 Generator With Static ExcitationDocument15 pagesGE Power Systems: Description 7FH2 Generator With Static ExcitationAlexferminNo ratings yet

- CIBI of GT # 5 Frame VI at IOCL VadodaraDocument3 pagesCIBI of GT # 5 Frame VI at IOCL Vadodaramahesh_rathoreNo ratings yet

- Gas Turbine ControlDocument9 pagesGas Turbine ControlHBNBILNo ratings yet

- EngDocument44 pagesEngzomglolzscribdNo ratings yet

- 3 System Process Outline - SLP R2Document56 pages3 System Process Outline - SLP R2Pirun Sirimangkalo100% (1)

- I Am Wondering If There Is Any Value To Adding Cdms To My GT With Dln. Does Anyone Have These Systems? and If So Which Ones Would You RecommendDocument11 pagesI Am Wondering If There Is Any Value To Adding Cdms To My GT With Dln. Does Anyone Have These Systems? and If So Which Ones Would You RecommendSahariar Bin ShafiqueNo ratings yet

- Gas Turbine Order Data SampleDocument13 pagesGas Turbine Order Data Samplesajjad_naghdi241100% (2)

- Performance CurvesDocument22 pagesPerformance Curvesamir moniriNo ratings yet

- Major InspectionDocument54 pagesMajor InspectionPhong leNo ratings yet

- Actividad para Plantas TérmicasDocument40 pagesActividad para Plantas Térmicaspedro peresNo ratings yet

- Gas ValveDocument9 pagesGas ValveJJNo ratings yet

- 6FA DLN 2.6 Extended Interval Combustion System - GEA17898 PDFDocument1 page6FA DLN 2.6 Extended Interval Combustion System - GEA17898 PDFLenin RamonNo ratings yet

- Cable Trays RequirementDocument1 pageCable Trays RequirementSulaiman JafferyNo ratings yet

- Psib 20150212Document10 pagesPsib 20150212Léandre Ettekri Ndri100% (1)

- TIL 2363 - IGV Inspection and Maintenance For Gear & Rack TypeDocument11 pagesTIL 2363 - IGV Inspection and Maintenance For Gear & Rack TypeBouazzaNo ratings yet

- Equipment Definition: Component LiteratureDocument5 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- DLN Controls Code Development 9fa+ EnhancedDocument28 pagesDLN Controls Code Development 9fa+ Enhancednabil160874100% (1)

- 2.3 MBJ Starting Motor SystemDocument6 pages2.3 MBJ Starting Motor SystemmiladNo ratings yet

- Dry Low NoxDocument10 pagesDry Low NoxIvan Poma Montes100% (2)

- Safety Bulletin: GE Power & Water 6B Endcover Damage PSSB 20140714A - R1 Product ServiceDocument2 pagesSafety Bulletin: GE Power & Water 6B Endcover Damage PSSB 20140714A - R1 Product ServiceLéandre Ettekri Ndri100% (1)

- Gea32081a LM6000 - Pa - Us - R1 - LRDocument1 pageGea32081a LM6000 - Pa - Us - R1 - LRErik Van GroningenNo ratings yet

- GE 6FA TurbineDocument1 pageGE 6FA TurbinehenriquezrsNo ratings yet

- Limiting The Gas Turbine Load and Operating at Base LoadDocument6 pagesLimiting The Gas Turbine Load and Operating at Base Loadramkrishna100% (2)

- Mark V Voter MismatchDocument6 pagesMark V Voter Mismatchnabil160874No ratings yet

- Gek 106844 PDFDocument10 pagesGek 106844 PDFIvan Poma MontesNo ratings yet

- المواد المرمزة والمطلوبة ترميزها بملف واحدDocument247 pagesالمواد المرمزة والمطلوبة ترميزها بملف واحدMahdi HassanNo ratings yet

- 11-Presentation MitchCohen PDFDocument32 pages11-Presentation MitchCohen PDFbigsteve9088No ratings yet

- GTDocument122 pagesGTAnand Patel100% (1)

- DLN1+ Combustion Upgrade Solution: Fact SheetDocument1 pageDLN1+ Combustion Upgrade Solution: Fact SheetAhmad Riaz Khan100% (1)

- 10-03-2008 Power in MEADocument30 pages10-03-2008 Power in MEAMohammed YusufNo ratings yet

- Igv 7eaDocument2 pagesIgv 7eaSamir Benabdallah100% (1)

- Gas Turbine Engines Characteristics and Performance Combustion ChamberDocument2 pagesGas Turbine Engines Characteristics and Performance Combustion ChamberNicolas Guatibonza L100% (1)

- GE Oil & Gas Aeroderivative Gas Turbine: Emission Reduction Techniques DLE1.0 SystemDocument46 pagesGE Oil & Gas Aeroderivative Gas Turbine: Emission Reduction Techniques DLE1.0 SystemJuan Manuel100% (2)

- 9fa ProbsDocument12 pages9fa ProbsMarbz Al MonteNo ratings yet

- 9FA Recommended Parts ListingDocument1 page9FA Recommended Parts Listingalexandr_popov_2No ratings yet

- GT Trips List Generic PDFDocument13 pagesGT Trips List Generic PDFHassanSaidi100% (1)

- Ansaldo Thomassen - CMU (2014)Document4 pagesAnsaldo Thomassen - CMU (2014)guerrezNo ratings yet

- Stage 1 Shroud For FS7001BDocument1 pageStage 1 Shroud For FS7001Bteedee1100% (1)

- Customer Course CatalogDocument119 pagesCustomer Course CatalogNguyễn Vạn ThắngNo ratings yet

- Combustion EnvelopDocument19 pagesCombustion Envelopferas_elnggar100% (1)

- GT-1064-Disconnection and Removal, #1 Bearing Area Probes and TCPLsDocument20 pagesGT-1064-Disconnection and Removal, #1 Bearing Area Probes and TCPLsMadih ElghannamNo ratings yet

- GeneratorDocument32 pagesGeneratordhammikanavaratneNo ratings yet

- Xerox: OrdinaryDocument1 pageXerox: Ordinaryvijay kumarNo ratings yet

- GT-1065 - Disconnection and Removal, #2 Bearing Area Probes and TCPLsDocument14 pagesGT-1065 - Disconnection and Removal, #2 Bearing Area Probes and TCPLsMadih ElghannamNo ratings yet

- GT-1064-Disconnection and Removal, #1 Bearing Area Probes and TCPLsDocument20 pagesGT-1064-Disconnection and Removal, #1 Bearing Area Probes and TCPLsMadih ElghannamNo ratings yet

- GT-1002-Flame Detectors and Spark Plugs, Disconnection and RemovalDocument12 pagesGT-1002-Flame Detectors and Spark Plugs, Disconnection and RemovalMadih ElghannamNo ratings yet

- GT-1041-Wheelspace TCPLS, Disconnection and RemovalDocument12 pagesGT-1041-Wheelspace TCPLS, Disconnection and RemovalMadih ElghannamNo ratings yet

- 102 00553 0619 Olin Sodium Hypochlorite ManualDocument39 pages102 00553 0619 Olin Sodium Hypochlorite ManualMadih ElghannamNo ratings yet

- HP Bypass ValvesDocument3 pagesHP Bypass ValvesMadih ElghannamNo ratings yet

- Confirmation Copybook Cursive SssDocument1 pageConfirmation Copybook Cursive SssMadih ElghannamNo ratings yet

- P1650 H1 Perkins 4016TAG1ADocument11 pagesP1650 H1 Perkins 4016TAG1AMadih ElghannamNo ratings yet

- 4016TAG1A-4016TAG2A Perkins TechexpoDocument10 pages4016TAG1A-4016TAG2A Perkins TechexpoMadih ElghannamNo ratings yet

- 4016TAG1ADocument2 pages4016TAG1AMadih ElghannamNo ratings yet

- International Journal of Impact Engineering: Ganesh Thiagarajan, Anirudha V. Kadambi, Stephen Robert, Carol F. JohnsonDocument12 pagesInternational Journal of Impact Engineering: Ganesh Thiagarajan, Anirudha V. Kadambi, Stephen Robert, Carol F. JohnsonOmer PolatNo ratings yet

- Emf Questions For AssignmentDocument7 pagesEmf Questions For AssignmentDrGopikrishna PasamNo ratings yet

- ADocument22 pagesAPrasun Kumar DasNo ratings yet

- Bezema Acrylate Styrene BasisDocument3 pagesBezema Acrylate Styrene BasisClub classic 350No ratings yet

- Geopier-Handbook FinalDocument5 pagesGeopier-Handbook Finalykp1234No ratings yet

- The Starting of Turbine Engines in HelicoptersDocument8 pagesThe Starting of Turbine Engines in HelicoptersAnonymous lEX5U51wOANo ratings yet

- Lack of PrivacyDocument3 pagesLack of PrivacyflabelNo ratings yet

- Loss of Anchorage of Miniscrews: A 3-Dimensional Assessment: Original ArticleDocument8 pagesLoss of Anchorage of Miniscrews: A 3-Dimensional Assessment: Original ArticlePrevita NindaNo ratings yet

- First Quarter-Gr4-Ww-Pt-With-Answers-KeyDocument35 pagesFirst Quarter-Gr4-Ww-Pt-With-Answers-KeyEurika LimNo ratings yet

- Notes: General Steel Fabrication Notes: Carbon Steel Fabrication Notes: Stainless Steel FabricationDocument6 pagesNotes: General Steel Fabrication Notes: Carbon Steel Fabrication Notes: Stainless Steel FabricationAquiles MartinezNo ratings yet

- Fms Belts Tech Info 316 enDocument22 pagesFms Belts Tech Info 316 encarpataniaNo ratings yet

- Price List: LTM 019A W.E.F 02.04.2022Document60 pagesPrice List: LTM 019A W.E.F 02.04.2022Ashish100% (1)

- ACSR Rail ZTTDocument6 pagesACSR Rail ZTTAntony Cesar Caballero IbarraNo ratings yet

- ASTM A304-05e2 ÓÐÄ© Ë Ã Ð Ãí ÐÔÒ Çó ÄºÏ Ð Ö°ô Ä Ä Êõ Æ (Ó ÎÄ) PDFDocument50 pagesASTM A304-05e2 ÓÐÄ© Ë Ã Ð Ãí ÐÔÒ Çó ÄºÏ Ð Ö°ô Ä Ä Êõ Æ (Ó ÎÄ) PDFcvazquez999No ratings yet

- Factory Mutual Data Sheet 1-54 Roof LoadingDocument67 pagesFactory Mutual Data Sheet 1-54 Roof LoadingrshyamsNo ratings yet

- 13C2-B PumpDocument5 pages13C2-B PumpRicardo AnusoNo ratings yet

- EI2303 Industrial Instrumentation 2Document6 pagesEI2303 Industrial Instrumentation 2Ramanathan SunderNo ratings yet

- InterReach Unison DAS ManualDocument236 pagesInterReach Unison DAS ManualAlex CoronadoNo ratings yet

- Safari - 15 Nov 2019 at 10:13 PMDocument1 pageSafari - 15 Nov 2019 at 10:13 PMcrescente galendezNo ratings yet

- 03-SH Shuttle Valves Catalog PDFDocument14 pages03-SH Shuttle Valves Catalog PDFfrancis_15inNo ratings yet

- Bonding in SolidsDocument24 pagesBonding in SolidsMahesh KumarNo ratings yet

- Research On Sawdust and Coconut Peat As Particle BoardDocument11 pagesResearch On Sawdust and Coconut Peat As Particle BoardAecee Quibod OlivarNo ratings yet

- Chapter 7Document24 pagesChapter 7SaifAdamz'sNo ratings yet

- Nug Roho 2010Document22 pagesNug Roho 2010mukhammad nurdiansyahNo ratings yet

- Communication ProtocolDocument6 pagesCommunication Protocolgemni7No ratings yet

- Turbine Gas Meter From Manufacture Specifications.Document15 pagesTurbine Gas Meter From Manufacture Specifications.Ellen ShengNo ratings yet

- Session 208-Mike Lam-20 (Hydraulic-Workover Units-LW Completions)Document31 pagesSession 208-Mike Lam-20 (Hydraulic-Workover Units-LW Completions)Ruslan ZakirovNo ratings yet

- No. 117 - Workplace Safety and Health Act (Chapter 354A)Document3 pagesNo. 117 - Workplace Safety and Health Act (Chapter 354A)Chia Hock ChuanNo ratings yet

- ISO 9001 Quality ManualDocument33 pagesISO 9001 Quality Manualramrom100% (4)

GT-1033-Speed Pickups & #1 Bearing Seismic Probes, Disconnection and Removal

GT-1033-Speed Pickups & #1 Bearing Seismic Probes, Disconnection and Removal

Uploaded by

Madih ElghannamOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GT-1033-Speed Pickups & #1 Bearing Seismic Probes, Disconnection and Removal

GT-1033-Speed Pickups & #1 Bearing Seismic Probes, Disconnection and Removal

Uploaded by

Madih ElghannamCopyright:

Available Formats

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1033 9F, 9FA, 9FB, 6FA, 6B, 5P, 7E/EA, 9E, 7B 1 OF 11

REV OPERATION TITLE / DESCRIPTION PREPARED BY DATE APPROVED DATE

1.0 Tim Rinehart 3/19/2010 Tim Rinehart 3/19/2010

Schedule Task & Step Number: Speed Pickups & #1 Bearing Reference Drawing Title: Reference MLI or Cost Codes

Seismic Probes, Disconnection Magnetic Pickup Arrangement, Sensor

GT2110 and Removal Arrgt, Vibration Turb, Monitor - Bently MLI 0546, 1218, A138

Nevada

Task Overview - Instructions EHS Considerations Work Package Prerequisites

- This work package addresses the disconnection and - Reference applicable JSAs, and include their - Turning Gear Locked Out.

removal of the magnetic pickup (MPU) bracket, the information in Pre-Task Brief. - Check with operations or other site personnel about

reference probe (Keyphasor) and #1 bearing seismic - Fall Protection as required. any issues with speed, seismic or reference probes

probes, as applicable to scope and frame type. prior to removal. On site GE Controls FE or other

- Inspect all tooling/rigging prior to use.

Observe the following: qualified FE may need to troubleshoot prior to or in

- Scaffolding access to be supplied for safe conjunction with probe/bracket disassembly and

access and egress removal

Be aware of specific requirements.

- LOTO scheme including all devices going to JB58 (or

other JB for speed probes, vibration probes) isolated

QA/QC Concurrent signoff required. from potential sources of power during disconnection

Do not proceed past this step until signed. of JB58 (or equivalent) terminations.

Technical Regulatory Standard concern.

FME Requirements Special Tools Pre-Task Brief Sign-off

- See PSWI-MFE-009 – Foreign Material Exclusion for None. Field Engineer / Craft Supervisor shall provide overview/

definitions of FME Levels and requirements. briefing of this task prior to craft commencing work.

- Notify supervisor immediately if any materials, tools, Pre-task brief completed by:

or other items which enter the turbine.

Signature Date

Attachments to this Field Procedure:

Site Specific page .................................................

Deviation Record page (technical revs.)

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1033 9F, 9FA, 9FB, 6FA, 6B, 5P, 7E/EA, 9E, 7B 2 OF 11

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Speed Pickups & #1 Bearing Seismic Probes, Disconnection and Removal Tim Rinehart 3/19/2010

Step Section 0 – Index and General Information Verification

Index:

Section 0 – Index and General Information

Section 1 – Remove Speed Probe Bracket

Section 2 – Remove #1 Bearing Seismic Probes

This instruction addresses the removal of the magnetic speed probe pickup bracket (including the speed probes), reference

probe (keyphasor) and junction box JB58 (or equivalent), as well as #1 bearing seismic probes likely removed at this time. The

GE Field Engineer/Technical Advisor shall indicate exceptions to disconnection and/or removal for their workscope. It is

organized in two sections, one for the speed probe bracket and the other for the #1 bearing seismic probes, to allow either

set of devices to be removed first or omitted. Use judgment and consult with your supervisor or site FE on any preferred

practice.

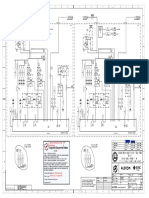

Typical configurations are shown in Figure 1 for a number of different unit types. Those configurations not applicable should

be lined out to avoid any possible confusion prior to releasing the Field Procedure to start work. Always refer to your unit

1.0 specific configuration to resolve any differences.

Notify your supervisor or site GE FE prior to removal of any speed probes, seismic probes, reference probe or cabling

found damaged, to assess probable cause and replacement requirements.

TIP – Occasionally, the load coupling guard bolting causes interference with the speed pickups, resulting in damage. These

guard bolts are sometimes shortened to protect the speed probes from damage. Review and comment accordingly for

disassembly and subsequent reassembly, as well as assessing need for further guidance if modifications required.

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1033 9F, 9FA, 9FB, 6FA, 6B, 5P, 7E/EA, 9E, 7B 3 OF 11

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Speed Pickups & #1 Bearing Seismic Probes, Disconnection and Removal Tim Rinehart 3/19/2010

Step Section 0 – Index and General Information Verification

GE Field Engineer to indicate applicable sections and Review areas for FE input ahead of time, where

provide any comments in the respective sections. feasible, to avoid delays in proceeding with steps

by craft and other technicians. FE Initial

2.0

Section 1 Required? Yes or No ___________

Section 1 – Remove Speed Probe Bracket

Section 2 – Remove #1 Bearing Seismic Probes Section 2 Required? Yes or No

FE/TA shall identify the frame size applicable to this document. (check applicable box to right of frame type)

9F. 9FA/B , 6FA , 6B , 7E, 7EA , 9E, , 5P FE Initial

3.0

__________

FE shall review section 1 and 2, and cross out figures that don’t apply to the frame type identified.

The Field Engineer/TA shall remove the last page of this procedure – Field Procedure Tracking Log. The Field FieldEngineer/

Engineer/TA shall complete the header information by adding the unit serial number and the specific part to TA Initial

4.0

which the Field Procedure will be applied. The Tracking Log shall be maintained in the Field Engineer/TA’s

office at all times. ___________

Return this Field Procedure to the Field Engineer or your Shift Supervisor when this activity is complete or at

5.0

the end of your shift, whichever happens first.

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1033 9F, 9FA, 9FB, 6FA, 6B, 5P, 7E/EA, 9E, 7B 4 OF 11

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Speed Pickups & #1 Bearing Seismic Probes, Disconnection and Removal Tim Rinehart 3/19/2010

Step Section 1 – Remove Speed Probe Bracket - Instructions Verification

Verify an appropriate LOTO of any potential power to the devices terminated at JB58 and JB55, prior to

disconnecting conduit to JB58, to allow moving the junction box, bracket and speed probes as an assembly.

FE Initial

1.0 Also, indicate whether Section 2 is also required at Section 2, Step 1. Review other potential interference

___________

issues with removal of the speed probe bracket and modify/comment as appropriate. Review applicable

conduits/conductors going back to turbine controller, and advise for following step.

There are 1 or 2 conduits coming into JB58 that direct the wires back to the turbine controller, and ARE the

ones to be disconnected to allow removal of the speed probe bracket and junction box.

2.0

Label or verify appropriate labeling for each of the wires coming from the conduit, terminating inside JB58,

and disconnect only those terminations and conduit run. The terminations to the devices will be left intact.

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1033 9F, 9FA, 9FB, 6FA, 6B, 5P, 7E/EA, 9E, 7B 5 OF 11

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Speed Pickups & #1 Bearing Seismic Probes, Disconnection and Removal Tim Rinehart 3/19/2010

Step Section 1 – Remove Speed Probe Bracket - Instructions Verification

Figure 1 – Examples of typical configurations

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1033 9F, 9FA, 9FB, 6FA, 6B, 5P, 7E/EA, 9E, 7B 6 OF 11

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Speed Pickups & #1 Bearing Seismic Probes, Disconnection and Removal Tim Rinehart 3/19/2010

Step Section 1 – Remove Speed Probe Bracket - Instructions Verification

Where applicable, carefully remove the 77RP (or other

designation for reference probe) located at or near the speed

probe bracket.

To prevent damage to the probe/cable while unscrewing the

probe, the cable should be free to slowly rotate and to prevent

binding while backing the probe out of the bracket.

Note: There will typically be a twist-type coaxial connection

approximately 20” from the tip of the probe. This connection

may be exposed or just inside a pull-box along the conduit. If

possible, disconnect at this point, otherwise open JB55, and

the Bently Nevada extension cable from this probe will be

there, typically coiled up. This probe is held in by a ¾” jam

3.0

nut which must be loosened, and the probe unscrewed from

the bracket to allow removal of the probe and it’s holder (quill).

See picture at right.

Once the probe is removed, carefully coil up any exposed

leads and tie off to prevent damage or interference during

removal of the speed probe bracket and subsequent work in

the area.

Additional instructions by FE:

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1033 9F, 9FA, 9FB, 6FA, 6B, 5P, 7E/EA, 9E, 7B 7 OF 11

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Speed Pickups & #1 Bearing Seismic Probes, Disconnection and Removal Tim Rinehart 3/19/2010

Step Section 1 – Remove Speed Probe Bracket - Instructions Verification

Insert a piece of cushioning material, i.e plastic/cardboard/heavy cloth between the speed probe bracket(s)

probe tips and the toothed wheel, prior to loosening the speed probe bracket bolts. This will help prevent

damage to the magnetic speed pickups coming into contact with the wheel during disassembly. Remove

and bag the fasteners removed and attach to the bracket for later assembly.

CAUTION:

The speed probe bracket is often heavy and awkward, and may require additional help or rigging to lift and

4.0 set off onto scaffold/platform or down to compartment floor. Contact your supervisor if you are unsure of

your ability to safely handle this item on your own to prevent personal injury or damage to hardware.

After checking that no further interference exists to prevent removing the speed probe bracket, lift and

remove the speed probe bracket and set aside, being careful not to damage the probes or conduits.

Check to be sure the spring dowel pins either stayed in place on the bearing pedestal, or stayed in the

bracket, but that they are not ‘loose’ anywhere. If they remove easily from the bearing pedestal, then

remove and place with the other hardware for reassembly later.

The GE Field Engineer/Technical Advisor or Craft Supervisor shall verify that all required removals have been

FE/Supv Initial

5.0 completed, that all parts have been bagged and/or tagged with the appropriate location clearly identified,

and that any required FME covers have been installed or reinstalled. ___________

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1033 9F, 9FA, 9FB, 6FA, 6B, 5P, 7E/EA, 9E, 7B 8 OF 11

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Speed Pickups & #1 Bearing Seismic Probes, Disconnection and Removal Tim Rinehart 3/19/2010

Step Section 2 – Remove #1 Bearing Seismic Probes - Instructions Verification

Carefully cut and discard any lock wire (if present) securing coaxial connections.

Disconnect twist connections at the seismic probes (39V-1A and 39V-1B) on top of the #1 bearing in Figure 1.

1.0 These should be hand tight and not require the use of wrenches to remove. Contact your shift supervisor or

GE field engineer before using wrenches on these fittings. After disconnecting these connections, gently coil

the cable back and tie up to prevent damage while moving the bracket and junction box assembly.

Refer back to Figure 1 for location of the probes, 39V-1A and 39V-1B. The probes are typically attached to a

common baseplate at the top center of the bearing bracket. Remove the three screws (typically ½” diameter

2.0 12 point) and lockwashers holding the seismic probe baseplate in place. Bag and tag the hardware, placing

a cloth or other cushion material around the probes to prevent damage. It is not necessary to remove the

probes from their common bracket.

The GE Field Engineer/Technical Advisor or Craft Supervisor shall verify that all required removals have been

completed, that all parts have been bagged and/or tagged with the appropriate location clearly identified, FE/Supv Initial

3.0

stored for subsequent cleaning/inspection/reassembly and that any required FME covers have been installed ___________

or reinstalled.

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1033 9F, 9FA, 9FB, 6FA, 6B, 5P, 7E/EA, 9E, 7B 9 OF 11

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Speed Pickups & #1 Bearing Seismic Probes, Disconnection and Removal Tim Rinehart 3/19/2010

SIGN-OFF TRANSLATION LIST

The blocks below are to be filled in to translate initials used within the Field Procedure to actual names.

If two or more people using this procedure have the same initials, they should be distinguished within the Field Procedure by adding a “1” or

“2” or other unique identifier that is also shown in the listing below. Be sure to print initials as you would within the document.

Craft and non-GE Craft and non-GE (continued)

INITIALS NAME (PRINT) COMPANY INITIALS NAME (PRINT) COMPANY

GE GE (continued)

INITIALS NAME (PRINT) INITIALS NAME (PRINT)

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1033 9F, 9FA, 9FB, 6FA, 6B, 5P, 7E/EA, 9E, 7B 10 OF 11

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Speed Pickups & #1 Bearing Seismic Probes, Disconnection and Removal Tim Rinehart 3/19/2010

Revision Date Revision Revision Details Approved By

March 19, 2010 1.0 Initial Issue Tim Rinehart

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1033 9F, 9FA, 9FB, 6FA, 6B, 5P, 7E/EA, 9E, 7B 11 OF 11

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Speed Pickups & #1 Bearing Seismic Probes, Disconnection and Removal Tim Rinehart 3/19/2010

Field Procedure Tracking Log

Unit Serial Number ____________________ Page 1 of __________

Work location (if this FP can be used multiple times/locations, i.e. coupling inspections “A” cplg, B LP Hood) ______________________

Issued Returned Status

Issued to

Date Time Date Time In process Complete

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

You might also like

- Dry Low Nox 2.0+ System Operation: Ge Power SystemsDocument10 pagesDry Low Nox 2.0+ System Operation: Ge Power SystemsFernando Piaggio100% (2)

- GT Hot Gas Path Inspection PDFDocument1 pageGT Hot Gas Path Inspection PDFNagarajakumar D100% (1)

- IGV Commissioning For AddFem POCO+ LogicDocument17 pagesIGV Commissioning For AddFem POCO+ LogicHankar Aravins100% (4)

- Generator VOL 8ADocument18 pagesGenerator VOL 8AEmadAlhosien Alhosien100% (1)

- C7 5-16-2010 Rev-01 Commented Trips, Alarms, Events, HoldsDocument34 pagesC7 5-16-2010 Rev-01 Commented Trips, Alarms, Events, Holdsbalumuriashok100% (1)

- Ia Caterpillar Specifications 3304 VehicularEngine TextDocument100 pagesIa Caterpillar Specifications 3304 VehicularEngine Textkatarkivos94% (16)

- GT-1065 - Disconnection and Removal, #2 Bearing Area Probes and TCPLsDocument14 pagesGT-1065 - Disconnection and Removal, #2 Bearing Area Probes and TCPLsMadih ElghannamNo ratings yet

- GT-1041-Wheelspace TCPLS, Disconnection and RemovalDocument12 pagesGT-1041-Wheelspace TCPLS, Disconnection and RemovalMadih ElghannamNo ratings yet

- GT-1002-Flame Detectors and Spark Plugs, Disconnection and RemovalDocument12 pagesGT-1002-Flame Detectors and Spark Plugs, Disconnection and RemovalMadih ElghannamNo ratings yet

- 07 Uch GT 9001e - PMDocument6 pages07 Uch GT 9001e - PMHassan Mahmood100% (1)

- SGC - GT Gas Turbine HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHDocument3 pagesSGC - GT Gas Turbine HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHjeromejoe100% (2)

- Bleed Valve FunctionDocument2 pagesBleed Valve FunctionajaysapruNo ratings yet

- Why Is DLN Tuning Done in GE Gas Turbines - What Is The Purpose To Do So - QuoraDocument2 pagesWhy Is DLN Tuning Done in GE Gas Turbines - What Is The Purpose To Do So - Quoraajo zinzoNo ratings yet

- The 9F Platform - A History of Refinement - Power Engineering InternationalDocument7 pagesThe 9F Platform - A History of Refinement - Power Engineering InternationalSujeet KumarNo ratings yet

- Gek 106852aDocument10 pagesGek 106852awednetoxNo ratings yet

- POTS - 27022021 - CI and MI Scope of WorkDocument10 pagesPOTS - 27022021 - CI and MI Scope of WorkPhong leNo ratings yet

- 07 Gas Turbine Valves - 0Document14 pages07 Gas Turbine Valves - 0VILAS VIJAYAN100% (2)

- Ge Gas Turbine Frame (9fa)Document7 pagesGe Gas Turbine Frame (9fa)ajo zinzoNo ratings yet

- GE Power Systems: Description 7FH2 Generator With Static ExcitationDocument15 pagesGE Power Systems: Description 7FH2 Generator With Static ExcitationAlexferminNo ratings yet

- CIBI of GT # 5 Frame VI at IOCL VadodaraDocument3 pagesCIBI of GT # 5 Frame VI at IOCL Vadodaramahesh_rathoreNo ratings yet

- Gas Turbine ControlDocument9 pagesGas Turbine ControlHBNBILNo ratings yet

- EngDocument44 pagesEngzomglolzscribdNo ratings yet

- 3 System Process Outline - SLP R2Document56 pages3 System Process Outline - SLP R2Pirun Sirimangkalo100% (1)

- I Am Wondering If There Is Any Value To Adding Cdms To My GT With Dln. Does Anyone Have These Systems? and If So Which Ones Would You RecommendDocument11 pagesI Am Wondering If There Is Any Value To Adding Cdms To My GT With Dln. Does Anyone Have These Systems? and If So Which Ones Would You RecommendSahariar Bin ShafiqueNo ratings yet

- Gas Turbine Order Data SampleDocument13 pagesGas Turbine Order Data Samplesajjad_naghdi241100% (2)

- Performance CurvesDocument22 pagesPerformance Curvesamir moniriNo ratings yet

- Major InspectionDocument54 pagesMajor InspectionPhong leNo ratings yet

- Actividad para Plantas TérmicasDocument40 pagesActividad para Plantas Térmicaspedro peresNo ratings yet

- Gas ValveDocument9 pagesGas ValveJJNo ratings yet

- 6FA DLN 2.6 Extended Interval Combustion System - GEA17898 PDFDocument1 page6FA DLN 2.6 Extended Interval Combustion System - GEA17898 PDFLenin RamonNo ratings yet

- Cable Trays RequirementDocument1 pageCable Trays RequirementSulaiman JafferyNo ratings yet

- Psib 20150212Document10 pagesPsib 20150212Léandre Ettekri Ndri100% (1)

- TIL 2363 - IGV Inspection and Maintenance For Gear & Rack TypeDocument11 pagesTIL 2363 - IGV Inspection and Maintenance For Gear & Rack TypeBouazzaNo ratings yet

- Equipment Definition: Component LiteratureDocument5 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- DLN Controls Code Development 9fa+ EnhancedDocument28 pagesDLN Controls Code Development 9fa+ Enhancednabil160874100% (1)

- 2.3 MBJ Starting Motor SystemDocument6 pages2.3 MBJ Starting Motor SystemmiladNo ratings yet

- Dry Low NoxDocument10 pagesDry Low NoxIvan Poma Montes100% (2)

- Safety Bulletin: GE Power & Water 6B Endcover Damage PSSB 20140714A - R1 Product ServiceDocument2 pagesSafety Bulletin: GE Power & Water 6B Endcover Damage PSSB 20140714A - R1 Product ServiceLéandre Ettekri Ndri100% (1)

- Gea32081a LM6000 - Pa - Us - R1 - LRDocument1 pageGea32081a LM6000 - Pa - Us - R1 - LRErik Van GroningenNo ratings yet

- GE 6FA TurbineDocument1 pageGE 6FA TurbinehenriquezrsNo ratings yet

- Limiting The Gas Turbine Load and Operating at Base LoadDocument6 pagesLimiting The Gas Turbine Load and Operating at Base Loadramkrishna100% (2)

- Mark V Voter MismatchDocument6 pagesMark V Voter Mismatchnabil160874No ratings yet

- Gek 106844 PDFDocument10 pagesGek 106844 PDFIvan Poma MontesNo ratings yet

- المواد المرمزة والمطلوبة ترميزها بملف واحدDocument247 pagesالمواد المرمزة والمطلوبة ترميزها بملف واحدMahdi HassanNo ratings yet

- 11-Presentation MitchCohen PDFDocument32 pages11-Presentation MitchCohen PDFbigsteve9088No ratings yet

- GTDocument122 pagesGTAnand Patel100% (1)

- DLN1+ Combustion Upgrade Solution: Fact SheetDocument1 pageDLN1+ Combustion Upgrade Solution: Fact SheetAhmad Riaz Khan100% (1)

- 10-03-2008 Power in MEADocument30 pages10-03-2008 Power in MEAMohammed YusufNo ratings yet

- Igv 7eaDocument2 pagesIgv 7eaSamir Benabdallah100% (1)

- Gas Turbine Engines Characteristics and Performance Combustion ChamberDocument2 pagesGas Turbine Engines Characteristics and Performance Combustion ChamberNicolas Guatibonza L100% (1)

- GE Oil & Gas Aeroderivative Gas Turbine: Emission Reduction Techniques DLE1.0 SystemDocument46 pagesGE Oil & Gas Aeroderivative Gas Turbine: Emission Reduction Techniques DLE1.0 SystemJuan Manuel100% (2)

- 9fa ProbsDocument12 pages9fa ProbsMarbz Al MonteNo ratings yet

- 9FA Recommended Parts ListingDocument1 page9FA Recommended Parts Listingalexandr_popov_2No ratings yet

- GT Trips List Generic PDFDocument13 pagesGT Trips List Generic PDFHassanSaidi100% (1)

- Ansaldo Thomassen - CMU (2014)Document4 pagesAnsaldo Thomassen - CMU (2014)guerrezNo ratings yet

- Stage 1 Shroud For FS7001BDocument1 pageStage 1 Shroud For FS7001Bteedee1100% (1)

- Customer Course CatalogDocument119 pagesCustomer Course CatalogNguyễn Vạn ThắngNo ratings yet

- Combustion EnvelopDocument19 pagesCombustion Envelopferas_elnggar100% (1)

- GT-1064-Disconnection and Removal, #1 Bearing Area Probes and TCPLsDocument20 pagesGT-1064-Disconnection and Removal, #1 Bearing Area Probes and TCPLsMadih ElghannamNo ratings yet

- GeneratorDocument32 pagesGeneratordhammikanavaratneNo ratings yet

- Xerox: OrdinaryDocument1 pageXerox: Ordinaryvijay kumarNo ratings yet

- GT-1065 - Disconnection and Removal, #2 Bearing Area Probes and TCPLsDocument14 pagesGT-1065 - Disconnection and Removal, #2 Bearing Area Probes and TCPLsMadih ElghannamNo ratings yet

- GT-1064-Disconnection and Removal, #1 Bearing Area Probes and TCPLsDocument20 pagesGT-1064-Disconnection and Removal, #1 Bearing Area Probes and TCPLsMadih ElghannamNo ratings yet

- GT-1002-Flame Detectors and Spark Plugs, Disconnection and RemovalDocument12 pagesGT-1002-Flame Detectors and Spark Plugs, Disconnection and RemovalMadih ElghannamNo ratings yet

- GT-1041-Wheelspace TCPLS, Disconnection and RemovalDocument12 pagesGT-1041-Wheelspace TCPLS, Disconnection and RemovalMadih ElghannamNo ratings yet

- 102 00553 0619 Olin Sodium Hypochlorite ManualDocument39 pages102 00553 0619 Olin Sodium Hypochlorite ManualMadih ElghannamNo ratings yet

- HP Bypass ValvesDocument3 pagesHP Bypass ValvesMadih ElghannamNo ratings yet

- Confirmation Copybook Cursive SssDocument1 pageConfirmation Copybook Cursive SssMadih ElghannamNo ratings yet

- P1650 H1 Perkins 4016TAG1ADocument11 pagesP1650 H1 Perkins 4016TAG1AMadih ElghannamNo ratings yet

- 4016TAG1A-4016TAG2A Perkins TechexpoDocument10 pages4016TAG1A-4016TAG2A Perkins TechexpoMadih ElghannamNo ratings yet

- 4016TAG1ADocument2 pages4016TAG1AMadih ElghannamNo ratings yet

- International Journal of Impact Engineering: Ganesh Thiagarajan, Anirudha V. Kadambi, Stephen Robert, Carol F. JohnsonDocument12 pagesInternational Journal of Impact Engineering: Ganesh Thiagarajan, Anirudha V. Kadambi, Stephen Robert, Carol F. JohnsonOmer PolatNo ratings yet

- Emf Questions For AssignmentDocument7 pagesEmf Questions For AssignmentDrGopikrishna PasamNo ratings yet

- ADocument22 pagesAPrasun Kumar DasNo ratings yet

- Bezema Acrylate Styrene BasisDocument3 pagesBezema Acrylate Styrene BasisClub classic 350No ratings yet

- Geopier-Handbook FinalDocument5 pagesGeopier-Handbook Finalykp1234No ratings yet

- The Starting of Turbine Engines in HelicoptersDocument8 pagesThe Starting of Turbine Engines in HelicoptersAnonymous lEX5U51wOANo ratings yet

- Lack of PrivacyDocument3 pagesLack of PrivacyflabelNo ratings yet

- Loss of Anchorage of Miniscrews: A 3-Dimensional Assessment: Original ArticleDocument8 pagesLoss of Anchorage of Miniscrews: A 3-Dimensional Assessment: Original ArticlePrevita NindaNo ratings yet

- First Quarter-Gr4-Ww-Pt-With-Answers-KeyDocument35 pagesFirst Quarter-Gr4-Ww-Pt-With-Answers-KeyEurika LimNo ratings yet

- Notes: General Steel Fabrication Notes: Carbon Steel Fabrication Notes: Stainless Steel FabricationDocument6 pagesNotes: General Steel Fabrication Notes: Carbon Steel Fabrication Notes: Stainless Steel FabricationAquiles MartinezNo ratings yet

- Fms Belts Tech Info 316 enDocument22 pagesFms Belts Tech Info 316 encarpataniaNo ratings yet

- Price List: LTM 019A W.E.F 02.04.2022Document60 pagesPrice List: LTM 019A W.E.F 02.04.2022Ashish100% (1)

- ACSR Rail ZTTDocument6 pagesACSR Rail ZTTAntony Cesar Caballero IbarraNo ratings yet

- ASTM A304-05e2 ÓÐÄ© Ë Ã Ð Ãí ÐÔÒ Çó ÄºÏ Ð Ö°ô Ä Ä Êõ Æ (Ó ÎÄ) PDFDocument50 pagesASTM A304-05e2 ÓÐÄ© Ë Ã Ð Ãí ÐÔÒ Çó ÄºÏ Ð Ö°ô Ä Ä Êõ Æ (Ó ÎÄ) PDFcvazquez999No ratings yet

- Factory Mutual Data Sheet 1-54 Roof LoadingDocument67 pagesFactory Mutual Data Sheet 1-54 Roof LoadingrshyamsNo ratings yet

- 13C2-B PumpDocument5 pages13C2-B PumpRicardo AnusoNo ratings yet

- EI2303 Industrial Instrumentation 2Document6 pagesEI2303 Industrial Instrumentation 2Ramanathan SunderNo ratings yet

- InterReach Unison DAS ManualDocument236 pagesInterReach Unison DAS ManualAlex CoronadoNo ratings yet

- Safari - 15 Nov 2019 at 10:13 PMDocument1 pageSafari - 15 Nov 2019 at 10:13 PMcrescente galendezNo ratings yet

- 03-SH Shuttle Valves Catalog PDFDocument14 pages03-SH Shuttle Valves Catalog PDFfrancis_15inNo ratings yet

- Bonding in SolidsDocument24 pagesBonding in SolidsMahesh KumarNo ratings yet

- Research On Sawdust and Coconut Peat As Particle BoardDocument11 pagesResearch On Sawdust and Coconut Peat As Particle BoardAecee Quibod OlivarNo ratings yet

- Chapter 7Document24 pagesChapter 7SaifAdamz'sNo ratings yet

- Nug Roho 2010Document22 pagesNug Roho 2010mukhammad nurdiansyahNo ratings yet

- Communication ProtocolDocument6 pagesCommunication Protocolgemni7No ratings yet

- Turbine Gas Meter From Manufacture Specifications.Document15 pagesTurbine Gas Meter From Manufacture Specifications.Ellen ShengNo ratings yet

- Session 208-Mike Lam-20 (Hydraulic-Workover Units-LW Completions)Document31 pagesSession 208-Mike Lam-20 (Hydraulic-Workover Units-LW Completions)Ruslan ZakirovNo ratings yet

- No. 117 - Workplace Safety and Health Act (Chapter 354A)Document3 pagesNo. 117 - Workplace Safety and Health Act (Chapter 354A)Chia Hock ChuanNo ratings yet

- ISO 9001 Quality ManualDocument33 pagesISO 9001 Quality Manualramrom100% (4)