Professional Documents

Culture Documents

GT-1065 - Disconnection and Removal, #2 Bearing Area Probes and TCPLs

GT-1065 - Disconnection and Removal, #2 Bearing Area Probes and TCPLs

Uploaded by

Madih ElghannamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GT-1065 - Disconnection and Removal, #2 Bearing Area Probes and TCPLs

GT-1065 - Disconnection and Removal, #2 Bearing Area Probes and TCPLs

Uploaded by

Madih ElghannamCopyright:

Available Formats

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1065 9F, 9FA, 9FB 1 OF 14

REV OPERATION TITLE / DESCRIPTION PREPARED BY DATE APPROVED DATE

1.0 Tim Rinehart 6/14/2010 Tim Rinehart 6/14/2010

Schedule Task & Step Number: Disconnection and Removal, #2 Reference Drawing Title: Reference MLI or Cost Codes

Bearing area probes and TCPLs Instrumentation Arrgt Brg 2, Sensor Arrgt

GT2110 MLI 235B, 218B, 1160

Vibration Turb

Task Overview - Instructions EHS Considerations Work Package Prerequisites

- Disassembly and removal of #2 Bearing area - Reference applicable SRAs, and include their - Turning gear locked out

proximity probes, seismic probes and information in Pre-Task Brief. - Lube oil system locked out

thermocouples. - Fall Protection as required. - Fire Protection System locked out for the zone

- Inspect all tooling/rigging prior to use. containing the exhaust tunnel bearing area.

Observe the following: - Scaffolding access to be supplied for safe access

and egress

Be aware of specific requirements.

Verification/Concurrent signoff required.

Do not proceed past this step until signed.

Technical Regulatory Standard concern.

FME Requirements Special Tools Pre-Task Brief Sign-off

- See PSWI-MFE-009 – Foreign Material Exclusion for - None Field Engineer / Craft Supervisor shall provide

definitions of FME Levels and requirements. overview/ briefing of this task prior to craft

- Notify supervisor immediately if any materials, commencing work.

tools, or other items which enter the turbine. Pre-task brief completed by:

- Assure bearing oil feeds and drains are

protected/covered whenever the bearing cap is

removed. Signature Date

Attachments to this Field Procedure:

Site Specific page.................................................

Deviation Record page (technical revs.) ...

(link to Deviation Record Form)

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1065 9F, 9FA, 9FB 2 OF 14

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Disconnection and Removal, #2 Bearing area probes and TCPLs Tim Rinehart 6/14/2010

Step Section 0 – Index and General Information Verification

Index:

Section 0 – Index and General Information

Section 1 – Remove Seismic Probes

Section 2 – Remove Radial Vibration Probes

Section 3 – Remove #2 Bearing Thermocouples

Section 4 – Final Review

This instruction addresses the proximity probes, seismic probes and thermocouples that may be removed as part of an

inspection involving removal or inspection of the #2 bearing, and associated devices. The GE Field Engineer/Technical

Advisor shall indicate exceptions to disconnection and/or removal for their workscope. It is organized in several sections, to

allow any set of devices to be removed first. Use judgment and consult with your supervisor or site FE on any preferred

practice.

Current design practice is assumed for the frame variations presented, with notes where some (but perhaps not all) variations

may exist. In all cases, review your unit’s drawing and configuration of devices, cabling, conduit, etc..

The GE FE shall mark up this document accordingly to provide clarity for those using it.

Device and junction box names, conduit and configuration may vary within and among frame types. Review the applicability

to your unit’s configuration and mark up document as appropriate to aid those doing the work.

Notify your supervisor or site GE FE prior to removal of any devices or cabling found damaged, to assess probable cause

and replacement requirements..

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1065 9F, 9FA, 9FB 3 OF 14

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Disconnection and Removal, #2 Bearing area probes and TCPLs Tim Rinehart 6/14/2010

Step Section 0 – Index and General Information Verification

GE Field Engineer to indicate applicable sections and comments. Review areas for FE input ahead of time,

where feasible, to avoid delays in workflow.

FieldEngineer/

1.0 Section 1 – Remove Seismic Probes Section 1 Required? Yes

or No

TA Initial

___________

Section 2 – Remove Radial Vibration Probes Section 2 Required? Yes

or No

Section 3 – Remove #2 Bearing Thermocouples Section 3 Required? Yes

or No

The Field Engineer/TA shall remove the last page of this procedure – Field Procedure Tracking Log. The Field FieldEngineer/

Engineer/TA shall complete the header information by adding the unit serial number and the specific part to TA Initial

2.0

which the Field Procedure will be applied. The Tracking Log shall be maintained in the Field Engineer/TA’s

office at all times. ___________

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1065 9F, 9FA, 9FB 4 OF 14

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Disconnection and Removal, #2 Bearing area probes and TCPLs Tim Rinehart 6/14/2010

Step Section 1 – Remove Seismic Probes - Instructions Verification

Return this Field Procedure to the Field Engineer or your Shift Supervisor when this activity is complete or at

1.0

the end of your shift, whichever happens first.

Disconnect twist-type coaxial connections at the seismic probes (39V-2A and 39V-2B) on top of the #2

bearing. Remove and discard any lock wire that may exist.

These coaxial connectors should be hand tight and typically do not require the use of wrenches to remove.

Contact your supervisor or GE field engineer before using wrenches on these fittings. After disconnecting

2.0

these connections, gently coil the cable back and tie up to prevent damage while removing or accessing the

#2 bearing.

If necessary for subsequent access/work, loosen and rotate conduits off to the sides, being careful not to

cause any movement that would kink or bind internal wires.

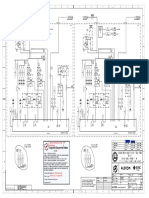

Refer to figure at right for location of the probes, 39V-

2A and 39V-2B. This is a view looking down at the top

of the #2 bearing cover.

The probes are attached to a common baseplate.

Loosen and remove these screws (typically ½”

3.0 diameter 12 point), and lockwashers holding the

seismic probe baseplate in place.

Bag and tag the hardware, placing a cloth or other

cushion material around the probes to prevent

damage. It is not necessary to remove the probes

from their common baseplate.

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1065 9F, 9FA, 9FB 5 OF 14

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Disconnection and Removal, #2 Bearing area probes and TCPLs Tim Rinehart 6/14/2010

Step Section 2 – Remove Radial Vibration Probes - Instructions Verification

Reference Figure 1 and 2 (or 3) for location of radial vibration probes. Contact GE Field Engineer for

assistance as needed to clarify design type and to determine extent of disassembly/disconnection required

since the probes are mounted in the lower half of the bearing.

Remove the Junction Box covering the probe to extension cable connection. Place parts in a bag/box and

mark for location removed for reassembly. Disconnect the coaxial connection between the probe and

1.0 extension cable. The connection will typically have shrink tubing that needs to be very carefully cut and

removed to allow disconnection of the coaxial connection. Exercise care to avoid cutting the probe or

extension cable sheathing. Discard the old shrink tubing.

For probes mounted as in Figure 3, disconnection of coaxial connection is required only in this step.

Refer to Figure 1. Do not loosen or remove the Proximity Probe Mount or disturb the jam nut, as this will

affect the ability to restore the probe back to original settings if probes are re-used, as they typically are.

Loosen the nut at the top of the Oil Tight Connectors and place the nuts in a bag or other container identified

the respective probe location, i.e 39VS-21 or 39VS-22. Keep all parts removed from each location separated

according to their as-found location and device identification.

2.0

Gripping the probe body, just above the Oil Tight Connector, turn counter clockwise to remove the probe

from the threaded quill connection near the probe tip.

If Figure 3 applicable, loosen jam nut and remove probe from holder.

Place probe with other hardware removed in a tagged container or bag for subsequent cleaning/inspection.

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1065 9F, 9FA, 9FB 6 OF 14

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Disconnection and Removal, #2 Bearing area probes and TCPLs Tim Rinehart 6/14/2010

Step Section 2 – Remove Radial Vibration Probes - Instructions Verification

Figure 1 – Radial Probe Locations and Details

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1065 9F, 9FA, 9FB 7 OF 14

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Disconnection and Removal, #2 Bearing area probes and TCPLs Tim Rinehart 6/14/2010

Step Section 2 – Remove Radial Vibration Probes - Instructions Verification

FIGURE 2 – Radial Probe and Thermocouple Exit Gland Locations

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1065 9F, 9FA, 9FB 8 OF 14

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Disconnection and Removal, #2 Bearing area probes and TCPLs Tim Rinehart 6/14/2010

Step Section 2 – Remove Radial Vibration Probes - Instructions Verification

Figure 3 – Alternative Proximity Probe and Thermocouple Gland Exits

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1065 9F, 9FA, 9FB 9 OF 14

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Disconnection and Removal, #2 Bearing area probes and TCPLs Tim Rinehart 6/14/2010

SECTION 3 – REMOVE #2 JOURNAL BEARING TCPLs (following removal of #2 bearing housing cover)

Step Section 3 – Remove #2 Journal Bearing TCPLs - Instructions Verification

Refer to Figure 2 or 3 for location of oil tight exit gland for thermocouple. GE Field Engineer shall note any

special requirements or adjustments to the removal of thermocouples, to account for variations in

older/newer designs, use of splicing, or need to remove TCPLs at all. As found photos are encouraged to

help visualize restoration of clamps, nichrome straps, conduit, etc for reassembly.

Some designs may have provisions in the ML235B drawing for Bearing 2 Instrumentation Arrangement, to

splice thermocouple connections.

Current designs require pulling the thermocouple from terminations at JB20G, and through internal conduit

runs within the oil drain piping.

FieldEngineer/

1.0 TA Initial

Given the variation in designs, and scope for removal of bearing lower half or not, the GE Field Engineer shall ___________

specify work required to remove thermocouples, if required at all.

TCPLs – Reused? YES

NO

Leads Pulled or Cut ? Specific removal instructions?

Comments: _______________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1065 9F, 9FA, 9FB 10 OF 14

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Disconnection and Removal, #2 Bearing area probes and TCPLs Tim Rinehart 6/14/2010

Step Section 3 – Remove #2 Journal Bearing TCPLs - Instructions Verification

2.0 Remove Thermocouples per GE Field Engineer directions in prior step and discussions.

Following removal of the #2 journal bearing lower half, GE Field Engineer shall comment on any subsequent

work required to remove the thermocouples from the journal bearing pads, if required. Older designs may

have the thermocouple potted with epoxy/equivalent, whereas newer designs use a retaining clip followed

by RTV potting.

Remove journal bearing thermocouples from pads? Yes No

FieldEngineer/

3.0 Enter N/A and initial following step if not required. TA Initial

Comments: ________________________________________________________________________________ ___________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

4.0 Remove #2 journal bearing thermocouples from pads, or as directed above.

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1065 9F, 9FA, 9FB 11 OF 14

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Disconnection and Removal, #2 Bearing area probes and TCPLs Tim Rinehart 6/14/2010

SECTION 4 – FINAL REVIEW

Step Section 4 – Final Review Verification

The Field Engineer has reviewed this document and the work performed using this document and found

both acceptable.

FieldEngineer/

1.0 Review the changes made to this Procedure (red lined sections and Deviation Form, if used). If there are TA Initial

procedural enhancements or errors which you would like to have considered for updates to this Field

___________

Procedure, submit a copy of the marked up Field Procedure (and Deviation Sheet) using the following link:

Request Revision to FP

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1065 9F, 9FA, 9FB 12 OF 14

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Disconnection and Removal, #2 Bearing area probes and TCPLs Tim Rinehart 6/14/2010

SIGN-OFF TRANSLATION LIST

The blocks below are to be filled in to translate initials used within the Field Procedure to actual names.

If two or more people using this procedure have the same initials, they should be distinguished within the Field Procedure by adding a “1” or

“2” or other unique identifier that is also shown in the listing below. Be sure to print initials as you would within the document.

Craft and non-GE Craft and non-GE (continued)

INITIALS NAME (PRINT) COMPANY INITIALS NAME (PRINT) COMPANY

GE GE (continued)

INITIALS NAME (PRINT) INITIALS NAME (PRINT)

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1065 9F, 9FA, 9FB 13 OF 14

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Disconnection and Removal, #2 Bearing area probes and TCPLs Tim Rinehart 6/14/2010

Revision Date Revision Revision Details Approved By

June 14, 2010 1.0 Initial Issue Tim Rinehart

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

FP # GE Energy Power Equipment Type: SHEET

Field Procedure Services

GT-1065 9F, 9FA, 9FB 14 OF 14

REV OPERATION TITLE / DESCRIPTION APPROVED BY DATE

1.0 Disconnection and Removal, #2 Bearing area probes and TCPLs Tim Rinehart 6/14/2010

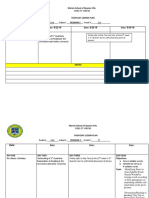

Field Procedure Tracking Log

Unit Serial Number ____________________ Page 1 of __________

Work location (if this FP can be used multiple times/locations, i.e. coupling inspections “A” cplg, B LP Hood) ______________________

Issued Returned Status

Date Time Issued to Date Time In process Complete

UNCONTROLLED WHEN PRINTED GE Proprietary

WHEN IN DOUBT – ASK! If found, return to GE Field Engineer

You might also like

- NEPQ_Black_Book_of_Calling_LeadsDocument20 pagesNEPQ_Black_Book_of_Calling_Leadsanonymous112anonymous112No ratings yet

- Kamal Alhallak, Adel Abdulhafid, Salem Tomi, Dima Omran - The Ultimate Guide For Laser and IPL in The Aesthetic Field-Springer (2023)Document350 pagesKamal Alhallak, Adel Abdulhafid, Salem Tomi, Dima Omran - The Ultimate Guide For Laser and IPL in The Aesthetic Field-Springer (2023)Jonathan Choi100% (1)

- Technical Information Letter: GE PowerDocument10 pagesTechnical Information Letter: GE PowerRichard Puicon PuyenNo ratings yet

- Computers: Acer - N20H2 : SF114-33Document2 pagesComputers: Acer - N20H2 : SF114-33Alhams TorrentNo ratings yet

- SCOPE-1 SECTION-2 CommssinoingDocument109 pagesSCOPE-1 SECTION-2 Commssinoingahmed100% (1)

- Soc 621 Final PaperDocument16 pagesSoc 621 Final Paperapi-478028340No ratings yet

- GT-1002-Flame Detectors and Spark Plugs, Disconnection and RemovalDocument12 pagesGT-1002-Flame Detectors and Spark Plugs, Disconnection and RemovalMadih ElghannamNo ratings yet

- GT-1033-Speed Pickups & #1 Bearing Seismic Probes, Disconnection and RemovalDocument11 pagesGT-1033-Speed Pickups & #1 Bearing Seismic Probes, Disconnection and RemovalMadih Elghannam100% (1)

- GT-1041-Wheelspace TCPLS, Disconnection and RemovalDocument12 pagesGT-1041-Wheelspace TCPLS, Disconnection and RemovalMadih ElghannamNo ratings yet

- SBLM2500 Ind 176Document5 pagesSBLM2500 Ind 176Daniil SerovNo ratings yet

- Steam Turbine UpgradesDocument3 pagesSteam Turbine UpgradesYugandhara Chakravarthy Kancherla100% (1)

- Bleed Valve FunctionDocument2 pagesBleed Valve FunctionajaysapruNo ratings yet

- Gas Turbine ConsultancyDocument4 pagesGas Turbine ConsultancyAek JayNo ratings yet

- The 9F Platform - A History of Refinement - Power Engineering InternationalDocument7 pagesThe 9F Platform - A History of Refinement - Power Engineering InternationalSujeet KumarNo ratings yet

- Major InspectionDocument54 pagesMajor InspectionPhong leNo ratings yet

- Psib 20160603aDocument3 pagesPsib 20160603aLéandre Ettekri Ndri100% (2)

- Retrofittability DLN Dle Systems PDFDocument10 pagesRetrofittability DLN Dle Systems PDFJJ100% (1)

- Safety Bulletin: GE Power & Water PDA Cable Packaging PSSB 20140613A Product ServiceDocument2 pagesSafety Bulletin: GE Power & Water PDA Cable Packaging PSSB 20140613A Product ServiceLéandre Ettekri NdriNo ratings yet

- TIL 1067 R4 - E Class Stage 2 Bucket Tip Shroud DeflectionDocument15 pagesTIL 1067 R4 - E Class Stage 2 Bucket Tip Shroud DeflectionBouazzaNo ratings yet

- Performance CurvesDocument22 pagesPerformance Curvesamir moniriNo ratings yet

- 110 T 8069Document8 pages110 T 8069Anthony MayNo ratings yet

- GE 6FA TurbineDocument1 pageGE 6FA TurbinehenriquezrsNo ratings yet

- Information Bulletin: Improving The Reliability of Medium and High Voltage Auxiliary EquipmentDocument2 pagesInformation Bulletin: Improving The Reliability of Medium and High Voltage Auxiliary EquipmentLéandre Ettekri NdriNo ratings yet

- 6FA DLN 2.6 Extended Interval Combustion System - GEA17898 PDFDocument1 page6FA DLN 2.6 Extended Interval Combustion System - GEA17898 PDFLenin RamonNo ratings yet

- Stage 1 Shroud For FS7001BDocument1 pageStage 1 Shroud For FS7001Bteedee1100% (1)

- Equipment Definition: Component LiteratureDocument5 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- GE Power Systems: Description 7FH2 Generator With Static ExcitationDocument15 pagesGE Power Systems: Description 7FH2 Generator With Static ExcitationAlexferminNo ratings yet

- GT Construction FeatureDocument64 pagesGT Construction FeatureIsuru Lakmuthu MudannayakeNo ratings yet

- Precondition For Turbine Box-UpDocument3 pagesPrecondition For Turbine Box-UpGopal RamalingamNo ratings yet

- 2 1 01 Auxiliary Gear BoxDocument30 pages2 1 01 Auxiliary Gear BoxHeryanto SyamNo ratings yet

- Geh 6721 - Vol - IiDocument1,009 pagesGeh 6721 - Vol - Iialaa fadhelNo ratings yet

- PDS 55910Document2 pagesPDS 55910daimaheshNo ratings yet

- Ansaldo Thomassen - Spare Parts (2014)Document4 pagesAnsaldo Thomassen - Spare Parts (2014)guerrezNo ratings yet

- SB LM2500 Ind 304 R3Document7 pagesSB LM2500 Ind 304 R3Daniil SerovNo ratings yet

- GT2019 90177Document11 pagesGT2019 90177Hiwa Khaledi100% (1)

- NIC - 07-37 - Rev-01 Technical Updates Web Portal GEDocument47 pagesNIC - 07-37 - Rev-01 Technical Updates Web Portal GEManuel L LombarderoNo ratings yet

- Main Works - Lincoln UK: Demag Delaval Industrial Turbomachinery LTDDocument39 pagesMain Works - Lincoln UK: Demag Delaval Industrial Turbomachinery LTDramlijavierNo ratings yet

- Actividad para Plantas TérmicasDocument40 pagesActividad para Plantas Térmicaspedro peresNo ratings yet

- PEi 20110301 Mar 2011Document180 pagesPEi 20110301 Mar 2011Iván Camilo DíezNo ratings yet

- 1 GE TG Frame 6B IM PlanningDocument6 pages1 GE TG Frame 6B IM PlanningJorge LuisNo ratings yet

- CIBI of GT # 5 Frame VI at IOCL VadodaraDocument3 pagesCIBI of GT # 5 Frame VI at IOCL Vadodaramahesh_rathoreNo ratings yet

- 07 Gas Turbine Valves - 0Document14 pages07 Gas Turbine Valves - 0VILAS VIJAYAN100% (1)

- Cable Trays RequirementDocument1 pageCable Trays RequirementSulaiman JafferyNo ratings yet

- PEI Gas Stea Turbine Directory 2013Document327 pagesPEI Gas Stea Turbine Directory 2013GodsNo ratings yet

- Psib 20160225a-R2Document7 pagesPsib 20160225a-R2Léandre Ettekri NdriNo ratings yet

- Gas Turbine Compressor IssuesDocument9 pagesGas Turbine Compressor IssuesJJ100% (1)

- 08C - Protection - SeqDocument16 pages08C - Protection - SeqService Port100% (2)

- EngDocument44 pagesEngzomglolzscribdNo ratings yet

- P23e-Al-0255 (Ge)Document48 pagesP23e-Al-0255 (Ge)jgvruizNo ratings yet

- 26, Til 1621 Prevention of Water Accumulation Inside The Atomizing Air SystemDocument5 pages26, Til 1621 Prevention of Water Accumulation Inside The Atomizing Air Systemankarao69No ratings yet

- TIL 2363 - IGV Inspection and Maintenance For Gear & Rack TypeDocument11 pagesTIL 2363 - IGV Inspection and Maintenance For Gear & Rack TypeBouazzaNo ratings yet

- TIL 2363 R1 - IGV Inspection and Maintenance For Gear & Rack TypeDocument15 pagesTIL 2363 R1 - IGV Inspection and Maintenance For Gear & Rack TypeBouazzaNo ratings yet

- Psib 20160225a-R3Document6 pagesPsib 20160225a-R3Léandre Ettekri Ndri100% (1)

- 07 Uch GT 9001e - PMDocument6 pages07 Uch GT 9001e - PMHassan Mahmood100% (1)

- Thermal Peaking PDFDocument26 pagesThermal Peaking PDFkhozaqiNo ratings yet

- Gasturbine sgt5 8000h H Klasse Performance PDFDocument10 pagesGasturbine sgt5 8000h H Klasse Performance PDFAbd Elrahman HamdyNo ratings yet

- TIL 1879 - TIL 1879 Installation and Maintenance Recommendations For Exhaust ThermocouplesDocument26 pagesTIL 1879 - TIL 1879 Installation and Maintenance Recommendations For Exhaust ThermocouplesBouazzaNo ratings yet

- Ger4208 CSA ConceptDocument22 pagesGer4208 CSA Conceptaxl1No ratings yet

- 2 1 01 Auxiliary Gear BoxDocument30 pages2 1 01 Auxiliary Gear BoxHeryanto SyamNo ratings yet

- GT-1064-Disconnection and Removal, #1 Bearing Area Probes and TCPLsDocument20 pagesGT-1064-Disconnection and Removal, #1 Bearing Area Probes and TCPLsMadih ElghannamNo ratings yet

- Itp Transfer Tower - Xls (Bvi Comment)Document52 pagesItp Transfer Tower - Xls (Bvi Comment)Alif Rahmat FebriantoNo ratings yet

- MPL - 027 Permit To Work Form - 11.02.2022 Umingan Crushing PlantDocument1 pageMPL - 027 Permit To Work Form - 11.02.2022 Umingan Crushing PlantMaria Geraldine Zervoulakos100% (1)

- Token Ring Technology ReportFrom EverandToken Ring Technology ReportNo ratings yet

- GT-1064-Disconnection and Removal, #1 Bearing Area Probes and TCPLsDocument20 pagesGT-1064-Disconnection and Removal, #1 Bearing Area Probes and TCPLsMadih ElghannamNo ratings yet

- GT-1033-Speed Pickups & #1 Bearing Seismic Probes, Disconnection and RemovalDocument11 pagesGT-1033-Speed Pickups & #1 Bearing Seismic Probes, Disconnection and RemovalMadih Elghannam100% (1)

- GT-1002-Flame Detectors and Spark Plugs, Disconnection and RemovalDocument12 pagesGT-1002-Flame Detectors and Spark Plugs, Disconnection and RemovalMadih ElghannamNo ratings yet

- 102 00553 0619 Olin Sodium Hypochlorite ManualDocument39 pages102 00553 0619 Olin Sodium Hypochlorite ManualMadih ElghannamNo ratings yet

- GT-1041-Wheelspace TCPLS, Disconnection and RemovalDocument12 pagesGT-1041-Wheelspace TCPLS, Disconnection and RemovalMadih ElghannamNo ratings yet

- Confirmation Copybook Cursive SssDocument1 pageConfirmation Copybook Cursive SssMadih ElghannamNo ratings yet

- HP Bypass ValvesDocument3 pagesHP Bypass ValvesMadih ElghannamNo ratings yet

- 4016TAG1A-4016TAG2A Perkins TechexpoDocument10 pages4016TAG1A-4016TAG2A Perkins TechexpoMadih ElghannamNo ratings yet

- P1650 H1 Perkins 4016TAG1ADocument11 pagesP1650 H1 Perkins 4016TAG1AMadih ElghannamNo ratings yet

- 4016TAG1ADocument2 pages4016TAG1AMadih ElghannamNo ratings yet

- Biosci 3Document15 pagesBiosci 3MARJORYNo ratings yet

- Zomato FindingsDocument24 pagesZomato FindingsNibu MathewNo ratings yet

- Autism TherapyDocument2 pagesAutism TherapyVasile PitelNo ratings yet

- Five-Spot Vs Crestal Waterflood PatternsDocument4 pagesFive-Spot Vs Crestal Waterflood PatternsWafindraNo ratings yet

- G.R. No. 198501 Kestrel Shipping Inc. v. MunarDocument12 pagesG.R. No. 198501 Kestrel Shipping Inc. v. MunarJa RuNo ratings yet

- Pink Yarn, Green Yarn, Crochet Hook, Black Safety Eyes, Stuffing, Crochet Needle, Sewing Needle, Thread, ScissorsDocument3 pagesPink Yarn, Green Yarn, Crochet Hook, Black Safety Eyes, Stuffing, Crochet Needle, Sewing Needle, Thread, ScissorsMinhh Hoàngg100% (1)

- Clear Rinse Off Conditioner PDFDocument2 pagesClear Rinse Off Conditioner PDFHoracio GutierrezNo ratings yet

- SA2 2014 English Course - ADocument8 pagesSA2 2014 English Course - AsunnyNo ratings yet

- Operation Manual: SUT06D40L16-20 SUT10D40L16-20 SUT06D60L21-20 SUT10D60L21-20Document64 pagesOperation Manual: SUT06D40L16-20 SUT10D40L16-20 SUT06D60L21-20 SUT10D60L21-20hungstampNo ratings yet

- Supply Chain Management - Pgfa1941Document9 pagesSupply Chain Management - Pgfa1941Ravina SinghNo ratings yet

- Xi English Set 1Document4 pagesXi English Set 1aashirwad2076No ratings yet

- Hang Out 3 Student - S Key PDFDocument19 pagesHang Out 3 Student - S Key PDFyuliNo ratings yet

- Barreira OMRON MS4800Document36 pagesBarreira OMRON MS4800sandrasandradaxanaNo ratings yet

- Flow Control Valves: 1 DescriptionDocument6 pagesFlow Control Valves: 1 Descriptionnotitle91No ratings yet

- Manufacturing Sector Hi Tech Aerospace Auto Industrial Medical Devices Chemicals & ProcessDocument9 pagesManufacturing Sector Hi Tech Aerospace Auto Industrial Medical Devices Chemicals & ProcessSambit RathNo ratings yet

- Datasheet Luxor 530W LX 530M 144 Bifacial HalfCell PERCDocument2 pagesDatasheet Luxor 530W LX 530M 144 Bifacial HalfCell PERCDimitarNo ratings yet

- The Functionalist's View On Family (Sociology)Document9 pagesThe Functionalist's View On Family (Sociology)Donique GrahamNo ratings yet

- Fides Et Veritas: Marian School of Quezon CityDocument3 pagesFides Et Veritas: Marian School of Quezon Cityprecious alcantaraNo ratings yet

- De Ce of Eterm Emen F The Mina NT by e Solu Ation y Pho Ubiliz Nofa Otom Zed P Alum Metric Prod Inum C Titr Uct Min Ratio NDocument2 pagesDe Ce of Eterm Emen F The Mina NT by e Solu Ation y Pho Ubiliz Nofa Otom Zed P Alum Metric Prod Inum C Titr Uct Min Ratio NRomy Iván Cruz VillarroelNo ratings yet

- Global Vaccine Action Plan: Tetanus & Difteri (TD/DPT)Document6 pagesGlobal Vaccine Action Plan: Tetanus & Difteri (TD/DPT)Gusti IndrakusumaNo ratings yet

- Home Learning Environment ECE 17Document11 pagesHome Learning Environment ECE 17Sheeva AbenidoNo ratings yet

- Jung Typology TestDocument2 pagesJung Typology TestPhuong Thanh ANNo ratings yet

- Fish MorphologyDocument9 pagesFish Morphologydev_sharma1986100% (1)

- IFIF@: Ehicle Request Form & Rigging PlanDocument1 pageIFIF@: Ehicle Request Form & Rigging PlanfahadullahNo ratings yet

- Polymer Modified Concrete - Types, Properties and ApplicationsDocument3 pagesPolymer Modified Concrete - Types, Properties and ApplicationssahilkaushikNo ratings yet

- Food Facility Self Inspection ChecklistDocument2 pagesFood Facility Self Inspection Checklistmelisizwe2016No ratings yet