Professional Documents

Culture Documents

Numaligarh Refinery Expansion Project: Welding Procedure Specification (W.P.S)

Numaligarh Refinery Expansion Project: Welding Procedure Specification (W.P.S)

Uploaded by

Sumanta KuilaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Numaligarh Refinery Expansion Project: Welding Procedure Specification (W.P.S)

Numaligarh Refinery Expansion Project: Welding Procedure Specification (W.P.S)

Uploaded by

Sumanta KuilaCopyright:

Available Formats

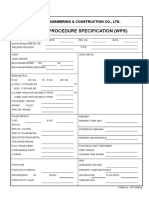

NUMALIGARH REFINERY EXPANSION PR

OWNER : M/S. NUMALIGARH REFINERY LIMITED

MPMC : M/S. TECHNIP INDIA LIMITED

CONTRACTOR : M/S. NF FORGINGS PRIVATE LIMITED

WELDING PROCEDURE SPECIFICATION (W.

PQR DOC NO:-

WPS DOC NO:-

WELDING PROCESS:

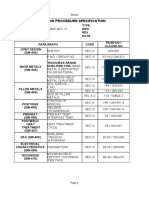

JOINTS (QW-402)

JOINTS DESIGN

BACKING

BACKING MATERIAL

BASE MATERIAL (QW-403)

MATARIAL SPECIFICATION

GROUP NO

P. NO TO P. NO

THICKNESS RANGE

PIPE DIA RANGE

OTHERS

FILLER MATAEIAL(QW-404)

ROOT SUBSEQUENT

SFN

AWS CLASS

F-NO

A-NO

SIZE OF FILLER MATARIAL

DEPOSITED FILLER MATERIAL THICKNESS

THICKNESS RANGE OF GROOVE

THICKNESS RANGE OF FILLET

POSITION (QW-405)

POSITION OF GROOVE

POSITION OF FILLET

POSITION OF PROGRESSION

PREHEAT(QW-406)

PREHEAT TEMP (Mn)

PREHEAT TEMP (Max)

WELDNG PROCEDUR

FILLER METAL

PASS OR WELD LAYERS(S) PROCESS CLASS

ROOT

FILL & CAP

EFINERY EXPANSION PROJECT

DOC NO:

EDURE SPECIFICATION (W.P.S)

DATE

DATE

POST WELD HEATING(QW-407)

TEMPERATURE

TIME(MIN)

HEATING/COOLING RATE

GROOVE

GROOVE

GAS(QW-408)

PRESENT COMPOSITION

GAS(ES) MIXTURE FLOW RATE(LPM)

SHIELDING

TRAILING

BACKING

ELECTRICAL CHRACTERISTICS(QW-409)

CURRENTS

VOLTS

TUNGSTEN SIZE

MODE OF METAL TRANSFER

FILLER WIER SPEED RANGE

OTHER

TECHNIQUE CHRACTERISTICS(QW-410)

TRAVEL SPEED RANGE(mm/min)

STRING OR WEAVE

OSCILLATION (max)

MULTI OR SINGLE PASS

MULTIPLE OR SINGLE ELECTRODE

CONTACT TUBE TO WORK DISTANCE

WELDNG PROCEDURE

FILLER METAL CURRENTS

AMPS OR WIRE TRAVEL JOINTS

DIA. TYPE & POLARITY FEED SPEED VOLTS SPEED DETAILS

You might also like

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingPutry NHy Saya0% (1)

- Joint Detail (Qw-402)Document2 pagesJoint Detail (Qw-402)Nitesh Patel100% (3)

- UPSC New Syllabus & Tips To Crack IAS Preliminary & Mains Exam PDFDocument59 pagesUPSC New Syllabus & Tips To Crack IAS Preliminary & Mains Exam PDFPrateek SahniNo ratings yet

- 02-Welding Procedure SpecificationDocument4 pages02-Welding Procedure Specificationveera Satya saiNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Document2 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Vaibhav GuptaNo ratings yet

- Welding Procedure Specification (WPS) : JOINTS (QW-402)Document4 pagesWelding Procedure Specification (WPS) : JOINTS (QW-402)Andhira FarizkiNo ratings yet

- WPS PQR XLSXDocument4 pagesWPS PQR XLSXMd Sahabul IslamNo ratings yet

- Welding Procedure Specification (WPS) : Posco Engineering & Construction Co., LTDDocument2 pagesWelding Procedure Specification (WPS) : Posco Engineering & Construction Co., LTDMoroko690% (1)

- IRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Document4 pagesIRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Mostafizur RahmanNo ratings yet

- GMCo - WPSDocument8 pagesGMCo - WPSMohamed AtefNo ratings yet

- Joint (QW-402)Document3 pagesJoint (QW-402)Satyaprakash RayNo ratings yet

- Wps Requirement FormatDocument1 pageWps Requirement Formatpradip meneNo ratings yet

- Gulf Coast Welding Corp. Houston, Texas Orp.: Qw-483 Procedure Qualification RecordDocument2 pagesGulf Coast Welding Corp. Houston, Texas Orp.: Qw-483 Procedure Qualification RecordCubzlookNo ratings yet

- Welding Procedure SpecificationDocument12 pagesWelding Procedure Specificationsanjay sharmaNo ratings yet

- Final WPS - ItdcDocument2 pagesFinal WPS - ItdcsarancivilrajNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadNo ratings yet

- WPS&PQR FormsDocument4 pagesWPS&PQR FormsArab WeldersNo ratings yet

- P& E WPS Template Rev 00 - OfficialDocument3 pagesP& E WPS Template Rev 00 - OfficialRiaan PretoriusNo ratings yet

- Welding Procedure Specification (WPS) : Code: Asme BPV Code Sec IxDocument4 pagesWelding Procedure Specification (WPS) : Code: Asme BPV Code Sec IxLipika GayenNo ratings yet

- Suggested Format PQRDocument2 pagesSuggested Format PQRAngel RebolloNo ratings yet

- Formas Soldadura ASME IX 2017Document7 pagesFormas Soldadura ASME IX 2017Ulises GómezNo ratings yet

- ASME WPS-PQR-WQT CombinedDocument6 pagesASME WPS-PQR-WQT CombinedStan HonNo ratings yet

- Fcaw Wps-001a PDFDocument3 pagesFcaw Wps-001a PDFirfan bari100% (1)

- Neo Structo Construction Limited Welding Procedure Specifications (WPS) (QW-200.1, SEC IX, ASME Boiler and Pressure Vessel Code)Document6 pagesNeo Structo Construction Limited Welding Procedure Specifications (WPS) (QW-200.1, SEC IX, ASME Boiler and Pressure Vessel Code)rohitbhat2345No ratings yet

- Quality Control Form: N/A UP Hill Down HillDocument2 pagesQuality Control Form: N/A UP Hill Down HillAlesol EquipmentNo ratings yet

- Quality Control Form: N/A UP Hill Down HillDocument2 pagesQuality Control Form: N/A UP Hill Down HillAlesol EquipmentNo ratings yet

- Sample Editable WPSDocument2 pagesSample Editable WPSf silva-No ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Sample Editable WPSDocument2 pagesSample Editable WPSsbmmlaNo ratings yet

- Joint No: Backing: Yes No Backing Mat: N/ADocument1 pageJoint No: Backing: Yes No Backing Mat: N/ALipika GayenNo ratings yet

- WPS FormatDocument2 pagesWPS Formatakhilsyam21No ratings yet

- Welding Procedure Specification (WPS) (Asme Sec - Ix) : Manual Semi-Automatic Automatic MachineDocument1 pageWelding Procedure Specification (WPS) (Asme Sec - Ix) : Manual Semi-Automatic Automatic Machinesoroushsadeghi60No ratings yet

- WPS&PQR For PipeDocument5 pagesWPS&PQR For PipeKAMALNo ratings yet

- WPSDocument2 pagesWPSBalu SukumarNo ratings yet

- (Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Document2 pages(Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Quality LaveenaNo ratings yet

- Wps FormatDocument2 pagesWps FormatMeghan GhoneNo ratings yet

- WPS Final PLATE 13062018 RevisedDocument8 pagesWPS Final PLATE 13062018 RevisedPradip GhoshNo ratings yet

- Asme Sec Ix 2019 380Document1 pageAsme Sec Ix 2019 380Balkishan DyavanapellyNo ratings yet

- Tips Wps FormatDocument5 pagesTips Wps FormatWaqas WaqasNo ratings yet

- Form Qw-483 Suggested Format For Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code) Record Actual Variables Used To Weld Test CouponDocument2 pagesForm Qw-483 Suggested Format For Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code) Record Actual Variables Used To Weld Test CouponMijanur Rahman100% (1)

- Document No.: RevDocument2 pagesDocument No.: RevInaamNo ratings yet

- Procedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingDocument6 pagesProcedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingNovita Dwi IsnaeniNo ratings yet

- BPVC Ix qf-482bDocument1 pageBPVC Ix qf-482bEmma DNo ratings yet

- PQRDocument3 pagesPQRnazirulhakimNo ratings yet

- PQR FormatDocument2 pagesPQR FormatBE GNo ratings yet

- WpsDocument3 pagesWpsPankaj KumarNo ratings yet

- Procedure Qualification Record (PQR)Document3 pagesProcedure Qualification Record (PQR)surjithkocherilNo ratings yet

- Form PQR 1 AsmeDocument6 pagesForm PQR 1 AsmeZam Zam NoorNo ratings yet

- Wps PQR Welder Qualification Certification ConsultancyDocument2 pagesWps PQR Welder Qualification Certification ConsultancyEmam SayedNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document2 pagesQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 pagesWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- WPS FormDocument1 pageWPS FormNabil RadyNo ratings yet

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Document48 pagesQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Gas Pressure Reducing: Gas Pressure Reducing & Shut-Off Valve & Shut-Off Valve Series 71P11A Series 71P11ADocument4 pagesGas Pressure Reducing: Gas Pressure Reducing & Shut-Off Valve & Shut-Off Valve Series 71P11A Series 71P11AĐình Sơn HoàngNo ratings yet

- Bael-Tree Details and Medicinal UsesDocument4 pagesBael-Tree Details and Medicinal UsesSanjay PatilNo ratings yet

- MATH 4 PPT Q3 W4 - Lesson 52 - Quadrilateral 1Document17 pagesMATH 4 PPT Q3 W4 - Lesson 52 - Quadrilateral 1Erika Mae TupagNo ratings yet

- LTE TDD - Network - Export - 2018 - 07 - 04Document3,760 pagesLTE TDD - Network - Export - 2018 - 07 - 04saadNo ratings yet

- Perdev Module 3Document13 pagesPerdev Module 3Renelyn JacoNo ratings yet

- Cults and Temples of The Middle World (FG&G)Document77 pagesCults and Temples of The Middle World (FG&G)Paul SavvyNo ratings yet

- Tiny Talk 2 Teacher's BookDocument15 pagesTiny Talk 2 Teacher's BookAtena RaeisiNo ratings yet

- Uccx732X Dual 4-A Peak High-Speed Low-Side Power-Mosfet DriversDocument38 pagesUccx732X Dual 4-A Peak High-Speed Low-Side Power-Mosfet DriversTeles SilvaNo ratings yet

- Green Building Toward Construction Sustainability: Energy Efficiency With Material and Design AspectsDocument11 pagesGreen Building Toward Construction Sustainability: Energy Efficiency With Material and Design AspectsghchgNo ratings yet

- Water Content in SoilDocument4 pagesWater Content in SoilJohn Paul CristobalNo ratings yet

- Schiavi Enc Met Page015Document1 pageSchiavi Enc Met Page015Adel AdelNo ratings yet

- Straumann Product Catalogue 2018 2019Document260 pagesStraumann Product Catalogue 2018 2019kllasikalleNo ratings yet

- 10 Science TP 11 1Document5 pages10 Science TP 11 1Ananaya BansalNo ratings yet

- Lecture 4Document24 pagesLecture 4Geeta AroraNo ratings yet

- Therapeutic Diet Manual: DIRECTIVE #4311Document27 pagesTherapeutic Diet Manual: DIRECTIVE #4311DuNo ratings yet

- Urinalysis - Fatin AinaDocument14 pagesUrinalysis - Fatin AinaAl- ImanuddinNo ratings yet

- Visual Storytelling The Digital Video Documentary - Original PDFDocument44 pagesVisual Storytelling The Digital Video Documentary - Original PDFjparanoti100% (1)

- Practice Exam Linear Algebra PDFDocument2 pagesPractice Exam Linear Algebra PDFShela RamosNo ratings yet

- TDS 0033 FlexoTop 202003Document3 pagesTDS 0033 FlexoTop 202003Mearg NgusseNo ratings yet

- Background of Philippine Art and Literature in Romantic RealismDocument2 pagesBackground of Philippine Art and Literature in Romantic RealismRaldz CoyocaNo ratings yet

- How To Keep Your Brain HealthyDocument3 pagesHow To Keep Your Brain HealthySyahidah IzzatiNo ratings yet

- Dhauliganga ProjectDocument2 pagesDhauliganga ProjectAntra Chowdhury100% (1)

- Drawing Details: Cie 332 Quantity Surveying and Estimation Lecture Two Lecturer: Eng. Goodson MashekaDocument23 pagesDrawing Details: Cie 332 Quantity Surveying and Estimation Lecture Two Lecturer: Eng. Goodson MashekaPerpetual hubbyNo ratings yet

- Gds Manual Flo2d ProDocument182 pagesGds Manual Flo2d ProbycmNo ratings yet

- CWAG Rectangular CoordinatesDocument52 pagesCWAG Rectangular CoordinatesRolando MerleNo ratings yet

- Describe Physical and Chemical Change OperationallyDocument2 pagesDescribe Physical and Chemical Change OperationallyMaria Anna GraciaNo ratings yet

- CD Dye RD0005Document7 pagesCD Dye RD0005Juan CarlosNo ratings yet

- Sri Lank An Airline IndustryDocument29 pagesSri Lank An Airline IndustryTuan RifkhanNo ratings yet

- Electronics Cooling: Mechanical Power Engineering DeptDocument22 pagesElectronics Cooling: Mechanical Power Engineering DeptneilNo ratings yet