Professional Documents

Culture Documents

Er70s-2 MSDS

Er70s-2 MSDS

Uploaded by

Vinodh KannaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Er70s-2 MSDS

Er70s-2 MSDS

Uploaded by

Vinodh KannaCopyright:

Available Formats

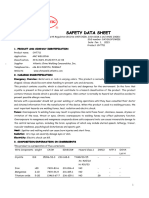

MATERIAL SAFETY DATA SHEET SECTION 6 – HEALTH HAZARD DATA

This Material Safety Data Sheet (MSDS) complies with the requirements of OSHA’s Hazard Communication Standard. Carcinogenicity: The composition of welding or brazing fumes may contain carcinogens, depending on several factors that

are unknown and unknowable to the product manufacturer (see Section 5). Always assume that welding or brazing fumes

ER 70S-2, ER 70S-3, ER70S-6 WELDING WIRE may contain toxic and/or carcinogenic materials, and follow sound Work/Hygiene practices as recommended by ANSI Z49.1.

Emergency Phone Number: Threshold Limit Value: The ACGIH recommended general limit for Welding Fume NOC – (Not otherwise Classified) is

5 mg/m3. ACGIH-1987-88 preface states that the TLV-TWA should be used as guides in the control of health hazards

866-734-3438 and should not be used as fine lines between safe and dangerous concentrations. See Section 5 for specific fume

Date: April 30, 2006 Product Information Number: 888-838-0615 constituents which may modify this TLV. Threshold Limit Values are figures published by the American Conference of

Government Industrial Hygienists. Units are milligrams per cubic meter of air. Effects of Overexposure: Electric arc

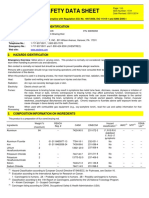

SECTION 1 – PRODUCT IDENTIFICATION welding may create one or more of the following health hazards: Fumes and Gases can be dangerous to your health.

Product Name/Class AWS A5.18, ER 70S-2, ER 70S-3, ER 70S-6 Welding Wire Common entry is by inhalation. Other possible routes are skin contact and ingestion. Short-term (acute) overexposure to

welding fumes may result in discomfort such as metal fume fever, dizziness, nausea, or dryness or irritation of nose,

Product Number 004023 throat, or eyes. May aggravate pre-existing respiratory problems (e.g. asthma, emphysema). Exposure to extremely high

levels of fluorides can cause abdominal pain, diarrhea, muscular weakness, and convulsions. In extreme cases it can

Manufacturer Radnor Welding Products 259 N. Radnor-Chester Road Suite 100 Radnor, PA 19087-5283 cause loss of consciousness and death. Long-term (chronic) overexposure to welding fumes can lead to siderosis (iron

deposits in lung) and may affect pulmonary function. Manganese overexposure can affect the central nervous system,

SECTION 2 – HAZARDOUS INGREDIENTS resulting in impaired speech and movement. Bronchitis and some lung fibrosis have been reported. Repeated exposure

ACGIH SARA to fluorides may cause excessive calcification of the bone and calcification of ligaments of the ribs, pelvis and spinal

Material CAS Number % By Weight TLV Section 313 column. May cause skin rash. Arc Rays can injure eyes and burn skin. Skin cancer has been reported. Electric Shock

can kill. If welding must be performed in damp locations or with wet clothing, on metal structures or when in cramped

Carbon 1333-86-4 <.50 3.5 MG/M3 Carbon N/A positions such as sitting, kneeling or lying, if there is a high risk of unavoidable or accidental contact with workpiece, use

Manganese 7439-96-5 <2.50 C 5MG/M3 Mn & Mn Yes the following equipment: Semiautomatic DC Welder, DC Manual (Stick) Welder, or AC Welder with Reduced Voltage

Silicon 7440-21-3 <1.50 10 MG/M3 Total N/A Control. Emergency and First Aid Procedures: Call for medical aid. Employ first aid techniques recommended by the

Copper 7440-50-8 <.50 .2 MG/M3 Yes American Red Cross. IF BREATHING IS DIFFICULT give oxygen. IF NOT BREATHING employ CPR

(Cardiopulmonary Resuscitation) techniques. IN CASE OF ELECTRICAL SHOCK, turn off power and follow

Molybdenum 7439-98-7 <.75 5 MG/M3 N/A recommended treatment. In all cases, call a physician.

Aluminum 7429-90-5 <.50 3

15 MG/M as Weld Yes HMIS Rating HMIS Scale NFPA Rating NFPA Scale

Titanium 7440-32-6 <.50 10 MG/M3 TiO AS N/A 4 = Severe Hazard 4 = Severe Hazard

Health = 2 Health = 1

Zirconium 7440-67-7 <.50 5 MG/M3 AS Zr N/A 3 = Serious Hazard 3 = Serious Hazard

Iron 7439-89-6 Balance 5 MG/M3 Fe203 Fe N/A Flammability = 0 2 = Moderate Hazard Flammability = 0 2 = Moderate Hazard

Reactivity = 0 1 = Slight Hazard Reactivity = 0 1 = Slight Hazard

SECTION 3 – PHYSICAL CHARACTERISTICS 0 = Minimal Hazard Other = 0 0 = Minimal Hazard

Boiling Point: Specific Gravity (H2O = 1): Solubility in Water:

N/A N/A N/A SECTION 7 – PRECAUTIONS for SAFE HANDLING and USE

Steps to Be Taken in Case Material Is Released or Spilled: N/A

Vapor Pressure (mm Hg): Melting Point: %Volatile:

N/A N/A N/A Waste Disposal Method: Prevent waste from contaminating surrounding environment. Discard product residue,

disposable container or liner in an environmentally acceptable manner, in full compliance with federal, state, and local

Vapor Density (Air = 1): Evaporation Rate (Butyl Acetate=1): Appearance and Odor: regulations.

N/A N/A Solid Wire or Rod. Precautions to Be Taken In Handling and Storing: N/A

SECTION 4 – FIRE and EXPLOSION HAZARD DATA Other Precautions: N/A

Flash Point (Method Used): LEL: N/A

Flammable Limits: SECTION 8 – CONTROL MEASURES

N/A UEL: N/A Respiratory Protection (Specify Type): Make sure inhaled air does not contain fume constituents above

Extinguishing Media: N/A permissible exposure levels.

Special Fire Fighting Procedures: Non Flammable. Welding arc and sparks can ignite combustibles and Ventilation: Use enough ventilation, local exhaust at the arc, or both to keep the fumes and gases from the worker’s

flammables. Refer to American National Standard Z49.1 for fire prevention during the use of welding and allied breathing zone and the general area. Train the welder to keep his head out of the fumes. Keep exposure as low as

procedures. possible.

Unusual Fire and Explosion Hazards: N/A Protective Gloves: Leather welding gloves. Eye Protection: Safety glasses with shaded lenses.

SECTION 5 – REACTIVITY DATA Other Protective Clothing or Equipment: Wear hand, head, and body protection which help to prevent injury from

Unstable Conditions to Avoid: N/A radiation, sparks and electrical shock or burns. See Z49.1. At a minimum this includes welder’s gloves and a protective

Stability face shield or goggles, and may include arm protectors, aprons, hats, shoulder protection, as well as heat-resistant

Stable clothing.

Incompatibility (Materials to Avoid): None Work/Hygienic Practices: For maximum safety: Be certified for, and wear a respirator at all times when welding or

Hazardous Decomposition or Byproducts: The composition and quality of welding fumes and gases are brazing.

dependent upon metal being welded, process, and electrode being used. Other factors include coatings on OTHER INFORMATION REQUIRED BY STATE OR FEDERAL LAW

the metal being welded (paint, plating or galvanizing), number of welders and volume of work area as

presence of contaminants in atmosphere. When electrode is consumed fume and gas decomposition California Proposition 65 Information: Warning: This product contains a chemical known to the State of

products generated are different in percent and form from ingredients listed in Section 2. Fume and gas California to cause cancer.

decomposition products, and not ingredients in electrode, are important. The concentration of given fume New Jersey Right-To-Know Information: 5 most predominant ingredients/hazardous and non-hazardous)

or gas component may decrease or increase by many times original concentration in electrode. New

compounds not in electrode may form decomposition products of normal operation include those 1. Iron; 2. Manganese; 3. Silicon; 4. Molybdenum; 5. Copper.

originating from volatilization, reaction, oxidation of materials in Section 2, plus those from base metal SARA Title III Notification Information: All chemical compounds marked with an asterisk (*) are toxic

and coating. chemicals subject to the reporting requirements of Section 313 of Title III of the Super Fund Amendments

Reasonably expected fume constituents of product could include primarily oxides of iron; secondarily and Reauthorization Act (SARA) of 1986 and 40 CFR Part 372.

complex oxides of manganese & silicon & aluminum. Gaseous reaction products – carbon monoxide, Disclaimer of Expressed and Implied Warranties: The information in this document is believed to be

carbon dioxide. Ozone and nitrogen oxides may be formed by radiation from arc, and shielding gases correct as of the date issued. However, no warranty of merchantability, fitness for any particular purpose,

when employed. One recommended way to determine composition and quantity of fumes and gases to or any other warranty is expressed or is to be implied regarding the accuracy or completeness of this

which workers are exposed is to take air sample from inside welders helmet or in working zone. See information, the results to be obtained from the use of this information or the product, the safety of this

AWS F1.1 and AWS F1.2-1985, available from American Welding Society. See AWS publication: product, or the hazards related to its use.

“Fumes and Gases in the Welding Environment”.

Hazardous May Occur Conditions to Avoid: N/A

Polymerization Will Not Occur

You might also like

- Sociology Tenth Canadian Edition 10Th Edition Full ChapterDocument41 pagesSociology Tenth Canadian Edition 10Th Edition Full Chapterclifton.barrocas861100% (28)

- Dha McqsDocument32 pagesDha Mcqssohailsu67% (3)

- TR 41 B - EN-LubDocument7 pagesTR 41 B - EN-LubVinodh KannaNo ratings yet

- EN - Panlube S 37Document4 pagesEN - Panlube S 37Vinodh Kanna100% (1)

- The Dangers of Cell Phones Persuasive Speech OutlineDocument5 pagesThe Dangers of Cell Phones Persuasive Speech OutlineMo Syafiq Ya Shak0% (1)

- Msds Product Name: Aws E7018 Welding ElectrodeDocument2 pagesMsds Product Name: Aws E7018 Welding ElectrodeAdel AbduoNo ratings yet

- MSDS E7018Document1 pageMSDS E7018Ahmad Abu Basil Izzuddin Nur Al AslamNo ratings yet

- Emergency Phone Number: 1-866-272-4378: Material Safety Data Sheet 6010 Welding ElectrodeDocument1 pageEmergency Phone Number: 1-866-272-4378: Material Safety Data Sheet 6010 Welding ElectrodeSona MahardhikaNo ratings yet

- 17.welding Rods - MSDSDocument1 page17.welding Rods - MSDSPrabath VlogsNo ratings yet

- MSDS Er70s 6Document1 pageMSDS Er70s 6RosyidiMuhammadMahfudzNo ratings yet

- Material Safety Data Sheet: Emergency Phone Number: 1-866-272-4378Document1 pageMaterial Safety Data Sheet: Emergency Phone Number: 1-866-272-4378So MayeNo ratings yet

- Murex Murexmatic S6 May 12 1999Document2 pagesMurex Murexmatic S6 May 12 1999aq.shuotNo ratings yet

- 51 EX Msds 9-07Document3 pages51 EX Msds 9-07Mohamed AdelNo ratings yet

- MSDS Flooded Lead AcidDocument4 pagesMSDS Flooded Lead AcidRonaldo RumbekwanNo ratings yet

- ZULFI E6013 Welding ElectrodesDocument1 pageZULFI E6013 Welding ElectrodesJunard M. Lu HapNo ratings yet

- 6010 Usf MSDS 12-06Document3 pages6010 Usf MSDS 12-06mohamed AdelNo ratings yet

- Avesta Ernicrmo-3: Material Safety Data Sheet Nickel Base Welding WireDocument7 pagesAvesta Ernicrmo-3: Material Safety Data Sheet Nickel Base Welding WireLawrence Lancy LoboNo ratings yet

- Trojan - MSDSDocument4 pagesTrojan - MSDSminh nguyễn mậu đoanNo ratings yet

- Rci RodDocument2 pagesRci Rodabdul rochimNo ratings yet

- Material Safety Data Sheet: What Is The Material and What Do I Need To Know in An Emergency?Document9 pagesMaterial Safety Data Sheet: What Is The Material and What Do I Need To Know in An Emergency?haharameshNo ratings yet

- La 71 MSDSDocument2 pagesLa 71 MSDSdeepak2803No ratings yet

- Stainless Steel Welding WireDocument2 pagesStainless Steel Welding WireAnonymous zfC1zo9CNo ratings yet

- MSDS Stainless Steel Welding Wire PDFDocument2 pagesMSDS Stainless Steel Welding Wire PDFIspinardi Harjanto100% (1)

- Tungsten MSDS 09Document2 pagesTungsten MSDS 09Serkan ApayNo ratings yet

- Aluminum Wires and Rods 1Document2 pagesAluminum Wires and Rods 1OteranmoralesNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument4 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelNo ratings yet

- 360, 370, 380 Brazing Rod MG MSDS 6-09Document3 pages360, 370, 380 Brazing Rod MG MSDS 6-09orcbane27No ratings yet

- 32 EX Msds 9-07Document3 pages32 EX Msds 9-07Mohamed AdelNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument4 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelNo ratings yet

- Material Safety Data Sheet: Section I - IdentificationDocument2 pagesMaterial Safety Data Sheet: Section I - IdentificationluisarmandomayonietoNo ratings yet

- Lincoln 5P+ MsdsDocument2 pagesLincoln 5P+ MsdssalcabesNo ratings yet

- pd3 Basket Assembly MsdsDocument10 pagespd3 Basket Assembly MsdsAnish PalNo ratings yet

- West Arco Safety SheetDocument7 pagesWest Arco Safety SheetScribdTranslationsNo ratings yet

- MSDS NiCrDocument2 pagesMSDS NiCrBety FajriaNo ratings yet

- In-W610 (Merit LMC 6 - Er70s-6) - 1Document2 pagesIn-W610 (Merit LMC 6 - Er70s-6) - 1Pratik LadNo ratings yet

- MX-A430MDocument7 pagesMX-A430MMr.HYCONo ratings yet

- Material Safety Data Sheet Material Safety Data Sheet: Section I - IdentificationDocument2 pagesMaterial Safety Data Sheet Material Safety Data Sheet: Section I - IdentificationAdel AbduoNo ratings yet

- Material Safety Data Sheet (MSDS)Document2 pagesMaterial Safety Data Sheet (MSDS)Heri SusantoNo ratings yet

- ARCAIR (MSDS) COPPERCLAD POINTED ELECTRODES Expires 16-07-02Document3 pagesARCAIR (MSDS) COPPERCLAD POINTED ELECTRODES Expires 16-07-02PubcrawlNo ratings yet

- Material Safety Data Sheet: Metglas 2714A Cobalt Based AlloyDocument8 pagesMaterial Safety Data Sheet: Metglas 2714A Cobalt Based AlloyHwalam LeeNo ratings yet

- MSDS AlloysDocument15 pagesMSDS AlloysMaryam EradewiNo ratings yet

- Mild Steel Solid Mig Wire MSDSDocument2 pagesMild Steel Solid Mig Wire MSDSsalcabesNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument5 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelNo ratings yet

- M S D S: Aterial Afety ATA HeetDocument4 pagesM S D S: Aterial Afety ATA HeetJhony MedranoNo ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoNo ratings yet

- BÖHLER (MSDS) SMAW-AVESTA 2205 E2209-15 Expires 15-12-05Document2 pagesBÖHLER (MSDS) SMAW-AVESTA 2205 E2209-15 Expires 15-12-05PubcrawlNo ratings yet

- Safety Data Sheet: 1. Chemical Product and Company IdentificationDocument7 pagesSafety Data Sheet: 1. Chemical Product and Company IdentificationMr.HYCONo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument5 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelNo ratings yet

- 2233N XUPERUS-en119310Document9 pages2233N XUPERUS-en119310Juan LondonoNo ratings yet

- 54L EutectrodeDocument9 pages54L EutectrodeJuan LondonoNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument4 pagesSafety Data Sheet: 1. Product and Company IdentificationMohamed AdelNo ratings yet

- Material Safety Data Sheet (MSDS) : EMERGENCY: 800-424-9300Document3 pagesMaterial Safety Data Sheet (MSDS) : EMERGENCY: 800-424-9300Darius DsouzaNo ratings yet

- Safety Data Sheet: 1. Product IdentificationDocument6 pagesSafety Data Sheet: 1. Product Identificationmohamed AdelNo ratings yet

- Samsung 25R MSDSDocument8 pagesSamsung 25R MSDSRais Ovadeyyanusasey AliemNo ratings yet

- MsdsDocument5 pagesMsdsLisa NurhasanahNo ratings yet

- MsdsDocument3 pagesMsdsTobi MazzoccaNo ratings yet

- Safety Data Sheet (MSDS CHT711 2023.1.1) (CHT711 JT-71T1-) From Atlantic 20231228Document5 pagesSafety Data Sheet (MSDS CHT711 2023.1.1) (CHT711 JT-71T1-) From Atlantic 20231228sergio.lopezNo ratings yet

- Fs20-201208 Password RemovedDocument3 pagesFs20-201208 Password RemovedRaron1No ratings yet

- 1 TufTrak EC SMAW Msds 2-10Document3 pages1 TufTrak EC SMAW Msds 2-10mohamed AdelNo ratings yet

- Flux Core Welding WireDocument3 pagesFlux Core Welding Wiremuhamad bukhari abu hassanNo ratings yet

- Bezpečnostní List S-717 - EngDocument8 pagesBezpečnostní List S-717 - Engz9zsbwnnfvNo ratings yet

- Occupational Radiation Protection in the Uranium Mining and Processing IndustryFrom EverandOccupational Radiation Protection in the Uranium Mining and Processing IndustryNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Standard 189Document1 pageStandard 189Vinodh KannaNo ratings yet

- Flow Meters and Level SensorsDocument1 pageFlow Meters and Level SensorsVinodh KannaNo ratings yet

- Gemba Observation SheetDocument2 pagesGemba Observation SheetVinodh KannaNo ratings yet

- Redimix FluxDocument15 pagesRedimix FluxVinodh KannaNo ratings yet

- Raw Water Recieving Areas & Tank DetilesDocument1 pageRaw Water Recieving Areas & Tank DetilesVinodh KannaNo ratings yet

- Aperam Hydrogen Applications en WebDocument6 pagesAperam Hydrogen Applications en WebVinodh KannaNo ratings yet

- Phosphoric (Aditya) MSDSDocument6 pagesPhosphoric (Aditya) MSDSVinodh KannaNo ratings yet

- Tds 4730Document3 pagesTds 4730Vinodh Kanna100% (1)

- Pancover MSDSDocument7 pagesPancover MSDSVinodh KannaNo ratings yet

- Msds-Lime PowderDocument6 pagesMsds-Lime PowderVinodh KannaNo ratings yet

- GeM Bidding 3972983Document7 pagesGeM Bidding 3972983Vinodh KannaNo ratings yet

- En 1440Document6 pagesEn 1440Vinodh KannaNo ratings yet

- Abstract HCLDocument3 pagesAbstract HCLVinodh KannaNo ratings yet

- Copper & Acid RequirementDocument1 pageCopper & Acid RequirementVinodh KannaNo ratings yet

- TR41B - e MSDSDocument1 pageTR41B - e MSDSVinodh KannaNo ratings yet

- Cswip Chapter 1-15 MCQ Part 1Document125 pagesCswip Chapter 1-15 MCQ Part 1Vinodh Kanna100% (1)

- Diabetes Complications EnglishDocument2 pagesDiabetes Complications Englishapi-509392844No ratings yet

- Gema Insan Company Profile IT & Medical (09 May2016) PDFDocument27 pagesGema Insan Company Profile IT & Medical (09 May2016) PDFzulkipliyaacobNo ratings yet

- Unit 6 Test: Global Listening Listening To Categorize InformationDocument3 pagesUnit 6 Test: Global Listening Listening To Categorize InformationViễn Phúu100% (1)

- SMS - Student Information BrochureDocument2 pagesSMS - Student Information Brochuredheeraj531No ratings yet

- Q1 Dll-Mapeh 10 - PeDocument8 pagesQ1 Dll-Mapeh 10 - PeGLADYS MAE DELA PENANo ratings yet

- Public Speaking 2020Document2 pagesPublic Speaking 2020Anm AranNo ratings yet

- Review: Different Activities of Moringa Oleifera TreeDocument4 pagesReview: Different Activities of Moringa Oleifera TreeInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Can Marijuana Help With or Prevent Alzheimer'sDocument10 pagesCan Marijuana Help With or Prevent Alzheimer'sLorina BoligNo ratings yet

- Syllabus With Nos of Reporters CHild and Adolescent PsychologyDocument2 pagesSyllabus With Nos of Reporters CHild and Adolescent PsychologyZienna M. GualvezNo ratings yet

- The Draft Canmeds 2015: Milestones GuideDocument52 pagesThe Draft Canmeds 2015: Milestones GuideFemin PrasadNo ratings yet

- EWESDocument10 pagesEWESPratham KatariyaNo ratings yet

- Specs For Eninst 620 040 600Document2 pagesSpecs For Eninst 620 040 600NicolaNo ratings yet

- Effects of A Risk and Resilience Course On Stress, Coping Skills, and Cognitive Strategies in College StudentsDocument7 pagesEffects of A Risk and Resilience Course On Stress, Coping Skills, and Cognitive Strategies in College StudentscrazyappleNo ratings yet

- Platyhelminthes - CestodaDocument35 pagesPlatyhelminthes - Cestodaerica williamsNo ratings yet

- Rapid Palatal ExpansionDocument24 pagesRapid Palatal Expansiondaniela2201No ratings yet

- REPUBLIC ACT NO. 10354 (The Responsible Parenthood and Reproductive Health Act of 2012) PDFDocument15 pagesREPUBLIC ACT NO. 10354 (The Responsible Parenthood and Reproductive Health Act of 2012) PDFYappi NaniNo ratings yet

- User Manual CardiostartDocument91 pagesUser Manual CardiostartSaul Rivera PerezNo ratings yet

- Oral Cancer ScreeningDocument9 pagesOral Cancer ScreeningenNo ratings yet

- 1st Lect 1st Semester 29.3.19 Introduction BioerhicsDocument23 pages1st Lect 1st Semester 29.3.19 Introduction BioerhicsInayatNo ratings yet

- Pds Morrison TKF ExportDocument1 pagePds Morrison TKF ExportixmorrisonNo ratings yet

- Tiktok SuplemenDocument53 pagesTiktok Suplemenfitriindriani025No ratings yet

- Tissue Plasminogen Activator and Thrombin.17Document2 pagesTissue Plasminogen Activator and Thrombin.17ellie<3No ratings yet

- 04 Handout 4Document2 pages04 Handout 4Dwayne JohnsonNo ratings yet

- Efectiveness WhatsApp Gruoup On Breastfeeding PracticesDocument10 pagesEfectiveness WhatsApp Gruoup On Breastfeeding PracticesrianiapriNo ratings yet

- Multi MacaDocument3 pagesMulti MacareenakotakNo ratings yet

- NCM116-LESSON1-RLE StressDocument5 pagesNCM116-LESSON1-RLE StressMilcah NuylesNo ratings yet

- 20 Working Length DeterminationDocument20 pages20 Working Length DeterminationModerator Zhi Ling YauNo ratings yet