Professional Documents

Culture Documents

SPS350LSA

SPS350LSA

Uploaded by

bereketOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SPS350LSA

SPS350LSA

Uploaded by

bereketCopyright:

Available Formats

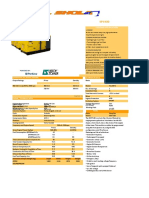

SPS350

STANDARD SPECIFICATIONS

1. ENGINE

Perkins four stroke heavy duty high performance

industrial type diesel engine

2. ENGINE FILTRATION SYSTEM

▪ Cartridge type dry air filter

▪ Two cartridge type fuel filters

▪ Full flow lube oil filter

All filters have replacable elements

3. COOLING RADIATOR

Radiator and cooling fan, complete with safety

guards,designed to cool the engine at high ambient

temperatures(consult your dealer for deration factors)

4. EXHAUST SYSTEM

Heavy duty Industrial Exhaust Silencer

Silencer noise reduction level 13 (dB)

Maximum allowable back pressure 10.0(kPa) @ 50 Hz

5. CIRCUIT BREAKER TYPE

ABB 3 pole MCCB.(4 pole is optional)

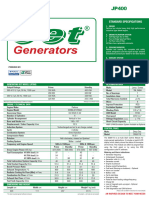

GENERATING SET MODEL (WPS350) ALTERNATOR DATA

POWERED BY :

Output Ratings Prime Standby Make Leroy Somer

380-415 V,3 ph,50 Hz,1500 rpm 350 kVA 400 kVA Model LSA TAL 046H

280 kW 320 kW No. of bearings 1

480 V,3 ph,60 Hz,1800 rpm 400 kVA 438 kVA Insulation Class H

At no load 3.5%

320 kW 350.4 kW Total Harmonic Content

At full load 5.0%

Wires 6

Power Factor : 0.8

ENGINE / TECHNICAL DATA Ingress Protection IP23

Engine Make Perkins Excitation System SHUNT

Engine Model 2206A-E13TAG2 Winding Pitch 2/3(n˚6)

Governing Type Electronic AVR Model R120

Number of Cylinders 6 Overspeed 2250 mn⁻¹

Cylinder Arrangement Vertical In Line Voltage Regulation ±1%

Bore and Stroke mm 130 x 157 Short Circuit Capacity >300%

Displacement / Cubic Capacity ltrs 12.5

CONTROL PANEL

Induction System Turbocharged, air to air

Cycle 4 stroke Make Deep Sea

Combustion System Direct Injection Model DSE7310

Compression Ratio 16.3:1 The DSE7310 is an Auto Start Control Module for

Rotation Anti-clockwise single genset applications.It includes a backlit LCD

Cooling System Water Cooled display which clearly shows the status of the engine

Frequency and Engine Speed 50Hz & 1500rpm 60Hz & 1800rpm all the times.This module can either be pr ogrammed

Prime Standby Prime Standby using the front panel or by using the DSE

Gross Engine Power kW(hp) 324(434) 368(493) 373(500) 407(546) configuration suitr PC software.

Fuel Consumption @50%load L/hr 37 - 43 - Metering and Alarm Indications:

@75%load L/hr 54 - 62 - ▪ Generator Frequency

@100%load L/hr 71 80 81 87 ▪ Underspeed, Overspeed

Total Lubrication System Capacity ltrs 40 40 40 40 ▪ Generator volts(L-L,L-N)

Total Coolant Capacity ltrs 51.4 51.4 51.4 51.4 ▪ Generator Current

Boost Pressure Ratio 2.8 3.2 3.1 3.4 ▪ Engine Oil Pressure

Exhaust Temperature °C 630 630 630 660 ▪ Engine Coolant Temperature

Radiator Cooling Air Flow(Min):m³/sec 9.4 9.4 12 12 ▪ Fuel Level

Combustion Air Flow:m³/min 21.3 23.6 27.4 29 ▪ Hours Run Counter

Exhaust Gas Flow:m³/min 56.6 64.8 67.5 73.5 ▪ Battery Volts

Fuel Tank Capacity: ltrs 525 525 525 525 ▪ Fail to start/stop

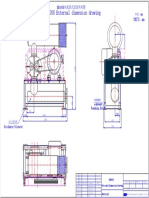

Dimension (mm) & Weight (Kg) Length Width Height Weight ▪ Emergency Stop

OPEN 3200 1110 2070 3366 ▪ Failed to reach loading voltage/frequency

SOUNDPROOF ▪ Charge fail

▪ Loss of magnetic pick-up signal-Optional

▪ Low DC Voltage

▪ CAN diagnostics and CAN fail/error

RATINGS DEFINITION STANDARD SPECIFICATIONS

Prime Power

These ratings are applicable for supplying continous electrical power(at variable load) 6. FUEL SYSTEM

in lieu of commercially purchased power.10% overload power is available for 1 hour On Generating sets upto 700kVA, the baseframe

in 12 hours continous operation. design is incorporated with an integral fuel tank with

Standby Power a capacity of approx. 8 hours running at full load.

These ratings are applicable for supplying continous electrical power(at variable load) The tank is supplied complete with fill cap breather,

in the event of a utility power failure.No overload is permitted on these ratings. fuel speed and return lines to the engine and drain plug.

STANDARD REFERENCE CONDITIONS 7. ALTERNATOR

Output ratings are presented at 25°C air inlet temperature,barometric pressure 100kPa, 7.1 INSULATION SYSTEM

relative humidity30%.This generating set is designed to operate at high ambient ▪ Insulation : Class H

temperatures(upto 55°C),humidity(upto 99%) and higher altitudes.De-ration may apply. ▪ All windings are impregnated in either a triple dip

Some of the sepcifications are not standard on all genset models. thermosetting liquid,oil and acid resisting polyester

varnish or vaccum pressure impregnated with a special

AVAILABLE OPTIONS AND ACCESSORIES polyester resin.

We offer a range of optional features and accessories to tailor our generating sets to ▪ Heavy coat of antitracking varnish additional protection

meet you power needs. against moisture or condenasation

OPTIONS ACCESSORIES

▪ A variety control aand synchronizing panels ▪ Genuine spare parts 7.2 AUTOMATIC VOLTAGE REGULATOR (AVR)

▪ Additional protection alarms and shutdowns ▪ Load banks The fully sealed AVR maintains the voltage regulation

▪ Water fuel seperator ▪ Auxiliary fuel tanks at ±0.5%. Nominal adjustment by means of a trim pot

▪ Water jacket heater ▪ Manual and automatic transfer incorporated on the AVR.

▪ Battery charger switches 7.3 MOTOR STARTING

An overload capacity equivalent to 300% of the full

QUALITY STANDARDS load impedance at zero power factor can be sustained

The equipment meets the following standards : for 10 sec.,when AREP or PMG option is fitted.

BS4999, BS5000 , BS5514 IEC 60034 , VDE0530 , NEMA MG 1.22 and ISO 8528.

8. MOUNTING ARRANGEMENT

WARRANTY 8.1 BASE FRAME

All of the generating sets are covered under a warranty policy for a period of 12 months. The complete generating set is mounted as a whole on a

Warranty of the equipment is in line with manufacturer's warranty terms and heavy duty fabricated steel baseframe.

conditions.

8.2 COUPLING

The engine and alternator are directly coupled by means

of an SAE flange.The engine flywheel is flexibly coupled

to the alternator rotor.

Authorised Dealer in UAE

8.3 ANTI-VIBRATION MOUNTING PADS

Anti-vibration pads are affixed between the engine /

alternator feet and the baseframe thus ensuring

complete vibration isolation of the rotating assembly.

AL SHOLA

PO Box 7350, Al Quoz-4, DUBAI

Phone: +971 4 3474781 8.4 SAFETY GUARDS

Fax: +971 4 3474791 The fan and fan drive along with the battery charging

Mobile+971 55 95 45 124 alternator are safety guard protected for personnel

Email: info@alshola.com protection.

9. FACTORY TESTS

▪Operation

The generating set is load tested

and Maintenance before

manual, dispatch.

circuit wiring

▪ All protective devices control functions and site load

conditions are simulated.The generator and it's

systems are checked before dispatch.

10. EQUIPMENT FINISHING

All mild steel components are fully degreased and

painted with powder coated paint to ensure maximum

scuff resistance and durability.

11. DOCUMENTATIONS

Operation and Maintenance manual, circuit wiring

diagrams and commissioning/fault finding instruction

leaflets are accompanied with the generator.

You might also like

- User Guide - Justice Rights and Values 2021-2027 FinalDocument25 pagesUser Guide - Justice Rights and Values 2021-2027 FinalNúria Sadurní BalcellsNo ratings yet

- Saep 100Document17 pagesSaep 100Aneesh JosephNo ratings yet

- 15 Series Sundstrand HydrostaticDocument30 pages15 Series Sundstrand HydrostaticEdward Falck100% (3)

- SPS400TALDocument2 pagesSPS400TALbereketNo ratings yet

- JP1000 (4008 30tag2)Document2 pagesJP1000 (4008 30tag2)aleenmalek2024No ratings yet

- JP400Document2 pagesJP400Sirwan Mustafa (Albajalan)No ratings yet

- Jp9 Lsac: Standard SpecificationsDocument2 pagesJp9 Lsac: Standard SpecificationssarahlawaNo ratings yet

- DEPCO DC-501 1800rpm - 1622605917Document2 pagesDEPCO DC-501 1800rpm - 1622605917Gab MercadoNo ratings yet

- Standard Specifications: Powered byDocument2 pagesStandard Specifications: Powered byወንዴ መካኒኩ ወንዴ አሰፉNo ratings yet

- Standard Specifications: Powered byDocument2 pagesStandard Specifications: Powered bysaramagiNo ratings yet

- Standard Specifications: Powered byDocument3 pagesStandard Specifications: Powered bysarahlawaNo ratings yet

- Fawde GS50FLD Spec - Faw - 40 KWDocument2 pagesFawde GS50FLD Spec - Faw - 40 KWomar bejaranoNo ratings yet

- Datasheet GrupoDocument2 pagesDatasheet GrupoRichard De La PeñaNo ratings yet

- Depco Power DPK-DB-100Document2 pagesDepco Power DPK-DB-100Johanna GironNo ratings yet

- Depco Power Generator: Standard SpecificationsDocument2 pagesDepco Power Generator: Standard SpecificationsRichard De La PeñaNo ratings yet

- Standard Specifications: Powered byDocument2 pagesStandard Specifications: Powered byAugusto AraujoNo ratings yet

- DC-35 1800RPMDocument2 pagesDC-35 1800RPMJunnie Alvin AgravanteNo ratings yet

- Standard Specifications: Alternator OptionsDocument2 pagesStandard Specifications: Alternator Optionssimeneh demelashNo ratings yet

- DC-850 60hzDocument2 pagesDC-850 60hzJunnie Alvin AgravanteNo ratings yet

- Fawde Gs33fld Spec - Faw - 26 KWDocument2 pagesFawde Gs33fld Spec - Faw - 26 KWPaul Cabello SalazarNo ratings yet

- Brosur Datasheet Sariling-Perkins-Sae 2500 P Silent PDFDocument6 pagesBrosur Datasheet Sariling-Perkins-Sae 2500 P Silent PDFPusat GensetNo ratings yet

- Weber - WPS 500Document4 pagesWeber - WPS 500Express Backup54No ratings yet

- Weber WVS 250Document4 pagesWeber WVS 250Express Backup54No ratings yet

- SS 9599243 1000006026 035Document11 pagesSS 9599243 1000006026 035rodrigue983No ratings yet

- AQT 1650 EditDocument3 pagesAQT 1650 EditbassemNo ratings yet

- MODEL: SC330 Industrial Range Powered by Cummins: Diesel Generating Set 400/230 V - 50 HZ - 3phaseDocument4 pagesMODEL: SC330 Industrial Range Powered by Cummins: Diesel Generating Set 400/230 V - 50 HZ - 3phaseDefly GustiNo ratings yet

- AQT 10 EditDocument3 pagesAQT 10 EditbassemNo ratings yet

- JP150Document2 pagesJP150Maroun El-MansabNo ratings yet

- AQT 2000 EditDocument3 pagesAQT 2000 EditbassemNo ratings yet

- AQT 500 EditDocument3 pagesAQT 500 EditbassemNo ratings yet

- Depco Power Generator: Standard SpecificationsDocument2 pagesDepco Power Generator: Standard SpecificationsJohanna GironNo ratings yet

- MODEL: SC388 Industrial Range Powered by Cummins: Diesel Generating Set 400/230 V - 50 HZ - 3phaseDocument4 pagesMODEL: SC388 Industrial Range Powered by Cummins: Diesel Generating Set 400/230 V - 50 HZ - 3phaseDefly GustiNo ratings yet

- STG FPT 65kvaDocument2 pagesSTG FPT 65kvamohamadNo ratings yet

- Image For Illustrative Purposes Only..: Generating Set Model (Pm1000)Document2 pagesImage For Illustrative Purposes Only..: Generating Set Model (Pm1000)Anamta KhanNo ratings yet

- Page: M-1 of M-8 © 2021 Caterpillar All Rights Reserved MSS-EPG-1160820256964075-002 PDFDocument8 pagesPage: M-1 of M-8 © 2021 Caterpillar All Rights Reserved MSS-EPG-1160820256964075-002 PDFDranreb Eric BersaminaNo ratings yet

- JP12 5Document2 pagesJP12 5Ahmad KassemNo ratings yet

- MSS Epg 18321546 164Document6 pagesMSS Epg 18321546 164kuruppuarunaNo ratings yet

- Weber - WBS 1250Document4 pagesWeber - WBS 1250Express Backup54No ratings yet

- Standard Specifications: Powered byDocument2 pagesStandard Specifications: Powered byKAMENo ratings yet

- AQT 250 EditDocument3 pagesAQT 250 EditbassemNo ratings yet

- Brosur Datasheet Sariling-Perkins-Sae 300 Kva Silent Type PDFDocument6 pagesBrosur Datasheet Sariling-Perkins-Sae 300 Kva Silent Type PDFPusat GensetNo ratings yet

- AQT 1250 EditDocument3 pagesAQT 1250 EditbassemNo ratings yet

- Generator OutputDocument1 pageGenerator OutputHamoda HananNo ratings yet

- AQT 2500 EditDocument3 pagesAQT 2500 EditbassemNo ratings yet

- T394X Doosan - TideDocument7 pagesT394X Doosan - Tideegc solutions ltda Jose ParraNo ratings yet

- SC88 Cummins GeneratorDocument4 pagesSC88 Cummins GeneratorChen CarolineNo ratings yet

- SS 30008689 1000028973 019Document7 pagesSS 30008689 1000028973 019Mohyedin Ganjian aboukheiliNo ratings yet

- SC475 Cummins GeneratorDocument4 pagesSC475 Cummins GeneratorChen CarolineNo ratings yet

- 5 C 4 D 3 B 26 C 08 D 29276Document4 pages5 C 4 D 3 B 26 C 08 D 29276Kanjeng Raden Aryo SaifuNo ratings yet

- Brosur Datasheet Sariling-Perkins-Sae 1100 Kva Open Type PDFDocument6 pagesBrosur Datasheet Sariling-Perkins-Sae 1100 Kva Open Type PDFPusat GensetNo ratings yet

- SP2030 50HZ Perkins Generator STAMFORDDocument4 pagesSP2030 50HZ Perkins Generator STAMFORDsunshinemachineryNo ratings yet

- Flyer 60kva PDFDocument4 pagesFlyer 60kva PDFgymbehNo ratings yet

- Cummins 80 KVADocument4 pagesCummins 80 KVAcv.rapipratamaNo ratings yet

- AQT 22 EditDocument3 pagesAQT 22 EditbassemNo ratings yet

- Brosur Perkins 400 KVADocument4 pagesBrosur Perkins 400 KVAAgung HermawanNo ratings yet

- AQT 220 EditDocument3 pagesAQT 220 EditbassemNo ratings yet

- SC500 G5 50HZ Cummins Generator STAMFORDDocument4 pagesSC500 G5 50HZ Cummins Generator STAMFORDChen CarolineNo ratings yet

- Technical Data: N/A Emissions 3-Phase Power Factor Factor Cos Φ = 0.8 60Hz/1800R.P.MDocument7 pagesTechnical Data: N/A Emissions 3-Phase Power Factor Factor Cos Φ = 0.8 60Hz/1800R.P.MJonathan CastilloNo ratings yet

- Cat C32 1000KVADocument10 pagesCat C32 1000KVAjohn BeltranNo ratings yet

- The Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationFrom EverandThe Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Chercher BOQDocument4 pagesChercher BOQbereketNo ratings yet

- Bahir Dar University Project - 37.5l-s-132m-1Document3 pagesBahir Dar University Project - 37.5l-s-132m-1bereketNo ratings yet

- Bemenet Resume 359Document1 pageBemenet Resume 359bereketNo ratings yet

- Effectiveness of Manual Bar Screen in Separating Solid Waste From Municipal Sewers of Khulna CityDocument12 pagesEffectiveness of Manual Bar Screen in Separating Solid Waste From Municipal Sewers of Khulna CitybereketNo ratings yet

- Chemical and Physical PropertiesDocument1 pageChemical and Physical PropertiesbereketNo ratings yet

- Receipt FT24058 NR3 VGDocument1 pageReceipt FT24058 NR3 VGbereketNo ratings yet

- 30MT Pole DesignDocument2 pages30MT Pole DesignbereketNo ratings yet

- Catalogue B TohinDocument10 pagesCatalogue B TohinbereketNo ratings yet

- Hesu PVC Pipe For Water SupplyDocument61 pagesHesu PVC Pipe For Water SupplybereketNo ratings yet

- GRP Piping ManufacturerDocument9 pagesGRP Piping ManufacturerbereketNo ratings yet

- Costing OverheadDocument5 pagesCosting OverheadbereketNo ratings yet

- Maf SparDocument1 pageMaf SparbereketNo ratings yet

- Tect and CommutioningDocument3 pagesTect and CommutioningbereketNo ratings yet

- CP Costs DataDocument4 pagesCP Costs DatabereketNo ratings yet

- To: Addis Ababa Water and Sewerage Authority Water and Sanitation Infrastructure Development DivisionDocument3 pagesTo: Addis Ababa Water and Sewerage Authority Water and Sanitation Infrastructure Development DivisionbereketNo ratings yet

- Surge VesselDocument2 pagesSurge VesselbereketNo ratings yet

- 400 Domestic Sewage Treatment Plant Equipment List: No. Description SpecificationsDocument6 pages400 Domestic Sewage Treatment Plant Equipment List: No. Description SpecificationsbereketNo ratings yet

- Pipe and Fitting Installation BreakdownDocument53 pagesPipe and Fitting Installation Breakdownbereket100% (2)

- DAGIMDocument2 pagesDAGIMbereketNo ratings yet

- SPS400TALDocument2 pagesSPS400TALbereketNo ratings yet

- Al Shola BrochureDocument8 pagesAl Shola BrochurebereketNo ratings yet

- Outline-BK6008 22kw-ModelDocument1 pageOutline-BK6008 22kw-ModelbereketNo ratings yet

- Warranty Certificate Copy SampleDocument1 pageWarranty Certificate Copy SamplebereketNo ratings yet

- Dashen Bank Check ListDocument2 pagesDashen Bank Check ListbereketNo ratings yet

- 2806a-E18tag2 SpecDocument5 pages2806a-E18tag2 SpecbereketNo ratings yet

- 2806A-E18TAG2A Technical DataDocument10 pages2806A-E18TAG2A Technical DatabereketNo ratings yet

- 2206AE13TAG2 Derate TablesDocument3 pages2206AE13TAG2 Derate Tablesbereket100% (1)

- Supply of HVAC Materials Lot III 0mjgukDocument1 pageSupply of HVAC Materials Lot III 0mjgukbereketNo ratings yet

- Ast IsoDocument1 pageAst IsobereketNo ratings yet

- Pebb Concept Applications in High Power Electronics ConvertersDocument6 pagesPebb Concept Applications in High Power Electronics ConvertersdineshpeterNo ratings yet

- Address Resolution Protocol ARP Spoofing Attack AnDocument13 pagesAddress Resolution Protocol ARP Spoofing Attack Anmauricio canoNo ratings yet

- Low-Noise Dual Pre-AmplifierDocument4 pagesLow-Noise Dual Pre-AmplifierkondratenkoNo ratings yet

- High Precision Load Cell AmplifierDocument2 pagesHigh Precision Load Cell AmplifierVinh Bùi ĐứcNo ratings yet

- 4000kVA 23kV TPS 0056 7547 50Hz Dyn5 A1 Siemens NEO-datasheetDocument4 pages4000kVA 23kV TPS 0056 7547 50Hz Dyn5 A1 Siemens NEO-datasheetgusfabi1No ratings yet

- International Journal of Education (IJE) : ScopeDocument2 pagesInternational Journal of Education (IJE) : ScopeCS & ITNo ratings yet

- IO - Collab - MS Teams Support GuideDocument18 pagesIO - Collab - MS Teams Support GuideBruno BaudruNo ratings yet

- Aadhaar CardDocument1 pageAadhaar Cardkgogoi462No ratings yet

- Classes ObjectsDocument34 pagesClasses ObjectsayyazmNo ratings yet

- Verizon BillDocument13 pagesVerizon Billspurlock90No ratings yet

- Huawei WLAN Service Holding Upon CAPWAP Link Disconnection Technical White PaperDocument12 pagesHuawei WLAN Service Holding Upon CAPWAP Link Disconnection Technical White PaperSyed Haider AliNo ratings yet

- Model Identification: 1999 Toyota RAV4 1999 Toyota RAV4Document28 pagesModel Identification: 1999 Toyota RAV4 1999 Toyota RAV4skilleddragonNo ratings yet

- C and D Model WiringDocument7 pagesC and D Model Wiringpaul savilleNo ratings yet

- Resume - Sandeep PatelDocument1 pageResume - Sandeep Pateljainvaibhav2006No ratings yet

- Compiled Finals StsDocument63 pagesCompiled Finals StsMaricel DefiestaNo ratings yet

- J (Entr: Misfiring On Several Cylinders SimultaneouslyDocument3 pagesJ (Entr: Misfiring On Several Cylinders SimultaneouslyocnogueiraNo ratings yet

- Muji mjbts-1 User-Manual-2049923Document24 pagesMuji mjbts-1 User-Manual-2049923ErlNo ratings yet

- Keepalived LVS TUN PDFDocument26 pagesKeepalived LVS TUN PDFchienkmaNo ratings yet

- What Is A Bowtie?: Structure Your ThinkingDocument2 pagesWhat Is A Bowtie?: Structure Your ThinkingMani KumarNo ratings yet

- 河北任县滏阳精工密封件厂Document86 pages河北任县滏阳精工密封件厂adam leeNo ratings yet

- 3 Flexipacket Hub A1200/A2200 Setting: 3.1 Hardware ConnectionDocument8 pages3 Flexipacket Hub A1200/A2200 Setting: 3.1 Hardware ConnectionMohammad FayedNo ratings yet

- Rec670 Iec61850 Pixit 2.2Document21 pagesRec670 Iec61850 Pixit 2.2Ho Van ToanNo ratings yet

- Catia in CivilDocument11 pagesCatia in Civilsharathr22No ratings yet

- NSTWPDocument442 pagesNSTWPborysmrNo ratings yet

- Concurrent EngineeringDocument3 pagesConcurrent EngineeringanurajNo ratings yet

- Access Router Cyclades-PR2000Document136 pagesAccess Router Cyclades-PR2000Alfredo AlvesNo ratings yet

- Spatial Information Systems (SIS) CoursesDocument4 pagesSpatial Information Systems (SIS) CoursesDo Duc HanhNo ratings yet