Professional Documents

Culture Documents

TGN 1 - Level 2 - Designing A Steel Beam

TGN 1 - Level 2 - Designing A Steel Beam

Uploaded by

Raymond KinnairdCopyright:

Available Formats

You might also like

- Eurocode Design Example BookDocument94 pagesEurocode Design Example BookGianni Iotu89% (9)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Risky Drinking and Alcohol Use Disorder - Epidemiology, Pathogenesis, Clinical Manifestations, Course, Assessment, and Diagnosis - UpToDateDocument12 pagesRisky Drinking and Alcohol Use Disorder - Epidemiology, Pathogenesis, Clinical Manifestations, Course, Assessment, and Diagnosis - UpToDateqerat88No ratings yet

- Designing A Steel Beam: Icon LegendDocument5 pagesDesigning A Steel Beam: Icon LegendAlina ShresthaNo ratings yet

- Designing A Steel Column - IStructEDocument4 pagesDesigning A Steel Column - IStructEVijayNo ratings yet

- Eurocode 3: Department of Architecture & Civil Engineering Department of Architecture & Civil EngineeringDocument42 pagesEurocode 3: Department of Architecture & Civil Engineering Department of Architecture & Civil EngineeringNazihahNo ratings yet

- Lec 01 - Steel and Introduction To AISC Steel ManualDocument26 pagesLec 01 - Steel and Introduction To AISC Steel ManualbilalNo ratings yet

- Comparative Study of Analysis and Design of R.C and Steel Structures (2015)Document12 pagesComparative Study of Analysis and Design of R.C and Steel Structures (2015)KhosroSherwaniNo ratings yet

- Structural Analysis and Design of Beam-Column Joint Connectionsfor Steel StructureDocument6 pagesStructural Analysis and Design of Beam-Column Joint Connectionsfor Steel StructureQurrain MirNo ratings yet

- SN42 - Curving SteelworkDocument2 pagesSN42 - Curving SteelworkxufafruitjuiceNo ratings yet

- Designing A Concrete Beam: Icon LegendDocument5 pagesDesigning A Concrete Beam: Icon LegendNitish TakalkarNo ratings yet

- IRJET Distortional Buckling Study of ColDocument5 pagesIRJET Distortional Buckling Study of ColssierroNo ratings yet

- Welding Design For Diaphragm ReinforcementDocument8 pagesWelding Design For Diaphragm ReinforcementmalithNo ratings yet

- DSS QB Unit-3 PDFDocument14 pagesDSS QB Unit-3 PDFDhaladhuli ChekravartyNo ratings yet

- Icquest2857 PDFDocument3 pagesIcquest2857 PDFaditya khatavkarNo ratings yet

- App7 EC3 Design PDFDocument45 pagesApp7 EC3 Design PDFAndreea Vaduva100% (1)

- Lecture 1 (Introduction)Document43 pagesLecture 1 (Introduction)hakim baharomNo ratings yet

- Laterally LoadDocument92 pagesLaterally LoadMadhusudan MadhuNo ratings yet

- Lec 1Document83 pagesLec 1Ash KongNo ratings yet

- CE8601-Design of Steel Structural Elements - 01 - by WWW - LearnEngineering.inDocument131 pagesCE8601-Design of Steel Structural Elements - 01 - by WWW - LearnEngineering.inC.V. SHARMAHNo ratings yet

- E26.To2 Steel PDFDocument10 pagesE26.To2 Steel PDFAmolsingh100No ratings yet

- Fundamentals of Structural Design Part of Steel StructuresDocument25 pagesFundamentals of Structural Design Part of Steel StructuresappleaeroNo ratings yet

- Chapter 7 ConnectionDocument140 pagesChapter 7 Connectionalafkhair tradingNo ratings yet

- Masonry Design Example Comparisons Using ASD and SD: OutlineDocument25 pagesMasonry Design Example Comparisons Using ASD and SD: OutlineRicardo Muñiz DelgadoNo ratings yet

- DSR Model Answer PaperDocument22 pagesDSR Model Answer PaperAsad HussainNo ratings yet

- Is12778 2004Document16 pagesIs12778 2004ershekarNo ratings yet

- Norsok N-004-2004 Steel Frame Design Manual For: ISO SAP071709M24 Rev. 0 Berkeley, California, USA July 2009Document29 pagesNorsok N-004-2004 Steel Frame Design Manual For: ISO SAP071709M24 Rev. 0 Berkeley, California, USA July 2009drakor saveNo ratings yet

- Steel Frame Design Manual: Norsok N-004 2013Document21 pagesSteel Frame Design Manual: Norsok N-004 2013Angel VargasNo ratings yet

- Development of High Strength Steels For Automobiles: Nippon Steel Technical Report No. 88 July 2003Document6 pagesDevelopment of High Strength Steels For Automobiles: Nippon Steel Technical Report No. 88 July 2003Niken ApriliaNo ratings yet

- RCC Notes III II Strctral-EngineeringDocument84 pagesRCC Notes III II Strctral-Engineeringvenu madhavNo ratings yet

- 5 Introduction To Structural Steel ConstructionDocument20 pages5 Introduction To Structural Steel ConstructionKosygin LeishangthemNo ratings yet

- SFD N004 2013 PDFDocument21 pagesSFD N004 2013 PDFMohamed Abo-ZaidNo ratings yet

- Lateral Torsional Buckling: Icon LegendDocument3 pagesLateral Torsional Buckling: Icon LegendAl JameelNo ratings yet

- Building SteelsDocument17 pagesBuilding Steelsarnold12345No ratings yet

- ERSS-Lecture 8 (ChiewSP 6mar20)Document41 pagesERSS-Lecture 8 (ChiewSP 6mar20)sunilarunaNo ratings yet

- TheStructuralEngineer 28 Technical GuidaDocument3 pagesTheStructuralEngineer 28 Technical GuidaMladen MilićevićNo ratings yet

- Syllabus As Per WeightageDocument1 pageSyllabus As Per WeightageSatish VarakNo ratings yet

- DSR 2019 Winter Model Answer PaperDocument22 pagesDSR 2019 Winter Model Answer PaperJay KshirsagarNo ratings yet

- Seismic Load For Steel Frame ExampleDocument6 pagesSeismic Load For Steel Frame ExampleChesta GuptaNo ratings yet

- Structural Design of Steel StructuresDocument43 pagesStructural Design of Steel Structureskiran sreekumarNo ratings yet

- DSS PMT Part 1Document57 pagesDSS PMT Part 12KE18CV007 D R ANJITHA CivilNo ratings yet

- Finite Element Analysis and Tests On Bolted End-Plate by Shi 2004Document12 pagesFinite Element Analysis and Tests On Bolted End-Plate by Shi 2004fahmi aballiNo ratings yet

- Introd-Steel Struc.Document4 pagesIntrod-Steel Struc.Fuad AhmedinNo ratings yet

- Reinforcement Bars Tying Types in Reinforced ConcreteDocument6 pagesReinforcement Bars Tying Types in Reinforced ConcreteAreyLearnerNo ratings yet

- Standard 2 5 5 8: Object IndexDocument9 pagesStandard 2 5 5 8: Object IndexanhthoNo ratings yet

- Effect of Skew Angle On Static Behaviour of Reinforced Concrete Slab Bridge DecksDocument9 pagesEffect of Skew Angle On Static Behaviour of Reinforced Concrete Slab Bridge DecksAshish RanaNo ratings yet

- Phase IV Welder Module 1.1Document23 pagesPhase IV Welder Module 1.1Magdi SiamNo ratings yet

- Biaxial Bending in Columns: Icon LegendDocument2 pagesBiaxial Bending in Columns: Icon LegendGaurav BhendeNo ratings yet

- Assignment 3Document3 pagesAssignment 3clinton D'SouzaNo ratings yet

- American Institute of Steel CoAnchor Rods (2004) 2nd Edition 29Document1 pageAmerican Institute of Steel CoAnchor Rods (2004) 2nd Edition 29behnam fallahNo ratings yet

- Zona PanelDocument7 pagesZona PanelrobertNo ratings yet

- Steel BridgesDocument15 pagesSteel BridgessudhakarkadiNo ratings yet

- Introduction of Steel SectionDocument44 pagesIntroduction of Steel SectionAmirul Asyraf Bin Mohd BekeriNo ratings yet

- Comparison of Experimental Strength of R PDFDocument5 pagesComparison of Experimental Strength of R PDFPiyush PrajapatiNo ratings yet

- Improvement of Through Thickness Properties of SSDocument15 pagesImprovement of Through Thickness Properties of SSYuk Fan LeeNo ratings yet

- Camber Calculation PDFDocument10 pagesCamber Calculation PDFsoroware100% (1)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Hand Book For Steel Structure Quality Control on SiteFrom EverandHand Book For Steel Structure Quality Control on SiteNo ratings yet

- Tegral Flat Roof DeckingDocument28 pagesTegral Flat Roof DeckingRaymond KinnairdNo ratings yet

- Flood Precast - Super Wideslab Load Span TablesDocument1 pageFlood Precast - Super Wideslab Load Span TablesRaymond KinnairdNo ratings yet

- Flowforge DetailsDocument1 pageFlowforge DetailsRaymond KinnairdNo ratings yet

- Baseplate SketchDocument1 pageBaseplate SketchRaymond KinnairdNo ratings yet

- Creagh Concrete - Precast Flooring and StairsDocument12 pagesCreagh Concrete - Precast Flooring and StairsRaymond KinnairdNo ratings yet

- Positive Eating Positive LivingDocument2 pagesPositive Eating Positive LivingRaymond KinnairdNo ratings yet

- BS5628 3Document136 pagesBS5628 3Raymond KinnairdNo ratings yet

- (New) Chapter 3 Methodology - CommentedDocument6 pages(New) Chapter 3 Methodology - CommentedkkkNo ratings yet

- Contract Price Adjustment Provisions Cpap Work GroupsDocument8 pagesContract Price Adjustment Provisions Cpap Work Groupstholoana sentiNo ratings yet

- BC 245 M - DataDocument2 pagesBC 245 M - DataHany AhmedNo ratings yet

- Programs of Non-Government OrganizationsDocument27 pagesPrograms of Non-Government OrganizationsPhili-Am I. OcliasaNo ratings yet

- Unit 4-From Recusrsive EstimationDocument17 pagesUnit 4-From Recusrsive EstimationTufail DarNo ratings yet

- Structural Functionalism 2019-2020Document39 pagesStructural Functionalism 2019-2020Jesa Mae Vitales VergaraNo ratings yet

- Lavel A1 Oral ExamDocument9 pagesLavel A1 Oral ExamFatma BrahamNo ratings yet

- Working in Close Proximity To Overheadpowerlines: Huawei ConfidentialDocument5 pagesWorking in Close Proximity To Overheadpowerlines: Huawei ConfidentialmosesNo ratings yet

- CH 08Document21 pagesCH 08Juan PepeNo ratings yet

- 1 Place ValueDocument4 pages1 Place ValueKNAH TutoringNo ratings yet

- IELTS Essay and Letter Writing VocabularyDocument8 pagesIELTS Essay and Letter Writing Vocabularyraghav88No ratings yet

- ITU-T G.655 (11!2009) Characteristics of A Non-Zero Dispersion-Shifted Single-Mode Optical Fibre and CableDocument24 pagesITU-T G.655 (11!2009) Characteristics of A Non-Zero Dispersion-Shifted Single-Mode Optical Fibre and CableHilman NurzenNo ratings yet

- Savings Indias MedicalDocument259 pagesSavings Indias MedicalultimategoonNo ratings yet

- Hopkins, Michael (2007-01-25) - "Saving Time". Nature Magazine, Vol 445, p344-345.Document2 pagesHopkins, Michael (2007-01-25) - "Saving Time". Nature Magazine, Vol 445, p344-345.Save Standard TimeNo ratings yet

- PPM Brochure AcrulogDocument2 pagesPPM Brochure AcrulogadrianchoingNo ratings yet

- Kembang SepatuDocument8 pagesKembang SepatuDina Putri Sri UtamiNo ratings yet

- Biological ControlDocument15 pagesBiological Controlsandy candyNo ratings yet

- Đáp Án C A The Growth of Bike-Sharing Schemes Around The WorldDocument4 pagesĐáp Án C A The Growth of Bike-Sharing Schemes Around The WorldThu An TranNo ratings yet

- 21TH PRO Invitation For Schools - DepEd BataanDocument2 pages21TH PRO Invitation For Schools - DepEd BataanFranz Lorenz FuentesNo ratings yet

- Review Session5 Hoop Tension (4 Slides)Document5 pagesReview Session5 Hoop Tension (4 Slides)Benjie MorenoNo ratings yet

- L2 A2PLUS U1 Basics Grammar VocabularyDocument2 pagesL2 A2PLUS U1 Basics Grammar VocabularyÄÐåm Dris Said100% (1)

- Time Table Fall 2022 V1.4Document6 pagesTime Table Fall 2022 V1.4Bushi BaloochNo ratings yet

- Advanced 2 - Final Oral Test - Type A - Teacher SDocument5 pagesAdvanced 2 - Final Oral Test - Type A - Teacher SBárbara MirelleNo ratings yet

- Gen 002: Understanding The Self Lesson 5 and 6Document14 pagesGen 002: Understanding The Self Lesson 5 and 6Akira Poscablo PiranteNo ratings yet

- Mystic-AC-FR-SF UPH240062-3 Interfabrics BS5852 CertificateDocument4 pagesMystic-AC-FR-SF UPH240062-3 Interfabrics BS5852 Certificateandy.maldiniNo ratings yet

- Gy4006 L6 Gis 2023Document39 pagesGy4006 L6 Gis 2023Karrie ChambersNo ratings yet

- Shell Rimula R3 Turbo 15W-40Document2 pagesShell Rimula R3 Turbo 15W-40HUM CIREBON DFLTSNo ratings yet

- Grade 10 History - Text BookDocument150 pagesGrade 10 History - Text BookAzmaFaique100% (1)

- Book 1 - Unit 6Document19 pagesBook 1 - Unit 6Phương NguyễnNo ratings yet

TGN 1 - Level 2 - Designing A Steel Beam

TGN 1 - Level 2 - Designing A Steel Beam

Uploaded by

Raymond KinnairdOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TGN 1 - Level 2 - Designing A Steel Beam

TGN 1 - Level 2 - Designing A Steel Beam

Uploaded by

Raymond KinnairdCopyright:

Available Formats

›

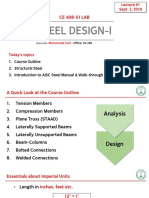

Note 1 Level 2

www.thestructuralengineer.org

Technical TheStructuralEngineer 25

Technical Guidance Note January 2013

Designing a steel beam

Introduction ICON W Principles of steel

This Technical Guidance Note is the first of the Level 2 guides. Guides in LEGEND beam design

this next level build on what has been described previously in the Level 1

series. The topics covered at Level 2 are of a more complex nature as they W Applied practice

typically deal with the design of elements as opposed to core concepts

such as loading and stability. As such, the amount of prior knowledge the

reader is assumed to have is at the very least the contents of relevant Level W Worked example

1 Technical Guidance Notes.

The subject of this guide is the design of non-composite steel beams to BS W Further reading

EN 1993-1-1 – Eurocode 3: Design of Steel Structures – Part 1-1: General

Rules for Buildings. It covers both restrained and unrestrained rolled steel

‘I’ and ‘H’ beam sections. It does not encompass the design of ‘T’ sections, W Web resources

hollow sections, castellated beams, angles and welded sections.

Principles of steel Description Variable

beam design b Width of flange

The key to understanding the design of h Depth of beam

steel beams is to determine whether or

not the beam is restrained against lateral z-z Minor axis

torsional buckling. This subject is covered

in the Level 1 (No. 16) Technical Guidance y-y Major axis

Note: Lateral torsional buckling. If a beam is

restrained, all that needs to be checked is d Depth of web

the bending moment and shear resistance

of the beam as well as serviceability limits

tw Thickness of web

against the applied load/actions. All

tf Thickness of flange

of which are based on the beam’s core

properties. r Radius of root fillet between web and flange

If the beam is unrestrained along any part Wpl,y Plastic section modulus about the y-y axis

of its length however, then there is a risk

it will fail due to lateral torsional buckling. Wel,y Elastic section modulus about the y-y axis

To address this, Eurocode 3 establishes

a reduction factor that is applied to the iz Radius of gyration about the z-z axis

bending moment resistance of the beam.

Calculating this factor is the cornerstone A Cross sectional area of the beam

of unrestrained steel beam design within

Eurocode 3. Iyy Second moment of area about the y-y axis

Frequent references will be made on the

section variables throughout this guide. You

N Figure 1

Beam section notation used in Eurocode 3

are advised therefore to examine Figure 1

for the definition and nomenclature of these grades of steel most commonly used in strength. Table 1 defines what the yield

variables. the construction industry within the UK. strength should be for the most common

S275’s nominal yield strength is 275 N/mm2 ranges of thicknesses found in open rolled

Steel material properties and Grade S355’s nominal yield strength steel sections. These figures are based on

The density of steel is 7850 kg/m3 and the is 355 N/mm2. The actual yield strength is the values given in BS EN 10025 Hot Rolled

Young’s Modulus (E) is 210,000 N/mm2. dependent on the maximum thickness of Products of Structural Steels, which is the

an element within a steel section, as the product standard for rolled steel sections of

S275 and S355 are the two strength thicker the element the lower the yield various sub-grades.

TSE13_25-29.indd 25 19/12/2012 10:13

›

Note 1 Level 2

26 TheStructuralEngineer Technical

January 2013 Technical Guidance Note

Table 1: Yield strength fy vs. element thickness

Yield strength fy for Yield strength fy for element Yield strength fy for element

Grade element thickness thickness > 16mm thickness > 40mm

< 16mm (N/mm2) and < 40mm (N/mm2) and < 63mm (N/mm2)

S275 275 265 255

S355 355 345 335

Classification of beam sections of the elements must lie. These limits are

Clause 5.5.2 in BS EN 1993-1-1 groups steel further modified based on the yield strength

beams into four classifications. These of the material; this is defined via

classifications are based on a steel beam coefficient ε thus:

section’s resistance to suffering from a local

failure due to buckling: 2

235 N/mm

f =

Class 1/‘Plastic’ These sections can form fy

a plastic hinge when a bending moment is

applied to them without suffering from local Where:

buckling failure. ε is the coefficient for section classification

fy is the yield strength of the steel, based on

Class 2/‘Compact’ These sections cannot element thickness

properly develop a plastic hinge as their

ability to rotate is limited before local Table 2 indicates the limiting values for

buckling failure occurs. various classes of section for both of the

elements identified in Figure 2. If any of the

Class 3/‘Semi-Compact’ These are ratios go beyond those stated in Table 2 the

sections that can withstand elastic stresses, section is considered to be in the Class 4

specifically at the extreme fibres of the category.

section, but cannot form a plastic hinge.

This has the effect of negating their plastic

Table 2: Limiting values of geometries

bending moment capacity.

for section classes 1-3

Class 4/‘Slender’ Sections that will fail

Class Web Flange

due to local buckling prior to the point of

yield stress. Their plastic bending capacity 1 c/t ≤ 72ε c/t ≤ 9ε

therefore is non-existent.

2 c/t ≤ 83ε c/t ≤ 10ε

When determining the classification of a

section, typically two parts of a rolled steel 3 c/t ≤ 124ε c/t ≤ 14ε

beam section are considered. For a simply

supported beam, these are the edge of

the top flange and the web, both of which Shear capacity

are subjected to compression stress due Typically the component of the beam that

to bending. Figure 2 indicates where these takes the majority of the applied shear

elements lie within a rolled steel beam section. force is its web. There are instances where

stiffeners are installed in order to support

Table 5.2 in Clause 5.5 of BS EN 1993-1-1 high shear loads, but this is very much the

defines the limits within which the geometry exception rather than the rule.

"Guides in this

next level build

on what has

been described

previously in the

E Figure 2

Elements

of a rolled steel Level 1 series"

beam that

determine its

classification

TSE13_25-29.indd 26 19/12/2012 10:13

www.thestructuralengineer.org

27

All steel beams must satisfy the following fy Lateral torsional buckling

expression: M c,Rd = W y Clause 6.3.2.3 of BS EN 1993-1-1 describes

c M0 how the value of χLT is related to the

V Ed

# 1 Where: slenderness of the beam. This is related

V c, Rd

Wy is the major axis section modulus of the to the distance between restraints to the

Where: beam based on its classification: element of the beam that is subject to

VEd is the applied shear force Wy = Wpl,y (Plastic section modulus) compression. For simply supported beams it

Vc,Rd is the design shear resistance for Class 1 or 2 is its upper-most flange. This is known as the

Wy = Wel,y (Elastic section modulus) non-dimensional slenderness ( m LT ) and is

In the case of Class 1 and 2 rolled steel for Class 3 defined thus:

beams, the design shear resistance is Wy = Weff,y (Minimum effective section W y fy

designated as Vpl,RD and is defined in Clause modulus) for Class 4 m LT =

6.2.6, equation 6.18 of BS EN 1993-1-1 as: fy is the yield strength of the steel, based on M cr

element thickness Where:

A v (f y / 3)

V pl,Rd = γM0 is the partial factor for the resistance of Wy and fy are as per previous definitions

c M0 cross-sections, which in the UK is set at 1.0 Mcr is the elastic critical moment for lateral

Where: torsional buckling, which is based on the

Av is the cross section area of the part of the The bending moment resistance should be slenderness of the beam

beam that is resisting shear. For ‘I’ and ‘H’ reduced if the applied shear force is more

sections this can conservatively be taken to than half of the plastic shear resistance Mcr is not defined within Eurocode 3, which

be htw, which is the cross sectional area of the of the beam. Where it exceeds this value, offers no guidance in calculating its value.

web and the thickness of the flange (Figure 3). Clause 6.2.8 of BS EN 1993-1-1 applies. This There are however, many direct methods

places a modification factor against the yield for calculating slenderness, the most simple

For all other classes of beam sections, you are strength, thus: of which is described in this guide.

referred to Clause 6.2.6 (4) of BS EN 1993-1-1

for determining their design shear resistance. Modified yield strength = (1-ρ)fy Slenderness

For ‘H’ and ‘I’ sections it is possible to

Where: use simplified methods to calculate the

` 2V - 1j

2

relative slenderness of the beam. The most

Ed conservative method is defined in Table 1.1

t =

V pl,Rd of NCCI: Determination of non-dimensional

slenderness of I and H sections SN002a-

This modified yield strength is then inserted EN-EU. It is based on applying the following

into the calculation that determines bending equations that vary depending on the grade

moment resistance. of steel being used:

For Class 4 sections you are required to For S275 Grade steel:

:L D

follow the guidance given in BS EN 1993-1-

5 – Eurocode 3: Design of Steel Structures

– Part 1-5: Plated Structural Elements. Class iz

m LT =

4 sections are not found in rolled ‘I’ and 96

‘H’ elements and are therefore beyond the For S355 Grade steel:

scope of this guide.

:L D

In the case of an unrestrained portion of iz

m LT =

a beam, a factor is applied to the bending 85

moment resistance (Mb,Rd) that takes into Where:

account the risk of lateral torsional buckling. L is the distance between restraints to the

This is described Clause 6.3.2.1 (3) of BS EN compression flange of the beam

N Figure 3

Approximate extent of web

resisting shear in a steel beam

1993-1-1, in equation 6.55 as: iz is the radius of gyration about the minor

fy axis of the beam

Clause 6.2.6 of BS EN 1993-1-1 has a more M b, Rd = | LT W y

accurate equation that takes into account c M1 While valid, this method is very conservative

the radii of the root fillet to the web-to- Where: as it ignores the bending moment diagram

flange interface of the ‘H’ and ‘I’ sections. Wy is the major axis section modulus of the of the beam and can therefore result in

These can be used if you are finding it beam based on its classification and is the oversized members. There is however,

difficult to satisfy the shear resistance same for restrained beams a more accurate yet complex method

requirements. fy is the yield strength of the steel, based on that does take into account the bending

element thickness moment diagram and is described in

Bending moment resistance γM1 is the partial factor for resistance of NCCI: Determination of non-dimensional

of steel beams members subject to instability, which in slenderness of I and H sections SN002a-

BS EN 1993-1-1 defines the bending moment the UK is set at 1.0 EN-EU. It is strongly recommended that

resistance of restrained steel beams (Mc,Rd) χLT is the reduction factor that takes into you examine this method in order to design

in clause 6.2.5(2) as: account lateral torsional buckling more efficiently sized steel beams.

TSE13_25-29.indd 27 19/12/2012 10:13

›

Note 1 Level 2

28 TheStructuralEngineer Technical

January 2013 Technical Guidance Note

There are further methods in determining Serviceability

Mcr described in the Non-Contradictory The vertical deflection limits for steel beams "Class 4 sections

Complimentary Information website for

structural steelwork.

can be found in the Clause NA.2.23 of the UK

National Annexe to BS EN 1993-1-1. Table 3 are not found in

Once the non-dimensional slenderness is

is based on these stated limits, which are for

the deflection due to unfactored imposed rolled ‘I’ and ‘H’

established, the value of χLT is determined

using equation 6.57 of Clause 6.3.2.3 of BS

loads/variable actions only.

elements and are

EN 1993-1-1 thus:

Table 3: Vertical deflection to steel beams beyond the scope

| LT =

U LT +

1

2 2

U LT - b m LT

Beam type/structure Deflection limit of this guide"

U LT = 0.5 61 + a LT ( m LT - m LT, 0) + b m LT@

2 Cantilever Length/180

Where: Beams supporting Eurocode 0.

The values of β and m LT,0 are defined as brittle finishes

Span/360 Applied practice

0.4 and 0.75 respectively, as described in

Clause NA.2.17 of NA to BS EN 1993-1-1.

All other conditions Span/200 The applicable codes of practice for

αLT is the imperfection factor and is found designing steel beams are as follows:

in Table 6.3 of BS EN 1993-1-1, which reads Purlins and To suit cladding

against the steel beam’s buckling curve. cladding rails system BS EN 1993-1-1 Eurocode 3: Design of

Steel Structures – Part 1-1: General Rules for

The buckling curves are labelled ‘a’ to ‘d’ Buildings

and can be found in Clause NA.2.17 of NA In addition to deflection, it is prudent to

to BS EN 1993-1-1. The buckling curve is check the vibration of the beam i.e. its BS EN 1993-1-1 UK National Annex to

dependent upon the h/b ratio of the beam dynamic response. Technical Guidance Note Eurocode 3: Design of Steel Structures –

section. No. 11, Level 1 explains how to do this. Part 1-1: General Rules for Buildings

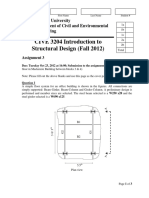

Worked example

A simply supported, unrestrained steel beam spanning 8m is supporting another steel

beam in the middle of its span. The ultimate load from this beam is 500 kN, while the

serviceability load due to variable actions is 200 kN. The floor structure consists of one

way spanning precast concrete planks with a screed and tiled finish. These planks span

parallel to the steel beam and hence do not provide lateral restraint. Determine what size

of beam is required to support this load, assuming the steel grade to be S355.

TSE13_25-29.indd 28 19/12/2012 10:13

www.thestructuralengineer.org

29

Glossary and

further reading

Reduction factor – A variable applied to

the bending moment resistance of a beam

due to the fact that it is unrestrained and

hence subject to lateral torsional buckling.

Rolled steel section – A steel element

that is cast to a pre-set size and not built up

from separate plate elements.

Section classification – A categorisation

of steel elements that is based on the

element’s ability to develop a plastic hinge

when placed under load.

Further Reading

The Institution of Structural Engineers

(2010) Manual for the Design of Steelwork

Building Structures to Eurocode 3 London:

The Institution of Structural Engineers

Steel Construction Institute (2009) Steel

Building Design. Worked Examples for

Students (P387) Ascot, Berkshire: SCI

The Institution of Structural Engineers

(2012) ‘Principles of design’ The Structural

Engineer Vol. 90 (1) pp. 40-41

The Institution of Structural Engineers

(2012) ‘Derivation of dead loads’ The

Structural Engineer Vol. 90 (1) pp. 43-45

The Institution of Structural Engineers

(2012) ‘Derivation of imposed loads’ The

Structural Engineer Vol. 90 (2) pp. 46-48

The Institution of Structural Engineers

(2012) ‘Derivation of wind load’ The

Structural Engineer Vol. 90 (2) pp. 49-52

The Institution of Structural Engineers

(2012) ‘Derivation of snow load’ The

Structural Engineer Vol. 90 (3) pp. 22-24

The Institution of Structural Engineers

(2012) ‘Lateral torsional buckling’ The

Structural Engineer Vol. 90 (16) pp. 28-30

Eurocode 0.

Web

resources

Tata Steel Interactive ‘Blue Book’:

www.tatasteelconstruction.com/en/design_

guidance/the_blue_book/

Non-Contradictory Complimentary

Information website for structural steelwork:

www.steel-ncci.co.uk/

TSE13_25-29.indd 29 19/12/2012 10:13

You might also like

- Eurocode Design Example BookDocument94 pagesEurocode Design Example BookGianni Iotu89% (9)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Risky Drinking and Alcohol Use Disorder - Epidemiology, Pathogenesis, Clinical Manifestations, Course, Assessment, and Diagnosis - UpToDateDocument12 pagesRisky Drinking and Alcohol Use Disorder - Epidemiology, Pathogenesis, Clinical Manifestations, Course, Assessment, and Diagnosis - UpToDateqerat88No ratings yet

- Designing A Steel Beam: Icon LegendDocument5 pagesDesigning A Steel Beam: Icon LegendAlina ShresthaNo ratings yet

- Designing A Steel Column - IStructEDocument4 pagesDesigning A Steel Column - IStructEVijayNo ratings yet

- Eurocode 3: Department of Architecture & Civil Engineering Department of Architecture & Civil EngineeringDocument42 pagesEurocode 3: Department of Architecture & Civil Engineering Department of Architecture & Civil EngineeringNazihahNo ratings yet

- Lec 01 - Steel and Introduction To AISC Steel ManualDocument26 pagesLec 01 - Steel and Introduction To AISC Steel ManualbilalNo ratings yet

- Comparative Study of Analysis and Design of R.C and Steel Structures (2015)Document12 pagesComparative Study of Analysis and Design of R.C and Steel Structures (2015)KhosroSherwaniNo ratings yet

- Structural Analysis and Design of Beam-Column Joint Connectionsfor Steel StructureDocument6 pagesStructural Analysis and Design of Beam-Column Joint Connectionsfor Steel StructureQurrain MirNo ratings yet

- SN42 - Curving SteelworkDocument2 pagesSN42 - Curving SteelworkxufafruitjuiceNo ratings yet

- Designing A Concrete Beam: Icon LegendDocument5 pagesDesigning A Concrete Beam: Icon LegendNitish TakalkarNo ratings yet

- IRJET Distortional Buckling Study of ColDocument5 pagesIRJET Distortional Buckling Study of ColssierroNo ratings yet

- Welding Design For Diaphragm ReinforcementDocument8 pagesWelding Design For Diaphragm ReinforcementmalithNo ratings yet

- DSS QB Unit-3 PDFDocument14 pagesDSS QB Unit-3 PDFDhaladhuli ChekravartyNo ratings yet

- Icquest2857 PDFDocument3 pagesIcquest2857 PDFaditya khatavkarNo ratings yet

- App7 EC3 Design PDFDocument45 pagesApp7 EC3 Design PDFAndreea Vaduva100% (1)

- Lecture 1 (Introduction)Document43 pagesLecture 1 (Introduction)hakim baharomNo ratings yet

- Laterally LoadDocument92 pagesLaterally LoadMadhusudan MadhuNo ratings yet

- Lec 1Document83 pagesLec 1Ash KongNo ratings yet

- CE8601-Design of Steel Structural Elements - 01 - by WWW - LearnEngineering.inDocument131 pagesCE8601-Design of Steel Structural Elements - 01 - by WWW - LearnEngineering.inC.V. SHARMAHNo ratings yet

- E26.To2 Steel PDFDocument10 pagesE26.To2 Steel PDFAmolsingh100No ratings yet

- Fundamentals of Structural Design Part of Steel StructuresDocument25 pagesFundamentals of Structural Design Part of Steel StructuresappleaeroNo ratings yet

- Chapter 7 ConnectionDocument140 pagesChapter 7 Connectionalafkhair tradingNo ratings yet

- Masonry Design Example Comparisons Using ASD and SD: OutlineDocument25 pagesMasonry Design Example Comparisons Using ASD and SD: OutlineRicardo Muñiz DelgadoNo ratings yet

- DSR Model Answer PaperDocument22 pagesDSR Model Answer PaperAsad HussainNo ratings yet

- Is12778 2004Document16 pagesIs12778 2004ershekarNo ratings yet

- Norsok N-004-2004 Steel Frame Design Manual For: ISO SAP071709M24 Rev. 0 Berkeley, California, USA July 2009Document29 pagesNorsok N-004-2004 Steel Frame Design Manual For: ISO SAP071709M24 Rev. 0 Berkeley, California, USA July 2009drakor saveNo ratings yet

- Steel Frame Design Manual: Norsok N-004 2013Document21 pagesSteel Frame Design Manual: Norsok N-004 2013Angel VargasNo ratings yet

- Development of High Strength Steels For Automobiles: Nippon Steel Technical Report No. 88 July 2003Document6 pagesDevelopment of High Strength Steels For Automobiles: Nippon Steel Technical Report No. 88 July 2003Niken ApriliaNo ratings yet

- RCC Notes III II Strctral-EngineeringDocument84 pagesRCC Notes III II Strctral-Engineeringvenu madhavNo ratings yet

- 5 Introduction To Structural Steel ConstructionDocument20 pages5 Introduction To Structural Steel ConstructionKosygin LeishangthemNo ratings yet

- SFD N004 2013 PDFDocument21 pagesSFD N004 2013 PDFMohamed Abo-ZaidNo ratings yet

- Lateral Torsional Buckling: Icon LegendDocument3 pagesLateral Torsional Buckling: Icon LegendAl JameelNo ratings yet

- Building SteelsDocument17 pagesBuilding Steelsarnold12345No ratings yet

- ERSS-Lecture 8 (ChiewSP 6mar20)Document41 pagesERSS-Lecture 8 (ChiewSP 6mar20)sunilarunaNo ratings yet

- TheStructuralEngineer 28 Technical GuidaDocument3 pagesTheStructuralEngineer 28 Technical GuidaMladen MilićevićNo ratings yet

- Syllabus As Per WeightageDocument1 pageSyllabus As Per WeightageSatish VarakNo ratings yet

- DSR 2019 Winter Model Answer PaperDocument22 pagesDSR 2019 Winter Model Answer PaperJay KshirsagarNo ratings yet

- Seismic Load For Steel Frame ExampleDocument6 pagesSeismic Load For Steel Frame ExampleChesta GuptaNo ratings yet

- Structural Design of Steel StructuresDocument43 pagesStructural Design of Steel Structureskiran sreekumarNo ratings yet

- DSS PMT Part 1Document57 pagesDSS PMT Part 12KE18CV007 D R ANJITHA CivilNo ratings yet

- Finite Element Analysis and Tests On Bolted End-Plate by Shi 2004Document12 pagesFinite Element Analysis and Tests On Bolted End-Plate by Shi 2004fahmi aballiNo ratings yet

- Introd-Steel Struc.Document4 pagesIntrod-Steel Struc.Fuad AhmedinNo ratings yet

- Reinforcement Bars Tying Types in Reinforced ConcreteDocument6 pagesReinforcement Bars Tying Types in Reinforced ConcreteAreyLearnerNo ratings yet

- Standard 2 5 5 8: Object IndexDocument9 pagesStandard 2 5 5 8: Object IndexanhthoNo ratings yet

- Effect of Skew Angle On Static Behaviour of Reinforced Concrete Slab Bridge DecksDocument9 pagesEffect of Skew Angle On Static Behaviour of Reinforced Concrete Slab Bridge DecksAshish RanaNo ratings yet

- Phase IV Welder Module 1.1Document23 pagesPhase IV Welder Module 1.1Magdi SiamNo ratings yet

- Biaxial Bending in Columns: Icon LegendDocument2 pagesBiaxial Bending in Columns: Icon LegendGaurav BhendeNo ratings yet

- Assignment 3Document3 pagesAssignment 3clinton D'SouzaNo ratings yet

- American Institute of Steel CoAnchor Rods (2004) 2nd Edition 29Document1 pageAmerican Institute of Steel CoAnchor Rods (2004) 2nd Edition 29behnam fallahNo ratings yet

- Zona PanelDocument7 pagesZona PanelrobertNo ratings yet

- Steel BridgesDocument15 pagesSteel BridgessudhakarkadiNo ratings yet

- Introduction of Steel SectionDocument44 pagesIntroduction of Steel SectionAmirul Asyraf Bin Mohd BekeriNo ratings yet

- Comparison of Experimental Strength of R PDFDocument5 pagesComparison of Experimental Strength of R PDFPiyush PrajapatiNo ratings yet

- Improvement of Through Thickness Properties of SSDocument15 pagesImprovement of Through Thickness Properties of SSYuk Fan LeeNo ratings yet

- Camber Calculation PDFDocument10 pagesCamber Calculation PDFsoroware100% (1)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Hand Book For Steel Structure Quality Control on SiteFrom EverandHand Book For Steel Structure Quality Control on SiteNo ratings yet

- Tegral Flat Roof DeckingDocument28 pagesTegral Flat Roof DeckingRaymond KinnairdNo ratings yet

- Flood Precast - Super Wideslab Load Span TablesDocument1 pageFlood Precast - Super Wideslab Load Span TablesRaymond KinnairdNo ratings yet

- Flowforge DetailsDocument1 pageFlowforge DetailsRaymond KinnairdNo ratings yet

- Baseplate SketchDocument1 pageBaseplate SketchRaymond KinnairdNo ratings yet

- Creagh Concrete - Precast Flooring and StairsDocument12 pagesCreagh Concrete - Precast Flooring and StairsRaymond KinnairdNo ratings yet

- Positive Eating Positive LivingDocument2 pagesPositive Eating Positive LivingRaymond KinnairdNo ratings yet

- BS5628 3Document136 pagesBS5628 3Raymond KinnairdNo ratings yet

- (New) Chapter 3 Methodology - CommentedDocument6 pages(New) Chapter 3 Methodology - CommentedkkkNo ratings yet

- Contract Price Adjustment Provisions Cpap Work GroupsDocument8 pagesContract Price Adjustment Provisions Cpap Work Groupstholoana sentiNo ratings yet

- BC 245 M - DataDocument2 pagesBC 245 M - DataHany AhmedNo ratings yet

- Programs of Non-Government OrganizationsDocument27 pagesPrograms of Non-Government OrganizationsPhili-Am I. OcliasaNo ratings yet

- Unit 4-From Recusrsive EstimationDocument17 pagesUnit 4-From Recusrsive EstimationTufail DarNo ratings yet

- Structural Functionalism 2019-2020Document39 pagesStructural Functionalism 2019-2020Jesa Mae Vitales VergaraNo ratings yet

- Lavel A1 Oral ExamDocument9 pagesLavel A1 Oral ExamFatma BrahamNo ratings yet

- Working in Close Proximity To Overheadpowerlines: Huawei ConfidentialDocument5 pagesWorking in Close Proximity To Overheadpowerlines: Huawei ConfidentialmosesNo ratings yet

- CH 08Document21 pagesCH 08Juan PepeNo ratings yet

- 1 Place ValueDocument4 pages1 Place ValueKNAH TutoringNo ratings yet

- IELTS Essay and Letter Writing VocabularyDocument8 pagesIELTS Essay and Letter Writing Vocabularyraghav88No ratings yet

- ITU-T G.655 (11!2009) Characteristics of A Non-Zero Dispersion-Shifted Single-Mode Optical Fibre and CableDocument24 pagesITU-T G.655 (11!2009) Characteristics of A Non-Zero Dispersion-Shifted Single-Mode Optical Fibre and CableHilman NurzenNo ratings yet

- Savings Indias MedicalDocument259 pagesSavings Indias MedicalultimategoonNo ratings yet

- Hopkins, Michael (2007-01-25) - "Saving Time". Nature Magazine, Vol 445, p344-345.Document2 pagesHopkins, Michael (2007-01-25) - "Saving Time". Nature Magazine, Vol 445, p344-345.Save Standard TimeNo ratings yet

- PPM Brochure AcrulogDocument2 pagesPPM Brochure AcrulogadrianchoingNo ratings yet

- Kembang SepatuDocument8 pagesKembang SepatuDina Putri Sri UtamiNo ratings yet

- Biological ControlDocument15 pagesBiological Controlsandy candyNo ratings yet

- Đáp Án C A The Growth of Bike-Sharing Schemes Around The WorldDocument4 pagesĐáp Án C A The Growth of Bike-Sharing Schemes Around The WorldThu An TranNo ratings yet

- 21TH PRO Invitation For Schools - DepEd BataanDocument2 pages21TH PRO Invitation For Schools - DepEd BataanFranz Lorenz FuentesNo ratings yet

- Review Session5 Hoop Tension (4 Slides)Document5 pagesReview Session5 Hoop Tension (4 Slides)Benjie MorenoNo ratings yet

- L2 A2PLUS U1 Basics Grammar VocabularyDocument2 pagesL2 A2PLUS U1 Basics Grammar VocabularyÄÐåm Dris Said100% (1)

- Time Table Fall 2022 V1.4Document6 pagesTime Table Fall 2022 V1.4Bushi BaloochNo ratings yet

- Advanced 2 - Final Oral Test - Type A - Teacher SDocument5 pagesAdvanced 2 - Final Oral Test - Type A - Teacher SBárbara MirelleNo ratings yet

- Gen 002: Understanding The Self Lesson 5 and 6Document14 pagesGen 002: Understanding The Self Lesson 5 and 6Akira Poscablo PiranteNo ratings yet

- Mystic-AC-FR-SF UPH240062-3 Interfabrics BS5852 CertificateDocument4 pagesMystic-AC-FR-SF UPH240062-3 Interfabrics BS5852 Certificateandy.maldiniNo ratings yet

- Gy4006 L6 Gis 2023Document39 pagesGy4006 L6 Gis 2023Karrie ChambersNo ratings yet

- Shell Rimula R3 Turbo 15W-40Document2 pagesShell Rimula R3 Turbo 15W-40HUM CIREBON DFLTSNo ratings yet

- Grade 10 History - Text BookDocument150 pagesGrade 10 History - Text BookAzmaFaique100% (1)

- Book 1 - Unit 6Document19 pagesBook 1 - Unit 6Phương NguyễnNo ratings yet