Professional Documents

Culture Documents

Asme B16.19-1951

Asme B16.19-1951

Uploaded by

Jeetendra MhatreOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asme B16.19-1951

Asme B16.19-1951

Uploaded by

Jeetendra MhatreCopyright:

Available Formats

A M E R C A N S T A

Ma Ilea ble-1 ron

Screwed Fittings

ASA lll6.19-1951

·----::::.

300 Lb

UDC 621.643.4:669.13

(R \~~<3j

B~T COPY AVAJLABLE

~on6or6 Reproduced By GLOBAL J

ENGINEERING DOCUMENTS

Heating, Piping, and Air Conditioning With The Pennission Of ANSI

Contractors National Association Under Royalty Agreement

Manufacturers Standardization Society of the

Valve and Fittings Industry

The American Society of Mechanical Engineers

Putfi6~eJ t'J

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

29 West 39th Street, New York 18, N. Y.

Off\CtP.L APPi\-J'.JEC C02Y

--`,,`,,```,,,,``,,`,,,,``,,``-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME Licensee=Larsen & Toubro - OGSP/5954522005, User=Mhatre, Jeetendra

No reproduction or networking permitted without license from IHS Not for Resale, 04/22/2014 03:33:58 MDT

Foreword

T Standardization

HE development of this standard was initi:lted in 1930 by the Manufacturers'

Society of the Valve and Fittings Industry in cooperation

with the Association of American Railroads. The first edition of the MSS standard

was published in 1932 under the title, 300-Lb Malleable-Iron Screwed Fittings

(SP-31).

After further study in the latest practice the MSS Ferrous Screw Fittings Com-

mittee completed a revised edition, dated 1950, which was in agreement with the

Association of American Railroads Purchase Specification M-404.

--`,,`,,```,,,,``,,`,,,,``,,``-`-`,,`,,`,`,,`---

The American Standards Association authorized the organization of Sectional

Committee 816 on the Standardization of Pipe Flanges and Flanged Fittings in

1921 with the following organizations as joint sponsors: Heating, Piping, and Air

Conditioning Contractors' National Association; Manufacturers' Standardization

Society of the Val,·e and Fittings Industry; and The American Society of Mechani-

cal Engineers.

The MSS presented its Standard Practice No. SP-31-1950 to Subcommittee No.2

on Screwed Fittings of ASA Sectional Committee 816. It was accepted and, in

turn, Subcommittee No. 2 distributed a draft dated June, 1950, to the members

of the sectional committee for approval by l.::tter ballot.

Following approval of the sectional committee and sponsor bodies, the proposal

was presented to the American Standards Association with recommendation for

approval as an American Standard. This approval was granted on March 28,1951.

Copyright, 1951, by

The American Society of Mechanical Engineers

Printed in U. S. A.

Copyright ASME International

Provided by IHS under license with ASME Licensee=Larsen & Toubro - OGSP/5954522005, User=Mhatre, Jeetendra

No reproduction or networking permitted without license from IHS Not for Resale, 04/22/2014 03:33:58 MDT

Officers of Sectional Committee on

Standardization of Pipe Flanges and Fittings

Dr. E. LaCrosse, Chairman L. W. Benoit, Secretary

Personnel of Subcommittee No.l on Screwed Fittings

L. W. Kattelle, Chairman, Asst. Chief Engr., Walworth Company, New York, N.Y.

F. J. Allen, Product Engr., York Corporation, York Pa.

C. T. Baker, Cons. Engr., 1070 Spring St., Atlanta, Ga.

L. W. Benoit, Exec. Secy., Manufacturers Standardization Society of the Valve & Fittings

Industry, New York, N. Y.

A. L. Brown, Asst. Mgr. & Chief Engr., Associated Factory Mutual Fire Ins. Co., Boston, Mass.

Bureau of Ships, Code 350 (liaison), Department of the Navy, Washington, D. C.

T. M. Dugan, 1308 Freemont St., McKeesport, Pa.

S. G. Flagg, Pres., Stanley G. Flagg & Co., Inc., Philadelphia, Pa.

E. L. Jacobsen, Engr., Esso Engrg Oept., Standard Oil Development Co., Elizabeth, N.J.

W. P. Kliment, Engr. of Standards, Crane Company, Chicago, Ill.

F. B. Lasette, Frank B. Lasette, Inc., Long Island City, N. Y.

Rowland Tompkins, Pres., Rowland Tompkins & Son, New York, N.Y.

H. L. Underhlll, Shelter Island Heights, N. Y.

T. E. Ve1tfort, Mgr., Copper & Brass Research Association, New York, N.Y.

F. L. Scovill, Jr. (alternate forT. E. Vdtfort), Asst. to Mgr., Copper & Brass Research Associa-

tion, New York, N.Y.

J. H. Wllllams, Mech. Engr., Grinnell Corporation, Providence, R.I.

J. H. Zlnk, Pres., Heat & Power Corporation, Baltimore, Md.

Any part of this standard may be quoted. Credit Jines should read: "Extracted

from American Standard Malleable-Iron Screwed Fittings, 300 L!J (ASA Br6.u;-

I95I), with the permission of the publisher, The American Society of Mechanical

Engineers, 29 West .39th Street, New York r8, N. Y."

--`,,`,,```,,,,``,,`,,,,``,,``-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME Licensee=Larsen & Toubro - OGSP/5954522005, User=Mhatre, Jeetendra

No reproduction or networking permitted without license from IHS Not for Resale, 04/22/2014 03:33:58 MDT

American Standard

Malleable-Iron Screwed Fittings

300Lb

Introductory Notes

1 Scope 5.2 The manufacturer shall be prepared to

1.1 This standard practice covers minimum certify that his product has been so produced and

requirements for 300-lb malleable-iron screwed that the chemical and physical properties: thereof

fittings in sizes 1/ 4 to 3 in., inclusive. as proved by test spectmens, are equal to the re-

quirements specified in ASTM Specifications for

2 Pressure Ratings Cupola Malleable Iron (A197) as a minimum.

2.1 All fittings made to the requirements of 6 Tolerances

this standard shall have maximum nonshock serv-

ice ratings as follows: 6.1 It is reco~nized that some variations are

STEAM AND OIL absolutely unavotdable in the making of patterns

and castings.

1

/c to 3 in., incl. 300 lb at 550 F

LIQ.UID AND GAS AT 150 F

6.2 The equipment shall be designed:to pro-

duce castings of metal thicknesses not less than

1

/c to 1 in., incl. 2000 lb those given in the tables. Metal thickness of

11/ 4 to 2 in., incl. 1500 lb fittings shall at no point be less than 90 per cent

2 /t and 3 in., 1000 lb

1

of thickness given in the tables.

2.2 Street elbows are not recommended for 6.3 The following tolerances shall be per-

pressures above 600 lb. mitted in center-to-end dimensions of fittings.

3 Size Tolerances for end-to-end dimensions, and length

of couplings and reducers shall be twice those

3.1 The size of the fittings scheduled in the given. The largest opening in reducing:fittings

following tables is identified by the corresponding governs the tolerance to be applied to all openings.

nominal pipe size. These tolerances do not apply to return bends and

3.2 In the case of reducing tees, the size of caps.

the larger run opening shall be given first, followed

by the size of the opening at the opposite end of Tolerances for Center-to-End Dlmenalona

the run. The size of the branch opening is given Nominal Plus or

l11.st. Pipe Size Minus

'4'- Marking · '/• 0.04

•;. 0.05

4.1 Each fitting shall be marked for identifica- '/., •;, 0.06

tion with 1, Jl/, 0.07

Jl/., 2 0.08

(a) maker's name or sr,mbol; 21/., 3 0.10

(b) the numerals "300 ';

(c) the letters "MI" to designate malleable

iron; 7 Threading

(d) the size; 7.1 All fittings shall be threaded with Ameri-

(e) other markings as permitted by MSS can Standard Taper Pipe Threads (ASA B2.1)

Standard Practice Marking System for and the variations in the threading shall be limited

Valves, Fittings, Flanges, and Unions to one turn Jarge or one turn small from the gaging

(SP-25) and AAR standards. face of ring, and gaging notch on plug, when using

working gages. When gaging mternal .threads

S Material the notch sliould be flush with the bottom of the

5.1 The dimensions prescribed in this stand- chamfer, which shall be considered as being the

ard are based upon malleable-iron castings of a intersection of the chamfer cone and the pitch

high quality produced under regular control of cone of the thread. This depth is apJlroximately

chemical and physical properties by a recognized equal to one-half thread from the face _of the

process. fitting.

5

March, J9SI

--`,,`,,```,,,,``,,`,,,,``,,``-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME Licensee=Larsen & Toubro - OGSP/5954522005, User=Mhatre, Jeetendra

No reproduction or networking permitted without license from IHS Not for Resale, 04/22/2014 03:33:58 MDT

7.2 All internal threads shall be countersunk four or more ribs unless the left-hand opening is

a distance of not less than one half of the pitch of clearlr marked "L," in which case the use of ribs

the thread at an angle of approximately 45 deg is optional with the manufacturer.

with the axis of the thread, and all external threads

shall be chamfered at an angle of 30 to 45 deg with 9 Flttlna Dimensions

the axis, both for the purpose of easier entrance

in makin$ a joint and for protection of the thread. 9.1 Tables of center-to-end _dimensions are

Countersmkmg and chamfering shall be concentric given for both straight and reducing fittings.

with the threads. 9.2 The dimensions in the tables of reducing

7.3 The length of threads specified in all fittings are for use only when making patterns for

tables shall be measured to include the counter- the specific reducing fitting in question and do not

sink or chamfer. apply when a lar~er size pattern is bushed to make

the reducing fittmg wanted.

7.4 The maximum allowable variation in

ali~nment of threads of all openings of screw 10 Plugs, Bushings, and.Locknuts

fittings shall be 1/ 1e in. in 1 ft.

10.1 For dimensions and sizes_ of plugs, bush-

8 Ribs ings, and locknuts to be used in connection with

8.1 The addition of ribs or lugs is permitted 300-lb malleable-iron screwed fittings, see Ameri-

on screw fittings. Where ribs are used, it is can Standard for Ferrous Plugs,:Bushings, and

recommended that their thickness shall be the Locknuts (ASA B16.14).

same as specified for metal thickness of the fitting.

8.2 Right-hand couplings shall have not more 11 Face Bevel

than two ribs. 11.1 A bevel not exceeding S_deg is permitted

8.3 Right- and left-hand couplings shall have on the faces of fitting openings.

--`,,`,,```,,,,``,,`,,,,``,,``-`-`,,`,,`,`,,`---

TEE CROSS

Table 1 Dimensions of 90-Deg Elbows, Tees, Crosses, and 45-Dea Elbows

(Straight Sizes)

Center-to- Center- Inside Diameter

Nomi- End, Elbows, to-End, Le~~ Width

of of Fitting Metal

Outside

Diameter

nal Pipe Tees, and 45-Deg Thread, Band, F Thick- of-Band,

Size Crosses Elbows Min Min ness Min

c

A

0.94 0.81

B

0.43 --- E

0.38

Min Max

-0.584 G H

~

0.540 0.14 0.93

1.06 0.88 0.47 0.44 0.675 0.719 0.15 1.12

1.25 1.00 0.57 0.840 0.897

~

0.50 0.16 1.34

1.44 1.13 0.64 0.56 1.050 1.107 0.18 1.63

1 1.63 1.31 0.75 0.62 1.315 1.385 0.20 1.95

1!1 1.94 1.50 0.84 0.69 1.660 1.730 0.22 2.39

1 Vz 2.13 1.69 0.87 0.75 1.900 1.970 0.24 2.68

2 2.50 2.00 1.00 0.84 2.375 2.445 0.26 3,28

2 1h 2.94 2.25 1.11 0.94 2.875 2.975 0.31 3.86

3 3.38 2.50 1.23 1.00 3.500 3.600 0.35 4.62

All dimens1ons are giVen m mches.

6

Copyright ASME International

Provided by IHS under license with ASME Licensee=Larsen & Toubro - OGSP/5954522005, User=Mhatre, Jeetendra

No reproduction or networking permitted without license from IHS Not for Resale, 04/22/2014 03:33:58 MDT

Malleable-Iron Screwed Fittings, 300 Lb

Table l Center-to-End Dimensions of 90·

Deg Elbows Table 3 Center-to-End Dimensions of. Tees

(Reducing Sizes) (Reducing Sizes)

Nominal Center-to-End Nominal Center-to-End

Pipe Pipe

Size z Size X y z

X

1.19 1.19 - 1.19 - 1.19 1.19

~~~

1 X 3,4

1.31

1.50

1.38

1.56

~X~X%

~X 1

X h

1.25

1.31

1.19

1.31

1.25

1.38

1.75 1.81 ~XY4X~

11~ X 1 3~ X 1fz X ~ 1.44 1.38 1.44

Ph X 11~ 2.00 2.06 1X1X3A 1.50 1.50 1:56

2X Ph 2.25 2.38 1 X 1 X~ 1.44 1.44 1.50

21/z X 2 2.69 2.75 1 X 1X a 1.31 1.31 1.44

3X2lfz 3.06 3.31 1X3,4X1 1.63 1.56 1.63

All dimensions are given in inches. 1}fX1~,xt 1.75 1.75 1.81

For dimensions not ~ven see Table 1. 1~4 X1~,x3,4 1.63 1.63 1.75

Reducing 8izes of littmgs for which dimensions are not given 1~,x1v,x~ 1.50 1.50 1.69

in tables may be produced from regular patterns for listed 1V,X1X1 1 , 1.94 1.81 1.94

sizes by sand bushing.

2.00 2.06

l~Xl~X"A

2.00

1.81 1.81 2.00

11~X1

xt X1

x:a~ 1.69 1.69 1.88

1.63 1.63 1.81

zX1~xfVz

1 X1 X1

1 2.13 2.06 2.13

2X2Xl}l 2.25 2.25 2.38

2X2X1Y, 2.13 2.13 2.31

2X2X1 2.00 2.00 2.25

2X2X 3.4 1.81 1.81 2.13

2X2X1h 1. 75 1.75 .2.Jl6

2Xl1hX2 2.50 2.38 :2~

21hX2~ X2 2.69 2.69 2.75

2~X2~X1lfz

2 aX2X21h

2.44

2.94

2.44

2.75

2.63

2.94

3X3X2lfz 3.06 3.06 3.31

3X3X2 2.81 2.81 3.13

3X2lfaX3 3.38 3.31 3.38

All dimensions are given in inches.

For dimensions not given see Table 1.

Reducing sizes of fittings for which dimensions are not given

in tables mar be produced from regular patterns for listed

sizes by sand bushing.

--`,,`,,```,,,,``,,`,,,,``,,``-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME Licensee=Larsen & Toubro - OGSP/5954522005, User=Mhatre, Jeetendra

No reproduction or networking permitted without license from IHS Not for Resale, 04/22/2014 03:33:58 MDT

Malleable-Iron Screwed Fittings, 300 Ub

COUPLINGS WITH BANDS COUPLINGS WITHOUT BANDS

Table 4 Dimensions of Couplings

Outside

Nominal ~~

Width

of

Inside

Diameter

of Fitting Metal

Diameter

of

Outside

Diameter Le:F

Pipe Thread, Band, Tblc:k· Coupling of Band Str~t

Size Min Min F ness Mm• Min•• Coup g

B B Min Max G H, H w

0.43 0.38 0.540 0.584 0.14 0.820 0.93 1.375'

1

ij 0.47

0.57

-.64

0.75

0.44

0.50

0.56

0.62

0.675 0.719

0.840 0.897

1.050 1.107

1.315 1.385

0.15

0.16

0.18

0.20

0.975

1.160

1.410

1.715

1.12

1.34

1.63

1.95

1.625

1.875

2.125

2.376

1}1 0.84 0.69 1.660 1.730 0.22 2.100 2.39 2.875

1 VI 0.87 0.75 1.900 1.970 0.24 2.380 2.68 2.875

2 1.00 0.84 2.375 2.445 0.26 2.895 3.28 3.625

21f.& 1.17 0.94 2.875 2.975 0.31 3.495 3.86 4.125

3 1.23 1.00 3.500 3.600 0.35 4.200 4.62 4.125

..

All damensaons are gaven an mthes •

• Ha diameter is standard for couplings without bands. H 1 equals F minimum plus 2G.

•• H minimum is for couplings wath bands and is optional with the manufacturer.

For information on ribs see Introductory Note 8.

8

--`,,`,,```,,,,``,,`,,,,``,,``-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME Licensee=Larsen & Toubro - OGSP/5954522005, User=Mhatre, Jeetendra

No reproduction or networking permitted without license from IHS Not for Resale, 04/22/2014 03:33:58 MDT

Malleable-Iron Screwed Fittings, 300 Lb

Table 5 Dimensions of Reducing Couplings

Nominal Length

Pipe

Size w

o/aX~ 1.44

1fz X ~ 1.69

1/zX 1 4 1.69

~~~

1.75

1.75

%x% 1.75

1 X 3A 2.00

1 X~ 2.00

1X 2.00

1 X 1/4 2.00

1}). X 1 2.38

1 ~X 3A 2.38

11j, X 1/z 2.38

1~X11/, 2.6il

1 X 1 2.69

1 1~X 3A 2.69

1 zX1fz 2.69

2 X 11~ 3.19

2 X 114 3.19

2 X 1 3.19

2 X 3~ 3.19

2 X 12 3.19

2!1 X 2 3.69

2VzX1'h 3.69

3X21/z 4.06

3X2 4.06

3 X 11/z 4.06

All dimensions are given in inches.

For dimensions not ,pven see Table 1.

Reducing sizes of titungs for which dimensions are not given

in the tables may be produced from regular patterns for listed

sizes by sand bushing.

--`,,`,,```,,,,``,,`,,,,``,,``-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME Licensee=Larsen & Toubro - OGSP/5954522005, User=Mhatre, Jeetendra

No reproduction or networking permitted without license from IHS Not for Resale, 04/22/2014 03:33:58 MDT

Malleable-Iron Screwed Fittings, 300 Ub

CAPS WITH RECESS CAPS WITHOUT RECESS

Table 6 Dimensions of Caps

Inside

Le~pb Width Diameter Metal Thickness Outside

Nominal of of Fitting Diameter

Pipe Thread, Band, of Band, ::Height,

Size Min Min F Min Rec:om.• Min .oMin**

G, p

B

0.43 - E

0,38 -0,540 -0.584

Min Mu:: G

0.14 0.18

H

0.93 0.78

~

0.47 0.44 0.675 0.719 0.15 0.19 1.12 0.83

0.57 0.50 0.840 0.897 0.16 0.20 1.34 0.98

0.64 0.56 1.050 1.107 0.18 0.23 1.63 1.08

1 Y4 0.75 0.62 1.315 1.385 0.20 0.25 1.95 1.26

1!1 0.84 0.69 1.660 1.730 0.22 0.28 2.39 1.38

1 Vz 0.87 0.75 1.900 1.970 0.24 0.30 2.68 1.43

2 1.00 0.84 2.375 2.445 0.26 0.33 3.28 1.68

21/:& 1.17 0.94 2.875 2.975 0.31 0.39 3.86 2.06

3 1.23 1.00 3.500 3.600 0.35 0.44 4.62 2.17

All dtmenstons are g~vcn tn tnchcs.

• Dimension G, is recommended but shall in no case be less than dimension G.

•• Dimension P may be varied to comply with manufacturer's practice and for caps without

recess shall be of such height that the length of effective thread shall be not less than B. All

other dimensions shall be as specified for other caps.

10

--`,,`,,```,,,,``,,`,,,,``,,``-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME Licensee=Larsen & Toubro - OGSP/5954522005, User=Mhatre, Jeetendra

No reproduction or networking permitted without license from IHS Not for Resale, 04/22/2014 03:33:58 MDT

Table 7 Dimensions of 90-Deg and 45-Deg Street Elbows

90-Deg Elbows 45-Deg Elbows Inside Outside Length Mu

Length Width Diameter Diam- of Port

Center Center of of of Metal eter External

Nominal Thick· D!am·

Pipe Center- to Center- to Thread, Band, Fitting of Thread, eter

to-End Male to-End Male Min Min ness Band, Min

Size Male

End End F Min End

c B

1;4

A

0.94

1.06

J

1.44

1.63

..

K

..

B

0.43

E

0.38 ---Min

0.540 0.584

Mu G

0.14 0.93

L

0.40

0.41

N

0.26

0.47 0.675 0.719 0.15 1.12

~

0.44 0.36

3A

1.25

1.44

2.00

2.19

1:oo

1.13

1:38

1.56

0.57

0.64

0.50

0.56

0.840 0.897

1.050 1.107

0.16

0.18

1.34

1.63

0.53

0.55

0.49

0.67

1 1.63 2.56 1.31 1.P.\ 0.75 0.62 1.315 1.385 0.20 1.95 0.68 0.88

11f4 1.94 2.88 1.50 2.13 0.84 0.69 1.660 1.730 0.22 2.39 0.71 1.16

11/z 2.13 3.13 1.69 2.31 0.87 0.75 1.900 1.970 0.24 2.68 0.72 1.35

2 2.50 3.69 2.00 2.69 1.00 0.84 2.375 2.445 0.26 3.28 0.76 1.75

.... ..

21fz 2.94 4.50 1.17 0.94 2.875 2.975 0.31 3.86 1.14 2.16

3 3.38 5.13 .. 1.23 1.00 3.500 3.600 0.35 4.62 1.20 2.67

All dtmenstons arc g1Vcn tn tnches.

Table 8 Dimensions of Return Bends

Center-to-Center Inside

Length Width Diameter Metal Outside

Nominal of of of Fitting Thick- Diameter

M

--`,,`,,```,,,,``,,`,,,,``,,``-`-`,,`,,`,`,,`---

Pipe Thread, Band, ness of Band,

Size Min Min F Min

Close Medium Open

Pattern Pattern Pattern B E Min Mu o• R

1 1 3A 21fz 3 0.75 0.62 1.315 1.385 0.20 1.95

2~z 3 0.84 0.69 1.660 1.730 0.22 2.39

111~

21!4

1z 3 3~ 6 0.87 0.75 1.900 1.970 0.24 2.68

2 4 6 8 1.00 0.84 2.375 2.445 0.26 3.28

All dimensions are given in inches.

Dimension N may be varied to comply with manufacturer's practice.

It is recommended that the distance from end of fitting to center of radius R be approximately equal to

dimension B; radius R is recommended as being one-half of dimension M.

• Dimension G is shown the same as for other 300-lb fittings. It is recommended that G for return bends

be increased by 10 per cent or more.

11

Copyright ASME International

Provided by IHS under license with ASME Licensee=Larsen & Toubro - OGSP/5954522005, User=Mhatre, Jeetendra

No reproduction or networking permitted without license from IHS Not for Resale, 04/22/2014 03:33:58 MDT

American Standards for Pipe, Piping Code,

Pipe Flanges and Fittings

TITLE PRICE

Malleable-Iron Screwed Fittings, 300 Lb (B16.19-1951) ............................ . $0.60•

C I Pipe Flanges and Flanged Fittings, Class 125 (816.1-1948) ..................... . 0.65

C I Pipe Flanges and Flanged Fittings Class 250 (B16b-19H) ...................... . 0.55

C I Pipe Flanges and Flanged Fittings (for 800 Lb Hydraulic Pressure) (B16b1-1931; re-

affirmed in 1947) .......................................................... · ·. 0.45

C I Pipe Flanges and Flanged Fittings (for Maximum WSP of 25 Lb) (B16b2-1931; re-

affirmed in 194 7) .......................................................... · .. 0.50

Malleable-Iron Screwed Fittings, 150 Lb (B16c-1939) .............................. . 0.60

C I Screwed Fittings for 125 and 250 Lb (B16.4-1949) ............................. . 0.60

Steel Pipe Flanges and Flanged Fittings (Bl6e-1939) with Supplement 1 (B16e6-1949) .. 1.85

Supplement No. 1 to Steel Pipe Flanges and Flanged Fittings (B16e6-1949) .......... . 0.40

Steel Butt-Welding Fittings (B16.9-1940; reaffirmed in 1947) ....................... . 0.50

Face-to-Face Dimensions of Ferrous Flanged and Welding End Valves (B16.1Q-1939;

reaffirmed in 1947). . ...................................................... . 0.65

Steel Socket-Welding Fittings (B16.11-1946) ...................................... . 0.60

Ferrous Plugs, Bushings, and Lock Nuts with Pipe Threads (B16.14-1949) .......... . 0.40

Brass or Bronze Screwed Fittings, 125 Lb (B16.15-1947) ........................... . 0.65

C 1 Pipe Flanges and Flanged Fittings for Refrige;ant Piping, Class 300 (B16.16-1948) .. . 0.45

Brass or Bronze Screwed Fittings, 250 Lb (B16.17-1949) ........................... . 0.35

Cast-Brass Solder-Joint Fittings'(B16.18-1950) .................................... . 0.75

Code for Pressure Piping (Power, Gas and Air, Oil, District Heating, Refrigeration,

Fabrication Details, Materials, and Appendix) (B31.1-1951) ...................... . 3.50

Wrought-Steel and Wrought-Iron Pipe (B36.10-1950) .............................. . 0.65

Stainless Steel Pipe (B36.19-1949) ............................................... . 0.30

Pipe Threads (B2.1-1945) ...................................................... . 1.50

Scheme for the Identification of Piping Systems (AlJ-1928; reaffirmed 1947) ......... . 0.60

20% Discount to ASME Members.

• §luantities in lots of 10, $1.80; 25, $12.00; 50, $21.50; 75, $33.75; 100, '$11.00.

A binder is available for holding these standards. It holds twenty-five (15) pamphlets and gives

every advantage of a bound book together with the added convenience which coma from the ability to

insert, remove, or transpose sections of the contents. Price $3.15 postpaid.

A complete list of American Standards published by The American Society of Mechanical Engi-

neers obtainable upo11 request.

--`,,`,,```,,,,``,,`,,,,``,,``-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME Licensee=Larsen & Toubro - OGSP/5954522005, User=Mhatre, Jeetendra

No reproduction or networking permitted without license from IHS Not for Resale, 04/22/2014 03:33:58 MDT

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BS en 10029 PDFDocument17 pagesBS en 10029 PDFJeetendra MhatreNo ratings yet

- P - NumberDocument1 pageP - NumberJeetendra MhatreNo ratings yet

- Asme B16.44-2012Document24 pagesAsme B16.44-2012Jeetendra MhatreNo ratings yet

- AstmDocument6 pagesAstmJeetendra MhatreNo ratings yet

- Procedure For UTDocument26 pagesProcedure For UTJeetendra Mhatre100% (3)

- Radiant - Technical Data Sheet - Slip-On FlangesDocument1 pageRadiant - Technical Data Sheet - Slip-On FlangesSandeep GalhotraNo ratings yet

- Dypro Valvulas de VenteoDocument6 pagesDypro Valvulas de VenteoJuanPerezRooneyNo ratings yet

- Yamaha TDM 900 Parts List WWW - Manualedereparatie.info PDFDocument79 pagesYamaha TDM 900 Parts List WWW - Manualedereparatie.info PDFDiaconu AlinNo ratings yet

- General QuestionnaireDocument9 pagesGeneral Questionnairehemant1284No ratings yet

- Guidelines For Selection of Strainers August 2006 EditionDocument10 pagesGuidelines For Selection of Strainers August 2006 EditionEver Briceño100% (1)

- SBLM2500 IND 178rev1Document18 pagesSBLM2500 IND 178rev1Daniil SerovNo ratings yet

- Service Manual: For The HM40B and HM47B Rider Sweeper Sweeper For: Training Troubleshooting Adjustments JDocument39 pagesService Manual: For The HM40B and HM47B Rider Sweeper Sweeper For: Training Troubleshooting Adjustments JMiao MikeNo ratings yet

- Design Application HairpinDocument23 pagesDesign Application Hairpinkinjalpatel12345No ratings yet

- Powell API602 Forged Steel ValveDocument50 pagesPowell API602 Forged Steel Valvedragon2065No ratings yet

- 3fa9 1993Document44 pages3fa9 1993motorciNo ratings yet

- Polyurea Hot Spray Steel Surfaces Method StatementDocument9 pagesPolyurea Hot Spray Steel Surfaces Method StatementGvsr SunnyNo ratings yet

- Torque Table UPG GR ASME Raised Steel Ring Full GasketDocument1 pageTorque Table UPG GR ASME Raised Steel Ring Full GasketgonzalezlopezjNo ratings yet

- ARAMCO Interview 2015 PDFDocument15 pagesARAMCO Interview 2015 PDFm.srinivasanNo ratings yet

- Flanges Connecting Dimension According To DIN EN 1092-1 and DIN 2501-1Document2 pagesFlanges Connecting Dimension According To DIN EN 1092-1 and DIN 2501-1Lasandu WanniarachchiNo ratings yet

- Biological Odour Control System Specification - R1Document24 pagesBiological Odour Control System Specification - R1Hedi Ben MohamedNo ratings yet

- Cla-Val: Fire Protection Pressure Relief ValveDocument2 pagesCla-Val: Fire Protection Pressure Relief ValveShoaib AhmedNo ratings yet

- Piping Fabrication, Installation, Erection, and TestingDocument33 pagesPiping Fabrication, Installation, Erection, and Testingaop1046889% (9)

- WWW - Imp-Ta - Si WWW - Imp-Ta - Si: Control The Stream Control The StreamDocument16 pagesWWW - Imp-Ta - Si WWW - Imp-Ta - Si: Control The Stream Control The StreamCedoNo ratings yet

- Critical Service Catalog en 08 2016Document72 pagesCritical Service Catalog en 08 2016Mukiara LuffyNo ratings yet

- LEDE Products Catalog - CompressedDocument24 pagesLEDE Products Catalog - CompressedAhmad ShiplyNo ratings yet

- Manuals Series HSJ Safety Valves Crosby en en 5193124Document12 pagesManuals Series HSJ Safety Valves Crosby en en 5193124Ravi pathakNo ratings yet

- Packing List - TRANSPORTDocument11 pagesPacking List - TRANSPORTTerluka DalamNo ratings yet

- Boiler Feed Pump Vol-1 PDFDocument609 pagesBoiler Feed Pump Vol-1 PDFabhay100% (1)

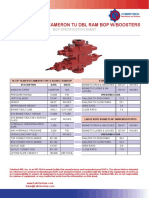

- 18.750 10000 Cameron Double Ram Bop Lbs Bonnets Spec SheetDocument1 page18.750 10000 Cameron Double Ram Bop Lbs Bonnets Spec SheetJoel SNo ratings yet

- Volume-II, Technical SpecificationsDocument116 pagesVolume-II, Technical SpecificationsNaveen NagisettiNo ratings yet

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFDocument1 page4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFabdullah amanullah0% (1)

- Released: Company Document No: Document ClassDocument32 pagesReleased: Company Document No: Document ClassShajahan AsanarNo ratings yet

- Spirax Sarco ValveDocument3 pagesSpirax Sarco ValveDerick MendozaNo ratings yet

- Rajesh .M. Nambiar: ObjectiveDocument7 pagesRajesh .M. Nambiar: ObjectiveAlka BhatpudeNo ratings yet