Professional Documents

Culture Documents

LT - 01 FBS Ii Mauerwerk en

LT - 01 FBS Ii Mauerwerk en

Uploaded by

Alberto MasanetOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LT - 01 FBS Ii Mauerwerk en

LT - 01 FBS Ii Mauerwerk en

Uploaded by

Alberto MasanetCopyright:

Available Formats

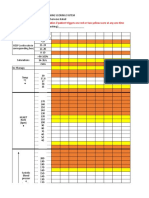

Loads

Concrete screw UltraCut FBS II US/SK

Permissible loads1)2) for a single anchor in masonry for Push-through installation.

For the design the complete current assessment ETA-20/0134 of 14.07.2022 has to be considered.

Min. Brick raw Minimum brick Nominal Mini- Maximum Permis- Permissi- Minimum Minimum

compres- density dimensions ancho- mum Installa- sible ble shear spacing5) edge dis-

sive brick rage member tion tensile load4) tance5)

strength depth thick- torque load4) parallel6)

ness

fb ρ (L x W x H) hnom hmin Timp. max3) Nperm Vperm║ smin║ / smin┴ cmin

Type [N/mm²] [kg/dm³] [mm] [mm] [mm] [Nm] [kN] [kN] [mm] [mm]

Solid brick Mz, acc. to EN 771-1

FBS II 6 ≥ 12.0 ≥ 1.8 240 x 115 x 71 ≥ 40 ≥ 115 80 0.54 0.34 80 50

FBS II 6 ≥ 16.0 ≥ 1.8 240 x 115 x 71 ≥ 40 ≥ 115 80 0.60 0.40 80 50

FBS II 6 ≥ 17.5 ≥ 1.8 240 x 115 x 71 ≥ 40 ≥ 115 80 0.66 0.40 80 50

FBS II 8 ≥ 12.0 ≥ 1.8 240 x 115 x 71 ≥ 50 ≥ 115 80 0.46 1.37 80 60

FBS II 8 ≥ 16.0 ≥ 1.8 240 x 115 x 71 ≥ 50 ≥ 115 80 0.54 1.60 80 60

FBS II 8 ≥ 17.5 ≥ 1.8 240 x 115 x 71 ≥ 50 ≥ 115 80 0.57 1.66 80 60

FBS II 10 ≥ 12.0 ≥ 1.8 240 x 115 x 71 ≥ 55 ≥ 115 80 0.40 1.26 80 70

FBS II 10 ≥ 16.0 ≥ 1.8 240 x 115 x 71 ≥ 55 ≥ 115 80 0.46 1.46 80 70

FBS II 10 ≥ 17.5 ≥ 1.8 240 x 115 x 71 ≥ 55 ≥ 115 80 0.49 1.51 80 70

Solid brick Mz, nordic, acc. to EN 771-1

FBS II 6 ≥ 16.0 ≥ 1.8 228 x 108 x 54 ≥ 40 ≥ 108 80 0.34 0.31 80 50

FBS II 6 ≥ 20.0 ≥ 1.8 228 x 108 x 54 ≥ 40 ≥ 108 80 0.40 0.37 80 50

FBS II 8 ≥ 16.0 ≥ 1.8 228 x 108 x 54 ≥ 50 ≥ 108 80 0.46 1.34 80 60

FBS II 8 ≥ 20.0 ≥ 1.8 228 x 108 x 54 ≥ 50 ≥ 108 80 0.51 1.49 80 60

FBS II 10 ≥ 16.0 ≥ 1.8 228 x 108 x 54 ≥ 55 ≥ 108 80 0.37 1.23 80 70

FBS II 10 ≥ 20.0 ≥ 1.8 228 x 108 x 54 ≥ 55 ≥ 108 80 0.43 1.37 80 70

Solid sand-lime brick KS, acc. to EN 771-2

FBS II 6 ≥ 12.0 ≥ 1.8 240 x 115 x 71 ≥ 40 ≥ 115 80 0.43 0.51 80 50

FBS II 6 ≥ 16.0 ≥ 1.8 240 x 115 x 71 ≥ 40 ≥ 115 80 0.49 0.60 80 50

FBS II 6 ≥ 20.0 ≥ 1.8 240 x 115 x 71 ≥ 40 ≥ 115 80 0.54 0.66 80 50

FBS II 8 ≥ 12.0 ≥ 1.8 240 x 115 x 71 ≥ 50 ≥ 115 80 0.54 0.66 80 60

FBS II 8 ≥ 16.0 ≥ 1.8 240 x 115 x 71 ≥ 50 ≥ 115 80 0.60 0.74 80 60

FBS II 8 ≥ 20.0 ≥ 1.8 240 x 115 x 71 ≥ 50 ≥ 115 80 0.69 0.83 80 60

FBS II 10 ≥ 12.0 ≥ 1.8 240 x 115 x 71 ≥ 55 ≥ 115 80 0.54 0.89 80 70

FBS II 10 ≥ 16.0 ≥ 1.8 240 x 115 x 71 ≥ 55 ≥ 115 80 0.63 1.00 80 70

FBS II 10 ≥ 20.0 ≥ 1.8 240 x 115 x 71 ≥ 55 ≥ 115 80 0.69 1.11 80 70

Perforated sand-lime brick KSL, acc. to EN 771-2

FBS II 6 ≥ 10.0 ≥ 1.4 240 x 175 x 113 ≥ 40 ≥ 175 65 0.09 0.80 80 50

FBS II 6 ≥ 12.0 ≥ 1.4 240 x 175 x 113 ≥ 40 ≥ 175 65 0.11 0.94 80 50

FBS II 6 ≥ 16.0 ≥ 1.4 240 x 175 x 113 ≥ 40 ≥ 175 65 0.14 1.17 80 50

FBS II 6 ≥ 17.5 ≥ 1.4 240 x 175 x 113 ≥ 40 ≥ 175 65 0.17 1.26 80 50

FBS II 8 ≥ 10.0 ≥ 1.4 240 x 175 x 113 ≥ 50 ≥ 175 65 0.26 0.66 80 60

FBS II 8 ≥ 12.0 ≥ 1.4 240 x 175 x 113 ≥ 50 ≥ 175 65 0.29 1.03 80 60

FBS II 8 ≥ 16.0 ≥ 1.4 240 x 175 x 113 ≥ 50 ≥ 175 65 0.37 1.40 80 60

FBS II 8 ≥ 17.5 ≥ 1.4 240 x 175 x 113 ≥ 50 ≥ 175 65 0.40 1.49 80 60

FBS II 10 ≥ 10.0 ≥ 1.4 240 x 175 x 113 ≥ 55 ≥ 175 65 0.23 0.77 80 70

FBS II 10 ≥ 12.0 ≥ 1.4 240 x 175 x 113 ≥ 55 ≥ 175 65 0.26 1.23 80 70

FBS II 10 ≥ 16.0 ≥ 1.4 240 x 175 x 113 ≥ 55 ≥ 175 65 0.34 1.66 80 70

FBS II 10 ≥ 17.5 ≥ 1.4 240 x 175 x 113 ≥ 55 ≥ 175 65 0.37 1.77 80 70

1)

The partial safety factors for material resistance as regulated in assessment as well as a partial safety factor for load actions of γL = 1.4 are considered. Load values are valid for zinc-pla-

ted steel all sizes and head shapes, for stainless steel R for the sizes 8 and 10. Exakt values see ETA.

2)

The given loads are valid for installation and use of fixations in dry masonry, use category d/d, width of the joints wj ≤ 3 mm and general purpose mortar with strength class M2.5 -M9.

Further information and details on drill hole preparation, etc., see ETA.

3)

Maximum allowable device torque for installation with any tangential impact screw driver. Further technical data see ETA.

4)

In the case of combinations of tensile and shear loads, bending moments and reduced edge and axial spacings (anchor groups), the design must be carried out in accordance with the

provisions of the complete assessment.

5)

Minimum feasible spacing resp. edge distance. Details as well as to the distances to joints see assessment.

6)

Shear load parallel to the vertical joint. Load reduction for shear load perpendicular to the vertical joint see ETA.

You might also like

- How To Properly Size Box PlenumsDocument5 pagesHow To Properly Size Box PlenumsAnwar Syed100% (4)

- Build Up Rate Format - PavingDocument4 pagesBuild Up Rate Format - PavingFaiz Ahmad83% (6)

- Concrete Pool Design Based On ACI 318-14: Input Data & Design SummaryDocument6 pagesConcrete Pool Design Based On ACI 318-14: Input Data & Design Summaryadmin cabuildersNo ratings yet

- Hatz Dieselmotoren ES71 E785 Service Manual in German (Auf Deutsch)Document63 pagesHatz Dieselmotoren ES71 E785 Service Manual in German (Auf Deutsch)czwnkNo ratings yet

- Week 7: Squat Bench Deadlift Weight LbsDocument4 pagesWeek 7: Squat Bench Deadlift Weight LbsArndrit KucukuNo ratings yet

- Screenshot 2023-11-16 104650.pngDocument1 pageScreenshot 2023-11-16 104650.pngGILANG NUGROHONo ratings yet

- F1 SpecsDocument3 pagesF1 SpecsJefri MarpaungNo ratings yet

- Dimensional Chart For Tri-Clamp GasketsDocument2 pagesDimensional Chart For Tri-Clamp GasketsVinh TonyNo ratings yet

- Foodlog Date3Document1 pageFoodlog Date3api-732128857No ratings yet

- Feed Specifications - IngredientsDocument5 pagesFeed Specifications - IngredientsGanesh KashinathNo ratings yet

- Livro 3Document2 pagesLivro 3Natalia RochaNo ratings yet

- TDS - Insulation PressboardDocument2 pagesTDS - Insulation PressboardRoger FloresNo ratings yet

- Map 1Document1 pageMap 1Kice InfosystemsNo ratings yet

- UASSDocument10 pagesUASSEriko Arvin KaruniawanNo ratings yet

- Daily Analysis Report 2Document1 pageDaily Analysis Report 2henryakun002No ratings yet

- HGBXDocument1 pageHGBXmktg2No ratings yet

- Three Phase Synchronous Generators: MJL Series 160 - 200 FRAME SIZESDocument6 pagesThree Phase Synchronous Generators: MJL Series 160 - 200 FRAME SIZESandriusNo ratings yet

- Flextensional Piezoelectric Actuator (2) - 1Document4 pagesFlextensional Piezoelectric Actuator (2) - 1dany weinfeldNo ratings yet

- Vazões Gotejo NetafimDocument4 pagesVazões Gotejo NetafimAnderson Chagas BarbosaNo ratings yet

- Haematology Reference IntervalsDocument1 pageHaematology Reference Intervalslolz0037No ratings yet

- Engine 2az Fe Engine 240218 132742Document3 pagesEngine 2az Fe Engine 240218 132742Alexander LópezNo ratings yet

- Drawing Stages For Liquid-Liquid ExtractionDocument8 pagesDrawing Stages For Liquid-Liquid ExtractionLong NguyenNo ratings yet

- Viscosity TablesDocument4 pagesViscosity TablesAshwin ShettyNo ratings yet

- Quiznos Nutrition Information 2010: Everyday Value Deli SubsDocument17 pagesQuiznos Nutrition Information 2010: Everyday Value Deli Subsio84No ratings yet

- Marelli Gen PDFDocument26 pagesMarelli Gen PDFenkzNo ratings yet

- PX432 WhitediffDocument1 pagePX432 WhitediffOluwasegun AndrewNo ratings yet

- STD Material Composition List For LabDocument14 pagesSTD Material Composition List For LabAshok DevihosurNo ratings yet

- Juntas Reinz Vr-Agri-2015 - 16Document188 pagesJuntas Reinz Vr-Agri-2015 - 16Lola RodriguezNo ratings yet

- 120-Kld Stp-Structure Section DWGDocument1 page120-Kld Stp-Structure Section DWGTech MongerNo ratings yet

- Black Striped WallabyDocument1 pageBlack Striped WallabygypsymaudsleyNo ratings yet

- Lemper ElanDocument10 pagesLemper ElanElan Patria NusadiNo ratings yet

- Speed Variators CHV SeriesDocument5 pagesSpeed Variators CHV SeriesWalter Perez MNo ratings yet

- PX425 Lysebio - H1500 - H2500Document1 pagePX425 Lysebio - H1500 - H2500NAKANWAGI JOSLYLINENo ratings yet

- 층간변위Document12 pages층간변위윤주상No ratings yet

- February 2 2017 - Sheet1Document1 pageFebruary 2 2017 - Sheet1api-347896282No ratings yet

- Tehnicki - Podaci HATZ MotoriDocument4 pagesTehnicki - Podaci HATZ MotoriVikko TriNo ratings yet

- TOP-2ME S Single-Phase MotorDocument2 pagesTOP-2ME S Single-Phase MotornguyenmainamNo ratings yet

- Control-Valve-Handbook-En-3661206 Pages 121-130Document10 pagesControl-Valve-Handbook-En-3661206 Pages 121-130trevNo ratings yet

- LT 01 Fbsii-T4 Sen Aip V1Document1 pageLT 01 Fbsii-T4 Sen Aip V1Alberto MasanetNo ratings yet

- Viscosity Values From Cole-ParmerDocument1 pageViscosity Values From Cole-Parmergalaxy grandNo ratings yet

- Injection Pump Test Specifications 191000-490#Document3 pagesInjection Pump Test Specifications 191000-490#Miguel Rojas100% (1)

- Difftrol: LOT Control ABX LysebioDocument2 pagesDifftrol: LOT Control ABX LysebioTarunNo ratings yet

- Aparelho Soldar MIG 170 - 5de5Document1 pageAparelho Soldar MIG 170 - 5de5Edmundo CunhaNo ratings yet

- Hematology Controls: Assay Values and Expected RangesDocument3 pagesHematology Controls: Assay Values and Expected RangesJoAn VaMoNo ratings yet

- Description Nos Dia Spacing L L D Nos Unit WT Total WT SL No Total LengthDocument4 pagesDescription Nos Dia Spacing L L D Nos Unit WT Total WT SL No Total LengthpalaniNo ratings yet

- Jis G3106Document1 pageJis G3106jhephe46No ratings yet

- Pages From Ufc - 3 - 340 - 02Document1 pagePages From Ufc - 3 - 340 - 02M. Murat ErginNo ratings yet

- 0-Sales - Invoice-Waghade Kirana ShopDocument1 page0-Sales - Invoice-Waghade Kirana ShopPankaj NimjeNo ratings yet

- ALT279 Azul Brochure ESP FV-webDocument2 pagesALT279 Azul Brochure ESP FV-webCBautista 2015XDsNo ratings yet

- 2 - Detalhe - Forever - TabelaComparativadePreos - Dezembro21Document1 page2 - Detalhe - Forever - TabelaComparativadePreos - Dezembro21wanessarabelo7No ratings yet

- Cardio Pulmonary Resuscitation Dose ChartDocument1 pageCardio Pulmonary Resuscitation Dose ChartUNICORN TIMENo ratings yet

- Executive Summary For HMA Mix DesignDocument10 pagesExecutive Summary For HMA Mix DesignMUHAMMED KASSIMNo ratings yet

- Cell Name Original Value Final ValueDocument3 pagesCell Name Original Value Final ValueGeorge CastilloNo ratings yet

- PX431 Lysebio 2Document1 pagePX431 Lysebio 2Ahmet DemirNo ratings yet

- Contact Doctor For Early Interventation If Patient Triggers One Red or Two Yellow Score at Any One TimeDocument4 pagesContact Doctor For Early Interventation If Patient Triggers One Red or Two Yellow Score at Any One TimeBozdemonNo ratings yet

- 44.11 42.68 18.92 5x5mm 5x10mm Control: Moisture Content (%)Document4 pages44.11 42.68 18.92 5x5mm 5x10mm Control: Moisture Content (%)ricardoNo ratings yet

- Communication: Subject: Title: ProductDocument2 pagesCommunication: Subject: Title: ProductManikantan RamanathanNo ratings yet

- Lift Max (LBS) Round To:: Squat 170 5 Bench 120 Deadlift 180Document10 pagesLift Max (LBS) Round To:: Squat 170 5 Bench 120 Deadlift 180Uniworse seNo ratings yet

- The Nuts and Bolts of "Let's Make An Error"Document7 pagesThe Nuts and Bolts of "Let's Make An Error"Mayukh Dutta ChowdhuryNo ratings yet

- ABC BC Products EnglishDocument1 pageABC BC Products EnglishbmxmmxNo ratings yet

- Viscosity - Temperature Chart: Input DataDocument6 pagesViscosity - Temperature Chart: Input DatasamgajeraNo ratings yet

- Bing WallpaperDocument1 pageBing WallpaperAlberto MasanetNo ratings yet

- LT 01 Fbsii-T1 Sen Aip V1Document1 pageLT 01 Fbsii-T1 Sen Aip V1Alberto MasanetNo ratings yet

- Ma 01 Fbs-Ii-8-14-Gvz All V1Document4 pagesMa 01 Fbs-Ii-8-14-Gvz All V1Alberto MasanetNo ratings yet

- LT 01 Fbsii-T4 Sen Aip V1Document1 pageLT 01 Fbsii-T4 Sen Aip V1Alberto MasanetNo ratings yet

- HVAC&R Question BankDocument3 pagesHVAC&R Question BankChirag kumarNo ratings yet

- Advantage-Disadvantage VRFDocument13 pagesAdvantage-Disadvantage VRFRatnasariPurnadewi100% (3)

- Welded Wire Reinforcement WWM WWR Common SizesDocument2 pagesWelded Wire Reinforcement WWM WWR Common Sizesgullipalli100% (1)

- Numerical Modelling of ShotcreteDocument435 pagesNumerical Modelling of Shotcreteaecom2009No ratings yet

- Welcome TO Daman & Vapi: Insat Trading CompanyDocument19 pagesWelcome TO Daman & Vapi: Insat Trading CompanyPranay BubnaNo ratings yet

- Cross 9LVR 0050 5Document17 pagesCross 9LVR 0050 5Chitharanjan VishnukripalNo ratings yet

- Precast Segmental Box Girder Bridges PDFDocument15 pagesPrecast Segmental Box Girder Bridges PDFJoni BarjonoNo ratings yet

- General Material List BlankDocument4 pagesGeneral Material List BlankNavin NarineNo ratings yet

- Calculation Sheet For Q-Pipe Rack Steel StrcutureDocument66 pagesCalculation Sheet For Q-Pipe Rack Steel StrcutureclarkgaguiNo ratings yet

- Sample Calculation Safe Bearing Capacity & Safe Bearing Pressure of Squre FootingDocument2 pagesSample Calculation Safe Bearing Capacity & Safe Bearing Pressure of Squre Footingdharmpal yadavNo ratings yet

- Dupa StandardDocument12 pagesDupa StandardElectrical Section Provincial Capitol of LagunaNo ratings yet

- Formal Interpretations 2012Document5 pagesFormal Interpretations 2012sgttomasNo ratings yet

- Pile Cap and CaissonsDocument6 pagesPile Cap and Caissonsanju krishnaNo ratings yet

- Structural Modeling For Lateral Stiffness in Historic Truss BridgesDocument9 pagesStructural Modeling For Lateral Stiffness in Historic Truss BridgesDARSHAN ROYGAGANo ratings yet

- Load Calculations: Due To Dead Load (All Floors)Document2 pagesLoad Calculations: Due To Dead Load (All Floors)BIGG BOSSNo ratings yet

- Interim PHD ReportDocument54 pagesInterim PHD Reportjblaze747No ratings yet

- Expansion Joints - SN1Document38 pagesExpansion Joints - SN1Aslam KyonNo ratings yet

- Sewerage and Sewage Treatment of Panvel, Maharashtra (Presentation) PDFDocument38 pagesSewerage and Sewage Treatment of Panvel, Maharashtra (Presentation) PDFDhruv MudgalNo ratings yet

- Timber AssignDocument17 pagesTimber AssignRashid AliNo ratings yet

- 1.fabrication and Installation of Pipe SupportDocument5 pages1.fabrication and Installation of Pipe Supportsethu1091100% (3)

- JL-97-September-October AASHTO-PCI-ASBI Segmental Box Girder Standards A New Product For Grade Separations and Interchange BridgesDocument11 pagesJL-97-September-October AASHTO-PCI-ASBI Segmental Box Girder Standards A New Product For Grade Separations and Interchange BridgesAriel JimNo ratings yet

- Correcting SPT Values: Muni Budhu "Foundations and Earth Retaining Structures", John Wiley & Sons, NY, 2007Document5 pagesCorrecting SPT Values: Muni Budhu "Foundations and Earth Retaining Structures", John Wiley & Sons, NY, 2007LavanyanNo ratings yet

- Load and Resistance Factor Rating of Concrete Segmental Bridges - AASHTO Manual For Bridge Evaluation Provisions and Special ConsiderationsDocument3 pagesLoad and Resistance Factor Rating of Concrete Segmental Bridges - AASHTO Manual For Bridge Evaluation Provisions and Special ConsiderationsKY PengNo ratings yet

- Technical Report On Magnesium SuperplasticityDocument22 pagesTechnical Report On Magnesium Superplasticityashvani0% (1)

- How To Calculate Flat Plate Thickness of Flat Bottom Storage TankDocument3 pagesHow To Calculate Flat Plate Thickness of Flat Bottom Storage TankInamullah KhanNo ratings yet

- JB GT Mall Town Center Cost Breakdown - CivilDocument7 pagesJB GT Mall Town Center Cost Breakdown - CivilMarcjun Colmo AlegradoNo ratings yet

- 3029 FM LabDocument36 pages3029 FM Labmohammed sallemNo ratings yet