Professional Documents

Culture Documents

Drasta C 5022: Utilisations

Drasta C 5022: Utilisations

Uploaded by

Anya PamungkasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drasta C 5022: Utilisations

Drasta C 5022: Utilisations

Uploaded by

Anya PamungkasCopyright:

Available Formats

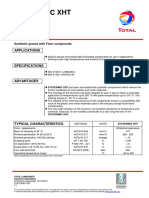

DRASTA C 5022

Metalworking

Accelerated cold quenching oil.

UTILISATIONS

Quenching of alloy steels and case-hardened or nitrided steels.

All types of furnaces with separate or built-in tanks.

Working temperature : 30°C to 80°C.

ADVANTAGES

Excellent resistance to oxidation and thermal changes owing to:

- the use of highly refined base oils,

- the presence of effective and durable antioxidant additives which give long bath

life.

High flash point to ensure risk-free operation in the utilisation temperature range.

Low volatility limits evaporation loss and the formation of vapours and fumes.

Effective, durable cooling powers guarantee mechanical properties achieved

after quenching (hardness, depth of hardness).

Low fluidity at the temperature of use reduces loss by entrainment, resulting in

product savings.

Aromatic-free oil for better workplace environment.

TYPICAL CHARACTERISTICS METHODS UNITS DRASTA C 5022

3

Density at 15°C ISO 3675 kg/m 838

Viscosity at 40°C ISO 3104 mm²/s 21.5

Cleveland flash point ISO 2592 °C 222

Above characteristics are mean values given as an information.

TOTAL LUBRIFIANTS

INDUSTRIE

29-04-2015

DRASTA C 5022

1/1

This lubricant used as recommended and for the application for which it has been designed does not present any particular risk.

A material safety data sheet conforming to the regulations in use in the E.C. is obtainable via your commercial adviser www.quick-fds.com.

You might also like

- CPSMDocument1 pageCPSMAnya PamungkasNo ratings yet

- Installation and Parts Manual D6R - D6TDocument23 pagesInstallation and Parts Manual D6R - D6TJUAN CARLOS PAZ100% (3)

- The Life and Ministry of Apostle PeterDocument113 pagesThe Life and Ministry of Apostle PeterDukejack100% (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Marine Equivalent Lubrication ComparisionDocument1 pageMarine Equivalent Lubrication Comparisionparag7676100% (3)

- 503hoja-tecnica-MOLYKOTE® 44 MediumDocument2 pages503hoja-tecnica-MOLYKOTE® 44 MediumeariesilvapcNo ratings yet

- Molykote G-2003Document2 pagesMolykote G-2003Luz Angela GuerreroNo ratings yet

- Technicaldatasheet (TDS) 33mediumextremelowtemperaturegrease English 12062022Document2 pagesTechnicaldatasheet (TDS) 33mediumextremelowtemperaturegrease English 12062022pmf engineering limitedNo ratings yet

- Shell Thermia B PDFDocument2 pagesShell Thermia B PDFEduardo Dreifus100% (1)

- MOLYKOTE 44 - MediumDocument2 pagesMOLYKOTE 44 - MediumCesar AlejandroNo ratings yet

- Mak Quenching Oil CDocument1 pageMak Quenching Oil CPaviter SinghNo ratings yet

- Molykote G 1001 PdsDocument2 pagesMolykote G 1001 PdsDicky PratamaNo ratings yet

- FT Hydrelf Ds 46 (Anglais)Document1 pageFT Hydrelf Ds 46 (Anglais)Arturo Yakisich CabreraNo ratings yet

- Shell Heat Transfer Oil S2X TDSDocument2 pagesShell Heat Transfer Oil S2X TDSrudiarto 07No ratings yet

- ALBIDA GREASE HDX 2 TdsDocument2 pagesALBIDA GREASE HDX 2 TdsaryawigiNo ratings yet

- Shell Diala S3 ZX-IG DriedDocument2 pagesShell Diala S3 ZX-IG DriedAnonymous oAbjbl4HNo ratings yet

- Shell Heat Transfer Oil S2Document2 pagesShell Heat Transfer Oil S2Mudabbir Shan Ahmed100% (2)

- Roto Inject Fluid NDURANCE enDocument2 pagesRoto Inject Fluid NDURANCE enMartín BaezaNo ratings yet

- Graisse N 31315Document1 pageGraisse N 31315kirandhivya1821No ratings yet

- Roto Inject Fluid NDURANCE: Atlas Copco LubricantsDocument2 pagesRoto Inject Fluid NDURANCE: Atlas Copco LubricantsJoao BotasNo ratings yet

- TDS - Total - Statermic XHT - HNN - 201412 - enDocument1 pageTDS - Total - Statermic XHT - HNN - 201412 - enNibaldo KamelNo ratings yet

- Roto Synthetic Fluid ULTRA: High Quality Synthetic Oil For Demanding ApplicationsDocument2 pagesRoto Synthetic Fluid ULTRA: High Quality Synthetic Oil For Demanding ApplicationsJoao BotasNo ratings yet

- Preslia 32-100 Eng PDFDocument1 pagePreslia 32-100 Eng PDFAxel Mahya AvichenaNo ratings yet

- Unirex N Series PDFDocument3 pagesUnirex N Series PDFAbdulSattarNo ratings yet

- Altis Mv2: ApplicationsDocument1 pageAltis Mv2: ApplicationsM.TayyabNo ratings yet

- Shell Heat Transfer Oil S2 TDSDocument2 pagesShell Heat Transfer Oil S2 TDSHemanthNo ratings yet

- Shell Corena Oil P 150Document2 pagesShell Corena Oil P 150Secundar UtilizatorNo ratings yet

- Castrol Aditivo MicrofluxDocument3 pagesCastrol Aditivo MicrofluxmaykolperezrojoNo ratings yet

- Atlascopco Oil DatasheetDocument2 pagesAtlascopco Oil DatasheetAmirmasoudNo ratings yet

- MOLYKOTE 33 Light Extreme Low Temperature Grease 80-3098E-01Document2 pagesMOLYKOTE 33 Light Extreme Low Temperature Grease 80-3098E-01pmf engineering limitedNo ratings yet

- Doosan MAN02Document1 pageDoosan MAN02ironiteNo ratings yet

- LOCTITE SI 5927 RED en - GLDocument2 pagesLOCTITE SI 5927 RED en - GLOmer IkhlasNo ratings yet

- Product Information: Special Tec AA 10W-30 BenzinDocument1 pageProduct Information: Special Tec AA 10W-30 BenzinMuhNo ratings yet

- 259Document1 page259thanhhuyenNo ratings yet

- Ficha Oleo Termico - UnlockedDocument2 pagesFicha Oleo Termico - UnlockedWisard MagalhãesNo ratings yet

- TDS - Total - Dacnis 68 - 25o - 202008 - enDocument1 pageTDS - Total - Dacnis 68 - 25o - 202008 - enMuhammmad Naqi RazaNo ratings yet

- Data Sheet 2935016922 - RotoSyntheticFluid - ULTRA - enDocument2 pagesData Sheet 2935016922 - RotoSyntheticFluid - ULTRA - enMohamed Abd-alfattah100% (1)

- MOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01Document2 pagesMOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01MAHESH BELENo ratings yet

- Molylub GoldTex T 32 KnittingDocument1 pageMolylub GoldTex T 32 KnittingismoyoNo ratings yet

- PDSDetail PageDocument2 pagesPDSDetail PageDavid ChuNo ratings yet

- Gpcdoc Gtds Shell Gadus s3 v460xd 2 (En) TdsDocument2 pagesGpcdoc Gtds Shell Gadus s3 v460xd 2 (En) TdsRoger ObregonNo ratings yet

- DacnisDocument1 pageDacnisironiteNo ratings yet

- Air Tool Oil s2 A 100Document2 pagesAir Tool Oil s2 A 100José Edgar Rodriguez BritoNo ratings yet

- High Temperature-Grease-pds-EngDocument3 pagesHigh Temperature-Grease-pds-Engdavide comuzziNo ratings yet

- P004785 Special Tec AA 10W 30 Benzin 22 en - GBDocument1 pageP004785 Special Tec AA 10W 30 Benzin 22 en - GBAbdulsalamNo ratings yet

- RS Ultra Latest MSDSDocument2 pagesRS Ultra Latest MSDSRamraj EnterprisesNo ratings yet

- MOLYKOTE 1000 Paste 71-0218H-01Document2 pagesMOLYKOTE 1000 Paste 71-0218H-01Victor PomboNo ratings yet

- MOLYKOTE - HP-300 - Grease - 80-3103E-01Document2 pagesMOLYKOTE - HP-300 - Grease - 80-3103E-01jtelloNo ratings yet

- Technical Data Sheet: Totalenergies LubrifiantsDocument1 pageTechnical Data Sheet: Totalenergies Lubrifiantsbovewom991No ratings yet

- TDS - Total - Hydransafe-Hfdu-68 - NTS - 201207 - en - Usa - Ester BaseDocument2 pagesTDS - Total - Hydransafe-Hfdu-68 - NTS - 201207 - en - Usa - Ester BaseMaxNo ratings yet

- Multis Ep 3Document1 pageMultis Ep 3Sami KahtaniNo ratings yet

- Molykote Food Grade EP Bearing Grease - PDSDocument2 pagesMolykote Food Grade EP Bearing Grease - PDSabc xyzNo ratings yet

- Poly Gear PG en PDFDocument2 pagesPoly Gear PG en PDFAlfredo CarlosNo ratings yet

- MOLYKOTE Multilub Synthetic High Performance Grease 01-1050A-01Document2 pagesMOLYKOTE Multilub Synthetic High Performance Grease 01-1050A-01pmf engineering limitedNo ratings yet

- 6322 Product InfoDocument2 pages6322 Product InfoVendy KurniawanNo ratings yet

- Gpcdoc Sa Tds ThermiaDocument2 pagesGpcdoc Sa Tds ThermiaAbdelrahman MagdyNo ratings yet

- Heat Transfer OilDocument2 pagesHeat Transfer OilDony LieNo ratings yet

- Introduction to Microsystem Technology: A Guide for StudentsFrom EverandIntroduction to Microsystem Technology: A Guide for StudentsRating: 5 out of 5 stars5/5 (1)

- Automotive Paints and CoatingsFrom EverandAutomotive Paints and CoatingsHans-Joachim StreitbergerNo ratings yet

- Welding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesFrom EverandWelding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesRating: 1 out of 5 stars1/5 (1)

- Tds Total Quartz 9000 Energy 0w-40 By3 202009 enDocument2 pagesTds Total Quartz 9000 Energy 0w-40 By3 202009 enAnya PamungkasNo ratings yet

- 08 DN Super Turbine Oil SeriesDocument2 pages08 DN Super Turbine Oil SeriesAnya PamungkasNo ratings yet

- Total Nevastane Xs 80 Food Grade GreaseDocument2 pagesTotal Nevastane Xs 80 Food Grade GreaseAnya PamungkasNo ratings yet

- Planetelf Acd 68 TDS v171023Document1 pagePlanetelf Acd 68 TDS v171023Anya PamungkasNo ratings yet

- The Influence of Graphite Solid Additives, Mos2 and Ptfe On Changes in Shear Stress Values in Lubricating GreasesDocument12 pagesThe Influence of Graphite Solid Additives, Mos2 and Ptfe On Changes in Shear Stress Values in Lubricating GreasesAnya PamungkasNo ratings yet

- Irresistible Value Propositions r2Document28 pagesIrresistible Value Propositions r2Anya PamungkasNo ratings yet

- Consolidated Financial Statement BRNA Des 2017Document153 pagesConsolidated Financial Statement BRNA Des 2017Anya PamungkasNo ratings yet

- Australia's Liquid Fuel Security: A Report For NRMA Motoring and ServicesDocument24 pagesAustralia's Liquid Fuel Security: A Report For NRMA Motoring and ServicesAnya PamungkasNo ratings yet

- Infopublik20140605154724 Perusahaan PDFDocument33 pagesInfopublik20140605154724 Perusahaan PDFLowdy FilanNo ratings yet

- SampleDocument59 pagesSampleAnya PamungkasNo ratings yet

- The Setting SunDocument11 pagesThe Setting Sunrahafalasaker22No ratings yet

- Anna FreudDocument3 pagesAnna FreudDaba DashievNo ratings yet

- End Length OffsetsDocument5 pagesEnd Length OffsetsvardogerNo ratings yet

- ANS Drugs - SANGALANG, AQ - #SGD - PANOSOJBA - C6 - AY2022-2023Document8 pagesANS Drugs - SANGALANG, AQ - #SGD - PANOSOJBA - C6 - AY2022-2023Jasper PanosoNo ratings yet

- LP40W LED Driver 2017Document4 pagesLP40W LED Driver 2017Daniel MéndezNo ratings yet

- High Thrust Temperature Problem PetroRabigh MACDocument8 pagesHigh Thrust Temperature Problem PetroRabigh MACmsh16000No ratings yet

- Which Psychotropic Medications Induce He PDFDocument9 pagesWhich Psychotropic Medications Induce He PDFnisastNo ratings yet

- RECON-BRX-2017-Reverse Engineering Satellite Based IP Content DistributionDocument32 pagesRECON-BRX-2017-Reverse Engineering Satellite Based IP Content DistributionpaulNo ratings yet

- 11 - John Laurents - Pavemetrics - 3D Transverse Road ProfilingDocument74 pages11 - John Laurents - Pavemetrics - 3D Transverse Road ProfilingOrlando Rojas100% (1)

- Call For Internship With CSIR-NEERI in Association With CARE INC, USADocument2 pagesCall For Internship With CSIR-NEERI in Association With CARE INC, USANikNo ratings yet

- Babu AstrologyDocument11 pagesBabu AstrologysureshbabubnysNo ratings yet

- SSP MonitoringDocument2 pagesSSP MonitoringcolosseusdNo ratings yet

- Artificial Intelligence & Machine Learning: Career GuideDocument18 pagesArtificial Intelligence & Machine Learning: Career Guidekallol100% (1)

- Basics of ProgrammingDocument126 pagesBasics of ProgrammingabinayaNo ratings yet

- WilcoxRandR 2009 1introduction BasicStatisticsUndersDocument6 pagesWilcoxRandR 2009 1introduction BasicStatisticsUndersanothervagabondNo ratings yet

- Mechanical Design Engineer IIIDocument5 pagesMechanical Design Engineer IIIcrismg1No ratings yet

- 206 Quiz and Exam QuestionsDocument3 pages206 Quiz and Exam QuestionsTimothy Paul RossNo ratings yet

- Transmission: Section F Section FDocument1 pageTransmission: Section F Section FSzabolcs Ignátisin0% (1)

- Hari Donthireddy Resume-3Document1 pageHari Donthireddy Resume-3api-667792083No ratings yet

- Handshake Job Interview QuestionsDocument4 pagesHandshake Job Interview QuestionslhnguyenwpiNo ratings yet

- Full Body Exercises: For Stroke PatientsDocument26 pagesFull Body Exercises: For Stroke PatientsVinod VermaNo ratings yet

- The Masterpieces of The Ohio Mound BuildersDocument136 pagesThe Masterpieces of The Ohio Mound BuildersRob StoneNo ratings yet

- Hyperion 2 PDFDocument1 pageHyperion 2 PDFAbhishek Gite100% (1)

- mddn413 Project 3 KDC Logotype BriefDocument2 pagesmddn413 Project 3 KDC Logotype Briefapi-269292118No ratings yet

- Serial No.8 Designing and Managing ServicesDocument18 pagesSerial No.8 Designing and Managing ServicesPhD ScholarNo ratings yet

- Alaris™ PK Syringe Pump: Directions For UseDocument50 pagesAlaris™ PK Syringe Pump: Directions For UseSalim AloneNo ratings yet

- H.C. Starck Tungsten Powders - Empowering Innovative CustomersDocument16 pagesH.C. Starck Tungsten Powders - Empowering Innovative CustomerszahiraNo ratings yet

- MariammanDocument9 pagesMariammanolivernora777No ratings yet