Professional Documents

Culture Documents

Codigos M-2

Codigos M-2

Uploaded by

Claudio Cordero Ramírez0 ratings0% found this document useful (0 votes)

5 views1 pageOriginal Title

CODIGOS M-2

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

5 views1 pageCodigos M-2

Codigos M-2

Uploaded by

Claudio Cordero RamírezCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 1

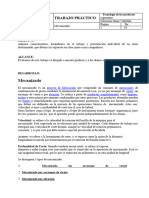

dane 2003 Operator's Manual

wee QD

M93 Start Axis Position Capture

Mg4 Stop Axis Position Capture

M95 Sleep Mode

M96 Jump if No Input

M97 Local Sub-Program Call

MgB ‘Sub-Program Call

go Sub-Program Return or Loop

M109 Interactive User Input

Moo Stop Program

‘The M00 code is used to stop a program. It stops the spindle, tums off the coolant and stops interpretation

look-ahead processing, The program pointer will advance to the next block and stop. Pressing CYCLE START

will continue program operation from the next block. If the through-spindle coolant option is On, MOO will

shut it off

Mot Optional Program Stop

The M01 code is identical to MOO except that it only stops if OPTIONAL STOP is turned on from the front

panel. CYCLE START will continue program operation from the next block, Ifthe through-spindle coolant option

is On, MO1 will shut it off

Mo2 Program End

The M02 code will stop program operation the same as MOO, but does not advance the program pointer to the

next block

Mo3 Spindle Forward (CW)

‘The M03 code will start the spindle moving in a clockwise direction at whatever speed was previously set.

Block activation will be delayed until the spindle reaches about 90% of commanded speed.

When Parameter 278 bit 10, “CNCR SPINDLE, "is set to 1, block activation does not depend on the spindle

coming up to speed. Interpolated motion will not be initiated until spindle speed is reached, but other

commands, such as rapid motion, will be

Mo4 Spindle Reverse (CCW)

The M04 code will start the spindle moving is a counterclockwise direction at whatever speed was previously

set. Block activation will be delayed until the spindle reaches about 90% of commanded speed.

When Parameter 278 bit 10, "CNCR SPINDLE, " is set to 1, block activation does not depend on the spindle

coming up to speed. Interpolated motion will not be initiated until spindle speed is reached, but other

commands, such as rapid motion, will be.

Running an M04 command with through-spindle coolant on is not recommended.

MOS Spindle Stop

The M05 code is used to stop the spindle. The block is delayed until the spindle slows to less than 10 rpm.

Mo6 Tool Change

The MO6 code is used to initiate a tool change. If the spindle is running, it will be stopped. No axis commands

are required prior to the tool change unless there is a problem with tool/partifixture clearance. The Z axis will

automatically move up to the machine zero position and the selected tool (Tnn) will be put into the spindle. The

Tnn must be in the same block as the M06 or in a previous block. The Z axis will remain at machine zero. The

spindle will not start again after the tool change until itis commanded, but the Snnnn speed and gear will be

unchanged. The coolant pump will be turned off during a tool change.

When the through-spindle coolant (TSC) is On, M06 will orient the spindle and move the Z axis to tool change

position, turn off the TSC pump, purge the coolant from the drawbar, then perform a tool change. TSC will

remain Off until an M88 is called.

96-8000 rev AMAS— 261

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- parte de plato 1Document1 pageparte de plato 1Claudio Cordero RamírezNo ratings yet

- Metodologia MaquinadoDocument27 pagesMetodologia MaquinadoClaudio Cordero RamírezNo ratings yet

- MPS 31 BrochureDocument2 pagesMPS 31 BrochureClaudio Cordero RamírezNo ratings yet

- Dimensionamiento Del Equipo de TraslacioDocument513 pagesDimensionamiento Del Equipo de TraslacioClaudio Cordero RamírezNo ratings yet

- MV Series MachineDocument1 pageMV Series MachineClaudio Cordero RamírezNo ratings yet

- MecanizadosDocument20 pagesMecanizadosClaudio Cordero RamírezNo ratings yet

- Direcciones Alfabeticas1Document1 pageDirecciones Alfabeticas1Claudio Cordero RamírezNo ratings yet

- Hotel Amaranto Zuzaca de San Ramón Sociedad AnónimaDocument1 pageHotel Amaranto Zuzaca de San Ramón Sociedad AnónimaClaudio Cordero RamírezNo ratings yet

- Pe Ci 2 2022Document4 pagesPe Ci 2 2022Claudio Cordero RamírezNo ratings yet

- FORMULASDocument1 pageFORMULASClaudio Cordero RamírezNo ratings yet

- Codigos M-1Document1 pageCodigos M-1Claudio Cordero RamírezNo ratings yet

- Estructura de Programa HaasDocument1 pageEstructura de Programa HaasClaudio Cordero RamírezNo ratings yet

- Instituto Tecnologico y de Estudios SupeDocument113 pagesInstituto Tecnologico y de Estudios SupeClaudio Cordero RamírezNo ratings yet

- Direcciones Alfabeticas4Document1 pageDirecciones Alfabeticas4Claudio Cordero RamírezNo ratings yet

- Direcciones Alfabeticas3Document1 pageDirecciones Alfabeticas3Claudio Cordero RamírezNo ratings yet

- Direcciones Alfabeticas2Document1 pageDirecciones Alfabeticas2Claudio Cordero RamírezNo ratings yet

- G74 - RANURADO PROFUNDO EN CARA FINAL (Taladrado/Ranurado) : G74 R - G74 X - Z - P - Q - R - FDocument2 pagesG74 - RANURADO PROFUNDO EN CARA FINAL (Taladrado/Ranurado) : G74 R - G74 X - Z - P - Q - R - FClaudio Cordero RamírezNo ratings yet

- Codigos G-1Document1 pageCodigos G-1Claudio Cordero RamírezNo ratings yet

- Practica de Procesos de Fabricacion No 7Document12 pagesPractica de Procesos de Fabricacion No 7Claudio Cordero RamírezNo ratings yet