Professional Documents

Culture Documents

RT02

RT02

Uploaded by

اسران احمدOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RT02

RT02

Uploaded by

اسران احمدCopyright:

Available Formats

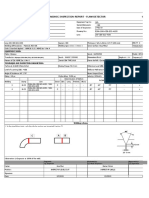

CSWIP 3.

2 TTRAINING REPORT RT 02

DATE OF INSPECTION: 4.8.15 INSPECTION COMPANY: TWI NDT

REPORT NUMBER: 1970 CLIENT: Tramcar

WELDING PROCESS: MMA 111 WELD REFERENCE: 47

JOINT GEOMETRY SURFACE CONDITION: As welded MMA 111

TEST PROCEDURE: 131

STAGE OF TEST: After PWHT

25mm

2.5mm SCOPE OF INSPECTION: 100%

MATERIAL: C-Mn

Source Strength: 60 Ci FFD/SFD: 150 mm

- Bevel Angle 30o + 5o, - 0o

- Root Gap 2.5mm. KV's: N/A mA's: N/A

- Plate thickness 25 mm

-Weld Length Screen type: Pb Exposure: 4Ci mins

Focal Spot: Source Size: 2x3 mm

FILM TYPE: AGFA D4 IQI TYPE: AL

DEVELOPMENT: 4 mins @ 20oC manual FIXING CONDITIONS 6 mins @ 20oC

RADIOGRAPHIC TECHNIQUE: SWSI ISOTOPE TYPE: Co 60

TEST RESULTS

FILM ID SEN % DENSITY COMMENTS ACTION

1-2 2% 4-5 No defects observed Accept

2-3 2% 2-3 burn trhough of 6mm Accept

3-4 2% 2-3 No defects observed Accept

4-5 2% 2-3 No defects observed Accept

5-6 2% 2-3 Non-Metallic inclusions Reject

TEST LIMITATIONS:

TEST OPERATOR: Sjones REPORT DATE: 4.8.15

SIGNATURE: S Jones OPERATORS QUALIFICATION: CSWIP L2 (EN ISO9712)

SJ Training RT01

You might also like

- RT VL 4023 SPOOL PIECEDocument1 pageRT VL 4023 SPOOL PIECEsanthakumarNo ratings yet

- RT VG5409Document1 pageRT VG5409santhakumarNo ratings yet

- MT02Document1 pageMT02اسران احمدNo ratings yet

- Gpti Qicl J931 Mut 041Document3 pagesGpti Qicl J931 Mut 041uselessinstaid52No ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- Gpti Qicl J931 Mut 002Document2 pagesGpti Qicl J931 Mut 002uselessinstaid52No ratings yet

- WpsDocument4 pagesWpsMahfudRido'iRonggomaniaNo ratings yet

- Gpti Qicl 032Document2 pagesGpti Qicl 032uselessinstaid52No ratings yet

- 11-03-2020 C1 Gland Steam Super Heater - UTDocument4 pages11-03-2020 C1 Gland Steam Super Heater - UTDave CheungNo ratings yet

- Example of Inspection Report 2Document3 pagesExample of Inspection Report 2SAIFUDDIN NUR AKMALNo ratings yet

- 10CDCF LM-1600406 (PFGD)Document2 pages10CDCF LM-1600406 (PFGD)Sohaib AhmadNo ratings yet

- Ultrasonic Test Report: Before AfterDocument7 pagesUltrasonic Test Report: Before AfterMenad SalahNo ratings yet

- Kamlesh Kumar Singh Engineers Pvt. LTDDocument24 pagesKamlesh Kumar Singh Engineers Pvt. LTDAADARSHNo ratings yet

- Example of Inspection Report 3Document11 pagesExample of Inspection Report 3SAIFUDDIN NUR AKMALNo ratings yet

- Gpti Qicl J931 Mut 004Document3 pagesGpti Qicl J931 Mut 004uselessinstaid52No ratings yet

- Board Line: - 022 66595154: As Per Iso 2341Document1 pageBoard Line: - 022 66595154: As Per Iso 2341BARKAT ALINo ratings yet

- F.O. ADSS SpecificationDocument4 pagesF.O. ADSS SpecificationDinatel ComercialNo ratings yet

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- PQR Gmaw3gDocument4 pagesPQR Gmaw3gdevendrasingh2021100% (3)

- 915MHZ Fiberglass AntennaDocument6 pages915MHZ Fiberglass AntennaRidho FikriNo ratings yet

- CNT230025 C3 HRSG - Air Tank TCV020&PCV068Document6 pagesCNT230025 C3 HRSG - Air Tank TCV020&PCV068Dave CheungNo ratings yet

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderNo ratings yet

- Ut ProcedureDocument2 pagesUt ProcedureJJ WeldingNo ratings yet

- WPS PQR FormulirDocument2 pagesWPS PQR FormulirAZaiNo ratings yet

- He Mrut 005Document3 pagesHe Mrut 005Hao TranNo ratings yet

- Doosan Power Systems India PVT Limited: Magnetic Particle Examination ReportDocument1 pageDoosan Power Systems India PVT Limited: Magnetic Particle Examination ReportBalkishan DyavanapellyNo ratings yet

- He Mrut 006Document3 pagesHe Mrut 006Hao TranNo ratings yet

- GNL3Z PJ Piping InspectionDocument29 pagesGNL3Z PJ Piping Inspectiondon_romanticko281236No ratings yet

- Ut PQRDocument10 pagesUt PQRArvind Sahani100% (1)

- Inspection Report: Setcore Arabia Petroleum ServiceDocument1 pageInspection Report: Setcore Arabia Petroleum ServiceMahmoud SalahNo ratings yet

- Scope: Method Statement For Welding ControlDocument6 pagesScope: Method Statement For Welding ControlSIBINNo ratings yet

- Rp-20-Ut-011-Tcr-Saudi CementDocument1 pageRp-20-Ut-011-Tcr-Saudi CementRonel John Rodriguez CustodioNo ratings yet

- Coil # 25 Inlet C-Scan ReportDocument5 pagesCoil # 25 Inlet C-Scan ReportdrakeNo ratings yet

- 4-Lembar Pengesahan PengujiDocument163 pages4-Lembar Pengesahan PengujiNico Achmad ZulviansyahNo ratings yet

- UT ReportDocument1 pageUT ReportAmit HasanNo ratings yet

- 31-03-2020 C1 Generator Rotor Hydrogen Seal Ring - UTDocument6 pages31-03-2020 C1 Generator Rotor Hydrogen Seal Ring - UTDave CheungNo ratings yet

- Prova Ne TerheqjDocument1 pageProva Ne TerheqjBislim BrahajNo ratings yet

- 13. 0983-23 RT-056-056 DNE-USE จ.พะเยา Pipe Ø 1800 T. 16.0 mm 19-7-23Document14 pages13. 0983-23 RT-056-056 DNE-USE จ.พะเยา Pipe Ø 1800 T. 16.0 mm 19-7-23Wisüttisäk PeäröönNo ratings yet

- WQT UT REPORTDocument1 pageWQT UT REPORTDHANEESH VELLILAPULLINo ratings yet

- 12 MT ProcedureDocument17 pages12 MT ProcedureThân KhaNo ratings yet

- Ut 2829Document1 pageUt 2829quality cncNo ratings yet

- Doosan Power Systems Indai PVT Limited: System CalibrationDocument3 pagesDoosan Power Systems Indai PVT Limited: System CalibrationBalkishan DyavanapellyNo ratings yet

- WPQ Ejcom Nr476Document13 pagesWPQ Ejcom Nr476Touil HoussemNo ratings yet

- 1515-WD .Weld Procedures and Welder Qualifications 19 Aug 2016Document64 pages1515-WD .Weld Procedures and Welder Qualifications 19 Aug 2016ivan sulistianNo ratings yet

- Quality NDT Services: To, Techspeq SolutionsDocument1 pageQuality NDT Services: To, Techspeq Solutionsomkar.baswar99No ratings yet

- WPS Format For AWS D1.1 - PQR - SMAWDocument3 pagesWPS Format For AWS D1.1 - PQR - SMAWThe Welding Inspections Community100% (3)

- Sim900 Reliability Test ReportDocument19 pagesSim900 Reliability Test ReportJaan TammNo ratings yet

- Customer Details:: Test Reading STD - Reading Error Uncertainty S.NoDocument2 pagesCustomer Details:: Test Reading STD - Reading Error Uncertainty S.NomaniNo ratings yet

- B Scan - C Scan - D ScanDocument52 pagesB Scan - C Scan - D ScanHee Wee JianNo ratings yet

- Ec-2692-220-2 - Void 4SDocument3 pagesEc-2692-220-2 - Void 4SMatheus Fabrício TeixeiraNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- Certificado EsparragosDocument8 pagesCertificado EsparragosJesus CondoriNo ratings yet

- Transformer Test ReportDocument46 pagesTransformer Test ReportAkshay GatkalNo ratings yet

- Coil # 29 Inlet C-Scan ReportDocument5 pagesCoil # 29 Inlet C-Scan ReportdrakeNo ratings yet

- M Rogers: Radiographic Test Report Bad Example 5Document1 pageM Rogers: Radiographic Test Report Bad Example 5Sundar KumarNo ratings yet

- 14 78 90 9932 - NDT Procedure For Internal X-Ray Radiographic Testing Rev. BDocument14 pages14 78 90 9932 - NDT Procedure For Internal X-Ray Radiographic Testing Rev. BSajjad k. AmhawiNo ratings yet

- Arandela Plana Galv Cal 58Document1 pageArandela Plana Galv Cal 58knery684No ratings yet

- NDT-SA-SATORP-UTT-60-RV00 Date-15 Aug-2023Document10 pagesNDT-SA-SATORP-UTT-60-RV00 Date-15 Aug-2023Md Abu Hanif RajuNo ratings yet