Professional Documents

Culture Documents

Sistema de Lubricación

Sistema de Lubricación

Uploaded by

Hector HerreraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sistema de Lubricación

Sistema de Lubricación

Uploaded by

Hector HerreraCopyright:

Available Formats

SISTEMA DE LUBRICACIÓN

Traducido por: Enrique Fernández V.

tecnico mecanico

U.T.F.S.M

SERIE 4000 12/16V MANUAL DE SERVICIO

C 180 – SISTEMA DE LUBRICACION

Section Page

C 181.05 LUBE OIL PUMP WITH DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1095

C 181.05.01 General View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1097

C 181.05.04 Before-Removal Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1098

C 181.05.05 Removal of Lube Oil Pump with Drive . . . . . . . . . . . . . . . . . . . . . . C -1099

C 181.05.08 Inspection and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1102

C 181.05.11 Installation of Lube Oil Pump with Drive . . . . . . . . . . . . . . . . . . . . C -1106

C 181.05.12 After-Installation Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1110

C 183.05 OIL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1111

C 183.05.01 General View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1113

C 183.05.02 Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1114

C 183.05.04 Before-Removal Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1115

C 183.05.05 Removal of Oil Filter and Centrifugal Oil Filter . . . . . . . . . . . . . . C -1116

C 183.05.06 Disassembly of Centrifugal Oil Filter Assembly . . . . . . . . . . . . . C -1124

C 183.05.08 Inspection and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1128

C 183.05.10 Assembly of Oil Filter, Centrifugal Oil Filter and Oil Filter

Service Maintenance Alert System . . . . . . . . . . . . . . . . . . . . . . . . C -1133

C 183.05.11

Installation of Oil Filter, Centrifugal Oil Filter and Oil Filter

Service Maintenance Alert System . . . . . . . . . . . . . . . . . . . . . . . . C -1138

C 183.05.12 After-Installation Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1152

C 183.05 M MARINE OIL HEAT EXCHANGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1153

C 183.05.01 M General View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1155

C 183.05.04 M Before-Removal Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1156

C 183.05.05 M Removal of the Oil Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . C -1157

C 183.05.08 M Inspection, Cleaning and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . C -1161

C 183.05.11 M Installation of the Oil Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . C -1163

C 183.05.12 M After-Installation Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1166

C 184.05 CENTRIFUGAL OIL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1167

C 184.05.01 General View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1169

C 184.05.04 Before-Removal Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1171

C 184.05.05 Removal of Centrifugal Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1172

C 184.05.06 Disassembly of Centrifugal Oil Filter . . . . . . . . . . . . . . . . . . . . . . . C -1174

C 184.05.11 Installation of Centrifugal Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . C -1175

C 184.05.12 After-Installation Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1177

C 185.05 OIL COOLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1179

C 185.05.01 General View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1181

C 185.05.04 Before-Removal Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1182

All information subject to change without notice.

Copyright © DETROIT DIESEL CORPORATION C -1091

SERIE 400012/16V MANUAL DE SERVICIO

C 185.05.05 Removal of Oil Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1183

C 185.05.08 Inspection and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1191

C 185.05.11 Installation of Oil Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . C -1197

C 185.05.12 After-Installation Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1207

C 186.05 OIL SYSTEM FOR PISTON COOLING . . . . . . . . . . . . . . . . . . . . . . . . . C -1209

C 186.05.01 General View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1211

C 186.05.02 Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1213

C 186.05.04 Before-Removal Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1214

C 186.05.05 Removal of Oil System for Piston Cooling . . . . . . . . . . . . . . . . . . C -1215

C 186.05.08 Inspection and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1220

C 186.05.11 Installation of Oil System for Piston Cooling . . . . . . . . . . . . . . . . C -1225

C 186.05.12 After-Installation Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1234

C 187.05 OIL SUPPLY LINES FOR EXHAUST TURBOCHARGER . . . . . . . . C -1235

C 187.05.01 General View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1237

C 187.05.04 Before-Removal Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1238

C 187.05.05 Removal of Oil Supply Hoses for Exhaust Turbocharger . . . . C -1239

C 187.05.08 Inspection and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1241

C 187.05.11 Installation of the Oil Supply Lines for Turbocharger . . . . . . . . C -1243

C 187.05.12 After-Installation Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1244

C 188.05 OIL RETURN LINES FOR TURBOCHARGER . . . . . . . . . . . . . . . . . . C -1245

C 188.05.01 General View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1247

C 188.05.04 Before-Removal Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1248

C 188.05.05 Removal of the Oil Return Lines for Turbocharger . . . . . . . . . . C -1249

C 188.05.08 Inspection and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1251

C 188.05.11 Installation of the Oil Return Lines for Turbocharger . . . . . . . . C -1253

C 188.05.12 After-Installation Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1254

C 185.10.01 M Marine Oil Supply Lines for Turbocharger . . . . . . . . . . . . . . . . . . C -1255

C 185.10.04 M Before-Removal Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1256

C 185.10.05 M Removal of the Oil Supply Lines for Turbocharger . . . . . . . . . . C -1257

C 185.10.08 M Inspection and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1260

C 185.10.11 M Installation of the Oil Supply Lines for Turbocharger . . . . . . . . C -1261

C 185.10.12 M After-Installation Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1264

C 185.25.01 M Marine Oil Return Lines for Turbocharger . . . . . . . . . . . . . . . . . . C -1265

C 185.25.04 M Before-Removal Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1266

C 185.25.05 M Removal of the Oil Return Lines for Turbocharger . . . . . . . . . . C -1267

C 185.25.08 M Inspection and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1270

C 185.25.11 M Installation of the Oil Return Lines for Turbocharger . . . . . . . . C -1271

C 185.25.12 M After-Installation Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1274

All information subject to change without notice.

C -1092 Copyright © DETROIT DIESEL CORPORATION

SERIE 400012/16V MANUAL DE SERVICIO

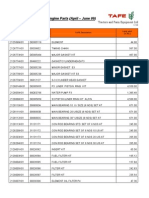

Ver Figura742 para una vista general del sistema de lubricacion.

1. Carter 5. Sistema de Enfriamiento de Aceite (Enfriador de Aceite)

2. Caja de Engranajes Contiene la Bomba de 6. Filtro Centrifugo de Aceite

Aceite y las Valvulas de Presion de Aceite

3. Damper 7. Cabezal de Filtros de Aceite

4. Carcaza de Distribucion Contiene los Circuitos de Aceite 8. Filtros de Aceite

Figura 742 Vista General del Sistema de Lubricacion

All information subject to change without notice.

Copyright © DETROIT DIESEL CORPORATION C -1093

SERIE 400012/16V MANUAL DE SERVICIO

All information subject to change without notice.

C -1094 Copyright © DETROIT DIESEL CORPORATION

SERIE 400012/16V MANUAL DE SERVICIO

C 181.05 – BOMBA DE ACEITE CON MANDO

Seccion Pag

C 181.05.01 Vista General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1097

C 181.05.04 Antes-Operaciones de Desmontaje. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1098

C 181.05.05 Desmontaje de la Bomba de Aceite con su Mando . . . . . . . . . . . . . . . C -1099

C 181.05.08 Inspeccion y Reparacion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1102

C 181.05.11 Instalacion de la Bomba de Aceite con su Mando. . . . . . . . . . . . . . . C -1106

C 181.05.12 Despues-Operaciones de Instalacion. . . . . . . . . . . . . . . . . . . . . . . . . . . . C -1110

All information subject to change without notice.

Copyright © DETROIT DIESEL CORPORATION C -1095

SERIE 400012/16V MANUAL DE SERVICIO

All information subject to change without notice.

C -1096 Copyright © DETROIT DIESEL CORPORATION

SERIE 400012/16V MANUAL DE SERVICIO

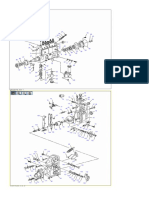

C 181.05.01 – VISTA GENERAL

Ver Figura743 para una vista general de la bomba de aceite con su mando.

1. Perno Hexagonal 6. Perno Racor

2. Brida de sujeccion de cañeria 7. Anillos sello (Cu)

3. Ojal plastico 8. Regulador de Presion

4. Soporte 9. Golilla

5. Linea de Aceite 10. Perno Hexagonal

Figura 743 Vista General de la Bomba de Aceite con Mando

All information subject to change without notice.

Copyright © DETROIT DIESEL CORPORATION C -1097

SERIE 400012/16V MANUAL DE SERVICIO

C 181.05.04 – ANTES-OPERACIONES DE DESMONTAJE

Lista de la Tabla 102 son la Operaciones Antes de Desmontar la Bomba de Lubricacion con mando.

Nivel de Mantencion Operación Referencia

1, 2, 3 Desabilite la energia al Motor Revise la Operators Guide

1, 2, 3 Drene el aceite del motor Revise la Operators Guide

1, 2, 3 Retire el Carter Revise la sección C 014.05.05

1, 2, 3 Retire los soportes de motor, de la carcasa Revise la sección C 231.05.05

1 = El motor esta completamente desarmado.

2 = El motor ha sido retirado pero no completamente desarmado

3 = El motor permanece instalado.

Tabla102 Antes- Operaciones de Desmontaje

All information subject to change without notice.

C -1098 Copyright © DETROIT DIESEL CORPORATION

SERIE 400012/16V MANUAL DE SERVICIO

C 181.05.05 – DESMONTAJE DE LA BOMBA DE ACEITE

Realice los siguientes pasos para retirar la bomba de aceite.

1. Para retirar la bomba con la válvula de alivio, retire los pernos hexagonales (1) (17mm) de la

bomba de aceite, y retire la bomba fuera de la caja de distribucion. Ver Figura 744.

1. Pernos Hexagonales

Figura744 Desmontaje de la Bomba de Aceite con la Válvula de Alivio (Relief)

2. Para quitar la linea de alta presion de aceite, retire los pernos hexagonales(4) y la brida

central. Ver Figura 745

All information subject to change without notice.

Copyright © DETROIT DIESEL CORPORATION C -1099

SERIE 400012/16V MANUAL DE SERVICIO

1. Perno Racor 3. Perno Racor

2. Linea de alta presion de aceite 4. Perno hexagonal

Figura745 Desmontaje de la Linea de Alta Presion de Aceite

3. Retire el perno racor (1) de la linea de alta presion de aceite (2) frontal de la caja de distribucion

y el perno racor (3) de la valvula reguladora de aceite

4. Retire la linea de alta presion de aceite.

NOTA:

Para una clara visibilidad el damper debera ser desmontado. Ver Figura 745.

All information subject to change without notice.

C -1100 Copyright © DETROIT DIESEL CORPORATION

SERIE 400012/16V MANUAL DE SERVICIO

5. Retire las empaquetaduras.

6. Para quitar la válvula reguladora de presión, retire el regulador de la carcaza. Ver Figura 746.

Figura 746 Desmontaje de la Válvula Reguladora de Presión

All information subject to change without notice.

Copyright © DETROIT DIESEL CORPORATION C -1101

SERIESERVICE

400012/16V MANUAL

MANUAL

DE SERVICIO16V

C 181.05.08 – INSPECCION Y REPARACION

Linea de Alta Presion de Aceite

Realice los siguientes pasos para la impección y reparacion de la linea de alta presión de aceite:

1. Limpie todos los componentes.

Para evitar lesiones a los ojos al usar aire comprimido, use

una protección adecuada (lentes de seguridad o mascara) y

no exeda 276 kPa (40 lb/in.2) de presion de aire.

2. Limpie la linea de alta presión de aceite con un limpiador adecuado y sopletee con aire comprimido.

3. Impeccione visualmente los componentes por desgaste o daños.

[a] Si los componentes estan estropeados o dañados, reparelos o reemplacelos si es nesesario.

[b] Si el daño no admite reparación, es nesesario reemplzar el componente.

[c] Si no se encuentra desgaste o daño, continue la impección.

4. Visualmente revise las superficies de sellado por posibles irregularidades o marcas.

[a] Si se encuentran irregularidades, maquinee las superficies de sellado.

[b] Si no se encuentran irregularidades en la superficie de sellado, continue la impección.

5. Visualmente revise los pernos racor por desgaste o daños y los hilos para un facil movimiento.

[a] Si los pernos racor se encuentran estropeados o dañados, o los hilos no permiten un facil

movimiento, es nesesario reemplazar el perno.

[b] Si los pernos no se encuentan estropeados o dañados y los hilos permiten un facil movimiento

continue la inspección.

6. Reemplace las empaquetaduras.

NOTA:

Asegurese que todas las partes estan perfectamente limpias.

Bomba de Aceite con Válvula de Alivio (válvula de seguridad o relief )

Siga los siguientes pasos para inspeccionar y reparar la bomba de aceite con válvula de alivio:

NOTA:

No desarme la bomba de aceite.

All information subject to change without notice.

C -1102 Copyright © DETROIT DIESEL CORPORATION

SERIE 400012/16V MANUAL DE SERVICIO

1. Usando el metodo de test de grietas con polvo magnetico fluorecente, revise el engranaje

de mando(1) por posibles trizaduras. Ver Figura747.

1. Engranaje de Mando 2. Carcaza de la Bomba de Aceite

Figura 747 Bomba de Aceite con Valvula de Alivio

[a] Si se encuentran grietas, reemplace el engraneje de mando.

[b] Si no se encuentran grietas, continue la inspección.

2. Usando un metodo de test de grietas, inspeccione la carcaza de la bomba de aceite (2) por trizaduras.

[a] Si se encuentran grietas, reemplace la carcaza de la bomba de aceite.

[b] Si no se encuentran grietas, continue la inspección.

3. Visualmente inspeccione los dientes del emgranaje por desgaste, muescas o cortes.

[a] Si los dientes se encuentran dañado, con muescas o cortados, pase (oilstone) o esmeril

como sea nesesario.

[b] Si el daño no admite reparación, reemplace el engranaje de mando.

[c] Si los dientes del engranaje no estan dañados, con muescas o cortados, continue la inspección.

4. Visualmente inspeccione la bomba de aceite por desgastes menores, rayas o muescas.

[a] Si encuentra daños menores, rayas o muescas, rebaje con "oilstone" o tela esmeril (lija)

[b] Si el daño esta mas alla de una reparación, reemplace la bomba.

[c] Si no se encuentran daños, rayas o muescas, continue con la inspección.

All information subject to change without notice.

Copyright © DETROIT DIESEL CORPORATION C -1103

SERIE 400012/16V MANUAL DE SERVICIO

5. Visualmente inspeccione todos los sellos y superficies de acople por desgaste, rayas o muescas.

[a] Si los sellos o superficies de acople tienen desgaste, rayas o muescas, repare si es

nesesario.

[b] Si los sellos o superficies de acople no muestran desgaste, rayas o muescas, continue con

la inspección.

6. Visualmente impeccione los pernos de anclaje por desgaste o daño y los hilos por un facil movimiento.

[a] Si los pernos estan estropeados o dañados, o los hilos no tienen facil movimiento, es

nsesario reemplazar los pernos.

[b] Si los pernos racor no estan deteriorados o dañados y los hilos presentan un facil movimiento,

continue la inspección.

NOTA:

Asegurese que las partes esten perfectamente limpias.

NOTA:

La presión de apertura de la válvula de alivio es 15 bar.

Válvula Reguladora de Presión

Siga los siguientes pasos para inspeccionar y reaparar la valvula reguladora de presión:

NOTA:

No desarme la valvula reguladora de presión de aceite.

1. Visualmente impeccione la válvula reguladora de presión por daños.

[a] Si la valvula reguladora de presión esta dañada, es nesesario reemplazarla.

[b] Si la válvula reguladora de presión no esta dañada, continue la impección.

2. Visualmente inspeccione la superficie de sellado (1) por desniveles.

[a] Si la superficie de sellado es desigual, es nesesario alisar con lija.

All information subject to change without notice.

C -1104 Copyright © DETROIT DIESEL CORPORATION

SERIE 400012/16V MANUAL DE SERVICIO

[b] Si la superficie de sellado no esta a desnivel, continue con la inspección. Vea Figura 748.

1. Superficies de Sellado

Figura74 Inspección de las Superficies de Sellado de la Válvula Reguladora de Presión

Para evitar lesiones a personas, tenga cuidado al tratar con

fluidos bajo presión. Los fluidos bajo presión tiene la fuerza

para penetrar la piel. Estos fluidos pueden causar cortes

menores o abrir la piel. Si es herido por un escape de fluido

vea un doctor inmediatamente. El no tratarse inmediatamente

puede resultar en infecciones o reacciones adversas al fluido.

3. Visualmente inspeccione la presión de apertura de la válvula reguladora de presión.

NOTA:

La válvula limita el flujo de aceite para mantener una presión constante de 5.5 bar± 1

mantenida hasta el ultimo metal de cigueñal. La temperatura media es de 90°C a 100 °C

La presión de diseño de la bomba de aceite n/min n/max es de 1.5 bar/7 bar.

4. Si se exede o no se alcanza la presión de apertura, reemplace la valvula reguladora de presión.

All information subject to change without notice.

Copyright © DETROIT DIESEL CORPORATION C -1105

SERIE 400012/16V MANUAL DE SERVICIO

C 181.05.11 – INSTALACION DE LA BOMBA DE ACEITE

Siga los siguientes pasos para la instalación de la bomba de aceite con mando:

1. Para instalar la bomba de aceite, limpie las superficies de sellado de la caja de distribución. Ver Figura 749

NOTA:

Al realizar cualquier tarea asegurese que los componentes estan perfectamente limpios.

1. Pernos hexagonales

Figura 749 Installación de la Bomba de Aceite con Válvula de Alivio.

2. Inserte la bomba de aceite en la caja de distribución, asegurese que los engranajes encajan correctamente.

3. Instale los pernos hexagonales (1) en la bomba de aceite, no se aprietan totalmente.

4. Para los limites de torque, remitase a la sección A 003.

All information subject to change without notice.

C -1106 Copyright © DETROIT DIESEL CORPORATION

SERIE 400012/16V MANUAL DE SERVICIO

5. Para instalar la válvula reguladora de presión, cubra el O-ring con vaselina e instalelo

en la ranura (1) de la valvula reguladora de presión. Ver Figura 750.

NOTE:

Asegurese que las partes esten perfectamente limpias.

1. Ranura

Figura 750 Instalación de la Valvula Reguladora de Presión.

6. Instale la válvula reguladora de presión en la caja de distribución y apriete a lo especificado.

Remitase a la sección A003.

All information subject to change without notice.

Copyright © DETROIT DIESEL CORPORATION C -1107

SERIE 400012/16V MANUAL DE SERVICIO

Para evitar lesiones en los ojos cuando salten partes, use

una adecuada protección en los ojos (lentes de seguridad

o mascara) y no exeda 276 kPa (40 lb/in.2) de presión de aire.

7. Para instalar la linea de alta presion de aceite, soplete la linea (1) con aire comprimido

y asegurese que quede perfectamente limpia. Ver Figura 751.

1. Linea de Alta Presión de Aceite 3. Perno Racor

2. Brida central.

Figura751 Instalación de la Linea de Alta Presión de Aceite

8. Instale golillas de cobre nuevas.

9. Instale el perno racor(3) en la valvula reguladora de presióny la caja de distribución.

10. No apriete los pernos racor totalmente.

11. Monte el soporte libre de tensión. Ver Figura 743.

All information subject to change without notice.

C -1108 Copyright © DETROIT DIESEL CORPORATION

SERIE 400012/16V MANUAL DE SERVICIO

12. Instale la brida central (2). Ver Figura 743.

13. Instale los pernos racor (3) libres de tensión. Ver Figura 743.

NOTA:

En algunos motores, se instalan dos golillas de cobre. Cuando reistale la válvula

reguladora, deben usarse dos golillas de cobre.

All information subject to change without notice.

Copyright © DETROIT DIESEL CORPORATION C -1109

SERIE 400012/16V MANUAL DE SERVICIOERIES

AL 4000 12/16V SERVICE MANU

C 181.05.12 – DESPUES-OPERACIONES DE INSTALACION

Lista de la tabla 103 son las operaciones despues de instalar la bomba de aceite con mando.

Nivel de Mantención Operacion Referencia

1, 2, 3 Instale el Carter Remitase a la sección C 014.05.11

1, 2, 3 Instale los soportes de motor Remitase a la sección C 231.05.11

1, 2, 3 Llene el sitema con aceite de motor Remitase a la Operators Guide

1, 2, 3 Abilite la energia al motor Remitase a la OperatorsGuide

1 = El motor completamente desarmado.

2 = El motor desmontado pero no desarmado completamente.

3 = El motor permanece instalado.

Tabla103 Despues-Operaciones de Instalación

All information subject to change without notice.

C -1110 Copyright © DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

C 183.05 – FILTRO DE ACEITE

Seccion Pag

C 183.05.01 Vista General.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1119

C 183.05.02 Herramientas Especiales ........................................ C-1120

C 183.05.04 Operaciones antes de sacar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1121

C 183.05.05 Remocion de filtros de aceite y filtro centrifugo . . . . . . . . . . . . . . . . . . . . C-1121

C 183.05.06 Desmontaje del Filtro centrifugo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1129

C 183.05.08 Inspección y Reparación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1148

C 183.05.10 Ensamblaje del Filtro de Aceite y servicio al los filtros

Mantención al Sistema de Alerta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1148j

C 183.05.11 Instalación de Filtros de Aceite, Filtro Centrifugo y Servicio

Sistema de Alerta de Mantención . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1148ac

C 183.05.12 Operaciones despues de la instalación . . . . . . . . . . . . . . . . . . . . . C-1148al

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1117

SERIE 4000 MANUAL DE SERVICIO

(Rev. 3/01) All information subject to change without notice.

C-1118 From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

C 183.05.01 – VISTA GENERAL

Ver Figura 752 Para una vista general de los Filtros de Aceite.

1. O-ring 8. Perno

2. O-ring 9. Cabezal De Filtros de Aceite

3. O-ring 10. Filtro de Aceite

4. Filtro Centrifugo de Aceite 11. Soporte del Montaje de los Filtros de Aceite

5. Perno Exagonal 12. Perno Exagonal

6. O-ring 13. Perno Exagonal

7. Golilla. 14. Sistema de Alerta de Mantención

Figura 752 Vista General de los Filtros de Aceite

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1119

SERIE 4000 MANUAL DE SERVICIO

C 183.05.02 – HERRAMIENTAS ESPECIALES

Listado de (Tabla 104) las herramientas especiales requeridas para la mantención de los filtros de aceite

y filtro centrifugo.

Aplicación Numero

Llave de correa para filtros de aceite —

Herramienta de desmontaje del Rotor, Filtro centrifugo de 4–Litros DDC 23540434

Herramienta de desmontaje del Rotorr, Filtro centrifugo de 2–Litros DDC 23540262

Herramienta de extracción del tubo , Filtro centrifugo de 2–Litros DDC 23540261

Tabla 104 Herramientas Especiales

(Rev. 3/01) All information subject to change without notice.

C-1120 From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIES 4000 12/16V SERVICE MANUAL

C 183.05.04 – ANTES DE - OPERACIONES DE DESMONTAJE

Lista de la Tabla 105 son las operaciones antes de sacar los filtros de aceite y filtro centrifugo.

Nivel de Mantención Operación Referencia

1, 2, 3 Corte la energia y coloque lockout al motor Remitase a la Operators Guide

1, 2, 3 Drene el refrigerante del motor Remitase a la Operators Guide

Remitase a la sección C 184.05.05

1, 2, 3 Drene el aceite del filtro centrifugo de aceite

C 184.05.05

1 = El motor es completamente desarmado.

2 = El motor es retirado pero no completamente desarmado.

3= El motor permanece instalado.

Tabla 105 Antes de las Operaciones de Desmontaje

All information subject to change without notice.

Copyright © DETROIT DIESEL CORPORATION C -1115

SERIES 4000 12/16V SERVICE MANUAL

C 183.05.05 – DESMONTAJE DE LOS FILTROS DE ACEITE Y CENTRIFUGO

Desmontaje de los filtros de aceite

Siga los siguientes pasos para desmontar los filtros de aceite:

1. Instale la llave de faja en el filtro.

2. Gire el filtro con la llave de faja en sentido contrareloj para soltar.

3. Despues de vaciar el filtro de aceite, retirelo con la llave de faja. Ver Figura 753.

Figura 753 Desmontaje de los Filtros de Aceite con LLave de Faja

4. Repita los pasos hasta que los cuatro (4) filtros sean retirados.

All information subject to change without notice.

C -1116 Copyright © DETROIT DIESEL CORPORATION

SERIES 4000 12/16V SERVICE MANUAL

5. Sosteniendo firmemente el adaptador (niple) (1) con una llave desconecte la linea de aceite.

Ver Figura 754.

1. Adaptador (niple) 3. Abrazadera de anclaje

2. Conección de la linea de Aceite 4. Sensor de Presión de Aceite

Figura 754 Remoción del Sensor de Presión de Aceite

6. Retire la abrazadera de anclaje (3) y desconecte el arnes del sensor de presión de aceite (4).

NOTA:

Realice un registro fotografico del punto de anclaje de la abrazadera para evitar una incorrecta

reinstalación, que puede causar un malfuncionamiento del motor.

7. Destornille el sensor de presión de aceite (4).

8. Despues de retirarlo, selle las aberturas con tapones adecuados.

All information subject to change without notice.

Copyright © DETROIT DIESEL CORPORATION C -1117

SERIES 4000 12/16V SERVICE MANUAL

9. Sostenga firmemente el adaptador (niple) (5) con una llave y desconecte las lineas de aceite (1)

y (2). Ver Figura 755.

1. Linea de aceite (Fan) 4. Sensor de Temperatura de Acete

2. Linea de Aceite (Fan) 5. Adaptador (Niples)

3. Sensor de Presión de Carter

Figura755 Remoción del Sensor de Temperatura de Aceite y Sensor de Presión

de Carter

10. Retire la abrazadera de sujección y desconecte los arneses del sensor de temperatura de aceite y del

sensor de presión de carter (3).

NOTA:

Realice un registro fotografico del punto de anclaje de la abrazadera para evitar una incorrecta

reinstalación, que puede causar un malfuncionamiento del motor.

11. Retire el sensor de temperatura de aceite(4) y el sensor de presión del block de cilindros (carter) (3).

12. Despues de retiarlos, selle las aberturas con tapones adecuados.

All information subject to change without notice.

C -1118 Copyright © DETROIT DIESEL CORPORATION

SERIES 4000 12/16V SERVICE MANUAL

13. Retire los pernos del filtro centrifugo (2) y retire el conjunto del filtro centrifugo

(1) del cabezal de filtros de aceite. Ver Figura 756.

1. Conjunto del Filtro Centrifugo 3. Pernos del Cabezal de Filtros de Aceite

2. Prenos de anclaje al Cabezal de Filtros de Aceite

Figura 756 Desmontaje del Conjunto Filtro Centrifugo del Cabezal de Filtros

14. Retire los pernos del cabezal de filtros de aceite.

All information subject to change without notice.

Copyright © DETROIT DIESEL CORPORATION C -1119

SERIES 4000 12/16V SERVICE MANUAL

15. Retire los pernos y golillas (2) del cabezal de filtros y del soporte (1). Ver Figura 757.

1. Soporte 2. Pernos hexagonales y golillas

Figura757 Remoción del Cabezal de Filtros de Aceite

All information subject to change without notice.

C -1120 Copyright © DETROIT DIESEL CORPORATION

SERIES 4000 12/16V SERVICE MANUAL

16. Es nesesario sellar las aberturas de la caja de distribución de refrigerante (1) con tapones

adecuados. Ver Figura 758.

1. Aberturas en la Caja de Distribución de Refrigerante

Figura 758 Sellado de las Aberturas en la Caja de Distribución de

de Refrigerante con Tapones Adecuados

All information subject to change without notice.

Copyright © DETROIT DIESEL CORPORATION C -1121

SERIES 4000 12/16V SERVICE MANUAL

Desmontaje de la Válvula/Resorte By-Pass de los Filtros de Aceite

Siga los siguientes pasos para retirar la válvula By-pass de los filtros de aceite y el resorte del

cabezal de filtros de aceite. Ver Figura 759.

1. Tapon

Figura 759 Ubicación By-Pass

1. Retire el tapon con O-ring del cabezal de filtros de aceite.

All information subject to change without notice.

C -1122 Copyright © DETROIT DIESEL CORPORATION

SERIES 4000 12/16V SERVICE MANUAL

2. Retire el resorte de la válvula by-pass. Ver Figura 760.

1. O-ring 8. Soporte del Cabezal de Filtros de Aceite

2. O-ring 9. Perno

3. O-ring 10. Perno

4. Golilla 11. Tapon de la Válvula By-Pass

5. Perno 12. O-ring

6. Cabezal de Filtros de Aceite 13. Válvula By-Pass

7. Filtro de Aceite 14. Resorte de la Válvula By-Pass

Figura 760 Vista general de los Filtros de Aceite

3. Retire la válvula by-pass del cabezal de filtros de aceite.

All information subject to change without notice.

Copyright © DETROIT DIESEL CORPORATION C -1123

SERIES 4000 12/16V SERVICE MANUAL

C 183.05.06 – DESARME DEL FILTRO CENTRIFUGO DE ACEITE

Siga los siguientes pasos para retirar y desarmar el conjunto del filtro centrifugo de aceite:

1. Detenga el motor y coloque lockout al motor.

NOTA:

Limpie el area alrededor del filtro centrifugo antes de desarmar. Ver Figura 761.

1. Tuerca de la cubierta 4. Cabezal de los Filtros de Aceite

2. Filtro Centrifugo de Aceite 5. Filtros de Aceite

3. Abrazadera

Figura 761 Ubicación del Filtro Centrifugo de Aceite

All information subject to change without notice.

C -1124 Copyright © DETROIT DIESEL CORPORATION

SERIES 4000 12/16V SERVICE MANUAL

PRECAUCION

El aceite de motor puede estar caliente y puede contener

residuos de la combustión que son dañinos para la salud.

Para evitar lesiones use guantes de protección. Evite exesivo

e intensivo con la piel. No inhale los vapores de aceite.

NOTA:

Para referencias, se encuntran las instrucciones de servicio por el exterior de la cubierta del

filtro centrifugo. Ver Figura 762.

1. Tuerca de la Cubierta 3. Cubierta

2. Instrucciones de Servicio 4. Abrazadera con Perno T

Figura 762 Remoción de la Abrazadera y la Tuerca de la Cubierta

2. Destornille la turca de la cubierta, retire la abrazadera.

3. Retire la cuvierta del filtro de aceite centrifugo.Ver Fugura 762.

4. Drene el aceite del rotor. Levantando el rotor de su base se puede mejorar el drenaje.

All information subject to change without notice.

Copyright © DETROIT DIESEL CORPORATION C -1125

SERIES 4000 12/16V SERVICE MANUAL

5. Retire el rotor verticalmente (hacia arriba) de su eje.

NOTICIA

El rotor debe ser retirado y cambiado desde el eje con cuidado

para asegurarse de no dañar los bujes del rotor.

El uso la herramienta especial 23540261 y 23540262 es

obligatorio para prevenir daños durante el desarme del rotor.

6. Asegure el armado y desarme del rotor con la herramienta especial P/N 23540262 (6906A).

Destornille la tuerca del rotor y separe la cubierta del cuerpo del rotor. Ver Figura 763.

Figura 763 Herramientas de Desarme y Extracción

7. Retire el tubo soporte usando la herramienta de extracción del tubo P/N 23540261 (6909A).

Ver Figura 764.

All information subject to change without notice.

C -1126 Copyright © DETROIT DIESEL CORPORATION

SERIES 4000 12/16V SERVICE MANUAL

1. Rotor Cover Plate 13. O-ring

2. Stiffener Plate 14. Cover Nut

3. Paper Insert 15. Cover Subassembly

4. Stand Tube 16. Band Clamp

5. Snap Ring 17. O-ring

6. O-ring 18. Body Assembly

7. Rotor Cover 19. Locating Pin

8. Nozzle 20. Shuttle

9. Bearing Tube Assembly 21. Spring

10. Pin 22. Washer

11. Cover Nut Tube 23. Plug

12. Pin

Figure 764 Exploded View of Centrifugal Oil Filter

All information subject to change without notice.

Copyright © DETROIT DIESEL CORPORATION C -1127

SERIE 4000 MANUAL DE SERVICIO

1. Plato de la tapa del rotor 14. Pin

2. Plato Endurecedor 15. O-ring

3. Cubierta del Rotor 16. Tuerca de la tapa

4. Papel Filtro 17. Cubierta

5. Tubo Posicionador 18. Abrasadera

6. Anillo 19. O-ring

7. O-ring 20. Eje

8. Pin Guia 21. Cuerpo

9. Tapa de Rotor de fondo 22. Valvula

10. Boquilla 23. Resorte

11. Buje del Tubo 24. Golilla

12. Pin 25. Tapon

13. Tuerca de la tapa

Figura 763 Vista del Filtro Centrifugo de 2 litros

5. Retire el rotor verticalmente verticalmente del eje Ver Figura 763.

NOTICIA

El rotor debe quitarse y colocarse con cuidado para asegurar

que los bujes del rotor no se dañen. El uso de la herramienta

especial DDC 23540261 y DDC 23540262 es obligatorio

para prevenir daño durante el desarme de el rotor.

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1133

SERIE 4000 MANUAL DE SERVICIO

6. Asegure el rotor y desarmelo con la herramienta DDC 23540262. Destornille la

tuerca de la tapa y separe la tapa del rotor del cuerpo apretando la tuerca

de la herramienta de desarme. Ver Figura 764.

Figure 764 Herramientas de desarme y extracción

7. Remueva el tubo de la posición usando la herramienta de extracción DDC 23540261.

Ver Figura 764.

Desmontaje del filtro centrifugo opcional de 4-Litros

Para una vision detallada del ensamble del filtro centrifugo de 4-litros (opcional), ver Figura 764a.

(Rev. 3/01) All information subject to change without notice.

C-1134 From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

1. Tuerca del Rotor 13. Tueca de la tapa

2. Cubierta del Rotor . 14. Pin de apriete

3. Seguro. 15. Cubierta o tapa

4. O-ring 16. O-ring

5. Papel filtro 17. Tuerca de la tapa

6. Rotor 18. Abrazadera

7. Plato conico de separación 19. O-ring

8. Seguro 20. Cuerpo

9. O-ring 21. Valvula

10. Base del rotor 22. Resorte

11. O-ring 23. Golilla

12. Tubo central con bujes 24. Plug

Figure 764a Vista del Filtro Centrifugo de 4 Litros

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1135

SERIE 4000 MANUAL DE SERVICIO

Realice los siguientes pasos para desmontar el filtro centrifugo de 4 litros:

PRECAUCION:

Para evitar lesiones por partidas accidentales del motor

durante el servicio al motor, desconecte/bloquee el

sistema de partida

PRECAUCION:

Para evitar lesiones por superficies calientes, deje enfriar el

motor antes de retirar cualquier componente, use guates

1. Limpie completamente la superficie externa del filtro centrifugo de 4 litros y las areas

que lo rodean.

2. Retire el clip de plastico de la abrazadera (3).

(Rev. 3/01) All information subject to change without notice.

C-1136 From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

3. Retire la abrazadera (3). Ver Figura 746b.

1. Tuerca y pin de la tapa 3. Abrazadera

2. Tapa del filtro centrifugo

Figura 764b Filtro Centrifugo de aceite de 4 litros

4. Suelte la turca de la tapa. Ver figura 764b.

5. Retire la tapa del filtro centrifugo (2). Ver Figura 764b.

NOTICIA:

Cuando retire o reemplace el rotor en el eje cuide de no dañar

los bujes

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1137

SERIE 4000 MANUAL DE SERVICIO

6. Levante el rotor (1). Deje decantar todo el aceite del rotor, esto se puede realizar

levantando el rotor sobre su eje. Retire el rotor verticalmente guiado por el eje.

Ver figura 764c.

1. Rotor

Figura 764c Desmontaje del Rotor

7. Usando la herramienta de desarme del rotor DDC 23540434 (2) (ver Figura 764d),

sostenga el rotor mientras usa una llave (2" o 49mm) para soltar la tuerca del rotor

(3). Ver Figura 764e.

(Rev. 3/01) All information subject to change without notice.

C-1138 From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

Figura 764d Herramienta de Desarme del Rotor, DDC 23540434

1. Herramienta de desarme del Rotor 3. Tuerca del rotor

2. LLave Francesa 4. Orificios para los pines de la herramienta de desarme

Figura 764e Remoción de la Tuerca del Rotor

8. Suelte la tuerca del rotorVer Figura 764e.

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1139

SERIE 4000 MANUAL DE SERVICIO

9. Retire la tapa del rotor (1). Ver Figura 764f. Ver Figura 764g.

1. Cubierta del Rotor

Figura 764f Desmontaje de la Tapa del Rotor

(Rev. 3/01) All information subject to change without notice.

C-1140 From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

1. Fondo de la tapa del Rotor 2. Aletas Direccionales

Figura 764g Lado interno de la Tapa del Rotor

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1141

SERIE 4000 MANUAL DE SERVICIO

10. Usando un destornillador (2), Haga palanca al papel filtro (1) sueltelo y retirelo

Ver Figura 764h.

1. Papel Filtro con suciedad 2. Destornillador

Figura 764h Desmontaje del Papel Sucio

(Rev. 3/01) All information subject to change without notice.

C-1142 From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

11. Retire toda la suciedad pegada en el rotor, en la pestaña del cuerpo. Ver Figura 764i.

Figura 764i Remoción de la suciedad pegada en el Rotor

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1143

SERIE 4000 MANUAL DE SERVICIO

12. Limpie la tapa del rotor. Ver Figura 764j.

Figura 764j Limpieza de la Tapa del Rotor

(Rev. 3/01) All information subject to change without notice.

C-1144 From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

13. Separe el cuerpo del rotor (2) de la base del rotor (1). Ver Figura 764k.

1. Base del Rotor 2. Cuerpo del Rotor

Figura 764k Desmontaje del cuerpo del Rotor

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1145

SERIE 4000 MANUAL DE SERVICIO

14. Retire el cono de separación (2) de la base del rotor. Ver Figura 764l.

1. Base del Rotor 2. Cono de Separación

Figura 764l Desmontaje de la Base del Rotor y Cono de Separación

(Rev. 3/01) All information subject to change without notice.

C-1146 From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

15. Limpie la base del rotor, el cono de separación y el cuerpo.. Ver Figura 764m.

1. Base del Rotor 2. Cono de separación

Figura 764m Limpieza de la Base del Rotor y Cono de Separación

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1147

SERIE 4000 MANUAL DE SERVICIO

C 183.05.08 – INSPECCION Y REPARACION

Inspección y Reparación del Cabezal de Filtros de Aceite

Realice los siguientes pasos para una impección y reparación del cabezal de filtros de aceite:

1. Visualmente revise todos los sellos, las superficies de unión de posibles rayaduras y/o daños

Ver Figura 765. Revise especialmente:

3 Adaptadores de acople (4).

3 Orificios con hilos (3).

3 Superficies de sellado (2).

3 Superficies de sellado del soporte.

3 Adaptador (1).

[a] Si los sellos, acoples y superficies estan dañadas, rayadas o muescas, rebaje con tela esmeril

[b] Si el daño es irreparable, reemplace los componentes que sea nesesario.

[c] Si las superficies de sellado, acoplamiento y deslizamiento no esta dañadas, rayadas o con

muescas, continue la impección.

1. Adaptador 3. Orificios con hilos

2. Superficies de sellado 4. Adaptadores de acople

Figura 765 Inspección del Cabezal de Filtros de Aceite

(Rev. 3/01) All information subject to change without notice.

C-1148 From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

2. Visualmente revise los componentes del cabezal de filtros de aceite por posibles daños,

revise todos los sellos, desgaste en superficies de unión y sellado, rayas y marcas.

[a] Si las superficies de sellado, acoplamiento y deslizamiento estan dañadas, rayadas o con

muescas, es nesesario repararlas.

[b] Si las superficies de sellado, acoplamiento y deslizamiento no admiten reparación,

reemplace los componentes que si es nesesario.

[c] Si las superficies de sellado, acoplamiento y deslizamiento no estan dañadas, rayadas

o con muescas continue la impección. Ver Figura 766.

1. Superficies de sellado del cabezal 3. Orificios con hilos

2. Superficie de sellado de los Orings 4. Válvula By-pass

Figura 766 Inspección del Cabezal de Filtros de Aceite

3. Revisiones en particular:

3 Orificios con Hilos (3).

3 Superficies de sellado.

3 Superficie de sellado de los Orings (2).

3 Superficie de sellado del cabezal (1).

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1148a

SERIE 4000 MANUAL DE SERVICIO

4. Inspecione los componentes por el menor desgaste, rayas o muescas.

[a] Si se encuentra desgaste, rayaduras o muescas, es nesesario reemplazar los componentes.

[b] Si no se encuentra desgaste, rayaduras o muescas, continue la impección.

5. Inspecione los hilos de los componentes para que tengan fácil movimiento.

[a] Si los hilos no presentan facilidad de movimiento, repare o reemplace el componente

donde se encuenta inserto el hilo.

[b] Si los hilos no presentan dificultad de movimiento, continue la impección.

6. Inspecione los tapones por fugas.

[a] Si los tapones presentan fugas, es nesesario reemplazarlos.

[b] Si los tapones no presentan fugas, continue la impección.

7. Reemplace las empaquetaduras, sellos y Orings.

8. Asegurese que las camaras de aceite y los pasajes de aceite esten limpios.

Cabezal de Filtros de Aceite

Siga los siguientes pasos para la instalación del cabezal de filtros de aceite.

NOTA:

Asegurese que las camaras de aceite y los pasajes de aceite esten limpios.

NOTA:

Antes de la instalación quite todos los tapones, tapas y cubiertas provisorias.

(Rev. 3/01) All information subject to change without notice.

C-1148b From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

Inspeccíon y Reparación del Filtro Centrifugo de Aceite

Realice los siguiente pasos para impeccionar o reparar el filtro centrifugo de 2-litros o de 4-litros:

1. Retire los depositos de lodos desde dentro del rotor usando una espatula. Los depositos de lodos

no deben exeder los 35 mm (1.4 plg) para el filtro centrifugo de 2-litros. Ver Figura 767. Para

el filtro de 4-litros los depositos de lodos no deben exceder los 45 mm (1.8 plg); ver Figura 767a.

Para evitar lesiones por inadecudo uso de quimicos, siga las

instrucciones de uso, manejo y desecho dadas por el

fabricante. Mantenga todas las precauciones indicadas.

To avoid injury from flying debris when using compressed

air, wear adequate eye protection (face shield or safety

goggles) and do not exceed 40 psi (276 kPa) air pressure.

2. Ensure that all rotor components (including the two nozzles located in the rotor body)

are thoroughly cleaned with a suitable cleaning fluid and free from debris before

reassembly. Blow dry with compressed air. If the nozzle is not open, clean with a soft

wire. See Figure 767 for the 2–liter centrifugal filter. For the optional 4–liter filter,

see Figure 767a.

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1148c

SERIE 4000 MANUAL DE SERVICIO

NOTA:

Care should be taken when cleaning each component. An unbalanced condition could

occur if all debris is not removed.

Despiece

de la Tapa

Despiece

del Rotor

Despiece

del Cuerpo

(Rev. 3/01) All information subject to change without notice.

C-1148d From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

1. Rotor Cover Plate 14. Pin

2. Stiffener Plate 15. O-ring

3. Rotor Cover 16. Cover Nut

4. Filter Paper 17. Cover Subassembly

5. Stand Tube 18. Band Clamp

6. Snap Ring 19. O-ring

7. O-ring 20. Shaft

8. Locating Pin 21. Body Assembly

9. Bottom Rotor Cover 22. Valve

10. Nozzle 23. Spring

11. Bearing Tube Assembly 24. Washer

12. Pin 25. Plug

13. Cover Nut Tube

Figura 767 Exploded View of 2–Liter Centrifugal Oil Filter

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1148e

SERIE 4000 MANUAL DE SERVICIO

1. Rotor Nut 13. Cover Nut Tube

2. Rotor Cover 14. Pin

3. Snap Ring 15. Cover

4. O-ring 16. O-ring

5. Filter Paper 17. Cover Nut

6. Rotor Body 18. Band Clamp

7. Separation Cone 19. O-ring

8. Snap Ring 20. Body Assembly

9. O-ring 21. Valve

10. Rotor Base 22. Spring

11. O-ring 23. Washer

12. Bearing Tube Assembly 24. Plug

Figura 767a Optional 4-Liter Centrifugal Oil Filter Assembly

(Rev. 3/01) All information subject to change without notice.

C-1148f From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

3. Visually inspect the rotor assembly for damage and wear.

[a] If rotor assembly is damaged or worn, replace component.

NOTA:

Optional 4–Liter Centrifugal Filter: If excessive wear or bearing play is evident (greater

than 0.25 mm clearance on either journal bearing), replace the bearing tube assembly,

P/N: 23540463 and/or the centrifugal body assembly, P/N: 23540454.

[b] If rotor assembly is not damaged, continue inspection.

4. For the optional 4–liter centrifugal oil filter assembly, inspect bearing tube for wear

and looseness.

[a] If worn or loose, replace the centrifugal body assembly, P/N: 23540454.

[b] If spindle is not worn or loose, reuse the assemly.

5. Visually inspect the assembly bearings for wear.

[a] If centrifugal assembly bearings are worn, replace component as necessary.

[b] If centrifugal assembly bearings are not worn, continue inspection.

6. Disassemble and visually inspect the bypass valve assembly.

[a] If the valve is damaged, replace centrifugal filter body assembly.

[b] If the valve is not damaged, continue inspection.

7. Visually inspect the centrifugal filter body O-ring for damage.

[a] If centrifugal filter body O-ring is damaged, replace component.

[b] If centrifugal filter body O-ring is not damaged, continue inspection.

8. Visually inspect and clean the O-ring groove on the body assembly.

9. Examine the rotor assembly and O-rings for damage.

[a] Replace gaskets, sealing rings and O-rings.

[b] Replace rotor assembly O-rings if necessary, or at intervals of 2500 hours, O-ring Kit

P/N: 23540471.

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1148g

SERIE 4000 MANUAL DE SERVICIO

NOTA:

Maintenance intervals for the centrifugal oil filter are dependent on a number of factors

and differ with operational environment.

NOTA:

The centrifugal oil filter assembly is fitted with a cut-off valve (COV) that is located in the

filter body. See Figure 767a, items 21, 22, 23, 24. The COV is designed to protect

the engine by stopping the supply of lube oil to the centrifuge at start-up and during

periods when the oil pressure is below the COV rating. This item is intended to provide

maintenance free operation for extended periods, and should only be disassembled and

inspected for damage if a problem becomes evident.

(Rev. 3/01) All information subject to change without notice.

C-1148h From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

Inspection and Repair of Oil Filter Bypass Valve and Spring

Perform the following steps for inspection and repair of oil filter bypass valve and spring.

1. Inspect the valve.

2. Clean components thoroughly.

3. Remove bypass valve plug, spring and valve. Inspect threads of components for ease

of movement and signs of wear.

[a] If valve shows excessive signs of wear or does not show ease of movement, replace

components.

[b] If no signs of excessive wear or restrictive movement, continue inspection.

4. Ensure that oil chambers and oil passages are clean.

5. Inspect plugs for leaks.

[a] If plugs show leaks, replace as necessary.

[b] If plugs do not show leaks, continue inspection.

6. Replace O-rings.

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1148i

SERIE 4000 MANUAL DE SERVICIO

C 183.05.10 – ASSEMBLY OF OIL FILTER, CENTRIFUGAL OIL FILTER AND

OIL FILTER SERVICE MAINTENANCE ALERT SYSTEM

Assembly of Centrifugal Oil Filter

To avoid injury from fire caused by a leaking centrifugal oil

filter, ensure the oil filter has been properly assembled prior

to starting.

Perform the following steps for the assembly of the centrifugal oil filter: Oil chambers and

passages must be clean.

1. To install centrifugal filter assembly, coat O-rings with petroleum jelly and insert into

groove of oil filter housing. See Figure 768.

1. Groove 2. Oil Filter Housing

Figura 768 Inserting O-rings into Groove of Oil Filter Housing

2. Install a new paper filter onto the rotor cover.

(Rev. 3/01) All information subject to change without notice.

C-1148j From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

3. Reassemble the rotor assembly, ensuring the rotor cover slot and rotor body pins are

aligned. If the pins are missing or damaged, it will be necessary to replace the complete

rotor assembly.

NOTICIA

Do not interchange rotor covers from other units, as pin

alignments may vary, resulting in uneven operation and leakage.

NOTA:

Do not omit the stiffener plate during assembly. It will result in improper component

stackup.

4. Install stiffener plate. If the stiffener plate is missing, replace it with a new plate.

5. Install the rotor cover nut and torque to 6 - 7 N·m (4.43 - 5.16 lb·ft).

NOTA:

The improved 2–liter centrifugal oil filter assembly with a pinned rotor shaft is a direct

replacement for the former assembly. The torque check on the rotor shaft is no longer

necessary on the improved filter assembly. See Figure 769.

1. Pinned Shaft 2. Recessed O-ring Land

Figura 769 Current 2–Liter Centrifugal Oil Filter Pinned Shaft and O-ring

Land

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1148k

SERIE 4000 MANUAL DE SERVICIO

6. If servicing the former centrifugal oil filter assembly, using the fabricated tool, check the

rotor shaft-to-body torque at 40 N·m (29.5 lb·ft). If shaft is loose, replace body assembly.

See Figure 769a.

1. One inch socket plug welded to pipe 4. Bolt 1/4 in. x 1-1/2 in. long with length

of safety chain for lock pin

2. Pipe 1 in. x 8.5 in. long 5. Rotor Shaft

3. Hole 9/32 in drilled through pipe, 1/2 in. from bottom

on center to align with hole in rotor shaft

Figura 769a Fabricated Tool for Former Filter Assembly

(Rev. 3/01) All information subject to change without notice.

C-1148l From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

7. Replace the rotor on the spindle and check that the rotor spins freely.

8. Examine the centrifugal body O-ring for damage and replace if necessary.

NOTA:

At 2500 hours, replace the O-ring.

9. Inspect and clean the centrifugal body O-ring groove.

10. Inspect the cover nut. If signs of previous oil leak exist, replace the O-ring.

11. Install the centrifugal cover and tighten the cover nut to a torque of 6 - 7 N·m (4.43 -

5.16 lb·ft).

NOTA:

Ensure the band clamp T-bolt threads are clean to provide proper clamp torque.

12. Install the band clamp and torque to 5 - 6 N·m (3.69 - 4.43 lb·ft) maximum. The band

clamp must fit securely during operation to prevent oil leaks.

13. Repeat step 11and step 12 to ensure cover nut and band clamp remain tight.

To avoid injury from fire caused by a leaking centrifugal oil

filter, ensure the oil filter has been properly assembled prior

to starting.

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1148m

SERIE 4000 MANUAL DE SERVICIO

14. Using a tie strap, place a service tag with date and hour of service around both sides of

the band clamp bolt and secure tightly. This tie strap will act as a safety tie to ensure the

band clamp remains secure and in place. See Figure 770.

1. Tie Strap 2. Oil Filter Clamp

Figura 770 Installation of Current 2–Liter Centrifugal Oil Filter Band Clamp

(Rev. 3/01) All information subject to change without notice.

C-1148n From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

15. With the engine oil level checked, start the engine and check for leaks or unusual noise.

For oil filter operation, see Figure 770a.

1. Cover Nut 4. Body Assembly

2. Cover Assembly 5. Cut-off Valve

3. Rotor Assembly

Figura 770a Operación del Filtro Centrifugo de Aceite

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1148o

SERIE 4000 MANUAL DE SERVICIO

Installation of 2-Liter Centrifugal Oil Filter Assembly to Oil Filter Housing

Assembly

Perform the following steps to install the 2–Liter centrifugal oil filter:

1. To install centrifugal filter assembly, coat O-rings with petroleum jelly and insert into

groove of oil filter housing. See Figure 770b.

1. Groove 2. Oil Filter Housing

Figura 770b Inserting O-rings into Groove of Oil Filter Housing

(Rev. 3/01) All information subject to change without notice.

C-1148p From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

2. Install centrifugal oil filter assembly and secure with washers and hex bolts.

See Figure 771. Refer to section A 003.

1. Hex Bolts 2. Centrifugal Oil Filter Assembly

Figure 771 Assembly of 2–Liter Centrifugal Oil Filter Assembly to the Oil

Filter Housing

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1148q

SERIE 4000 MANUAL DE SERVICIO

Optional 4-Liter Centrifugal Oil Filter Assembly

Follow these steps to assemble the 4-liter centrifugal oil filter:

NOTA:

Ensure all components are clean.

1. Assemble the separation cone (1) to the rotor base (2). See Figure 771a.

1. Separation Cone 2. Rotor Base

Figura 771a Separation Cone and Base Assembly

(Rev. 3/01) All information subject to change without notice.

C-1148r From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

2. Assemble rotor body (1) to the rotor base (2). See Figure 771b.

1. Rotor Body 2. Rotor Base

Figura 771b Rotor Body and Base Assembly

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1148s

SERIE 4000 MANUAL DE SERVICIO

3. Insert new filter paper (1). See Figure 771c.

NOTE:

It may be necessary to trim filter paper to fit.

1. Filter Paper

Figura 771c Insertion of Filter Paper

(Rev. 3/01) All information subject to change without notice.

C-1148t From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

4. Install rotor cover (1). See Figure 771d.

1. Rotor Cover

Figura 771d Install Rotor Cover

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1148u

SERIE 4000 MANUAL DE SERVICIO

5. Seat the cover to the body. See Figure 772.

1. Wrench 2. Cover Nut

Figura 772 Seat the Cover

(Rev. 3/01) All information subject to change without notice.

C-1148v From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

6. Using rotor cover holding tool (1), tighten rotor cover retaining nut (3). See Figure 773.

1. Rotor Cover Holding Tool 3. Rotor Cover Nut

2. Wrench 4. Pin Holes for Rotor Cover Holding Tool

Figura 773 Tighten Rotor Cover Nut

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1148w

SERIE 4000 MANUAL DE SERVICIO

Installation of Optional 4-Liter Centrifugal Oil Filter Assembly to Oil Filter

Housing Assembly

NOTE:

Ensure all parts are clean.

The centrifugal filter body must be clean. See Figure 773a.

1. Centrifugal Filter Body

Figura 773a Centrifugal Filter Body

(Rev. 3/01) All information subject to change without notice.

C-1148x From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

Install rotor assembly to the rotor shaft. See Figure 773b.

1. Rotor Assembly

Figura 773b Rotor Assembly Installation

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1148y

SERIE 4000 MANUAL DE SERVICIO

Follow these steps to assemble the optional 4–liter centrifugal oil filter to the adaptor plate:

1. Assemble the 4–liter centrifugal oil filter to the adaptor plate (3) with a new O-ring (2).

2. Attach the assembly to the oil filter housing (7) using washer (4) and bolts (5 and 6).

See Figure 773c.

1. Optional 4-Liter Centrifugal Oil Filter Assembly 5. Bolt, M12 x 1.75 x 45 mm

2. O-ring 6. Bolt, M12 x 1.75 x 90 mm

3. Adaptor Plate 7. Oil Filter Housing

4. Washer

Figura 773c Optional 4-Liter Centrifugal Oil Filter Assembly

(Rev. 3/01) All information subject to change without notice.

C-1148z From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

Perform the following steps to install the optional 4-liter centrifugal oil filter assembly:

1. Ensure centrifugal oil filter cover is clean, and install the cover to the filter base.

See Figure 773d.

1. Cover Nut and Pin 3. Cover Band Clamp

2. Centrifugal Oil Filter Cover

Figura 773d Optional 4-Liter Centrifugal Oil Filter

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1148aa

SERIE 4000 MANUAL DE SERVICIO

2. Install the band clamp around the body. Torque clamp nut to 8 - 10 N·m (6 - 7 lb·ft).

See Figure 773d.

To avoid injury from inhaling engine exhaust, always

operate the engine in a well-ventilated area. Engine

exhaust is toxic.

3. Start the engine and allow it to idle. Check for leaks.

4. Operate the engine for 3 - 5 minutes at no-load full rpm, and again check for leaks.

5. Shut the engine down and allow sufficient time for oil drain back; check the oil. Add

oil as required.

NOTICIA:

Install a plastic tie strap through both sides of the band clamp

and pull tightly. This acts as a safety tie to ensure the band clamp

remains in place.

6. Install a plastic tie strap through both sides of the cover band clamp (3), and pull tightly.

(Rev. 3/01) All information subject to change without notice.

C-1148ab From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

C 183.05.11 – INSTALLATION OF OIL FILTER, CENTRIFUGAL OIL FILTER

AND OIL FILTER SERVICE MAINTENANCE ALERT SYSTEM

Installation of Oil Filter Housing

Perform the following steps for the installation of the oil filter housing:

1. Coat O-ring with petroleum jelly and insert in groove on lube oil temperature sensor.

See Figure 773e.

1. Groove

Figura 773e Inserting O-ring into Groove on Oil Temperature Sensor

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1148ac

SERIE 4000 MANUAL DE SERVICIO

2. Install lube oil pressure sensor into oil filter housing and tighten to specification.

Refer to section A 003. See Figure 773f.

1. Threaded Adaptor 3. Cable Clamps

2. Oil Line Connection 4. Lube Oil Pressure Sensor

Figura 773f Installing Oil Line Threaded Adaptor into Oil Filter Housing

3. Install new O-ring on threaded adaptor (1) and coat with petroleum jelly.

4. Install threaded adaptor (1) into oil filter housing.

5. Hold threaded adaptor (1) firmly with open-end wrench and install oil line.

6. Attach cable connector and secure with cable clamps (3).

(Rev. 3/01) All information subject to change without notice.

C-1148ad From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

7. Install lube oil temperature sensor (2) into oil filter housing and tighten to specification.

Refer to section A 003. See Figure 773g.

1. Oil Line (Fan) 4. Threaded Adaptor

2. Oil Temperature Sensor 5. Threaded Adaptor

3. Crankcase Pressure Sensor

Figura 773g Installing Sensors into Oil Filter Housing

8. Install cylinder block pressure sensor (3) into oil filter housing and tighten to specification.

Refer to section A 003.

9. Coat O-ring with petroleum jelly and insert in groove on threaded adaptors (4) and (5).

10. Install threaded adaptor into oil filter housing.

11. Hold threaded adaptors (4) and (5) firmly with open-end wrench and install oil lines (1).

NOTE:

Use only DDC branded oil filters cartridges.

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1148ae

SERIE 4000 MANUAL DE SERVICIO

12. To install oil filter cartridges, visually inspect sealing ring of new oil filter cartridge, clean

as necessary and coat with oil. See Figure 773h.

Figura 773h Installing New Oil Filter Cartridge

NOTA:

Coat O-rings with petroleum jelly before installing.

13. Install oil filter Maintenance Alert System (MAS). See Figure 773k.

14. Install optional remote oil filters if applicable.

15. Install new oil filter cartridges and tighten manually.

NOTA:

Do not use any tool to attach oil filter cartridges.

16. After test run, inspect oil filters for leaks.

[a] If a oil filter is leaking, retighten manually as necessary.

(Rev. 3/01) All information subject to change without notice.

C-1148af From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

[b] If the oil filters are not leaking, continue installation.

17. Install tie strap (2) so that connector grommet and harness are connected by a tight

loop. See Figure 773i.

1. Harness 3. Crankcase Pressure

2. Tie Strap

Figura 773i Installing Harness Tie Strap

NOTA:

The harness must not slip out through the connector during engine operation.

Installation of Oil Filter Service Maintenance Alert System

Perform the following steps to install the oil filter service maintenance alert system.

NOTA:

The engine must be shut down with the safety lockout in place.

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1148ag

SERIE 4000 MANUAL DE SERVICIO

1. Remove the plug #1 and #2 from oil filter adaptor. See Figure 773j.

1. Plug 2. Plug

Figura 773j Oil Filter Adaptor Plug Locations

(Rev. 3/01) All information subject to change without notice.

C-1148ah From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

2. Ensure the sealing O-ring is in place and not damaged. Coat sealing O-ring with a light

film of lubricating oil. Install (1) fitting in location 1 loose. Install (1) adaptor assembly

into location #2 and torque to 110 - 121 N·m (81 - 89 lb·ft). See Figure 773k.

1. Fitting (Elbow) Assembly 5. Nut

2. Sensor 6. Adaptor

3. Seal Ring 7. Oil Feed Tube Assembly

4. Washer

Figura 773k Sistema de Alerta para Cambio de Filtros de Aceite

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1148ai

SERIE 4000 MANUAL DE SERVICIO

3. The sensor assembly includes a 30–foot wiring harness and a compression seal at the

sealing point. Install (1) sensor assembly to the top of adaptor assembly by turning the

sensor body nut and leave loose.

NOTA:

The entire sensor body will rotate!

NOTICIA

Do not attempt to separate the wiring harness from the sensor

assembly, as the waterproof sealing will be damaged.

4. Ensure the sealing O-ring is in place and not damaged. Coat sealing O-ring with a light

film of lubrication oil. Install (1) fitting in the bottom of the adaptor assembly.

5. Connect (1) oil feed tube to the two fittings and hand-tighten.

6. Torque fittings to 15 - 18 N·m (11 - 13 lb·ft). Torque adaptor to 110 - 121 N·m

(81 - 89 lb·ft). Torque sensor assembly to 37 N·m (27 lb·ft).

7. Connect the black wire from the sensor harness to the #953 ground circuit.

8. Connect the red wire from the sensor harness to #419 default circuit. This will

differ depending on the OEM’s control circuit. Refer to DDEC III/IV Single ECM

Troubleshooting Guide, 6SE497.

9. Test to ensure proper installation of switch as follows: Reconnect battery power. Then,

using a small screwdriver, depress the delta pressure switch through the base of the adaptor.

10. With the ignition on and the engine off, the “Check Engine” light should illuminate.

11. Start and run engine and check for leaks. Retighten fittings as required.

NOTA:

Installation of the oil filter service maintenance alert system kit without including the

update of the oil filter bypass valve and spring may result in incorrect operation of the oil

filter service maintenance alert system.

NOTA:

Refer to Detroit Diesel brochure 7SE270, Engine Requirements – Lubricating Oil, Fuel,

and Filters.

Installation of Oil Filter Bypass Valve and Spring

Perform the following steps for installation of oil filter bypass valve and spring into the oil

filter housing.

(Rev. 3/01) All information subject to change without notice.

C-1148aj From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIE 4000 MANUAL DE SERVICIO

1. Install bypass valve spring into bypass valve, then into the oil filter housing.

See Figure 773l.

1. O-ring 8. Oil Filter Mounting Bracket

2. O-ring 9. Hex Bolt

3. O-ring 10. Hex Bolt

4. Washer 11. Plug

5. Hex Bolt 12. O-ring

6. Oil Filter Housing Assembly 13. Bypass Valve

7. Oil Filter Cartridge 14. Bypass Valve Spring

Figura 773l Installation of Oil Filter Bypass Valve and Spring

All information subject to change without notice. (Rev. 3/01)

6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION From Bulletin 3-4000-01 C-1148ak

SERIE 4000 MANUAL DE SERVICIO

2. Install bypass valve into oil filter housing bore with valve seat towards bore.

3. Install bypass valve spring (14) into bypass valve opening.

4. Coat O-ring on thread plug (11) and coat O-ring (12) with petroleum jelly.

5. Install threaded plug from oil filter housing.

6. Torque threaded plug to 130 - 140 N·m (96 - 103 lb·ft).

C 183.05.12 – AFTER-INSTALLATION OPERATIONS

Listed in Table 106 are the After-Installation Operations for the oil filter.

Level of Maintenance Operation Reference

1, 2, 3 Fill engine oil in centrifugal filter as necessary Refer to section C 184.05.11

1, 2, 3 Inspect for leaks or unusual noise. —

1, 2, 3 Fill engine coolant system Refer to Operators Guide

1, 2, 3 Enable engine power Refer to Operators Guide

1 = The engine is to be completely disassembled.

2= The engine is to be removed but not completely disassembled.

3= The engine is to remain installed.

Tabla 106 After-Installation Operations

(Rev. 3/01) All information subject to change without notice.

C-1148al From Bulletin 3-4000-01 6SE4011 9910 Copyright © 2001 DETROIT DIESEL CORPORATION

SERIES 4000 12/16V SERVICE MANUAL

C 183.05.08 – INSPECTION AND REPAIR

Inspection and Repair of Oil Filter Housing Assembly

Perform the following steps for inspection and repair of the oil filter housing assembly:

1. Visually inspect all sealing, mating and sliding surfaces for wear, scoring and indentations.

See Figure 765. Inspect in particular:

3 Threaded studs (4).

3 Threaded bores (3).

3 Sealing surfaces (2).

3 Sealing surface for bracket.

3 Threaded adaptor (1).

[a] If sealing, mating and sliding surfaces are worn, scored or indented, rub down with

an emery cloth or an oilstone.

[b] If damage is beyond repair, replace components as necessary.

[c] If sealing, mating and sliding surfaces are not worn, scored or indented, continue

inspection.

1. Threaded Adaptor 3. Threaded Bores

2. Sealing Surfaces 4. Threaded Studs

Figure 765 Inspecting Oil Filter Housing Assembly

All information subject to change without notice.

C -1128 Copyright © DETROIT DIESEL CORPORATION

SERIES 4000 12/16V SERVICE MANUAL

2. Visually inspect components of oil filter housing for damage, inspecting all sealing,

mating and sliding surfaces for wear, scoring and indentations.

[a] If sealing, mating and sliding surfaces show wear, scoring or indentations, machine

as necessary.

[b] If sealing, mating and sliding surfaces are beyond repair, replace component as

necessary.

[c] If sealing, mating and sliding surfaces do not show wear, scoring or indentations,

continue inspection. See Figure 766.

1. Sealing Surface for Bracket 3. Threaded Bores

2. Seating Surfaces of O-rings 4. Plug, By-Pass Valve

Figure 766 Inspecting Oil Filter Housing Assembly

3. Inspect in particular:

3 Threaded bores (3).

3 Sealing surface.

3 Seating surface of O-rings (2).

3 Sealing surfaces for bracket (1).

4. Inspect components for minor wear, scoring and indentations.

[a] If wear, scoring or indentations are found, replace components as necessary.

[b] If no wear, scoring or indentations are found, continue inspection.

All information subject to change without notice.

Copyright © DETROIT DIESEL CORPORATION C -1129

SERIES 4000 12/16V SERVICE MANUAL

5. Inspect threads of components for ease of movement.

[a] If threads do not show ease of movement, rechase as necessary or replace component

with thread insert.

[b] If threads do not show difficulty in movement, continue inspection.

6. Inspect blanking plugs for leaks.

[a] If blanking plugs show leaks, replace as necessary.

[b] If blanking plugs do not show leaks, continue inspection.

7. Replace hose line as part of every W6 overhaul.

8. Replace gaskets, sealing rings and O-rings.

9. Ensure that oil chambers and oil passages are perfectly clean.