Professional Documents

Culture Documents

GSL Silica

GSL Silica

Uploaded by

prasadmvkCopyright:

Available Formats

You might also like

- Normas NES M1019Document12 pagesNormas NES M1019Margarita Torres FloresNo ratings yet

- Din 30670 - 2012Document37 pagesDin 30670 - 2012Hasan AlmohtasebNo ratings yet

- IGM Additives Product GuideDocument20 pagesIGM Additives Product GuideColoke AdesivosNo ratings yet

- BO-BoQ For Balance Civil & FinishingDocument16 pagesBO-BoQ For Balance Civil & FinishingcubadesignstudNo ratings yet

- Civil BOQ For STPDocument8 pagesCivil BOQ For STPImtiyaz Ahmad Zargar25% (4)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Multipurpose HallDocument31 pagesMultipurpose HallNaiyer AzamNo ratings yet

- (381611313) BOQ EarthworkDocument39 pages(381611313) BOQ EarthworkAshish SadaNo ratings yet

- BOQ - TaramaniDocument46 pagesBOQ - Taramanismith0% (1)

- Htl-Admin-Tender-Boq-23-07-2018-Steel Woks-Superstructure-VendorDocument15 pagesHtl-Admin-Tender-Boq-23-07-2018-Steel Woks-Superstructure-VendorMvv SatyanarayanaNo ratings yet

- Compound Wall OfferDocument4 pagesCompound Wall OfferMd AbidNo ratings yet

- BOQ - 1,2,3,4 - AKK BilaspurDocument77 pagesBOQ - 1,2,3,4 - AKK BilaspursonuNo ratings yet

- Quote Admin Road BoqDocument8 pagesQuote Admin Road BoqKarun AbrolNo ratings yet

- Workers_Canteen_Plumbing_Allied_work_BOQDocument3 pagesWorkers_Canteen_Plumbing_Allied_work_BOQKoneti JanardhanaraoNo ratings yet

- Rate CardsDocument32 pagesRate CardsSasanka SekharNo ratings yet

- Cecs-St-Boq-Vasant Kung Boundary Wall-R1Document2 pagesCecs-St-Boq-Vasant Kung Boundary Wall-R1aasifkhanNo ratings yet

- 070120231827-Price bidDocument4 pages070120231827-Price bidBhaswat KashyapNo ratings yet

- STP BoqDocument14 pagesSTP BoqanishmetaNo ratings yet

- Rate Total Rate: Material Labour Service Tax With No BenefitsDocument4 pagesRate Total Rate: Material Labour Service Tax With No BenefitsRita WallaceNo ratings yet

- Japhat Civil Work BoqDocument8 pagesJaphat Civil Work BoqsatyaprakashNo ratings yet

- 1-Factory Shed 5.8.21Document72 pages1-Factory Shed 5.8.21Harsh Bhavsar100% (1)

- 1.AKAR IMPEX PVT LTD - Civil BOQ - THDC-WTP QTY-CS - (NEW QUANTITY)Document19 pages1.AKAR IMPEX PVT LTD - Civil BOQ - THDC-WTP QTY-CS - (NEW QUANTITY)dineshNo ratings yet

- 1 - Enquiry (BOM - BOQ) - For New Chemical ShedDocument4 pages1 - Enquiry (BOM - BOQ) - For New Chemical Shedganeshsable247No ratings yet

- SampleDocument186 pagesSampleSANDESHNo ratings yet

- Rates FoundationDocument17 pagesRates FoundationMihir PanchalNo ratings yet

- RamDocument8 pagesRamsunaifctmNo ratings yet

- 2022.02.01 - Karnal Factory BoqDocument4 pages2022.02.01 - Karnal Factory Boqkunaal kakkarNo ratings yet

- SL No Tariff Description of Works Measurements:: Eq. Parts Length WidthDocument8 pagesSL No Tariff Description of Works Measurements:: Eq. Parts Length Widthshyamsundar_ceNo ratings yet

- ZDCSD Sad AsdfasfDocument20 pagesZDCSD Sad AsdfasfShruti ShahNo ratings yet

- Coal Yard Road Development JobDocument16 pagesCoal Yard Road Development JobSasanka SekharNo ratings yet

- DC Satpute BOQ 05-07-23 Revised 15% HikeDocument24 pagesDC Satpute BOQ 05-07-23 Revised 15% HikechetanjtNo ratings yet

- Ms - Sarayu EstimateDocument13 pagesMs - Sarayu EstimateSandgrouse RajNo ratings yet

- PrecastDocument2 pagesPrecastsmithNo ratings yet

- July Ipp Addtional JobDocument9 pagesJuly Ipp Addtional JobSasanka SekharNo ratings yet

- Scope of Work: Project Specification DetailsDocument10 pagesScope of Work: Project Specification DetailsArfhan ANo ratings yet

- Schedule of RatesDocument3 pagesSchedule of RatesNikki JainNo ratings yet

- Siemens Quote For Pump RoomDocument5 pagesSiemens Quote For Pump RoomNayan FataniaNo ratings yet

- Bo QDocument12 pagesBo QSatheesh SankarapillaiNo ratings yet

- Security RoomDocument7 pagesSecurity RoomHari PrasathNo ratings yet

- Kalay PanchayatDocument31 pagesKalay PanchayatRam Prasad PrabhudesaiNo ratings yet

- RateDocument51 pagesRatemukesh kumarNo ratings yet

- Summary of Cost For Construction of Labaratory Building Comsats AbbottabadDocument15 pagesSummary of Cost For Construction of Labaratory Building Comsats AbbottabadMuhammad AsadNo ratings yet

- Proposed Apartment at Shirala, Sangli: Owner - Tarangan Developers Building IDocument27 pagesProposed Apartment at Shirala, Sangli: Owner - Tarangan Developers Building IHusen GhoriNo ratings yet

- 20170709-Boq-Proposed Apartments-R0 PDFDocument7 pages20170709-Boq-Proposed Apartments-R0 PDFAtul Shrivastava100% (1)

- Schedule of Quantities of Road Work For M/S Ask Automobiles, BhiwadiDocument2 pagesSchedule of Quantities of Road Work For M/S Ask Automobiles, BhiwadiDada Chandan Das A&R DevelopersNo ratings yet

- TownhallDocument19 pagesTownhallSantosh BasnetNo ratings yet

- Aai Khowai ItemDocument5 pagesAai Khowai Itemarindam sarkarNo ratings yet

- Specification IndexDocument13 pagesSpecification IndexMAULIK RAVALNo ratings yet

- Excel QuantityDocument234 pagesExcel Quantityviveik_mudgalNo ratings yet

- Quantity Schedule For Both Entry Exit GatesDocument10 pagesQuantity Schedule For Both Entry Exit GatesMATRIX ENGINEERSNo ratings yet

- Annexure 4 - NIT BOQ - 20230524153716Document2 pagesAnnexure 4 - NIT BOQ - 20230524153716ABECPL Bina SiteNo ratings yet

- Civil, Structure and Water - Proofing WorksDocument2 pagesCivil, Structure and Water - Proofing WorksAditi Agrawal100% (1)

- Site Offices and HousingDocument38 pagesSite Offices and HousingMuhammad Al azaweyNo ratings yet

- Sub-Structure Section 2200Document3 pagesSub-Structure Section 2200aalignup arc & const. pvt ltdNo ratings yet

- Canteen and Dress Changing RoomDocument43 pagesCanteen and Dress Changing RoomJeevitha DeivasigamaniNo ratings yet

- Estimate of PQCDocument6 pagesEstimate of PQCMital DamaniNo ratings yet

- DH Bandipora 10 BeddedDocument44 pagesDH Bandipora 10 BeddedPuneet Shaily0% (1)

- Box Estimate.Document254 pagesBox Estimate.rahul sumanNo ratings yet

- Field Operator RoomDocument4 pagesField Operator RoomKANWARNo ratings yet

- Estimate For Construction of R.C.C. Bridge Over River Buribalason, at Jalasnijamtara, Phansidewa, SiliguriDocument15 pagesEstimate For Construction of R.C.C. Bridge Over River Buribalason, at Jalasnijamtara, Phansidewa, SiliguriRio HandokoNo ratings yet

- Copy of rajbiraj(1)Document10 pagesCopy of rajbiraj(1)Rahul ShahNo ratings yet

- Afcon BoqDocument3 pagesAfcon BoqBinni KNo ratings yet

- Schedule of Quantity For Industrial BuildingDocument4 pagesSchedule of Quantity For Industrial BuildingShashankSinghNo ratings yet

- Transaction Fee DetailsDocument1 pageTransaction Fee DetailsprasadmvkNo ratings yet

- TDV BT RoadsDocument2 pagesTDV BT RoadsprasadmvkNo ratings yet

- 229Document1 page229prasadmvkNo ratings yet

- printBoqItems Kovvur 14th FinDocument2 pagesprintBoqItems Kovvur 14th FinprasadmvkNo ratings yet

- Bores 287894Document3 pagesBores 287894prasadmvkNo ratings yet

- 141Document1 page141prasadmvkNo ratings yet

- 17 Ward TNKDocument4 pages17 Ward TNKprasadmvkNo ratings yet

- 1Document1 page1prasadmvkNo ratings yet

- 15 SchoolsDocument7 pages15 SchoolsprasadmvkNo ratings yet

- New Resume Sravan KumarDocument2 pagesNew Resume Sravan KumarprasadmvkNo ratings yet

- TRDocument1 pageTRprasadmvkNo ratings yet

- Guidelines For Candidates Along With The QuestionnaireDocument1 pageGuidelines For Candidates Along With The QuestionnaireprasadmvkNo ratings yet

- AccommodationDocument2 pagesAccommodationprasadmvkNo ratings yet

- Guidelines For Candidates V02Document2 pagesGuidelines For Candidates V02prasadmvkNo ratings yet

- NF72696126691531 ETicketDocument2 pagesNF72696126691531 ETicketprasadmvkNo ratings yet

- Emudhra 5785784Document1 pageEmudhra 5785784prasadmvkNo ratings yet

- Emudhra 5788078Document1 pageEmudhra 5788078prasadmvkNo ratings yet

- Admitcard ApeamcetDocument4 pagesAdmitcard ApeamcetprasadmvkNo ratings yet

- 812 3009 1 SPDocument9 pages812 3009 1 SPprasadmvkNo ratings yet

- Construction of Toilets To The Skating Ring at Jewal AppartmentDocument45 pagesConstruction of Toilets To The Skating Ring at Jewal AppartmentprasadmvkNo ratings yet

- Andhrabank: Applicationforadvances (Forconventionaladvances Lakhsonly)Document1 pageAndhrabank: Applicationforadvances (Forconventionaladvances Lakhsonly)prasadmvkNo ratings yet

- Contract Regn Class IIDocument2 pagesContract Regn Class IIprasadmvkNo ratings yet

- Transaction Fee DetailsDocument1 pageTransaction Fee DetailsprasadmvkNo ratings yet

- Welcome To Nagarjuna UniversityDocument1 pageWelcome To Nagarjuna UniversityprasadmvkNo ratings yet

- Final Bid Submission Declaration 1Document1 pageFinal Bid Submission Declaration 1prasadmvkNo ratings yet

- CCI06302017Document1 pageCCI06302017prasadmvkNo ratings yet

- Lesson - 01colour TherapyDocument7 pagesLesson - 01colour TherapyprasadmvkNo ratings yet

- Lesson - 02 Colour TherapyDocument11 pagesLesson - 02 Colour TherapyprasadmvkNo ratings yet

- CompoundwallDocument2 pagesCompoundwallprasadmvkNo ratings yet

- EstimateDocument4 pagesEstimateprasadmvkNo ratings yet

- PAINTS INVENTORY Apr.14 2016Document1 pagePAINTS INVENTORY Apr.14 2016Pavel ViktorNo ratings yet

- Soldaduras PlatinoDocument10 pagesSoldaduras PlatinoTaller Rupay AntüNo ratings yet

- Faren Buildcon Plasto ReadyDocument1 pageFaren Buildcon Plasto ReadyFaren TradersNo ratings yet

- TITANIUM INFORMATION G R O U P - TWI GlobalDocument36 pagesTITANIUM INFORMATION G R O U P - TWI GlobalBalaji Lubricants & ChemicalsNo ratings yet

- Velan Pressure Seal Valve CatalogDocument56 pagesVelan Pressure Seal Valve CatalogArtish PadaiyaNo ratings yet

- Balanlay-Narrative ReportDocument4 pagesBalanlay-Narrative ReportJhade Danes BalanlayNo ratings yet

- Clamps: Pull Clamping System Pull Clamping System Hook TypeDocument106 pagesClamps: Pull Clamping System Pull Clamping System Hook TypeCollin FarNo ratings yet

- European Polymer Journal: Nikhil Avinash Patil, James Njuguna, Balasubramanian Kandasubramanian TDocument22 pagesEuropean Polymer Journal: Nikhil Avinash Patil, James Njuguna, Balasubramanian Kandasubramanian TAshok Kumar BakshiNo ratings yet

- SBD en Technical Data SheetDocument8 pagesSBD en Technical Data SheetJonathanFallasNo ratings yet

- Utp 7015Document1 pageUtp 7015cesarlopezpolysiusNo ratings yet

- How To Build A Drill Press Table - The Family HandymanDocument2 pagesHow To Build A Drill Press Table - The Family HandymanahdickwongNo ratings yet

- Recent Advances in Turning With Textured Cutting Tools A ReviewDocument15 pagesRecent Advances in Turning With Textured Cutting Tools A ReviewAbhishek BihariNo ratings yet

- 1 s2.0 S1044580322004053 MainDocument16 pages1 s2.0 S1044580322004053 MainSree SabariNo ratings yet

- KOBELCO Reference Plant 171102Document23 pagesKOBELCO Reference Plant 171102Bảo BáchNo ratings yet

- Topmet Hires DatasheetDocument2 pagesTopmet Hires DatasheetRavi Shankar Dubey VickyNo ratings yet

- Brochure - SIL PT BarDocument4 pagesBrochure - SIL PT Barprashant patilNo ratings yet

- Method Statement For STG Foundation Basemat WorksDocument7 pagesMethod Statement For STG Foundation Basemat WorksBijaya RaulaNo ratings yet

- Internship Report of MuradDocument104 pagesInternship Report of Muradmosabbir rahmanNo ratings yet

- Manual Sierra Horizontal W.F. WellsDocument43 pagesManual Sierra Horizontal W.F. WellsDavidOlivaNo ratings yet

- Asme B5.10 1994Document41 pagesAsme B5.10 1994Rafael Ernesto Arias SandovalNo ratings yet

- Injection Molding Plastic ProductsDocument32 pagesInjection Molding Plastic ProductsTesfaye DegefaNo ratings yet

- Repair of Single Coat Inorganic Zinc SilDocument8 pagesRepair of Single Coat Inorganic Zinc SilLuís PiresNo ratings yet

- 3 - D Printer Carbon Fiber Reinforced WithDocument17 pages3 - D Printer Carbon Fiber Reinforced With19 CH 056 Vaishali VivekNo ratings yet

- Polystick Tu Plus Pds 8Document2 pagesPolystick Tu Plus Pds 8jgarciaNo ratings yet

- Coatings On Metal Fasteners: Part 1. Specification For General Requirements and Selection GuidelinesDocument17 pagesCoatings On Metal Fasteners: Part 1. Specification For General Requirements and Selection Guidelinesmohamed fayezNo ratings yet

- Comparative Evaluation Between E-Glass and Hemp Fiber Composites Application in Rotorcraft InteriorsDocument8 pagesComparative Evaluation Between E-Glass and Hemp Fiber Composites Application in Rotorcraft Interiorsmn.gautamNo ratings yet

- Catalogo Domus Wet Cleaning en 2020-142Document7 pagesCatalogo Domus Wet Cleaning en 2020-142Đinh Trọng NghĩaNo ratings yet

GSL Silica

GSL Silica

Uploaded by

prasadmvkOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GSL Silica

GSL Silica

Uploaded by

prasadmvkCopyright:

Available Formats

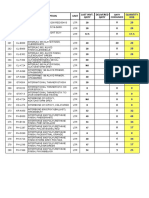

Sl No Brief Item Description Unit Quantity

A EARTH WORK

1 Cleaning the proposed area by cutting down plants/trees SQM 7500

including grubbing of stumps, roots, etc, clearing of all

vegetation, shrubs, debris, scrap and disposal of the same

outside the area of work or stack properly as directed and

approved by ENGINEER.

Not Required

2 Excavation below existing ground level at depths, as

indicated below, from the existing ground level, including

clearing away vegetation shoring/strutting as required,

dewatering wherever necessary, levelling and ramming the

stratum where the foundation rests, including all lifts

Loading, transporting and unloading excavated soil, slushy

soil and cleared vegetation to spoil ground and stacking

areas and levelling the spoil ground in layers of 300mm

etc. within all leads, Loading, transporting and unloading

selected excavated material from above and back filling

around foundation and compacting using hand held

mechanical vibrators, generally as directed by ENGINEER.

etc, complete, in all types of soil, soft as well as hard,

including soil intermixed with boulders and slushy soil.

Excavation in existing ground level for all other structures

(a) 0 m – 2.5 m CUM 2250 800 1800000

(b) 2.5 m and below CUM

3 Additional lead charges for transportation of every

additional 500m, beyond initial lead of 2.0km. upto 5km

including lead of unloading and stacking or disposing off

the same as directed by the ENGINEER. Complete for in

site quantity.

CUM 2250 225 506250

B BACK FILLING

4 Providing and filling approved quality sand of zone I and II

as per IS: 383, as bedding in pipe trenches for laying of

pipes etc., at all depths and to any section as shown on

construction drawings including compaction by flooding in

layers as per specification and as directed by ENGINEER.

CUM 3750 1800 6750000

C ANTI-TERMITE

5 Providing pre-constructional anti-termite treatment, and

creating a chemical barrier, under and on sides of

trenches, wall footings, top surface of plinth filling,

including junction of wall and floor along the perimeter of

building, expansion joints, surrounding pipes/conduits with

approved emulsifiable insecticides at the rates and

concentrations as per IS.6313 (Part-II) and as directed by

ENGINEER. Including all connected work such as de

watering as required.

SQM 6000 265 1590000

D CONCRETE -PCC

6 Providing and laying in position plain cement nominal mix

concrete with 40mm downgraded coarse aggregates

including providing side shuttering as required, placing

compacting curing etc complete including expenses

towards dewatering etc complete all as per specification

and as directed by ENGINEER.

7 Concrete grade M10 in levelling layer below foundations,

trenches, sumps, grade slabs, etc., and in fills

CUM 625 5800 3625000

E CONCRETE - RCC

8 Providing and placing in position reinforced cement

concrete of grade M30 with 20mm downgraded aggregate,

limiting W.C ratio to 0.45, including vibrating, curing, de-

watering wherever necessary, providing construction

joints, leaving cut outs / pockets, placing of inserts/

embedment's, etc., complete, including the cost of material

as per specifications and as directed by the ENGINEER

9 (a) Foundations for columns / walls and other structures,

Thrust block, Tie beams etc CUM 1750 10600 18550000

F REINFORCED BAR

10 Cleaning, cutting, bending, as per drawings and placing in

position high yield strength deformed reinforcement bars

(Fe 500 only) conforming to IS: 1786 at all locations and

levels including binding with soft annealed 16G black wire,

etc. complete as shown on drawings and as directed by

the Engineer (Binding wires shall be supplied by

CONTRACTOR. Cost of supply of binding wires shall be

included in the rates. No payment

Provded By Us

will be made for binding wires) TONS 500 0

G FORM WORK

11 Providing, fixing and removing formwork at all elevations

including providing all materials, labours, equipment's,

consumables, scaffolding, staging, providing pockets, etc

complete as per specifications, drawings, as directed &

approved by engineer in charge for the following :

Formwork using Plywood/steel SQM 6000 480 2880000

H STRUCTURAL STEEL

12 Supplying, detailing, fabricating, transporting to site of

erection, erecting in position at all levels, alignment and

final site welding/bolting of all structural components

fabricated out of steel conforming to IS 2062 including all

connected operations such as straightening of plates,

preparation of cutting plans, cutting, bending, grinding,

drilling of holes, assembly, providing erection bolts and nut

(weight not considered for payment) welding (weight not

considered for payment) including, edge preparation for

welding, pre heating of plates before welding, post heating,

sequencing of welding, testing of welders, inspection and

testing of welds, rectification/ correction of defective welds,

etc complete including providing erection mark, erection

scheme, protection against damage in transit, ensuring

stability of structure by installing temporary structure

(weight not payable) during erection, including supply of all

skilled labour, material, consumables, handling equipment,

during fabrication and erection and all other activities,

required for complete work as per specification,

construction drawings and instruction of ENGINEER (cost

of preparation of surface and painting will be paid for extra

against relevant items).

13 (a)Structural steel members fabricated exclusively of

plates confirming to Grade E 250 (Fe 410W) quality B

(Killed), of IS 2062 for components like, framing columns

and beams, box shaped internal columns, gable end

columns, cross beams, box shaped wall beams etc and all

structures fabricated exclusively

TONS 10000

14 (b)Structural steel member fabricated out of rolled steel

sections only and rolled steel section with cover plates

conforming to Grade E 250 (Fe 410W) quality A of IS2062,

such as columns, beams, trusses, vertical and horizontal

bracings, tie beams, struts, purlins, side girts, sag rods,

hangers, mono rail beam, stub column, walkways,

platforms, stair stringers, ladders.

TONS 40 Provided by Us

I MASONRY

15 Supplying, Providing and laying 230 thick brick masonry in

cement mortar 1:5 using approved quality bricks of class

3.5 conforming to IS: 1077 including steel wire fabric at the

junction of masonry and concrete, scaffolding, curing,

raking joints, etc. complete as per specifications and

drawings at all levels and locations.

SQM 1500 780 1170000

16 Providing Damp proof course, 75 mm thick with Cement

Concrete grade M20 using 20 mm downgraded aggregate

with approved water proofing compound to proportion

recommended by manufacturer including providing form

work/side shuttering as required vibrating, curing etc

complete.

SQM 10200 0

J FINISHES, PAINTING TO CONCRETE, PAINTING TO

PLASTERED SURFACES

17 Providing and applying two or more coats to give an even

shade of acrylic emulsion paint as per IS 5411, of

approved brand and shade to give smooth, hard, durable

and glossy finish over a coat of primer over prepared

plaster surface including surface preparation etc as per

manufacture’ instruction to complete.

SQM 3000 195 585000

18 Applying two coats of water bound distemper over one

coat of primer and two coat of putty as per IS 427, of

approved brand and manufacture to give an even shade

over a priming coat on plastered surfaces including surface

preparation etc. as per specifications

SQM

K PLASTERING

19 Providing 18 mm thick plain faced external plastering in

two layers, first layer of 12 mm in cement mortar 1:5 and

second layer of 6 mm in cement mortar 1:4 mixed with

approved water proofing compound (Cement to be used

shall be 8 kg/square meter of plastered surface) on the

surface of wall exposed to atmosphere at all levels as

required, curing, etc, complete Providing 12 mm thick

plain-faced cement plaster at all levels in cement mortar

1:4 (5 kg of cement per square meter of plastered surface)

on the internal faces of masonry and R.CC. surfaces at all

levels including scaffolding as required, curing, including

providing Plaster of Paris punning etc, complete

SQM 3000 685 2055000

L FLOOR FINISHES SQM 6600

M RUBBLE SOLING- 230 THK SQM 8000

N WATERPROOFING -

O GROUTING (Non Shrink grout M35) CUM 15

P METAL DECKING SHEET MINIMUM 1MM THICK SQM 700

You might also like

- Normas NES M1019Document12 pagesNormas NES M1019Margarita Torres FloresNo ratings yet

- Din 30670 - 2012Document37 pagesDin 30670 - 2012Hasan AlmohtasebNo ratings yet

- IGM Additives Product GuideDocument20 pagesIGM Additives Product GuideColoke AdesivosNo ratings yet

- BO-BoQ For Balance Civil & FinishingDocument16 pagesBO-BoQ For Balance Civil & FinishingcubadesignstudNo ratings yet

- Civil BOQ For STPDocument8 pagesCivil BOQ For STPImtiyaz Ahmad Zargar25% (4)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Multipurpose HallDocument31 pagesMultipurpose HallNaiyer AzamNo ratings yet

- (381611313) BOQ EarthworkDocument39 pages(381611313) BOQ EarthworkAshish SadaNo ratings yet

- BOQ - TaramaniDocument46 pagesBOQ - Taramanismith0% (1)

- Htl-Admin-Tender-Boq-23-07-2018-Steel Woks-Superstructure-VendorDocument15 pagesHtl-Admin-Tender-Boq-23-07-2018-Steel Woks-Superstructure-VendorMvv SatyanarayanaNo ratings yet

- Compound Wall OfferDocument4 pagesCompound Wall OfferMd AbidNo ratings yet

- BOQ - 1,2,3,4 - AKK BilaspurDocument77 pagesBOQ - 1,2,3,4 - AKK BilaspursonuNo ratings yet

- Quote Admin Road BoqDocument8 pagesQuote Admin Road BoqKarun AbrolNo ratings yet

- Workers_Canteen_Plumbing_Allied_work_BOQDocument3 pagesWorkers_Canteen_Plumbing_Allied_work_BOQKoneti JanardhanaraoNo ratings yet

- Rate CardsDocument32 pagesRate CardsSasanka SekharNo ratings yet

- Cecs-St-Boq-Vasant Kung Boundary Wall-R1Document2 pagesCecs-St-Boq-Vasant Kung Boundary Wall-R1aasifkhanNo ratings yet

- 070120231827-Price bidDocument4 pages070120231827-Price bidBhaswat KashyapNo ratings yet

- STP BoqDocument14 pagesSTP BoqanishmetaNo ratings yet

- Rate Total Rate: Material Labour Service Tax With No BenefitsDocument4 pagesRate Total Rate: Material Labour Service Tax With No BenefitsRita WallaceNo ratings yet

- Japhat Civil Work BoqDocument8 pagesJaphat Civil Work BoqsatyaprakashNo ratings yet

- 1-Factory Shed 5.8.21Document72 pages1-Factory Shed 5.8.21Harsh Bhavsar100% (1)

- 1.AKAR IMPEX PVT LTD - Civil BOQ - THDC-WTP QTY-CS - (NEW QUANTITY)Document19 pages1.AKAR IMPEX PVT LTD - Civil BOQ - THDC-WTP QTY-CS - (NEW QUANTITY)dineshNo ratings yet

- 1 - Enquiry (BOM - BOQ) - For New Chemical ShedDocument4 pages1 - Enquiry (BOM - BOQ) - For New Chemical Shedganeshsable247No ratings yet

- SampleDocument186 pagesSampleSANDESHNo ratings yet

- Rates FoundationDocument17 pagesRates FoundationMihir PanchalNo ratings yet

- RamDocument8 pagesRamsunaifctmNo ratings yet

- 2022.02.01 - Karnal Factory BoqDocument4 pages2022.02.01 - Karnal Factory Boqkunaal kakkarNo ratings yet

- SL No Tariff Description of Works Measurements:: Eq. Parts Length WidthDocument8 pagesSL No Tariff Description of Works Measurements:: Eq. Parts Length Widthshyamsundar_ceNo ratings yet

- ZDCSD Sad AsdfasfDocument20 pagesZDCSD Sad AsdfasfShruti ShahNo ratings yet

- Coal Yard Road Development JobDocument16 pagesCoal Yard Road Development JobSasanka SekharNo ratings yet

- DC Satpute BOQ 05-07-23 Revised 15% HikeDocument24 pagesDC Satpute BOQ 05-07-23 Revised 15% HikechetanjtNo ratings yet

- Ms - Sarayu EstimateDocument13 pagesMs - Sarayu EstimateSandgrouse RajNo ratings yet

- PrecastDocument2 pagesPrecastsmithNo ratings yet

- July Ipp Addtional JobDocument9 pagesJuly Ipp Addtional JobSasanka SekharNo ratings yet

- Scope of Work: Project Specification DetailsDocument10 pagesScope of Work: Project Specification DetailsArfhan ANo ratings yet

- Schedule of RatesDocument3 pagesSchedule of RatesNikki JainNo ratings yet

- Siemens Quote For Pump RoomDocument5 pagesSiemens Quote For Pump RoomNayan FataniaNo ratings yet

- Bo QDocument12 pagesBo QSatheesh SankarapillaiNo ratings yet

- Security RoomDocument7 pagesSecurity RoomHari PrasathNo ratings yet

- Kalay PanchayatDocument31 pagesKalay PanchayatRam Prasad PrabhudesaiNo ratings yet

- RateDocument51 pagesRatemukesh kumarNo ratings yet

- Summary of Cost For Construction of Labaratory Building Comsats AbbottabadDocument15 pagesSummary of Cost For Construction of Labaratory Building Comsats AbbottabadMuhammad AsadNo ratings yet

- Proposed Apartment at Shirala, Sangli: Owner - Tarangan Developers Building IDocument27 pagesProposed Apartment at Shirala, Sangli: Owner - Tarangan Developers Building IHusen GhoriNo ratings yet

- 20170709-Boq-Proposed Apartments-R0 PDFDocument7 pages20170709-Boq-Proposed Apartments-R0 PDFAtul Shrivastava100% (1)

- Schedule of Quantities of Road Work For M/S Ask Automobiles, BhiwadiDocument2 pagesSchedule of Quantities of Road Work For M/S Ask Automobiles, BhiwadiDada Chandan Das A&R DevelopersNo ratings yet

- TownhallDocument19 pagesTownhallSantosh BasnetNo ratings yet

- Aai Khowai ItemDocument5 pagesAai Khowai Itemarindam sarkarNo ratings yet

- Specification IndexDocument13 pagesSpecification IndexMAULIK RAVALNo ratings yet

- Excel QuantityDocument234 pagesExcel Quantityviveik_mudgalNo ratings yet

- Quantity Schedule For Both Entry Exit GatesDocument10 pagesQuantity Schedule For Both Entry Exit GatesMATRIX ENGINEERSNo ratings yet

- Annexure 4 - NIT BOQ - 20230524153716Document2 pagesAnnexure 4 - NIT BOQ - 20230524153716ABECPL Bina SiteNo ratings yet

- Civil, Structure and Water - Proofing WorksDocument2 pagesCivil, Structure and Water - Proofing WorksAditi Agrawal100% (1)

- Site Offices and HousingDocument38 pagesSite Offices and HousingMuhammad Al azaweyNo ratings yet

- Sub-Structure Section 2200Document3 pagesSub-Structure Section 2200aalignup arc & const. pvt ltdNo ratings yet

- Canteen and Dress Changing RoomDocument43 pagesCanteen and Dress Changing RoomJeevitha DeivasigamaniNo ratings yet

- Estimate of PQCDocument6 pagesEstimate of PQCMital DamaniNo ratings yet

- DH Bandipora 10 BeddedDocument44 pagesDH Bandipora 10 BeddedPuneet Shaily0% (1)

- Box Estimate.Document254 pagesBox Estimate.rahul sumanNo ratings yet

- Field Operator RoomDocument4 pagesField Operator RoomKANWARNo ratings yet

- Estimate For Construction of R.C.C. Bridge Over River Buribalason, at Jalasnijamtara, Phansidewa, SiliguriDocument15 pagesEstimate For Construction of R.C.C. Bridge Over River Buribalason, at Jalasnijamtara, Phansidewa, SiliguriRio HandokoNo ratings yet

- Copy of rajbiraj(1)Document10 pagesCopy of rajbiraj(1)Rahul ShahNo ratings yet

- Afcon BoqDocument3 pagesAfcon BoqBinni KNo ratings yet

- Schedule of Quantity For Industrial BuildingDocument4 pagesSchedule of Quantity For Industrial BuildingShashankSinghNo ratings yet

- Transaction Fee DetailsDocument1 pageTransaction Fee DetailsprasadmvkNo ratings yet

- TDV BT RoadsDocument2 pagesTDV BT RoadsprasadmvkNo ratings yet

- 229Document1 page229prasadmvkNo ratings yet

- printBoqItems Kovvur 14th FinDocument2 pagesprintBoqItems Kovvur 14th FinprasadmvkNo ratings yet

- Bores 287894Document3 pagesBores 287894prasadmvkNo ratings yet

- 141Document1 page141prasadmvkNo ratings yet

- 17 Ward TNKDocument4 pages17 Ward TNKprasadmvkNo ratings yet

- 1Document1 page1prasadmvkNo ratings yet

- 15 SchoolsDocument7 pages15 SchoolsprasadmvkNo ratings yet

- New Resume Sravan KumarDocument2 pagesNew Resume Sravan KumarprasadmvkNo ratings yet

- TRDocument1 pageTRprasadmvkNo ratings yet

- Guidelines For Candidates Along With The QuestionnaireDocument1 pageGuidelines For Candidates Along With The QuestionnaireprasadmvkNo ratings yet

- AccommodationDocument2 pagesAccommodationprasadmvkNo ratings yet

- Guidelines For Candidates V02Document2 pagesGuidelines For Candidates V02prasadmvkNo ratings yet

- NF72696126691531 ETicketDocument2 pagesNF72696126691531 ETicketprasadmvkNo ratings yet

- Emudhra 5785784Document1 pageEmudhra 5785784prasadmvkNo ratings yet

- Emudhra 5788078Document1 pageEmudhra 5788078prasadmvkNo ratings yet

- Admitcard ApeamcetDocument4 pagesAdmitcard ApeamcetprasadmvkNo ratings yet

- 812 3009 1 SPDocument9 pages812 3009 1 SPprasadmvkNo ratings yet

- Construction of Toilets To The Skating Ring at Jewal AppartmentDocument45 pagesConstruction of Toilets To The Skating Ring at Jewal AppartmentprasadmvkNo ratings yet

- Andhrabank: Applicationforadvances (Forconventionaladvances Lakhsonly)Document1 pageAndhrabank: Applicationforadvances (Forconventionaladvances Lakhsonly)prasadmvkNo ratings yet

- Contract Regn Class IIDocument2 pagesContract Regn Class IIprasadmvkNo ratings yet

- Transaction Fee DetailsDocument1 pageTransaction Fee DetailsprasadmvkNo ratings yet

- Welcome To Nagarjuna UniversityDocument1 pageWelcome To Nagarjuna UniversityprasadmvkNo ratings yet

- Final Bid Submission Declaration 1Document1 pageFinal Bid Submission Declaration 1prasadmvkNo ratings yet

- CCI06302017Document1 pageCCI06302017prasadmvkNo ratings yet

- Lesson - 01colour TherapyDocument7 pagesLesson - 01colour TherapyprasadmvkNo ratings yet

- Lesson - 02 Colour TherapyDocument11 pagesLesson - 02 Colour TherapyprasadmvkNo ratings yet

- CompoundwallDocument2 pagesCompoundwallprasadmvkNo ratings yet

- EstimateDocument4 pagesEstimateprasadmvkNo ratings yet

- PAINTS INVENTORY Apr.14 2016Document1 pagePAINTS INVENTORY Apr.14 2016Pavel ViktorNo ratings yet

- Soldaduras PlatinoDocument10 pagesSoldaduras PlatinoTaller Rupay AntüNo ratings yet

- Faren Buildcon Plasto ReadyDocument1 pageFaren Buildcon Plasto ReadyFaren TradersNo ratings yet

- TITANIUM INFORMATION G R O U P - TWI GlobalDocument36 pagesTITANIUM INFORMATION G R O U P - TWI GlobalBalaji Lubricants & ChemicalsNo ratings yet

- Velan Pressure Seal Valve CatalogDocument56 pagesVelan Pressure Seal Valve CatalogArtish PadaiyaNo ratings yet

- Balanlay-Narrative ReportDocument4 pagesBalanlay-Narrative ReportJhade Danes BalanlayNo ratings yet

- Clamps: Pull Clamping System Pull Clamping System Hook TypeDocument106 pagesClamps: Pull Clamping System Pull Clamping System Hook TypeCollin FarNo ratings yet

- European Polymer Journal: Nikhil Avinash Patil, James Njuguna, Balasubramanian Kandasubramanian TDocument22 pagesEuropean Polymer Journal: Nikhil Avinash Patil, James Njuguna, Balasubramanian Kandasubramanian TAshok Kumar BakshiNo ratings yet

- SBD en Technical Data SheetDocument8 pagesSBD en Technical Data SheetJonathanFallasNo ratings yet

- Utp 7015Document1 pageUtp 7015cesarlopezpolysiusNo ratings yet

- How To Build A Drill Press Table - The Family HandymanDocument2 pagesHow To Build A Drill Press Table - The Family HandymanahdickwongNo ratings yet

- Recent Advances in Turning With Textured Cutting Tools A ReviewDocument15 pagesRecent Advances in Turning With Textured Cutting Tools A ReviewAbhishek BihariNo ratings yet

- 1 s2.0 S1044580322004053 MainDocument16 pages1 s2.0 S1044580322004053 MainSree SabariNo ratings yet

- KOBELCO Reference Plant 171102Document23 pagesKOBELCO Reference Plant 171102Bảo BáchNo ratings yet

- Topmet Hires DatasheetDocument2 pagesTopmet Hires DatasheetRavi Shankar Dubey VickyNo ratings yet

- Brochure - SIL PT BarDocument4 pagesBrochure - SIL PT Barprashant patilNo ratings yet

- Method Statement For STG Foundation Basemat WorksDocument7 pagesMethod Statement For STG Foundation Basemat WorksBijaya RaulaNo ratings yet

- Internship Report of MuradDocument104 pagesInternship Report of Muradmosabbir rahmanNo ratings yet

- Manual Sierra Horizontal W.F. WellsDocument43 pagesManual Sierra Horizontal W.F. WellsDavidOlivaNo ratings yet

- Asme B5.10 1994Document41 pagesAsme B5.10 1994Rafael Ernesto Arias SandovalNo ratings yet

- Injection Molding Plastic ProductsDocument32 pagesInjection Molding Plastic ProductsTesfaye DegefaNo ratings yet

- Repair of Single Coat Inorganic Zinc SilDocument8 pagesRepair of Single Coat Inorganic Zinc SilLuís PiresNo ratings yet

- 3 - D Printer Carbon Fiber Reinforced WithDocument17 pages3 - D Printer Carbon Fiber Reinforced With19 CH 056 Vaishali VivekNo ratings yet

- Polystick Tu Plus Pds 8Document2 pagesPolystick Tu Plus Pds 8jgarciaNo ratings yet

- Coatings On Metal Fasteners: Part 1. Specification For General Requirements and Selection GuidelinesDocument17 pagesCoatings On Metal Fasteners: Part 1. Specification For General Requirements and Selection Guidelinesmohamed fayezNo ratings yet

- Comparative Evaluation Between E-Glass and Hemp Fiber Composites Application in Rotorcraft InteriorsDocument8 pagesComparative Evaluation Between E-Glass and Hemp Fiber Composites Application in Rotorcraft Interiorsmn.gautamNo ratings yet

- Catalogo Domus Wet Cleaning en 2020-142Document7 pagesCatalogo Domus Wet Cleaning en 2020-142Đinh Trọng NghĩaNo ratings yet