Professional Documents

Culture Documents

Exhaust

Exhaust

Uploaded by

Bala KrishnanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exhaust

Exhaust

Uploaded by

Bala KrishnanCopyright:

Available Formats

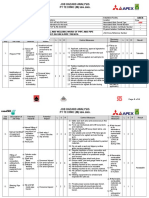

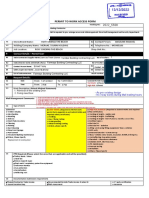

PTW Risk Assessment

ACTIVITY TITLE: RISK ASSESSMENT FOR EXHAUST FAN WORK

* Risk Assessment Additional Risk Residual Risk

No Hazard Hazard Controls

Causes Consequences Existing Controls

. Title Detail R

Planned/

P A E R Required P A E R RI

I

Location of Induction to

underground be conducted

utilities must be to all

Slip and

identified by persons

trips during

approved visiting the

site visit

and checking Presence of Fall on detection survey construction

spot M team and secured site.

Physical for location rubbles, E LO

01 stones, uneven leading to 2E 1E 1E 2E prior to any Briefed AD 1A 1A 1A 1A

Hazards of D W

ground surface personnel start of work Port rules

underground I

and untidy injury Proper and

utilities as U

per authority environment housekeeping must regulation.

M Housekeeping

drawing. be ensured.

Working area must to be

be free of hills followed

or any sloppy regularly.

ground surface

Induction to

be conducted

to all

persons

visiting the

Barricade and construction

Employees may Unskilled labors materials can be site.

assume Lack of shifted by All employees

awkward body ergonomics/manua M vehicles Survey must be L

positioning l handling Body pain E pegs/rebar’s properly

Ergonomic during training. Wrong Musculoske D must be capped. trained for

02 2D 1E 1E 2E 1A 1A 1A 1A O

Hazard barricading pushing and letal I Adequate rest to the work to

of areas to pulling injury. U be ensured for be done Daily

be excavated, procedure M the employees. TBT to be W

Surveying Lifting of heavy Employees must conducted

pegs objects not lift more before start

than 20kg of of work Job

load at a time rotation can

be practiced

for strenuous

continuous

works

CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022

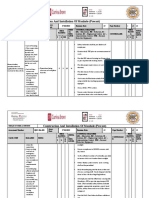

PTW Risk Assessment

Induction to be

conducted to

all persons

visiting the

Awkward

construction

positioning Precast concrete site.

during blocks to be All employees

placing of shifted to

M must be

precast Workers not location by

E properly

concrete being trained on Body pain mechanical means

Ergonomic D trained for the LO

03 blocks manual handling Musculoskele 2D 1E 1E 2E and not by manual. 1A 1A 1A 1A

Hazard I work to be done W

Lifting, Improper tal injury.

U Positioning can be Daily TBT to be

pushing and supervision done by block

M conducted

pulling of lifter Employees

Heavy loads before start of

must not lift more work Job

Awkward shape than 20kg of load rotation can be

of objects at one time. practiced for

strenuous

continuous

works

Provide heat

implemented, stop

stress training

all lifting

and emergency

operation during

response

thunderstorm, all

training to

work at heights

workers, Ensure

activity not

Working in to implement a

Poor visibility, limited to roof

adverse process for

slippery floor, work and

weather M assessing the

heat stress Fatality, scaffolding works

condition E environmental

illness, dust, Injury, Work are not allowed

Adverse e.g. sand D conditions and LO

04 struck by Delay, 3C 1A 1A 1A during heavy rain. 1A 1A 1A 1A

weather storm, high I comparing to W

lightning, fall Property Cool rest area and

wind, extreme U the TWL Heat

from heights & damage food storage area

temperature, M Stress index

falling object must be provided

rain, and implement

due to high wind Provision of

thunderstorm the requirement

appropriate

of the relevant

amounts of potable

work zone

drinking water

control measure

close to the

as per OSHAD-

worksite and

Cop Guideline.

appropriate

Display of

electrolyte should

posters

be provide as per

illustrating

CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022

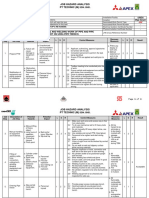

PTW Risk Assessment

guideline OSHAD monitoring of

Cop 8.0 and 9.0. hydration

states by urine

color in

toilets and

rest rooms.

Before any

Work will operation always

come to a check the liquid

standstill. levels such as

Reduced hydraulic oil,

Due to productivity coolant, oil, and Install

Failure of insufficient Broken fuel. barricades to

H confine the

machine hydraulic oil, bones, head Prepare the

Safety I area to LO

05 Falling from Coolant, Oil, injuries, 5D 4C 1A 1A lifting location 2A 1A 1A 1A

Hazard G authorized W

height (Boom and fuel affect where the boom

H personnel only.

Lift) Failure of mental lift will be

machine health positioned.

(person may Before commencing

become of work, inspect

scared of all controls for

height) proper

functioning.

All staff must be

supervised.

Targets should be

given and

encouraged to

Incompetent complete the

Staff causing targets within the Review risk

reduced time frame. assessments

Lack of

productivity Avoid lone periodically

attention. L

Work Load Lone Working working. All with staff and

06 Lack of training O -

Hazard affects the workers should be update if any

Lack of W

mental health monitored by the significant

awareness

being of site supervisor at changes are

staff all times there.

Violence Avoid lone

working. All

workers should be

monitored by the

site supervisor at

all times

CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022

PTW Risk Assessment

Implement the additional risk controls identified

Risk control-

Date Implemented by

1

Risk control-

Date Implemented by

2

Risk control-

Date Implemented by

3

Risk control-

Date Implemented by

4

Risk control-

Date Implemented by

5

Risk control-

Date Implemented by

6

It is important to monitor risk controls and review risk assessments regularly. Review is required when there is a change in the process, relevant legal

changes, and where a cause for concern has arisen. Reviews could be scheduled on an annual basis. If the risk assessment has substantially changed a new

risk assessment is warranted.

CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022

PTW Risk Assessment

Review date Reviewed by Authorized by

Notes: Include legal and advisory documentation that supports this risk assessment be listed. Such documentation includes Acts, Regulations, Standards, where applicable. If

the risk assessment for an identified hazard is ranked ’Low’ but the regulatory requirements have not been complied to while establishing and/or implementing controls, the

ranking for the assesses risk shall be considered ‘Very High’

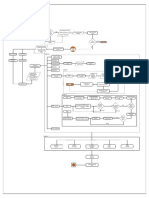

Risk Assessment Steps:

Step 1: Identify Hazards Title (e.g. Physical Hazard, Fire Hazard, and Electrical Hazards).

Step 2: List Hazards Details identified (e.g. Tripping Hazard, Flammable Materials stored,

Working in Electrical Cabinets).

Step 3: List Causes of Hazard (e.g. Untidy workplace, Hot work, un-isolated electrical

supply).

Step 4: List Consequences of Hazard (e.g. Personnel Injury, Fire, electric shock).

Step 5: Determine Likelihood and Consequences to People, Assets, Environment, and Reputation

from attached Risk Assessment Matrix (Page 2) (this should be the most probable outcome

without controls and should be listed as 2A, 3D etc.).

Step 6. Calculate the Risk Index using the Qualitative or Semi-Quantitative Risk Assessment

Matrix as deemed appropriate. This is a product of Likelihood and Consequence and should be Descriptor to assist in Qualitative Assessment of Likelihood/ Frequency of

stated Low, Medium, High or Very High). Likelihood Occurrence.

Step 7. List Existing Controls. (e.g. Tidy Site Policy, Hot Work Permit, Isolation of

Electrical Supply).

Step 8. List Safety Critical Activities and Additional Controls that may be deemed necessary

A Has occurred within port industry worldwide.

to reduce risk level to ALARP.

Step 9: Recalculate Likelihood and Consequences to People, Assets, Environment, and B Has occurred regionally within port industry or judged likely to have

Reputation from attached Risk Assessment Matrix. occurred.

Step 10. Recalculate the Risk Index. C Has occurred in port industry within UAE or judged likely to have

Step 11. If residual risk deemed to be High or Very High then risk must be reduced further occurred.

before proceeding, if risk is medium then note that risk reduction must be planned, monitored D Has occurred in port industry within UAE on an annual basis or judged

and documented, if risk is low then risk is acceptable without required further action. likely to have occurred.

E May occur in UAE port industry multiple times annually.

* Risk Assessment Matrix – Qualitative LIKELIHOOD

Consequences P= People A= Assets E= Environment R= Reputation A B C D E

5- Multiple Extensive International VERY

Massive effect

Catastrophic fatalities damage impact HIGH

Single fatality

4 - Severe or permanent Major damage Major effect National impact HIGH

disability

Major injury or Localized Localized

3 – Critical Considerable impact MEDIUM

health effects effect effect

Minor injury or

2 – Marginal Minor effect Minor effect Minor impact

health effects

Slight injury or

1 - Negligible Slight effect Slight effect Slight impact LOW

health effects

For additional information refer to HSE-COR-PRC-SYS-11 HSE Risks & Opportunities Management

CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022

You might also like

- Risk Assessment: Project Site Area: Asphalt Cutting LocationDocument4 pagesRisk Assessment: Project Site Area: Asphalt Cutting LocationRaza Ali Khan100% (8)

- Scientific Principles of Strength TrainingDocument38 pagesScientific Principles of Strength Trainingarkko5585% (13)

- MSC Nursing QN PaperDocument9 pagesMSC Nursing QN Papersanthyakunjumon100% (1)

- JSA Fitting and Welding Work For Pipe Trench InstalationDocument6 pagesJSA Fitting and Welding Work For Pipe Trench InstalationVishnu VijayanNo ratings yet

- Dismantling of WallDocument1 pageDismantling of WallChandruNo ratings yet

- Chipping Work ManuallyDocument1 pageChipping Work ManuallyMohammed Amer PashaNo ratings yet

- Chipping Work (Manually)Document1 pageChipping Work (Manually)ChandruNo ratings yet

- Scaffolding Staging Tower For Concr PumpDocument1 pageScaffolding Staging Tower For Concr Pumpasimnaqvi2008No ratings yet

- Underground Above Ground Drainage Works and Plumbing Works Risk AssessmentDocument4 pagesUnderground Above Ground Drainage Works and Plumbing Works Risk Assessmentmohsin.meizaNo ratings yet

- Qrc-Ra-004 - Re-Routing of Electrical CableDocument14 pagesQrc-Ra-004 - Re-Routing of Electrical CableKallem RajashekarNo ratings yet

- Ref: Section / Dept: Civil Activity: Risk Assessment For: y InitDocument1 pageRef: Section / Dept: Civil Activity: Risk Assessment For: y InitIndermohan MehtaNo ratings yet

- Ref: Section / Dept: Civil Activity: Risk Assessment For: y InitDocument1 pageRef: Section / Dept: Civil Activity: Risk Assessment For: y InitJack PNo ratings yet

- Jha Lifting Permit - Tower CraneDocument3 pagesJha Lifting Permit - Tower CraneJohn Ralph Vega100% (1)

- QRC-RA-013-Removal of Existing Road StructureDocument10 pagesQRC-RA-013-Removal of Existing Road StructureKallem RajashekarNo ratings yet

- Qrc-Ra-001-00-Road and Footpath Modification WorksDocument27 pagesQrc-Ra-001-00-Road and Footpath Modification WorksKallem RajashekarNo ratings yet

- TRA of Ladder & PlatformDocument2 pagesTRA of Ladder & PlatformASIF MUZAFFARNo ratings yet

- Demolition Work Risk Assesment - Al WaselDocument5 pagesDemolition Work Risk Assesment - Al Waselsarath SNo ratings yet

- ELEC/RA-001 Risk Assessment CCPP, MBPL: Pipe Rack and Bottom Ash AreaDocument12 pagesELEC/RA-001 Risk Assessment CCPP, MBPL: Pipe Rack and Bottom Ash AreaYuva samaj sewa TrustNo ratings yet

- JSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware HouseDocument9 pagesJSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware Houseradeep100% (1)

- HSE Risk Assessment - Stone Vanity TopDocument3 pagesHSE Risk Assessment - Stone Vanity TopAbrar AhmedNo ratings yet

- Safe Work Procedure On DuctingDocument5 pagesSafe Work Procedure On Ductingroland mago100% (1)

- C&C-EHS-F-002 HIRARC Working at Height (Roof Top)Document4 pagesC&C-EHS-F-002 HIRARC Working at Height (Roof Top)Najman HamdiNo ratings yet

- TRA of Ladder & PlatformDocument2 pagesTRA of Ladder & PlatformandreNo ratings yet

- Night Work Risk Assessment1Document1 pageNight Work Risk Assessment1Muhammad ShafiqNo ratings yet

- Job Safety AnalysisDocument4 pagesJob Safety Analysisnoahlungu96No ratings yet

- Observation 03Document4 pagesObservation 03rupeshkumarsingh3496No ratings yet

- Installation of FormworkDocument3 pagesInstallation of FormworkJhundel Factor PajarillagaNo ratings yet

- Job Safety Analysis (Jsa) : DQE International Iraq BranchDocument4 pagesJob Safety Analysis (Jsa) : DQE International Iraq Branchhassan100% (1)

- Risk Assessment For ExcavationDocument6 pagesRisk Assessment For ExcavationAhmed GamalNo ratings yet

- Excavation Level 2 Risk Assessment 26 3 06Document9 pagesExcavation Level 2 Risk Assessment 26 3 06MAB AliNo ratings yet

- Risk Assessmen For-Excavation-And-BackfillingDocument4 pagesRisk Assessmen For-Excavation-And-BackfillingEngrHazrat Maaz100% (1)

- Risk Assessment For ExcavationDocument8 pagesRisk Assessment For ExcavationAhmed GamalNo ratings yet

- QRC-RA-001-Construction and Installation of Manhole (Precast)Document10 pagesQRC-RA-001-Construction and Installation of Manhole (Precast)Kallem RajashekarNo ratings yet

- JS A Excavation Work For Electrical CableDocument3 pagesJS A Excavation Work For Electrical CableMohammed MinhajNo ratings yet

- Risk Assessment For MT Works in Port Road - DammamDocument4 pagesRisk Assessment For MT Works in Port Road - DammamRenatoNo ratings yet

- Appendix BDocument14 pagesAppendix Bmohsin.meizaNo ratings yet

- Risk Assessment For Electrical ConduitDocument6 pagesRisk Assessment For Electrical ConduitMustafa RazaNo ratings yet

- Task Risk Assessment For Lifting & Installation of Ladder and PlatformDocument3 pagesTask Risk Assessment For Lifting & Installation of Ladder and PlatformAftab QadirNo ratings yet

- Risk Assessment SurveyDocument2 pagesRisk Assessment Surveymohamed ghalyNo ratings yet

- IM-08-B HSE Wall Grinding For Finishing WorkDocument2 pagesIM-08-B HSE Wall Grinding For Finishing WorkAnsari HarisNo ratings yet

- HIRA - CONSOLIDATED of EPCDocument29 pagesHIRA - CONSOLIDATED of EPCMd Nurul Islam100% (1)

- RA-culvert Water IrrigationDocument8 pagesRA-culvert Water IrrigationArsh NazarNo ratings yet

- Jsa For HDDDocument3 pagesJsa For HDDKiên Đinh VănNo ratings yet

- Risk Assessment For Wall Panels InstallationDocument8 pagesRisk Assessment For Wall Panels InstallationAsh Soli0% (1)

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument6 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagya100% (1)

- Job Safety AnylsisDocument7 pagesJob Safety AnylsisMuhammad Fathli FirdausNo ratings yet

- Hazard Identification Risk Assessment and Control WorksheetDocument8 pagesHazard Identification Risk Assessment and Control WorksheetMERWIN ALDOVINONo ratings yet

- JRA 1Y-Centrifugal Pump Maintenance (Flowserve) - P-320CDocument5 pagesJRA 1Y-Centrifugal Pump Maintenance (Flowserve) - P-320CIlyasNo ratings yet

- Naf 2020 Ra 012 00Document12 pagesNaf 2020 Ra 012 00vinayNo ratings yet

- Risk AssessmentDocument13 pagesRisk Assessmentmohsin.meizaNo ratings yet

- JS A For Compressor Shelter SGSDocument3 pagesJS A For Compressor Shelter SGSwhtez0neNo ratings yet

- SWMS 049 (A) Install Ductwork Shaft &or PenoDocument5 pagesSWMS 049 (A) Install Ductwork Shaft &or Penosumontp2022No ratings yet

- RA - Stone Cladding WorkDocument5 pagesRA - Stone Cladding WorkArsh NazarNo ratings yet

- 50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Document3 pages50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Raza Muhammad SoomroNo ratings yet

- Risk Assessment LoaderDocument3 pagesRisk Assessment Loadermohamed ghalyNo ratings yet

- Jsa ExcavationDocument3 pagesJsa ExcavationCherrycherry BetonioNo ratings yet

- Hot Work: Job Hazard Analysis PT Technic (M)Document4 pagesHot Work: Job Hazard Analysis PT Technic (M)ShahrizatSmailKassim100% (1)

- Trough Protection RA - RevDocument9 pagesTrough Protection RA - RevSenthilnathan NagarajanNo ratings yet

- RA - Services Stair Installation - Al Dahra Food IndustriesDocument13 pagesRA - Services Stair Installation - Al Dahra Food IndustriesIbrahim EsmatNo ratings yet

- RA-Installation of GRP Pipe CulvertsDocument6 pagesRA-Installation of GRP Pipe CulvertsArsh NazarNo ratings yet

- Risk Assessment Tipu-PremierDocument6 pagesRisk Assessment Tipu-PremierFahad HayatNo ratings yet

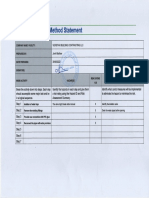

- Method of Statement and Risk Assessment FormDocument4 pagesMethod of Statement and Risk Assessment FormBala KrishnanNo ratings yet

- MSRADocument4 pagesMSRABala KrishnanNo ratings yet

- MSRA Form - Corian CounterDocument3 pagesMSRA Form - Corian CounterBala KrishnanNo ratings yet

- MSRA Door ReplacementDocument3 pagesMSRA Door ReplacementBala KrishnanNo ratings yet

- 2022 - 5508 - Roxy Cinema - Door ReplacementDocument3 pages2022 - 5508 - Roxy Cinema - Door ReplacementBala KrishnanNo ratings yet

- Layout Flow ChartDocument1 pageLayout Flow ChartBala KrishnanNo ratings yet

- Circular Inline FanDocument2 pagesCircular Inline FanBala KrishnanNo ratings yet

- Cable Gland Catalogue New-1Document30 pagesCable Gland Catalogue New-1Bala KrishnanNo ratings yet

- Cushy Foot CatalogueDocument6 pagesCushy Foot CatalogueBala KrishnanNo ratings yet

- Gdi and GemDocument32 pagesGdi and GemDaVid Silence KawlniNo ratings yet

- B.F SkinnerDocument11 pagesB.F SkinnerJoyceNo ratings yet

- Proposal Argument Essays Outline: Solution To Drunk DrivingDocument3 pagesProposal Argument Essays Outline: Solution To Drunk DrivingCharity WacekeNo ratings yet

- Types of WoundsDocument4 pagesTypes of WoundsPatrick Arvin Ballesteros BarcarseNo ratings yet

- The Effectiveness of Pre-Operative Deep BreathingDocument5 pagesThe Effectiveness of Pre-Operative Deep BreathingJulenda CintarinovaNo ratings yet

- Radfet DatasheetDocument6 pagesRadfet DatasheetNicholas EspinozaNo ratings yet

- Bioinformatics Sequence and Genome Analy PDFDocument3 pagesBioinformatics Sequence and Genome Analy PDFNatasha NawazNo ratings yet

- Critical Thinking 9-16Document17 pagesCritical Thinking 9-16chelseeNo ratings yet

- UntitledDocument536 pagesUntitledKnowledge PlanetNo ratings yet

- FDA Guideline CSVDocument66 pagesFDA Guideline CSVnagarajs50100% (2)

- Benefits of Cupping On Body HealthDocument15 pagesBenefits of Cupping On Body Healthviatul shuknaNo ratings yet

- YL NeneDocument10 pagesYL NeneHarindra DunuwilaNo ratings yet

- Caso Banacolombia. Ma Alejandra González PDFDocument16 pagesCaso Banacolombia. Ma Alejandra González PDFSusanaEscobarNo ratings yet

- 1 Persiapan Akreditasi Triennial 2 JciDocument21 pages1 Persiapan Akreditasi Triennial 2 Jcikata_imoetNo ratings yet

- Unit Secretary ResumeDocument6 pagesUnit Secretary Resumeaflkuapdc100% (1)

- Neelam Dissertation Final ProjectDocument78 pagesNeelam Dissertation Final ProjectNeelam SharmaNo ratings yet

- Introduction To Internal Medicine - PPTMDocument30 pagesIntroduction To Internal Medicine - PPTMAddyNo ratings yet

- Persiapan UN SMKDocument5 pagesPersiapan UN SMKBryce SchmidtNo ratings yet

- Rural Libraries, Village Knowledge Centre (VKC) and Concept of Rural Libraries and Knowledge Centre (RLKC) Bishnu Prasad Upadhaya, Ghanakanta Baruah College, Morigaon.Document3 pagesRural Libraries, Village Knowledge Centre (VKC) and Concept of Rural Libraries and Knowledge Centre (RLKC) Bishnu Prasad Upadhaya, Ghanakanta Baruah College, Morigaon.bishnupoudelNo ratings yet

- Requirement Status For Selected Person PATEL ROHITDocument5 pagesRequirement Status For Selected Person PATEL ROHITRohit PatelNo ratings yet

- Q2 Ucsp ExamDocument3 pagesQ2 Ucsp Examgianlee3No ratings yet

- Assasment, Treatment CelulitisDocument7 pagesAssasment, Treatment CelulitisSulistiyawati CuplizNo ratings yet

- Design Guidelines HospitalDocument39 pagesDesign Guidelines HospitalKhaled FacebNo ratings yet

- Kenneth Jake T. BatiduanDocument1 pageKenneth Jake T. BatiduanKenneth Jake BatiduanNo ratings yet

- Bridging The Gap How Community Health Workers Promote The Health of ImmigrantsDocument257 pagesBridging The Gap How Community Health Workers Promote The Health of ImmigrantsNidaUlfahNo ratings yet

- PSM Booster by DR Mukhmohit SinghDocument22 pagesPSM Booster by DR Mukhmohit Singhரஞ்சித் ரவிச்சந்தர்No ratings yet

- Kadiyawala Abdullatif A. Chinalatif@Gmail - Com +919714756754 Date of Birth:28/06/1987 ACADAMIC RECORDDocument2 pagesKadiyawala Abdullatif A. Chinalatif@Gmail - Com +919714756754 Date of Birth:28/06/1987 ACADAMIC RECORDGlenn SmithNo ratings yet

- Research Jan ClarenzDocument6 pagesResearch Jan ClarenzBiboy De ungriaNo ratings yet