Professional Documents

Culture Documents

AISI 1020 Steel, As Rolled

AISI 1020 Steel, As Rolled

Uploaded by

S.Mohana sundaramOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AISI 1020 Steel, As Rolled

AISI 1020 Steel, As Rolled

Uploaded by

S.Mohana sundaramCopyright:

Available Formats

Advertise with MatWeb!

Data sheets for over 155,000 metals, plastics, ceramics, and composites.

HOME •

SEARCH •

TOOLS •

SUPPLIERS •

FOLDERS •

ABOUT US •

FAQ •

LOG IN

Searches:

Advanced

| Category

| Property

| Metals

| Trade Name

| Manufacturer

| Recently Viewed Materials

AISI 1020 Steel, as rolled

Categories: Metal; Ferrous Metal; Carbon Steel; AISI 1000 Series Steel; Low Carbon Steel

Material Applications include parts in the case hardened condition where core strength is not critical, and for shafts of

Notes: larger cross section that are not highly stressed. Other uses include lightly stressed gears with hard wearing

surfaces and case hardened pins and chains.

Key Words: UNS G10200, AMS 5032, AMS 5045, ASTM A29, ASTM A108, ASTM A510, ASTM A519, ASTM A29, A108,

A510, A512, A513, A519, A544, A575 M10120, A576, A635, A659, A827, A830, BS 970 040A20, 050A20

(En2C), 050A20 (En2D), 060A20, BS 970 Part 1 070M20, DEF STAN95-1-1 C1020, SAE J412, SAE J414,

DIN 1.0402, AFNOR CC 20, UNI C 20, SS14 1450 (Sweden), SAE J403

Vendors: No vendors are listed for this material. Please click here if you are a supplier and would like information on

how to add your listing to this material.

Printer friendly version

Download as PDF

Download to Excel (requires Excel and Windows)

Export data to your CAD/FEA program

Add to Folder:

My Folder

0/0

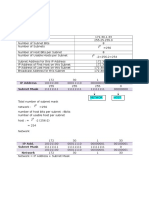

Physical Properties Metric English Comments

Density 7.87 g/cc 0.284 lb/in³ Typical for steel

Mechanical Properties Metric English Comments

Hardness, Brinell 143 143

Hardness, Knoop 163 163 Converted from Brinell

Hardness, Rockwell B 78 78 Converted from Brinell

Hardness, Vickers 149 149 Converted from Brinell

Tensile Strength, 450 MPa 65300 psi

Ultimate

Tensile Strength, Yield 330 MPa 47900 psi

Elongation at Break 36 % 36 % in 50 mm

Reduction of Area 59 % 59 %

Modulus of Elasticity 186 GPa 27000 ksi

Bulk Modulus 148 GPa 21500 ksi calculated from elastic modulus and Poisson's

ratio

Poissons Ratio 0.29 0.29

Shear Modulus 72.0 GPa 10400 ksi calculated from elastic modulus and Poisson's

ratio

Charpy Impact 16.9 J 12.5 ft-lb

@Temperature -30.0 °C @Temperature -22.0 °F

18.0 J 13.3 ft-lb

@Temperature -18.0 °C @Temperature -0.400 °F

20.0 J 14.8 ft-lb

@Temperature -3.00 °C @Temperature 26.6 °F

24.0 J 17.7 ft-lb

@Temperature 10.0 °C @Temperature 50.0 °F

41.0 J 30.2 ft-lb

@Temperature 38.0 °C @Temperature 100 °F

54.0 J 39.8 ft-lb

@Temperature 65.0 °C @Temperature 149 °F

61.0 J 45.0 ft-lb

@Temperature 95.0 °C @Temperature 203 °F

68.0 J 50.2 ft-lb

@Temperature 150 °C @Temperature 302 °F

Electrical Properties Metric English Comments

Electrical Resistivity 0.0000159 ohm-cm 0.0000159 ohm-cm condition unknown

@Temperature 0.000 °C @Temperature 32.0 °F

0.0000219 ohm-cm 0.0000219 ohm-cm condition unknown

@Temperature 100 °C @Temperature 212 °F

0.0000292 ohm-cm 0.0000292 ohm-cm condition unknown

@Temperature 200 °C @Temperature 392 °F

Thermal Properties Metric English Comments

CTE, linear 11.7 µm/m-°C 6.50 µin/in-°F

@Temperature 20.0 - 100 °C @Temperature 68.0 - 212 °F

12.1 µm/m-°C 6.72 µin/in-°F

@Temperature 20.0 - 200 °C @Temperature 68.0 - 392 °F

12.8 µm/m-°C 7.11 µin/in-°F

@Temperature 20.0 - 300 °C @Temperature 68.0 - 572 °F

13.3 µm/m-°C 7.39 µin/in-°F

@Temperature 20.0 - 400 °C @Temperature 68.0 - 752 °F

13.9 µm/m-°C 7.72 µin/in-°F

@Temperature 20.0 - 500 °C @Temperature 68.0 - 932 °F

14.4 µm/m-°C 8.00 µin/in-°F

@Temperature 20.0 - 600 °C @Temperature 68.0 - 1110 °F

14.8 µm/m-°C 8.22 µin/in-°F

@Temperature 20.0 - 700 °C @Temperature 68.0 - 1290 °F

Specific Heat Capacity 0.486 J/g-°C 0.116 BTU/lb-°F condition unknown

@Temperature >=100 °C @Temperature >=212 °F

0.519 J/g-°C 0.124 BTU/lb-°F

@Temperature 150 - 200 °C @Temperature 302 - 392 °F

0.599 J/g-°C 0.143 BTU/lb-°F

@Temperature 350 - 400 °C @Temperature 662 - 752 °F

Thermal Conductivity 51.9 W/m-K 360 BTU-in/hr-ft²-°F Typical steel

Component Elements Metric English Comments

Properties

Carbon, C 0.17 - 0.23 % 0.17 - 0.23 %

Iron, Fe 99.08 - 99.53 % 99.08 - 99.53 % As remainder

Manganese, Mn 0.30 - 0.60 % 0.30 - 0.60 %

Phosphorus, P <= 0.040 % <= 0.040 %

Sulfur, S <= 0.050 % <= 0.050 %

References for this datasheet.

Some of the values displayed above may have been converted from their original units and/or rounded in order to

display the information in a consistent format.

Users requiring more precise data for scientific or engineering

calculations can click on the property value to see the original value as well as raw conversions to

equivalent units.

We advise that you only use the original value or one of its raw conversions in your calculations to minimize rounding

error. We also ask that you

refer to MatWeb's terms of use regarding this information.

Click here to view

all the property values for this datasheet as they were originally entered into MatWeb.

Users viewing this material also viewed the following:

AISI 1020 Steel, cold rolled

AISI 1020 Steel, hot rolled, 19-32 mm (0.75-1.25 in) round

AISI 1020 Steel, normalized at 870°C (1600°F)

AISI 1020 Steel, annealed at 870°C (1600°F)

AISI 1020 Steel, hot rolled, quenched and tempered, 0.2% offset, 19-32 mm (0.75-1.25 in) round

M1020D / 6827

Subscribe to Premium Services

Searches:

Advanced •

Composition •

Property •

Material Type •

Manufacturer •

Trade Name •

UNS Number

Other Links:

Advertising •

Submit Data •

Database Licensing •

Web Design & Hosting •

Trade Publications

Supplier List •

Unit Converter •

Reference •

Links •

Help •

Contact Us •

Site Map •

FAQ •

Home

Follow @MatWeb

Please read our License Agreement regarding materials data and our Privacy Policy.

Questions or comments about MatWeb? Please contact us at

webmaster@matweb.com. We appreciate your input.

The contents of this web site, the MatWeb logo, and "MatWeb" are Copyright 1996-2022

by MatWeb, LLC. MatWeb is intended for personal, non-commercial

use. The contents, results, and technical data from this site

may not be reproduced either electronically, photographically or substantively without permission

from MatWeb, LLC.

You might also like

- SDII SpecificationDocument8 pagesSDII SpecificationJanusz BaranekNo ratings yet

- Aluminum 1060-Data-SheetDocument2 pagesAluminum 1060-Data-SheetMaruda8382No ratings yet

- AISI 4140 Steel, Oil Quenched, 650°C (1200°F) Temper, 25 MM (1 in PDFDocument2 pagesAISI 4140 Steel, Oil Quenched, 650°C (1200°F) Temper, 25 MM (1 in PDFDiegoAlvarezHuguezNo ratings yet

- AISI 1020 Steel, As RolledDocument3 pagesAISI 1020 Steel, As Rollednum fistismNo ratings yet

- AISI 1020 Steel, Normalized at 870°C (1600°F)Document2 pagesAISI 1020 Steel, Normalized at 870°C (1600°F)Vitor GodoyNo ratings yet

- Acero Inoxidable 405, Recocido, ChapaDocument1 pageAcero Inoxidable 405, Recocido, ChapaLorena Grijalba LeónNo ratings yet

- 304 Stainless Steel Tecnical DataDocument2 pages304 Stainless Steel Tecnical DataArmando MátalNo ratings yet

- 304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless SteelDocument2 pages304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless Steeldaniel enrique romero robayoNo ratings yet

- AISI 1018 SteelDocument1 pageAISI 1018 SteelsroenschNo ratings yet

- AISI 1035 SteelDocument2 pagesAISI 1035 SteelCarlos Andres Garcia MuñozNo ratings yet

- Aisi 5140Document2 pagesAisi 5140rumabiswas853No ratings yet

- 304 Stainless SteelDocument3 pages304 Stainless Steelnum fistismNo ratings yet

- MaterialData 6937Document1 pageMaterialData 6937Cristobal Gutierrez CarrascoNo ratings yet

- MaterialData 7754Document2 pagesMaterialData 7754Joko TriwardonoNo ratings yet

- AISI 4140 Steel, Normalized at 870°C (1600°F), Air Cooled, 25 MM (1 In.) RoundDocument2 pagesAISI 4140 Steel, Normalized at 870°C (1600°F), Air Cooled, 25 MM (1 In.) RoundGiancarlo PassalacquaNo ratings yet

- Acero Inox 410 MaterialData - 12949Document2 pagesAcero Inox 410 MaterialData - 12949Arturo AguilarNo ratings yet

- AISI 4340 Steel, Oil Quenched 845°C, 650°C (1200°F) TemperDocument2 pagesAISI 4340 Steel, Oil Quenched 845°C, 650°C (1200°F) TemperDiegoAlvarezHuguezNo ratings yet

- Aluminum 5182-H34: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum AlloyDocument2 pagesAluminum 5182-H34: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum AlloyLuis BadoffNo ratings yet

- Cold Drawn PDFDocument1 pageCold Drawn PDFAna Emily PrentissNo ratings yet

- AISI 1045 Steel, Hot Rolled, 19-32 MM (0.75-1Document2 pagesAISI 1045 Steel, Hot Rolled, 19-32 MM (0.75-1diego AlvarezNo ratings yet

- AISI 1050 Steel, As RolledDocument2 pagesAISI 1050 Steel, As RolledCristobal Gutierrez CarrascoNo ratings yet

- AISI 1022 Steel, Heat Treated, Quenched From Pot, 13.7 MM RoundDocument2 pagesAISI 1022 Steel, Heat Treated, Quenched From Pot, 13.7 MM RoundygfrostNo ratings yet

- Aluminum 7175 T736Document3 pagesAluminum 7175 T736TylerLALA100% (1)

- SNI 4658-2008-Pelek Kategori LDocument4 pagesSNI 4658-2008-Pelek Kategori LDimazNugrahaNo ratings yet

- Sandvik Cuprothal 10 Resistance Wire: Metal Nonferrous Metal Copper AlloyDocument1 pageSandvik Cuprothal 10 Resistance Wire: Metal Nonferrous Metal Copper AlloyLorena Grijalba LeónNo ratings yet

- Mechanical Properties of 1020Document2 pagesMechanical Properties of 1020Abdul RahmanNo ratings yet

- AISI 1015 Steel, Cold Drawn: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Low Carbon SteelDocument3 pagesAISI 1015 Steel, Cold Drawn: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Low Carbon SteelAleesha RehanNo ratings yet

- 303-Stainless Steel-Annealed BarDocument2 pages303-Stainless Steel-Annealed BarARUNKANNANNo ratings yet

- AISI 1050 Carbon Steel Wire AlloyDocument1 pageAISI 1050 Carbon Steel Wire Alloyjuprijupri25No ratings yet

- JIS S45C Steel, Normalized: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Medium Carbon SteelDocument1 pageJIS S45C Steel, Normalized: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Medium Carbon SteelPuji RiatnoNo ratings yet

- Aluminium A380Document1 pageAluminium A380Ashokkumar VelloreNo ratings yet

- AISI 4340 Steel, Oil Quenched 800°C (1470°F), 540°C (1000°F) Temper, 50 MM (2 inDocument2 pagesAISI 4340 Steel, Oil Quenched 800°C (1470°F), 540°C (1000°F) Temper, 50 MM (2 indiego AlvarezNo ratings yet

- SUS 316 Material Properties PDFDocument1 pageSUS 316 Material Properties PDFYudo ArdianNo ratings yet

- AISI 1045 SteelDocument3 pagesAISI 1045 Steelsenthil4youNo ratings yet

- MaterialData AISI-SAE101Document2 pagesMaterialData AISI-SAE101Ian KellyNo ratings yet

- 316 Stainless Steel, Annealed SheetDocument2 pages316 Stainless Steel, Annealed SheetZASSNo ratings yet

- 316-SS-annealed Bar and Cold DrawnDocument2 pages316-SS-annealed Bar and Cold DrawnARUNKANNANNo ratings yet

- Aisi 1030 SteelDocument2 pagesAisi 1030 SteelKhairul KaiNo ratings yet

- Aluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyDocument4 pagesAluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyJhonny IDNo ratings yet

- 303-Cruicible SteelDocument2 pages303-Cruicible SteelARUNKANNANNo ratings yet

- 304Document2 pages304julianmorantesNo ratings yet

- 316L-SS-annealed Bar and Cold DrawnDocument2 pages316L-SS-annealed Bar and Cold DrawnARUNKANNANNo ratings yet

- ASM Material Data Sheet 304Document2 pagesASM Material Data Sheet 304.xNo ratings yet

- S 45 CDocument1 pageS 45 CFahmi IrmanshahNo ratings yet

- Physical Properties Metric English: @strain 2.00 % @strain 2.00 %Document1 pagePhysical Properties Metric English: @strain 2.00 % @strain 2.00 %Rahul SanjayanNo ratings yet

- ASM Material Data Sheet PDFDocument2 pagesASM Material Data Sheet PDFtiele_barcelosNo ratings yet

- Properties s45cDocument3 pagesProperties s45ctomas duranNo ratings yet

- The Online Materials Database Sandvik 254 SMO Seamless Tube and PipeDocument2 pagesThe Online Materials Database Sandvik 254 SMO Seamless Tube and PipeSukhDeolNo ratings yet

- Aluminum 2014-T6 2014-T651 (Extended Form Data) : Advertise With Matweb!Document9 pagesAluminum 2014-T6 2014-T651 (Extended Form Data) : Advertise With Matweb!vishwanadh kNo ratings yet

- AISI Type 304L Stainless Steel Material Data - 12676Document1 pageAISI Type 304L Stainless Steel Material Data - 12676Ian Pillay100% (1)

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Document2 pagesArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinNo ratings yet

- 316 Stainless Steel, Anneal...Document3 pages316 Stainless Steel, Anneal...Moisés Vázquez ToledoNo ratings yet

- ASM Material Data SheetDocument2 pagesASM Material Data Sheetducchinh080No ratings yet

- Aisi 304Document2 pagesAisi 304Rohit100% (1)

- Alloy Copper C86400Document2 pagesAlloy Copper C86400ToảnNo ratings yet

- ASM Material Data SheetDocument2 pagesASM Material Data SheetMECHA ENGINEEERINGNo ratings yet

- Electrical Characterization of Organic Electronic Materials and DevicesFrom EverandElectrical Characterization of Organic Electronic Materials and DevicesNo ratings yet

- Fourier Series and Numerical Methods for Partial Differential EquationsFrom EverandFourier Series and Numerical Methods for Partial Differential EquationsNo ratings yet

- Microwave Devices, Circuits and Subsystems for Communications EngineeringFrom EverandMicrowave Devices, Circuits and Subsystems for Communications EngineeringRating: 4 out of 5 stars4/5 (1)

- Spheroidal GraphiteDocument1 pageSpheroidal GraphiteS.Mohana sundaramNo ratings yet

- Static & Dynamic Analysis of EN 47 Leaf Spring & E-Glass Fiber With Epoxy Resin Hardner Based Unidirection Laminated Composite Leaf SpringDocument6 pagesStatic & Dynamic Analysis of EN 47 Leaf Spring & E-Glass Fiber With Epoxy Resin Hardner Based Unidirection Laminated Composite Leaf SpringS.Mohana sundaramNo ratings yet

- Poisson's RatioDocument2 pagesPoisson's RatioS.Mohana sundaramNo ratings yet

- Nylon 6 - 6 - Plastic ProductsDocument3 pagesNylon 6 - 6 - Plastic ProductsS.Mohana sundaramNo ratings yet

- 918-Article Text-4053-1-10-20220108Document14 pages918-Article Text-4053-1-10-20220108S.Mohana sundaramNo ratings yet

- How Coatings Can Maximize Rolling Bearing Performance - Processing MagazineDocument14 pagesHow Coatings Can Maximize Rolling Bearing Performance - Processing MagazineS.Mohana sundaramNo ratings yet

- Analyze Contact Patterns For Uav Helicopter Transmission in Prototype TrialsDocument4 pagesAnalyze Contact Patterns For Uav Helicopter Transmission in Prototype TrialsS.Mohana sundaramNo ratings yet

- Material Properties of UHMW Polyethylene - ThermoplasticDocument4 pagesMaterial Properties of UHMW Polyethylene - ThermoplasticS.Mohana sundaramNo ratings yet

- Dimensionprogram Hardox 500tufDocument1 pageDimensionprogram Hardox 500tufS.Mohana sundaramNo ratings yet

- The Effect of Coating Thickness On Fatigue Properties of Steel Thermally Sprayed With Ni-Based Self-Fluxing AlloyDocument2 pagesThe Effect of Coating Thickness On Fatigue Properties of Steel Thermally Sprayed With Ni-Based Self-Fluxing AlloyS.Mohana sundaramNo ratings yet

- Coating Applications - Thermal Spray SocietyDocument4 pagesCoating Applications - Thermal Spray SocietyS.Mohana sundaramNo ratings yet

- Steel Chart - EN Series Steel Chart - Chemical Analysis & SpecificationsDocument3 pagesSteel Chart - EN Series Steel Chart - Chemical Analysis & SpecificationsS.Mohana sundaramNo ratings yet

- What Is A Post Weld Heat Treatment (PWHT) - Definition From CorrosionpediaDocument8 pagesWhat Is A Post Weld Heat Treatment (PWHT) - Definition From CorrosionpediaS.Mohana sundaramNo ratings yet

- 304 SS Grade SS 304Document3 pages304 SS Grade SS 304S.Mohana sundaramNo ratings yet

- Metals 08 00026Document13 pagesMetals 08 00026S.Mohana sundaramNo ratings yet

- Modelling The Meshing of Cycloidal GearsDocument4 pagesModelling The Meshing of Cycloidal GearsS.Mohana sundaramNo ratings yet

- Piano - Grade 3: Digital Grades: Technical WorkDocument1 pagePiano - Grade 3: Digital Grades: Technical WorkOpera Music CenterNo ratings yet

- Tire Size ChartDocument1 pageTire Size ChartdikidarmawanNo ratings yet

- P605 Manual - Book No. 577460-02 Rev.4Document180 pagesP605 Manual - Book No. 577460-02 Rev.4Eu UrsanuNo ratings yet

- Electric Charges and Fields 2ndPUC PYQsDocument2 pagesElectric Charges and Fields 2ndPUC PYQsXyzzNo ratings yet

- Analisis Sistem Usaha Tani Lidah BuayaDocument17 pagesAnalisis Sistem Usaha Tani Lidah BuayaSusyana IrianiNo ratings yet

- Handout 1844 AC1844 Introduction To Animation in AutoCAD 2012 Class HandoutDocument25 pagesHandout 1844 AC1844 Introduction To Animation in AutoCAD 2012 Class HandoutBahrul AliemNo ratings yet

- Linux and Bash Command Cheat Sheet - The BasicsDocument1 pageLinux and Bash Command Cheat Sheet - The BasicsAssil BouazizNo ratings yet

- How To Solve Blow Molding Problems PDFDocument24 pagesHow To Solve Blow Molding Problems PDFaleskytron100% (2)

- 4.2 Compound CylinderDocument5 pages4.2 Compound CylinderMohamad Amir HaziqNo ratings yet

- Correlation Between The Standard PenetrationDocument64 pagesCorrelation Between The Standard PenetrationDavid GurionNo ratings yet

- InstallDocument3 pagesInstallrenatoengenheiro184No ratings yet

- Global Mean and Standard Deviation: Year Mathematics Physics ChemistryDocument4 pagesGlobal Mean and Standard Deviation: Year Mathematics Physics ChemistryMelbinGeorgeNo ratings yet

- TWMC Price BookDocument221 pagesTWMC Price BookleelsNo ratings yet

- Book List For ParamaDocument6 pagesBook List For ParamaShafayet UddinNo ratings yet

- CableDocument12 pagesCableAbhijit PatilNo ratings yet

- Referat Engleza FandacheDocument10 pagesReferat Engleza FandacheLoredana CondreaNo ratings yet

- Technical Service Bulletin: ConditionDocument4 pagesTechnical Service Bulletin: ConditionAndres AvilaNo ratings yet

- Assigment Sheet Tast 2 Aina MardianaDocument10 pagesAssigment Sheet Tast 2 Aina MardianaAina MardianaNo ratings yet

- Proposal ETPDocument4 pagesProposal ETPBanerjee SuvranilNo ratings yet

- StrainGauges E1007ADocument92 pagesStrainGauges E1007AChristian Milenius TambunanNo ratings yet

- Evolution of The FIX EngineDocument2 pagesEvolution of The FIX Enginetmh115No ratings yet

- SMA - Module 2 (B)Document147 pagesSMA - Module 2 (B)Jessica GonsalvesNo ratings yet

- Quantitative Chapter 1 - Simple EquationDocument10 pagesQuantitative Chapter 1 - Simple EquationSWAGATAM BAZNo ratings yet

- Heat PinchDocument6 pagesHeat PinchYeeXuan TenNo ratings yet

- Test Report For Synchronous MachinesDocument60 pagesTest Report For Synchronous MachinesMaria MarcanoNo ratings yet

- Nta 855G Series PDFDocument4 pagesNta 855G Series PDFcalebwpbNo ratings yet

- APC Back-UPS 1000VA Without Battery With Selectable Charger and Flooded/SMF Compatible, 230V, IndiaDocument2 pagesAPC Back-UPS 1000VA Without Battery With Selectable Charger and Flooded/SMF Compatible, 230V, Indiaraj rajNo ratings yet

- Creative Media 17-06 PDFDocument21 pagesCreative Media 17-06 PDFsinduja.cseNo ratings yet