Professional Documents

Culture Documents

AGS2004 Rockatthecoringinterfacae

AGS2004 Rockatthecoringinterfacae

Uploaded by

hylmiapCopyright:

Available Formats

You might also like

- Astm D979-12 PDFDocument3 pagesAstm D979-12 PDFErwinBascon100% (1)

- Charger CatalogueDocument16 pagesCharger CatalogueNguyen Quang Sang0% (1)

- Hardness TestDocument8 pagesHardness TestEmanuel Calvin100% (1)

- Issues in Evaluating Capacity of Rock Socket Foundations KULHAWY and PRAKOSODocument11 pagesIssues in Evaluating Capacity of Rock Socket Foundations KULHAWY and PRAKOSOErisvaldo de LimaNo ratings yet

- Issues in Evaluating Capacity of Rock Socket FoundationsDocument11 pagesIssues in Evaluating Capacity of Rock Socket FoundationspaducoNo ratings yet

- Correlation Between Point Load Index and Very Low Uniaxial Compressive Strength of Some Iraqi RocksDocument14 pagesCorrelation Between Point Load Index and Very Low Uniaxial Compressive Strength of Some Iraqi RocksGbenga AdewumiNo ratings yet

- Using The Point Load Test To Determine The Uniaxial Compressive Strength of Coal Measure RockDocument10 pagesUsing The Point Load Test To Determine The Uniaxial Compressive Strength of Coal Measure RockgbutulescuNo ratings yet

- Using Point Load Test To Determine Uniaxial STR of Coal Meassure RockDocument10 pagesUsing Point Load Test To Determine Uniaxial STR of Coal Meassure RockScott Downs0% (1)

- Classifications WeakRockDocument13 pagesClassifications WeakRockrahulgeo05No ratings yet

- Predicting Uniaxial Compressive Strength by Point Load Test - Significance of Cone PenetrationDocument8 pagesPredicting Uniaxial Compressive Strength by Point Load Test - Significance of Cone PenetrationLucas Francisco Contreras TorresNo ratings yet

- Rock Strength As A Metric of Welding Intensity in Pyroclastic DepositsDocument10 pagesRock Strength As A Metric of Welding Intensity in Pyroclastic DepositsalgifarieidzamNo ratings yet

- Rock Mass Properties For Underground MinesDocument20 pagesRock Mass Properties For Underground MinesJuanPerezRooneyNo ratings yet

- Shear Strength of Rockfill Interfaces and Rock JoiDocument17 pagesShear Strength of Rockfill Interfaces and Rock JoiAlexandre RibeiroNo ratings yet

- The Influence of Core Sample Geometry On The Axial Point-Load TestDocument5 pagesThe Influence of Core Sample Geometry On The Axial Point-Load TestalgifarieidzamNo ratings yet

- Cai2014In SituRockSpallingStrengthnearExcavationBoundaries FinalDocument18 pagesCai2014In SituRockSpallingStrengthnearExcavationBoundaries FinalTemka dayanNo ratings yet

- Evaluation of Capacity of Rock Foundation Sockets KULHAWY AND PRAKOSO PDFDocument8 pagesEvaluation of Capacity of Rock Foundation Sockets KULHAWY AND PRAKOSO PDFErisvaldo de LimaNo ratings yet

- Index Properties of Intact RockDocument12 pagesIndex Properties of Intact RockChidi HenryNo ratings yet

- Grupo 1 Lessons Learned Using Empirical Methods Applied in Mining PDFDocument26 pagesGrupo 1 Lessons Learned Using Empirical Methods Applied in Mining PDFFidel Angel CercedoNo ratings yet

- Shear Strength of Rockfill Interfaces and Rock JointsDocument17 pagesShear Strength of Rockfill Interfaces and Rock Jointsakhila sNo ratings yet

- A Critical State Approach To Stability of Clay Shale For deDocument7 pagesA Critical State Approach To Stability of Clay Shale For derullyirwandiNo ratings yet

- GR0Document22 pagesGR0Madhavi Latha GaliNo ratings yet

- Ebs CohostDocument60 pagesEbs CohostGustavo RiosNo ratings yet

- Shear Strength of Rockfill Interfaces and Rock JoiDocument17 pagesShear Strength of Rockfill Interfaces and Rock JoiRodrigo De MeloNo ratings yet

- Shear Strength of Rockfill Interfaces and Rock JoiDocument16 pagesShear Strength of Rockfill Interfaces and Rock JoiDaniel MoravanskýNo ratings yet

- Cai-Kaiser2014 Article In-situRockSpallingStrengthNeaDocument17 pagesCai-Kaiser2014 Article In-situRockSpallingStrengthNeaJosé Vivanco NúñezNo ratings yet

- Practical Estimates of Rock Mass Strength 97Document24 pagesPractical Estimates of Rock Mass Strength 97Emanuel NicolásNo ratings yet

- Rock Mass Properties For Underground MinesDocument21 pagesRock Mass Properties For Underground Minesrobbyon100% (1)

- Strength Criterion For Rocks Under Compress - 2015 - Journal of Rock Mechanics ADocument6 pagesStrength Criterion For Rocks Under Compress - 2015 - Journal of Rock Mechanics ASEDIMNo ratings yet

- Interpretation of Ucs Test Results For Engineering Design: R. P. BewickDocument14 pagesInterpretation of Ucs Test Results For Engineering Design: R. P. BewickLuna RamirezNo ratings yet

- Friction Capacity of SoilDocument8 pagesFriction Capacity of SoilkushaljpNo ratings yet

- A New Approach To Estimate Side Resistance of Rock Socketed Drilled ShaftsDocument7 pagesA New Approach To Estimate Side Resistance of Rock Socketed Drilled Shafts樱满恋No ratings yet

- SCC Met SyllabusDocument9 pagesSCC Met SyllabusBoago KeofetlhileNo ratings yet

- Prediction of Rock Strength Using Drilling Data and Sonic LogsDocument4 pagesPrediction of Rock Strength Using Drilling Data and Sonic Logsziani1976No ratings yet

- Lee Et Al 2010 - Colour - Stresses in The Australian Tectonic Plate - Va...Document16 pagesLee Et Al 2010 - Colour - Stresses in The Australian Tectonic Plate - Va...Boris Leal MartinezNo ratings yet

- A Complement Gae 2011Document22 pagesA Complement Gae 2011AkshatshuklaNo ratings yet

- In SituNormalStiffnessofRockMassDocument8 pagesIn SituNormalStiffnessofRockMassSonal GeotechNo ratings yet

- Comparison - of - Strength-Based - Rock - Brittleness - Indi - Krehkosť Hornín Z UCS - DôležitéDocument8 pagesComparison - of - Strength-Based - Rock - Brittleness - Indi - Krehkosť Hornín Z UCS - DôležitéDaniel MoravanskýNo ratings yet

- Prone To Rock BurstingDocument8 pagesProne To Rock BurstingJoffy LouisNo ratings yet

- Chapter 11 of Rock Mass PropertiesDocument43 pagesChapter 11 of Rock Mass PropertiesJosé Luis Illanes100% (1)

- Kriteria Desain TunnelDocument18 pagesKriteria Desain TunnelgrahazenNo ratings yet

- Bewick Is RM 521Document15 pagesBewick Is RM 521Jacky_LEOLEONo ratings yet

- Rock Blasting 11Document29 pagesRock Blasting 11Alvaro Andres Bustamante Montenegro100% (1)

- Chapter 6 - Foundation in RockDocument52 pagesChapter 6 - Foundation in RockKoh Jia Jie100% (1)

- Drillability of FormationsDocument7 pagesDrillability of Formationsdrilling moneytreeNo ratings yet

- Strength Properties of Rock As An Index of BlastabilityDocument17 pagesStrength Properties of Rock As An Index of BlastabilityorazabilNo ratings yet

- 2017GeoOttawa Cu-SPTDocument9 pages2017GeoOttawa Cu-SPTAndrew WinnerNo ratings yet

- Deformability and Strength Parameters of RockmassDocument25 pagesDeformability and Strength Parameters of RockmassNadim527No ratings yet

- Stability Analysis of Tunnel OpeningsDocument11 pagesStability Analysis of Tunnel OpeningsBhaskar ReddyNo ratings yet

- Intact Rock StrengthDocument30 pagesIntact Rock StrengthMalik RizwanNo ratings yet

- Strength of Hard Rock PillarsDocument8 pagesStrength of Hard Rock PillarsArturo Pedro Salgado Medina100% (1)

- Shear Strength of Rockfill, Interfaces and Rock Joints, and Their Points of Contact in Rock Dump DesignDocument15 pagesShear Strength of Rockfill, Interfaces and Rock Joints, and Their Points of Contact in Rock Dump DesignThomas LawsonNo ratings yet

- 2017GeoOttawa Cu SPTDocument9 pages2017GeoOttawa Cu SPTAndresGarciaNo ratings yet

- RMR, Q, GsiDocument22 pagesRMR, Q, GsiSsasemUntNo ratings yet

- Lithospheric DiscontinuitiesFrom EverandLithospheric DiscontinuitiesHuaiyu YuanNo ratings yet

- Fault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureFrom EverandFault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureMarion Y. ThomasNo ratings yet

- Subduction Dynamics: From Mantle Flow to Mega DisastersFrom EverandSubduction Dynamics: From Mantle Flow to Mega DisastersGabriele MorraNo ratings yet

- X-ray Absorption Spectroscopy for the Chemical and Materials SciencesFrom EverandX-ray Absorption Spectroscopy for the Chemical and Materials SciencesNo ratings yet

- Atlas of Structural Geological Interpretation from Seismic ImagesFrom EverandAtlas of Structural Geological Interpretation from Seismic ImagesAchyuta Ayan MisraNo ratings yet

- Fluid Dynamics in Complex Fractured-Porous SystemsFrom EverandFluid Dynamics in Complex Fractured-Porous SystemsBoris FaybishenkoNo ratings yet

- (Book-2009) Shovel-Truck Systems Modelling, Analysis and CalculationsDocument170 pages(Book-2009) Shovel-Truck Systems Modelling, Analysis and Calculationsbqiushi67% (3)

- Wind TurbineDocument8 pagesWind TurbineDennyy IttyNo ratings yet

- Catalogo Jokab Safety - RTDocument18 pagesCatalogo Jokab Safety - RTDavid ZacariasNo ratings yet

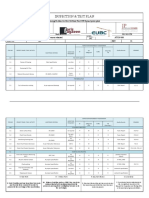

- Inspection & Test PlanDocument2 pagesInspection & Test PlanKhaled GamalNo ratings yet

- Agreed Site Measurement RecordDocument40 pagesAgreed Site Measurement Recordලහිරු විතානාච්චිNo ratings yet

- Trenchless Technologies ManualDocument186 pagesTrenchless Technologies ManualLuis Fernando Leon Lecca100% (1)

- AYC IC & ITP - GRP Shade InstallationDocument7 pagesAYC IC & ITP - GRP Shade Installationmoytabura96No ratings yet

- MOVIROLL&MOVICARTDocument23 pagesMOVIROLL&MOVICARTMoutaz IsmailNo ratings yet

- Lexus: U.S. ApplicationsDocument6 pagesLexus: U.S. ApplicationsEdixo ReyesNo ratings yet

- Amateur Radio Band Plan - Ham RadioDocument2 pagesAmateur Radio Band Plan - Ham Radiosherm77100% (1)

- STAMFORD Parts Manual Issue 13Document168 pagesSTAMFORD Parts Manual Issue 13Anonymous 4IAJBGeX100% (2)

- Comparison of Cryogenic Flow Boiling in Liquid Nitrogen and Liquid Hydrogen Chilldown ExperimentsDocument12 pagesComparison of Cryogenic Flow Boiling in Liquid Nitrogen and Liquid Hydrogen Chilldown Experimentsnewrajasingh100% (1)

- Comparison of Properties of Ionic and Covalent CompoundsDocument77 pagesComparison of Properties of Ionic and Covalent CompoundsDharlineNo ratings yet

- HP2 - Ra13Document174 pagesHP2 - Ra13YCE 2011No ratings yet

- DatasheetDocument2 pagesDatasheetMichael WongNo ratings yet

- DH DVR510451085116CDocument1 pageDH DVR510451085116CLuis SalazarNo ratings yet

- Dokumen - Tips - Piping Stress Analysis Design BasisDocument38 pagesDokumen - Tips - Piping Stress Analysis Design BasisDan PastorNo ratings yet

- Cargador 862 IIDocument2 pagesCargador 862 IIxvrspeedyNo ratings yet

- Bootstrap 4 Cheat Sheet 10v400 Alpha6Document12 pagesBootstrap 4 Cheat Sheet 10v400 Alpha6hero100% (1)

- 3600CE ManualDocument92 pages3600CE Manualيوسف عامرNo ratings yet

- 3D Printing by Zamir ShaikhDocument12 pages3D Printing by Zamir ShaikhPrince ZamerNo ratings yet

- Introduction To CDIODocument75 pagesIntroduction To CDIOJoselyn KarinaNo ratings yet

- "Racing in Their Blood" Ch. 6 ExcerptDocument45 pages"Racing in Their Blood" Ch. 6 ExcerptBentley Publishers100% (2)

- vnx.su дачия 1304-1305-1307 пикап ENGINE-F8QDocument620 pagesvnx.su дачия 1304-1305-1307 пикап ENGINE-F8Qcvn2No ratings yet

- Bob 1.0.1 Vulnhub WalkthroughDocument17 pagesBob 1.0.1 Vulnhub WalkthroughhexoNo ratings yet

- Sorento 2003 Steering - Electronic PwrSteeringDocument3 pagesSorento 2003 Steering - Electronic PwrSteeringHerowan YumaNo ratings yet

- 3D Printing SeminarDocument19 pages3D Printing SeminarManoj gowda kNo ratings yet

AGS2004 Rockatthecoringinterfacae

AGS2004 Rockatthecoringinterfacae

Uploaded by

hylmiapOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AGS2004 Rockatthecoringinterfacae

AGS2004 Rockatthecoringinterfacae

Uploaded by

hylmiapCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/297961662

Rock strength at the coring interface

Article · June 2004

CITATIONS READS

3 18,588

1 author:

Burt Look

Foundation Specialist Group

71 PUBLICATIONS 200 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Rapid and Direct Assessment of Bearing Capacity via Light Falling Weight Deflectomer View project

All content following this page was uploaded by Burt Look on 11 June 2017.

The user has requested enhancement of the downloaded file.

ROCK STRENGTH AT THE CORING INTERFACE

Burt Look

Connell Wagner Pty Ltd, Brisbane, Australia

ABSTRACT

Boreholes in rock usually involve drilling to practical tungsten carbide bit refusal and then changing the drilling

technique to rock coring. Often this change is used as an indication of a change in rock weathering or strength. Before

the commencement of rock coring the SPT result would typically be to refusal. After obtaining the rock core, point

load index tests are used to classify the rock strength. This paper examines the validity of the usual assumption of a

change in rock property at this drilling interface. The results show that a drilling interface does not necessarily translate

into a geological interface or change in rock properties. The current definition of SPT refusal level in rock is shown to

be inadequate, and the strength interpretation of such tests in rock is dependent on the rock type and defects of the rock.

1 INTRODUCTION

The Standard Penetration Tests (SPT) is discontinued when a total of 30 blows cause less than 100 mm penetration or

no measurable penetration occurs (Australian Standards, 1993). The limitations of stopping the SPT at 30 blows in the

seating drive for rock material was discussed in Look (1997). The commencement of rock coring occurs shortly after

SPT refusal and practical tungsten carbide bit refusal. Many borehole reports show a “jump” in classification at the

interface as the change in drilling technique to rock coring is often viewed as also a change in classification, e.g.

Extremely Weathered (XW) to Distinctly Weathered (DW) or very low strength to medium strength, etc.

While there is some dependence on the drilling rig and drilling techniques used, nature does not usually have a

pronounced transition for the same geological material unit. For the same material there is a transition from one zone

to another rather than the line on the borelog, which represents a geological model rather than a geological reality. The

drilling supervisor can provide a more accurate description from the rock core rather than the SPT sample or non-cored

drilling just above, especially if wash boring techniques are being used to advance the boreholes. Therefore the material

just above the start of coring is conservatively assumed to be a weaker grade of material. This is an implicit assumption

in many borelogs produced. Rock core samples are then used to carry out the visual strength classification, point load

index testing and other types of testing.

In some instances rock coring is not carried out and drilling is stopped at SPT or drilling refusal. This paper therefore

examines the more reliable rock core test results and compares with the SPT results near that interface with the aim to:

• Assess if the usually inferred change in rock strength does occur at that drilling interface i.e. is drilling interface =

geological interface and

• Determine the relationship between SPT values and rock strength.

2 BACKGROUND CONSIDERATIONS

Clayton (1995) provides the following relationship between the unconfined compressive strength (UCS) and the

corrected SPT value (N60) for weak rocks.

UCS ≥ 10 N60 (kPa) (1)

Broch and Franklin (1972) describe the point load index test and provided empirical relationships between the index

and uniaxial compressive strength (Equation 2). Broch and Franklin (1972) also recommend the strength classification

from extremely low to very high based on the point load index testing, and this classification has been adopted in the

Australian Standards (1993) for Geotechnical Site Investigations.

UCS = 24 Is(50) (2)

Therefore, if Equations 1 and 2 were valid, then one would expect

Is(50) ≥ 10 /24 N60 (kPa) = 0.4 N60 (kPa) or 0.4 * 10 -3 N60 (MPa) (3)

When tested for reasonableness then some values seem unrealistic. Only the “greater than” part of the equation

provides some comfort to the values obtained. For example:

Australian Geomechanics Vol 39 No 2 June 2004 105

ROCK STRENGTH AT THE CORING INTERFACE B LOOK

• A very low strength rock (Is(50) = 0.03 to 0.1 MPa) requiring an SPT in the range 72 to 240 seems reasonable,

however,

• A high strength rock (Is(50) > 1.0 MPa) requiring an N value of 2400 seems unreasonable.

Look and Griffiths (2001 and 2004) have shown that UCS / Is(50) ratio of 5 to 17 generally applies for the rocks in

South East Queensland and that data at the rock drilling interface was extended to incorporate the SPT N value used in

this analysis. Therefore, assuming Equation 1 is still valid and using the local data, then Table 1 provides the

corresponding relationships for the rocks in South East Queensland.

Table 1: Strength relationships between various tests.

Rock Type UCS - Is(50) Is(50) - N60 (MPa) Strength Classification from Is(50) values

ratio relationship derived from SPT N Values

100 200 400

From the Standard Ratio 24 I s (50) > 0.4 * 10 –3N60 (V. Low +) (Low +)

General (Brisbane rocks) 11* I s (50) > 0.9 * 10 -3 N60 (V. Low +) (Low +) (Medium +)

Tuff 18 I s (50) > 0.6* 10 -3 N60 (V. Low +) (Low +)

Phyllite 5 I s (50) > 2.0 * 10 -3 N60 (Low +) (Medium +)

Greywacke / Argillites 8 I s (50) > 1.2 * 10 -3 N60 (Low +) (Medium +)

* Varies from 12 to 9 for the Is(50) values in the axial and diametral direction, respectively

Table 1 is based on the assumption of the validity of Equation 1. This is subsequently shown to be invalid. Table 1

however serves to highlight that different rock types would have different strength implications for the same SPT value

e.g. an SPT of 400 could be a medium strength phyllite but a low strength Tuff. Note that even with an N value of 400

(usually inferred), a high strength rock has not been achieved using Equation 1, and in the case of the standard 24 ratio

usually applied, the rock is still low strength to even an N value of 700.

3 DATA ANALYSIS

Data from sites in the South East and central Queensland region, described in Look and Griffiths (2001 and 2004), have

been tabulated to assess any relationship between the point load index strengths and the standard penetration tests. The

inferred SPT was used by directly converting to a 300 mm standard penetration and the Is(50) data within 1 metre of the

SPT refusal was tabulated. The total relevant 89 data points from the 150 boreholes initially tabulated covered the

following rock types:

• Sandstones / Siltstones (19 data points)

• Tuff (10 data points)

• Phyllites (16 data points)

• Greywackes / Argillites (38 data points)

• Conglomerate (5 data points)

• Mudstone (1 data point)

The latter 2 rock types were generally excluded as insufficient data in the analysis of rock type trends or showed up as

outliers in the trend analysis. The rock weathering on which the point load testing was carried out was predominantly

Distinctly Weathered (DW) but 17 of the data points were Slightly Weathered (SW). In almost all cases the SPT refusal

rock just above was classified as a weathering grade lower. In many cases the classification was Highly Weathered

(HW) before the start of coring and Moderately Weathered (MW) for the cored samples. In order to establish trends the

data was sorted into:

• Defects

• Rock Types

• SPT N Values ranges

The analysis process involved starting with the total number of data points and progressively removing outliers until a

reasonable regression correlation was obtained. In many of the Tables below the strength range and SPT values have

been extrapolated nominally beyond the data points for completeness only.

3.1 DEFECTS

When considering the effects of defects on the rock strength, the linear trend analysis resulted in a very poor correlation.

Improved (but only marginally OK) correlation was obtained with exponential trends. Figure 1 shows all the 89 data

106 Australian Geomechanics Vol 39 No 2 June 2004

ROCK STRENGTH AT THE CORING INTERFACE B LOOK

points with 19 and 70 data point for defects less than or equal to 60 mm and greater than 60 mm, respectively. These

relationships are not considered meaningful.

4

3.5

Point Load Index (MPa)

3

2.5

2

1.5 y = 0.467e0.002x y = 0.441e0.001x

2

R = 0.028 (> 60mm) R2 = 0.016

1 (All Values)

0.5 y = 0.273e0.001x

R2 = 0.025 (< = 60mm)

0

0 100 200 300 400 500 600 700

Inferred SPT N - Value

< = 60mm > 60 mm Expon. (< = 60mm) Expon. (> 60 mm) Expon. (All Vallues)

Figure 1: Effect of Defects on N Value (No of points = 89).

3

Point Load Index (MPa)

2.5 y = 0.086e

0.010x

2

R = 0.336 (< = 60mm)

2

0.006x

y = 0.241e

1.5 2

R = 0.143

(All Values)

1

0.004x

y = 0.316e

0.5 2

R = 0.110 (> 60mm)

0

0 100 200 300 400

Inferred SPT N - Value

< = 60mm > 60 mm Expon. (< = 60mm)

Expon. (> 60 mm) Expon. (All Vallues)

Figure 2: Effect of Defects on N Value (No of points = 73 with outliers removed).

When the outlier points are removed the relationship improves significantly (Figure 2). Where the defects are less than

60 mm the correlation begin to show some meaningful relationship. Conversely when defects are greater than 60 mm

the correlation is weak. Table 2 provides the strength classification evident from this relationship. The approximate

UCS / N value ratio based on the general UCS / Is(50) ratio in Table 1 is also shown.

Australian Geomechanics Vol 39 No 2 June 2004 107

ROCK STRENGTH AT THE CORING INTERFACE B LOOK

Table 2: Rock Strength assessment from the SPT N Value (simplified)

Strength Is(50) SPT N Value Approximate UCS (kPa) / N

(MPa) Defects <= 60 Defects > 60 Defects <= 60 Defects > 60

(mm) (mm) (mm) (mm)

Extremely Low to Low < 0.3 < 125 < 300 25

40

Medium 0.3 – 1.0 125 – 250 25 to 45

High 1.0 – 3.0 250 – 350 300 – 550 45 – 95 40 – 60

Very to Extremely High > 3.0 > 350 > 550 95 60

This is for all rock types examined in this analysis, and N values above 350 have been extrapolated beyond the data

points shown. This limitation should be kept in mind.

3.2 ROCK TYPES

When the data is sorted into the various rock types, the limited data shows that any SPT value in tuff should be

disregarded, as a negative relationship is evident (Figure 3). This may suggest that at the drilling interface where this

data was obtained that some significant change in rock properties could be occurring. This correlates with the general

observation that the tuff has less of a weathering profile. The SPT in sandstone / siltstone provides the best correlation

for the rock types in this analysis. Table 2 can then be refined for the various rock types as shown in Table 3. Note that

this provides a picture different from the previous SPT values used for strength based on defects only.

Table 3: Rock Strength assessment from the SPT N Value for various rock types (simplified).

Strength Is(50) Value SPT N Value

(MPa) Phyllite Sandstones / Greywacke / Tuff

Siltstones Argillites

Extremely Low to Low < 0.3 < 100

< 100 < 200

Medium 0.3 – 1.0 100 – 200 No

High 1.0 – 3.0 100 – 200 200 – 300 200 – 500 Relationship

Very to Extremely High > 3.0 > 200 > 300 > 500

Table 3 also shows that the relationships of Table 1 would be generally incorrect by a factor of 4 to 5 and by an order of

magnitude for Equation 3. This data does not agree with Equation 1. Using local relationships of Table 3 then

Equation 1 may be valid for extremely low to low strength values only i.e. UCS less than 3 MPa. Above this value the

exponential nature of the trend line shows the estimation of UCS from a linear relationship would be significantly

underestimated. The approximate UCS / N value ratio based on the UCS / Is(50) ratio for the various rock types

provided in Table 1 is shown in Table 4.

The summary results of Table 3 should be read with the understanding of the limitations summarized in Table 5. The

outlier points were progressively removed until an “optimum” relationship was obtained. In the case of the tuff, the

removal of any outlier points resulted in a further decrease in the strength of the relationship. The approximate

percentage of points neglected provides an indication of the reliability of typical data obtained.

Table 4: UCS / SPT N Value ratio for various rock types (simplified).

Strength Is(50) Approximate UCS (kPa) / N

(MPa) Phyllite Sandstones / Greywacke / Argillites

Siltstones

Extremely Low to Low < 0.3 30

50 40

Medium 0.3 – 1.0 30 – 50

High 1.0 – 3.0 50 – 75 50 – 100 40 – 50

Very to Extremely High > 3.0 75 100 50

Table 5: Limitation of data set used in the Rock Strength assessment for various rock types.

SPT N Value

Data Used Phyllite Sandstones Greywacke / Tuff

Argillites

Total Number of Points 16 19 38 10

Data Points with outliers removed 12 17 22 10

% Neglected 25% 10% 40% 100%

108 Australian Geomechanics Vol 39 No 2 June 2004

ROCK STRENGTH AT THE CORING INTERFACE B LOOK

2.5

Point Load Index (MPa)

y = 0.34e 0 .0 1x

2 R2 = 0.43 Phy llite

1.5 y = 0.394e 0 .00 4 x

R2 = 0.328 Grey /A rg

y = 0.12e 0 .01 x

1 R2 = 0.45 Sands tone

0.5

y = 1.04e -0 .0 2 x

0 R2 = 0.09 Tuf f

0 100 200 300 400

Inferred SPT N- Value

Sands tones Grey w ac kes /A rgillites

Phy llites Tuf f

Ex pon. (Sands tones ) Ex pon. (Grey w ac kes /A rgillites )

Ex pon. (Phy llites ) Ex pon. (Tuf f )

Figure 3: Effect of Rock Types on N Value (No of points = 65 with outliers removed).

3.3 SPT N VALUES

Figure 4 shows the SPT data sorted with all values and then with the outliers removed. The data is then sorted into SPT

values less than 100, greater than 100 and greater than 120. This data shows that SPT N values less than 100 have little

relevance in terms of its relationship to strength data. SPT N values above 120 are generally 12 times much more

reliable than N values less than 100.

The regression correlation coefficient of 0.44 suggests that there is a high degree of scatter of results even after

removing the obvious outliers. This may be due to the following factors:

• The Is(50) test represents an intact strength (undisturbed) while the SPT produces a disturbed test.

• The Is(50) results represent both axial and diametral results

The results suggest that in order to use the SPT values with confidence the strength classification should be known

before. This seems to be contradictory as the intent is to use the SPT result to obtain the strength classification.

However there are instances when rock core samples are available to suggest the strength classification and additional

data from the SPT can then be used to refine the design.

4 CONCLUSIONS

Data from various geotechnical reports in different rock type in south east Qυeensland was analysed to show:

• An SPT value in rock has little engineering significance unless qualified in terms of the rock type, defects or a

prior knowledge of the rock strength classification. For example an SPT of 200 could mean a medium strength

rock with defects less than 60 mm or a low strength rock with defects greater than 60 mm. The value of 200

could also indicate a high strength phyllite or a low strength greywacke.

• SPT values are most reliable in the sandstone and siltstone and meaningless in tuff. This may indicate that for

tuff there is a sudden change in rock strength / weathering with drilling technique change, while for the other

rock types the change is a more gradual transition.

Australian Geomechanics Vol 39 No 2 June 2004 109

ROCK STRENGTH AT THE CORING INTERFACE B LOOK

2.5

y = 0.23 2e 0.009x

Point Load Index (MPa)

R 2 = 0 .0 37

N < 10 0 y = 0.270e 0.0 04 x y = 0.14e 0 .0 1x

2 R2 = 0.147 R2 = 0.44

N > 100 N > 120

1.5

y = 0.318e 0 .0 0 3x

R2 = 0.073

1 A ll - outiers remov ed

y = 0.438e 0.0 01 x

0.5 R2 = 0.017

A ll V alues

0

0 100 200 300 400

Inferred S P T N - V alue

A ll V alues A ll V alues - Outliers Remov ed

N < 100 N > 100

N > 120 Ex pon. (N < 100)

Ex pon. (A ll V alues ) Ex pon. (A ll V alues - Outliers Remov ed)

Ex pon. (N < 100) Ex pon. (N > 100)

Ex pon. (N > 120)

Figure 4: Reliability of SPT N Values (No of points = 71 with outliers removed).

• When the relationship of UCS ≥ 10 N60 (kPa) is used with UCS = 24 Is(50), meaningless values result at higher

values due to the exponential fit trend lines. Local relationships provided more meaningful results, but only for

rocks classified as low strength and would fit only a lower bound line for the data used herein. Therefore when

used with local UCS / Is(50) ratios the following relationships were more applicable and avoid the errors

associated with a simple linear extrapolation of one trend line

UCS ≥ 20 N60 (kPa) extremely low to low strength rocks (SPT < 200),

UCS ≥ 30 N60 (kPa) medium strength rocks,

UCS ≥ 40 N60 (kPa)… high strength rocks (SPT > 200)

UCS ≥ 50 N60 (kPa)… very to extremely high strength rocks

This seems to be contradictory, as the intent is to use the SPT result to obtain the strength classification. This

means that to be useful in design the rock cores must first be suitably classified in terms of strength before being

able to use the numerical SPT value in design. Due to the method of derivation the above relationship provides

the intact rock strength UCS value while the SPT N value represents a disturbed value.

• The data showed that an inferred SPT extrapolation less than 100 had little relevance to strength for engineering

design and only values above 120 show some correlation with strength. To be relevant the SPT refusal in rock

should therefore be defined as 40 blows / 100 mm penetration in the test drive. This is higher than the Australian

Standard of 30 blows / 100 mm penetration at any stage of the drive, i.e. seating or test drive.

5 REFERENCES

Clayton, C.R.I. (1995), “The Standard Penetration Test (SPT): Methods and Use “ CIRIA Report 143

Broch, E.M. and Franklin, JA (1972) “The Point Load Strength Test”, International Journal of Rock Mechanics and

Mineral Science, Volume 9: pp 669 – 697

Look, B.G. (1997), “The Standard Penetration Test Procedure in Soil Rock” Australian Geomechanics Journal,

Canberra, Vol. 32, pp 66-68.

Look, B.G. and Griffiths, S.G. (2001), “An engineering assessment of the strength and deformation properties of

Brisbane rocks,” Australian Geomechanics Journal, Canberra, Vol. 36, No. 3, pp 17-30.

Look, B.G. and Griffiths, S.G. (2004), “Rock Strength properties in south east Queensland,” 9th Australian New

Zealand Conference in Geomechanics, Auckland, New Zealand, Vol. 1, pp 196 - 203.

Standards Australia (1993), “Determination of the penetration resistance of a soil - Standard Penetration Test”

Australian Standard AS 1289 6.31. - 1993

Standards Australia (1993), “Geotechnical Site Investigations” Australian Standard AS 1726 - 1993

110 Australian Geomechanics Vol 39 No 2 June 2004

View publication stats

You might also like

- Astm D979-12 PDFDocument3 pagesAstm D979-12 PDFErwinBascon100% (1)

- Charger CatalogueDocument16 pagesCharger CatalogueNguyen Quang Sang0% (1)

- Hardness TestDocument8 pagesHardness TestEmanuel Calvin100% (1)

- Issues in Evaluating Capacity of Rock Socket Foundations KULHAWY and PRAKOSODocument11 pagesIssues in Evaluating Capacity of Rock Socket Foundations KULHAWY and PRAKOSOErisvaldo de LimaNo ratings yet

- Issues in Evaluating Capacity of Rock Socket FoundationsDocument11 pagesIssues in Evaluating Capacity of Rock Socket FoundationspaducoNo ratings yet

- Correlation Between Point Load Index and Very Low Uniaxial Compressive Strength of Some Iraqi RocksDocument14 pagesCorrelation Between Point Load Index and Very Low Uniaxial Compressive Strength of Some Iraqi RocksGbenga AdewumiNo ratings yet

- Using The Point Load Test To Determine The Uniaxial Compressive Strength of Coal Measure RockDocument10 pagesUsing The Point Load Test To Determine The Uniaxial Compressive Strength of Coal Measure RockgbutulescuNo ratings yet

- Using Point Load Test To Determine Uniaxial STR of Coal Meassure RockDocument10 pagesUsing Point Load Test To Determine Uniaxial STR of Coal Meassure RockScott Downs0% (1)

- Classifications WeakRockDocument13 pagesClassifications WeakRockrahulgeo05No ratings yet

- Predicting Uniaxial Compressive Strength by Point Load Test - Significance of Cone PenetrationDocument8 pagesPredicting Uniaxial Compressive Strength by Point Load Test - Significance of Cone PenetrationLucas Francisco Contreras TorresNo ratings yet

- Rock Strength As A Metric of Welding Intensity in Pyroclastic DepositsDocument10 pagesRock Strength As A Metric of Welding Intensity in Pyroclastic DepositsalgifarieidzamNo ratings yet

- Rock Mass Properties For Underground MinesDocument20 pagesRock Mass Properties For Underground MinesJuanPerezRooneyNo ratings yet

- Shear Strength of Rockfill Interfaces and Rock JoiDocument17 pagesShear Strength of Rockfill Interfaces and Rock JoiAlexandre RibeiroNo ratings yet

- The Influence of Core Sample Geometry On The Axial Point-Load TestDocument5 pagesThe Influence of Core Sample Geometry On The Axial Point-Load TestalgifarieidzamNo ratings yet

- Cai2014In SituRockSpallingStrengthnearExcavationBoundaries FinalDocument18 pagesCai2014In SituRockSpallingStrengthnearExcavationBoundaries FinalTemka dayanNo ratings yet

- Evaluation of Capacity of Rock Foundation Sockets KULHAWY AND PRAKOSO PDFDocument8 pagesEvaluation of Capacity of Rock Foundation Sockets KULHAWY AND PRAKOSO PDFErisvaldo de LimaNo ratings yet

- Index Properties of Intact RockDocument12 pagesIndex Properties of Intact RockChidi HenryNo ratings yet

- Grupo 1 Lessons Learned Using Empirical Methods Applied in Mining PDFDocument26 pagesGrupo 1 Lessons Learned Using Empirical Methods Applied in Mining PDFFidel Angel CercedoNo ratings yet

- Shear Strength of Rockfill Interfaces and Rock JointsDocument17 pagesShear Strength of Rockfill Interfaces and Rock Jointsakhila sNo ratings yet

- A Critical State Approach To Stability of Clay Shale For deDocument7 pagesA Critical State Approach To Stability of Clay Shale For derullyirwandiNo ratings yet

- GR0Document22 pagesGR0Madhavi Latha GaliNo ratings yet

- Ebs CohostDocument60 pagesEbs CohostGustavo RiosNo ratings yet

- Shear Strength of Rockfill Interfaces and Rock JoiDocument17 pagesShear Strength of Rockfill Interfaces and Rock JoiRodrigo De MeloNo ratings yet

- Shear Strength of Rockfill Interfaces and Rock JoiDocument16 pagesShear Strength of Rockfill Interfaces and Rock JoiDaniel MoravanskýNo ratings yet

- Cai-Kaiser2014 Article In-situRockSpallingStrengthNeaDocument17 pagesCai-Kaiser2014 Article In-situRockSpallingStrengthNeaJosé Vivanco NúñezNo ratings yet

- Practical Estimates of Rock Mass Strength 97Document24 pagesPractical Estimates of Rock Mass Strength 97Emanuel NicolásNo ratings yet

- Rock Mass Properties For Underground MinesDocument21 pagesRock Mass Properties For Underground Minesrobbyon100% (1)

- Strength Criterion For Rocks Under Compress - 2015 - Journal of Rock Mechanics ADocument6 pagesStrength Criterion For Rocks Under Compress - 2015 - Journal of Rock Mechanics ASEDIMNo ratings yet

- Interpretation of Ucs Test Results For Engineering Design: R. P. BewickDocument14 pagesInterpretation of Ucs Test Results For Engineering Design: R. P. BewickLuna RamirezNo ratings yet

- Friction Capacity of SoilDocument8 pagesFriction Capacity of SoilkushaljpNo ratings yet

- A New Approach To Estimate Side Resistance of Rock Socketed Drilled ShaftsDocument7 pagesA New Approach To Estimate Side Resistance of Rock Socketed Drilled Shafts樱满恋No ratings yet

- SCC Met SyllabusDocument9 pagesSCC Met SyllabusBoago KeofetlhileNo ratings yet

- Prediction of Rock Strength Using Drilling Data and Sonic LogsDocument4 pagesPrediction of Rock Strength Using Drilling Data and Sonic Logsziani1976No ratings yet

- Lee Et Al 2010 - Colour - Stresses in The Australian Tectonic Plate - Va...Document16 pagesLee Et Al 2010 - Colour - Stresses in The Australian Tectonic Plate - Va...Boris Leal MartinezNo ratings yet

- A Complement Gae 2011Document22 pagesA Complement Gae 2011AkshatshuklaNo ratings yet

- In SituNormalStiffnessofRockMassDocument8 pagesIn SituNormalStiffnessofRockMassSonal GeotechNo ratings yet

- Comparison - of - Strength-Based - Rock - Brittleness - Indi - Krehkosť Hornín Z UCS - DôležitéDocument8 pagesComparison - of - Strength-Based - Rock - Brittleness - Indi - Krehkosť Hornín Z UCS - DôležitéDaniel MoravanskýNo ratings yet

- Prone To Rock BurstingDocument8 pagesProne To Rock BurstingJoffy LouisNo ratings yet

- Chapter 11 of Rock Mass PropertiesDocument43 pagesChapter 11 of Rock Mass PropertiesJosé Luis Illanes100% (1)

- Kriteria Desain TunnelDocument18 pagesKriteria Desain TunnelgrahazenNo ratings yet

- Bewick Is RM 521Document15 pagesBewick Is RM 521Jacky_LEOLEONo ratings yet

- Rock Blasting 11Document29 pagesRock Blasting 11Alvaro Andres Bustamante Montenegro100% (1)

- Chapter 6 - Foundation in RockDocument52 pagesChapter 6 - Foundation in RockKoh Jia Jie100% (1)

- Drillability of FormationsDocument7 pagesDrillability of Formationsdrilling moneytreeNo ratings yet

- Strength Properties of Rock As An Index of BlastabilityDocument17 pagesStrength Properties of Rock As An Index of BlastabilityorazabilNo ratings yet

- 2017GeoOttawa Cu-SPTDocument9 pages2017GeoOttawa Cu-SPTAndrew WinnerNo ratings yet

- Deformability and Strength Parameters of RockmassDocument25 pagesDeformability and Strength Parameters of RockmassNadim527No ratings yet

- Stability Analysis of Tunnel OpeningsDocument11 pagesStability Analysis of Tunnel OpeningsBhaskar ReddyNo ratings yet

- Intact Rock StrengthDocument30 pagesIntact Rock StrengthMalik RizwanNo ratings yet

- Strength of Hard Rock PillarsDocument8 pagesStrength of Hard Rock PillarsArturo Pedro Salgado Medina100% (1)

- Shear Strength of Rockfill, Interfaces and Rock Joints, and Their Points of Contact in Rock Dump DesignDocument15 pagesShear Strength of Rockfill, Interfaces and Rock Joints, and Their Points of Contact in Rock Dump DesignThomas LawsonNo ratings yet

- 2017GeoOttawa Cu SPTDocument9 pages2017GeoOttawa Cu SPTAndresGarciaNo ratings yet

- RMR, Q, GsiDocument22 pagesRMR, Q, GsiSsasemUntNo ratings yet

- Lithospheric DiscontinuitiesFrom EverandLithospheric DiscontinuitiesHuaiyu YuanNo ratings yet

- Fault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureFrom EverandFault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureMarion Y. ThomasNo ratings yet

- Subduction Dynamics: From Mantle Flow to Mega DisastersFrom EverandSubduction Dynamics: From Mantle Flow to Mega DisastersGabriele MorraNo ratings yet

- X-ray Absorption Spectroscopy for the Chemical and Materials SciencesFrom EverandX-ray Absorption Spectroscopy for the Chemical and Materials SciencesNo ratings yet

- Atlas of Structural Geological Interpretation from Seismic ImagesFrom EverandAtlas of Structural Geological Interpretation from Seismic ImagesAchyuta Ayan MisraNo ratings yet

- Fluid Dynamics in Complex Fractured-Porous SystemsFrom EverandFluid Dynamics in Complex Fractured-Porous SystemsBoris FaybishenkoNo ratings yet

- (Book-2009) Shovel-Truck Systems Modelling, Analysis and CalculationsDocument170 pages(Book-2009) Shovel-Truck Systems Modelling, Analysis and Calculationsbqiushi67% (3)

- Wind TurbineDocument8 pagesWind TurbineDennyy IttyNo ratings yet

- Catalogo Jokab Safety - RTDocument18 pagesCatalogo Jokab Safety - RTDavid ZacariasNo ratings yet

- Inspection & Test PlanDocument2 pagesInspection & Test PlanKhaled GamalNo ratings yet

- Agreed Site Measurement RecordDocument40 pagesAgreed Site Measurement Recordලහිරු විතානාච්චිNo ratings yet

- Trenchless Technologies ManualDocument186 pagesTrenchless Technologies ManualLuis Fernando Leon Lecca100% (1)

- AYC IC & ITP - GRP Shade InstallationDocument7 pagesAYC IC & ITP - GRP Shade Installationmoytabura96No ratings yet

- MOVIROLL&MOVICARTDocument23 pagesMOVIROLL&MOVICARTMoutaz IsmailNo ratings yet

- Lexus: U.S. ApplicationsDocument6 pagesLexus: U.S. ApplicationsEdixo ReyesNo ratings yet

- Amateur Radio Band Plan - Ham RadioDocument2 pagesAmateur Radio Band Plan - Ham Radiosherm77100% (1)

- STAMFORD Parts Manual Issue 13Document168 pagesSTAMFORD Parts Manual Issue 13Anonymous 4IAJBGeX100% (2)

- Comparison of Cryogenic Flow Boiling in Liquid Nitrogen and Liquid Hydrogen Chilldown ExperimentsDocument12 pagesComparison of Cryogenic Flow Boiling in Liquid Nitrogen and Liquid Hydrogen Chilldown Experimentsnewrajasingh100% (1)

- Comparison of Properties of Ionic and Covalent CompoundsDocument77 pagesComparison of Properties of Ionic and Covalent CompoundsDharlineNo ratings yet

- HP2 - Ra13Document174 pagesHP2 - Ra13YCE 2011No ratings yet

- DatasheetDocument2 pagesDatasheetMichael WongNo ratings yet

- DH DVR510451085116CDocument1 pageDH DVR510451085116CLuis SalazarNo ratings yet

- Dokumen - Tips - Piping Stress Analysis Design BasisDocument38 pagesDokumen - Tips - Piping Stress Analysis Design BasisDan PastorNo ratings yet

- Cargador 862 IIDocument2 pagesCargador 862 IIxvrspeedyNo ratings yet

- Bootstrap 4 Cheat Sheet 10v400 Alpha6Document12 pagesBootstrap 4 Cheat Sheet 10v400 Alpha6hero100% (1)

- 3600CE ManualDocument92 pages3600CE Manualيوسف عامرNo ratings yet

- 3D Printing by Zamir ShaikhDocument12 pages3D Printing by Zamir ShaikhPrince ZamerNo ratings yet

- Introduction To CDIODocument75 pagesIntroduction To CDIOJoselyn KarinaNo ratings yet

- "Racing in Their Blood" Ch. 6 ExcerptDocument45 pages"Racing in Their Blood" Ch. 6 ExcerptBentley Publishers100% (2)

- vnx.su дачия 1304-1305-1307 пикап ENGINE-F8QDocument620 pagesvnx.su дачия 1304-1305-1307 пикап ENGINE-F8Qcvn2No ratings yet

- Bob 1.0.1 Vulnhub WalkthroughDocument17 pagesBob 1.0.1 Vulnhub WalkthroughhexoNo ratings yet

- Sorento 2003 Steering - Electronic PwrSteeringDocument3 pagesSorento 2003 Steering - Electronic PwrSteeringHerowan YumaNo ratings yet

- 3D Printing SeminarDocument19 pages3D Printing SeminarManoj gowda kNo ratings yet