Professional Documents

Culture Documents

2544 P502C10 Iso Amn23003003 0007 - 1

2544 P502C10 Iso Amn23003003 0007 - 1

Uploaded by

ahmed marieOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2544 P502C10 Iso Amn23003003 0007 - 1

2544 P502C10 Iso Amn23003003 0007 - 1

Uploaded by

ahmed marieCopyright:

Available Formats

IP

publish, reproduce or reverse engineer the same, in any manner, without MIDOR prior written consent and/or Technip Italy S.p.A. prior written consent, and shall not put in use the information for any purpose unrelated to that for which it has been transmitted to recipient. Any disclosure and

PIPING SPEC. SPEC. CORR. ALL. DES. PRESS. OPER. PRESS. DES. TEMP. OPER. TEMP. TEST PRESS. TEST. FLUID PAINT CRIT. NPD INS. INS. THK

P&ID TRACING PWHT NDT S BILL OF MATERIAL SKETCH LIST

N

This document and its attachments, if any, contains confidential and proprietary information belonging to MIDOR, and/or other third parties, including Technip Italy S.p.A. . The intended recipient of the information contained herein shall not divulge the same to any third party or sell, trade,

SPEC. MATERIAL RATING (mm) (Barg) (Barg) (°C) (°C) (Barg) PRESS TYPE PHASE NO. LINE (inch) TYPE (mm)

E POS DESCRIPTION THK1 THK2 ASBL/ IDENT DIAMETER QTY

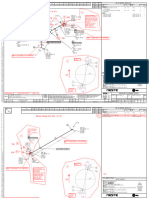

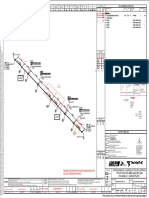

2544-23-PID-0021-003-1 A2A2MP CS 300 lbs 3 16.8 15 145 114 28.4 H L - A2 ALL 5 V 4 P 0 NO DEST (PCS/MM)

2544-23-PID-0021-003-1 A2A2MP CS 300 lbs 3 16.8 15 145 114 28.4 H L - A2 ALL 5 V 4 P 25

FABRICATION

1 Pipes (Length),ASME B36.10,ASTM A106 Gr.B + Sour S-STD S-STD 51 CPP2XFKY 4 2549

Service,BE,Seamless,51

2 90° Elb LR,ASME B16.9,ASTM A234 Gr.WPB + Sour Servi,BW S-STD S-STD 1 CDB4XJV1 4 1

Ends,Seamless,1

3 45° Elb LR,ASME B16.9,ASTM A234 Gr.WPB + Sour Servi,BW S-STD S-STD 1 CDB36BT2 4 1

CONT. ON Ends,Seamless,1

P502A30-AMN23003003-0004 4 WN Flg,ASME B16.5,ASTM A105N + Sour Service,RF/BW End,300 Lbs,1 S-STD 1 CFG4YCT1 4 3

E 101994815 ERECTION

N 102015194 5 SW Gk,ASME B16.20,RF as per ASME B16.5,-,300 Lbs,2 2 CMALED 4 2

4"NS EL.31252 6 SBlt 2 HHx N,ASME B1.1/ASME B18.2.2,Full Length Threaded,2 - 120 2 CBT8U82H 3/4 8

mm Length

1

7 SBlt 2 HHx N,ASME B1.1/ASME B18.2.2,Full Length Threaded,2 - 120 2 CBT8U82H 3/4 8

mm Length

S8 1 1

8 Support 2 APSUPP-P502C10-00616 4 1

STD

SB01-45-200 1 14

53

31195-90-80 FW

STD

WR00 F4 G5 B7

BT2 1

2

13 149 408 EL.31252

P502C10_AMN23003003_0007SP002 09

2

3 1

4 5

F4

3 39

5 REFERENCE POINT

45°

5 E 102017287

39

N 102013346

1

EL.30024

INSUL:

P-0 mm Col Line

1228

GPX1

INSUL:

P-25 mm

use of the contents hereof shall be subject to any subsisting agreements between MIDOR, Technip Italy S.p.A. and the intended recipient.

4"NS

BT1

REFERENCE POINT ne

E 101995210 Li 7 7

N 102021360 ol 7 2 20

C 1 CONN. TO

EL.30024 G PY 23-E-04D

8014 F4 G5 B6

Nozzle:T1

P502C10_AMN23003003_0007SP001 4 IN RFFE#300

E 101995210

N 102013346

EL.30023

TOTAL NUMBER OF SPOOLS: 2

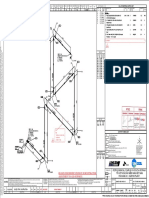

SUPPORT SYMBOLOGY

Y

COM STD or SPC support common SPC

to more than one line Special Piping Support

S-

e.g.: line support Refer to supp. dwgs collections 2544-"UNIT"-DW-1360-00

PRF STD Z X

STD or SPC support welded to pipe at Standard Piping Support

workshop during pipe spools prefabrication Refer to supp. dwgs collection 2544-00-STC-1390-00 INPUT AND OUTPUT

DATA FOR PIPELINE

MRS EFFORT ANALYSIS

Itemized Piping Supports ARE BASED ON

SYSTEM OF

For Itemized Piping Supports refer to Material Requisition 2544-00-MR-1383-001 COORDINATES AS

IN THE DRAWING

MIDOR REFINERY EXPANSION

1) ALL DIMENSIONS ARE IN MILLIMITERS 1) CONSTRUCTION LINE LIST: 2544-"UNIT"-NM-1300-12 4) CONSTRUCTION SPECIFICATION FOR PIPING PREFABRICATION ERECTION AND N WELD

REFERENCE

SYMBOLOGY

2) DIMENSIONS AND LAYOUT OF SOCKET WELDED AND THREADED LINES ARE INDICATIVE ONLY AND SHALL BE CHECKED

AT JOB SITE BEFORE ERECTION DOCUMENTS 2) PIPING MATERIAL CLASSES: 2544-00-JSD-1300-01 NON DESTRUCTIVE EXAMINATION: 2544-00-MS-1320-51 N FIELD WELD

NOTES - VALID ONLY FOR U/G PIPING SKETCHES - FOR DESIGN 3) TECHNICAL SPECIFICATION FOR PIPING PREFABRICATION 5) FOR STRESS ANALYSIS "FLEXIBILITY LEVELS" AND STRESS ANALYSIS TRACED LINE No. AMN23003003-A2A2MP-10"-P ISOMETRIC ID. P502C10-AMN23003003

3) TOTAL LENGTH OF U/G PIPING TO BE CONSIDERED INCLUSIVE OF EXPANSION JOINTS OR ANY EMBEDDED PIPE INTO PITS CONDITION CALCULATIONS NUMBERS REFER TO DOC.: 2544-"UNIT"-NM-1370-01

4) ISOMETRIC SKETCHES PREVAIL ON 2D AREA DRAWINGS AND ERECTION: 2544-00-MS-1300-02 SUPPORT

5) FOR 45deg MITER BENDS, ONLY ONE CONSTRUCTION WELD SHALL BE CONSIDERED (REF. TO APPLICABLE STANDARD) POSITION

PROJ. AREA DOC. TYPE SERVICE UNIT SEQUENCE N. SUBLINE SHEET OF SHEETS REV

1 15/12/2020 ISSUED FOR CONSTRUCTION R.CATA D.SORRP.MARC 0 26/06/2020 ISSUED FOR CONSTRUCTION R.CATA D.SORRP.MARC

REV DATE DESCRIPTION STRESS INSTR APPR. REV DATE DESCRIPTION STRESS INSTR APPR. REV DATE DESCRIPTION STRESS INSTR APPR.

2544 P502C10 ISO AMN 23 003003 0007 01 01 1

EXTRACTION DATE: 12/12/2020 13:53 KT–Kinetics Technology SpA - 00148 ROMA - Viale Castello della Magliana, 27

You might also like

- Motivation Letter Research Scientist VTTDocument1 pageMotivation Letter Research Scientist VTTTrinanda Rizqita RausyanfiqryNo ratings yet

- Refinements of The Ziegler Nichols Tuning Formula C.C PDFDocument8 pagesRefinements of The Ziegler Nichols Tuning Formula C.C PDFdautroc13No ratings yet

- Standards New Zeal and Catalogue at March 2009Document476 pagesStandards New Zeal and Catalogue at March 2009allistair_dNo ratings yet

- 2544 P502a20 Iso LPS23056329 0001 - 1Document2 pages2544 P502a20 Iso LPS23056329 0001 - 1ahmed marieNo ratings yet

- 2544 P502R10 Iso Amn23001002 0001 - 1Document4 pages2544 P502R10 Iso Amn23001002 0001 - 1ahmed marieNo ratings yet

- 2544 P502a20 Iso Awa23004007 0001 - 1Document3 pages2544 P502a20 Iso Awa23004007 0001 - 1ahmed marieNo ratings yet

- 036909C-2BAE02-ISO-SSC-24163-01-0F1S3-Isometric Sketch-Field Isometric - Modifications-CDocument2 pages036909C-2BAE02-ISO-SSC-24163-01-0F1S3-Isometric Sketch-Field Isometric - Modifications-CNguyenCanhBaoNo ratings yet

- 036909C 2bae07 Iso HL 24366 01 0S5Document7 pages036909C 2bae07 Iso HL 24366 01 0S5NguyenCanhBaoNo ratings yet

- 036909C 2CPR02 Iso en 56498 01 0S7Document8 pages036909C 2CPR02 Iso en 56498 01 0S7NguyenCanhBaoNo ratings yet

- 036909C 2cae02 Iso HL 26267 03 1F1S3Document2 pages036909C 2cae02 Iso HL 26267 03 1F1S3NguyenCanhBaoNo ratings yet

- Moves Change From Rev 1 To 1F1: Singapore Expansion ProjectDocument2 pagesMoves Change From Rev 1 To 1F1: Singapore Expansion ProjectLocus Jhun MichaelNo ratings yet

- Bill of Material Sketch List: Reason For Modifications by Subcontractor: Cut and Reweld Due Field Fabrication ErrorDocument7 pagesBill of Material Sketch List: Reason For Modifications by Subcontractor: Cut and Reweld Due Field Fabrication ErrorNguyenCanhBaoNo ratings yet

- 036909C 2CPR01 Iso en 23251 01 0S3Document1 page036909C 2CPR01 Iso en 23251 01 0S3NguyenCanhBaoNo ratings yet

- Bill of Material Sketch List: 3B M1 3B M1 3A M1 FDocument5 pagesBill of Material Sketch List: 3B M1 3B M1 3A M1 FNguyenCanhBaoNo ratings yet

- 036909C 2CAE06 ISO HBFW 51226 03 0F1S1 Isometric Sketch Field Isometric Modifications Code 3Document1 page036909C 2CAE06 ISO HBFW 51226 03 0F1S1 Isometric Sketch Field Isometric Modifications Code 3caochieuNo ratings yet

- 036909C 2bae03 Iso WG 29005 01 1F2S3 CDocument11 pages036909C 2bae03 Iso WG 29005 01 1F2S3 CNguyenCanhBaoNo ratings yet

- 036909C 2cae02 Iso HL 26330 06 0S2Document2 pages036909C 2cae02 Iso HL 26330 06 0S2NguyenCanhBaoNo ratings yet

- 036909C 2cae18 Iso en 23251 01 0S3Document1 page036909C 2cae18 Iso en 23251 01 0S3NguyenCanhBaoNo ratings yet

- 036909C 2CAE02 ISO HL 26118 01 0S1 Isometric Sketch Field Isometric Modifications Code 3Document3 pages036909C 2CAE02 ISO HL 26118 01 0S1 Isometric Sketch Field Isometric Modifications Code 3caochieuNo ratings yet

- Bill of Material Sketch ListDocument8 pagesBill of Material Sketch ListNguyenCanhBaoNo ratings yet

- 036909C 2cae05 Iso VT 27986 04 0S2Document1 page036909C 2cae05 Iso VT 27986 04 0S2NguyenCanhBaoNo ratings yet

- 036909C 2bae05 Iso FW 57372 01 1S2Document2 pages036909C 2bae05 Iso FW 57372 01 1S2NguyenCanhBaoNo ratings yet

- 036909C 2bae07 Iso CBD 24521 01 0S1 CDocument1 page036909C 2bae07 Iso CBD 24521 01 0S1 CNguyenCanhBaoNo ratings yet

- Reason For Modifications by Subcontractor: Adjustment Follow Actual Pipe Length, Add Detail Support As Per Site ConditionsDocument1 pageReason For Modifications by Subcontractor: Adjustment Follow Actual Pipe Length, Add Detail Support As Per Site ConditionsNguyenCanhBaoNo ratings yet

- Reason For Modifications by Subcontractor: Adjustment Follow Actual Pipe LengthDocument4 pagesReason For Modifications by Subcontractor: Adjustment Follow Actual Pipe LengthNguyenCanhBaoNo ratings yet

- Bill of Material Sketch List: Reason For Modifications by Subcontractor: Adjustment Pipe Length As Per Actual SiteDocument2 pagesBill of Material Sketch List: Reason For Modifications by Subcontractor: Adjustment Pipe Length As Per Actual SiteNguyenCanhBaoNo ratings yet

- Reason For Modifications by Subcontractor: Adjustment Follow Actual Pipe LengthDocument2 pagesReason For Modifications by Subcontractor: Adjustment Follow Actual Pipe LengthNguyenCanhBaoNo ratings yet

- 036909C 2BPR01 Iso SCS 23252 01 1S4 CDocument3 pages036909C 2BPR01 Iso SCS 23252 01 1S4 CNguyenCanhBaoNo ratings yet

- 036909C 2bae05 Iso SCS 23500 01 1S3Document4 pages036909C 2bae05 Iso SCS 23500 01 1S3NguyenCanhBaoNo ratings yet

- Col Line HDocument1 pageCol Line HAcfMacNo ratings yet

- 800 Col Line: Bill of Material Sketch ListDocument1 page800 Col Line: Bill of Material Sketch ListAcfMacNo ratings yet

- 036909C 2BPR01 Iso SCS 23253 01 0S4Document4 pages036909C 2BPR01 Iso SCS 23253 01 0S4NguyenCanhBaoNo ratings yet

- 072744C-RA1-DW-SW-31126-1-01 - 0 Change Joint TypeDocument3 pages072744C-RA1-DW-SW-31126-1-01 - 0 Change Joint TypeLocus Jhun MichaelNo ratings yet

- Angloamerican: 1 Rl1 1 Rl1Document1 pageAngloamerican: 1 Rl1 1 Rl1Luis Fernando GONZALES HUMIRENo ratings yet

- Angloamerican: 1 Rl1 1 Rl1Document1 pageAngloamerican: 1 Rl1 1 Rl1Luis Fernando GONZALES HUMIRENo ratings yet

- XLP Pre L13 WL13P40Document2 pagesXLP Pre L13 WL13P40Aria NickbakhtNo ratings yet

- 079254C 1g00u01 Iso CSW 1g00civ007 0001 - 0Document1 page079254C 1g00u01 Iso CSW 1g00civ007 0001 - 0Mahmoud HassanNo ratings yet

- 079254C 1g00u01 Iso CSW 1g00civ005 0001 - 0Document1 page079254C 1g00u01 Iso CSW 1g00civ005 0001 - 0Mahmoud HassanNo ratings yet

- Job No. 26418: CollahuasiDocument1 pageJob No. 26418: Collahuasicutcnc.concepcionNo ratings yet

- Singapore Expansion Project: Bill of Material Sketch ListDocument1 pageSingapore Expansion Project: Bill of Material Sketch ListLocus Jhun MichaelNo ratings yet

- Angloamerican: Ifc - Issued For ConstructionDocument1 pageAngloamerican: Ifc - Issued For ConstructionLuis Fernando GONZALES HUMIRENo ratings yet

- Cat - Dcs.sis - Controller d6mDocument2 pagesCat - Dcs.sis - Controller d6mFrancoNo ratings yet

- Angloamerican: Ifc - Issued For ConstructionDocument1 pageAngloamerican: Ifc - Issued For ConstructionLuis Fernando GONZALES HUMIRENo ratings yet

- MQ13 02 3210 3606 Loh 01 - R0 - RL1Document1 pageMQ13 02 3210 3606 Loh 01 - R0 - RL1Ruth Tecsi TCNo ratings yet

- Bill of MaterialsDocument1 pageBill of Materialsgoushbasha0% (1)

- KamranDocument1 pageKamranAnonymous BZQOJwWIh6No ratings yet

- 172 I1909e 000 46 DW 0105Document2 pages172 I1909e 000 46 DW 0105Jose Carlos Moraga LópezNo ratings yet

- Quality Control: Lap Joint DetailDocument2 pagesQuality Control: Lap Joint DetailariNo ratings yet

- XLP Pre L13 WL13P41Document2 pagesXLP Pre L13 WL13P41Aria NickbakhtNo ratings yet

- Phase-I: Job No. 26148Document1 pagePhase-I: Job No. 26148Rodrigo Andres CeledonNo ratings yet

- Observation April 01, 2021 - 01Document2 pagesObservation April 01, 2021 - 01Abdul RahmanNo ratings yet

- TabindaDocument1 pageTabindaAnonymous BZQOJwWIh6No ratings yet

- 3 P 132 9301 1a3a N 01 - Rev01Document1 page3 P 132 9301 1a3a N 01 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- 1C17 (KSS021-D-541) - Column-R0.1Document1 page1C17 (KSS021-D-541) - Column-R0.1mo3azNo ratings yet

- 145B58 (QTY 8NOS) ) ModelDocument1 page145B58 (QTY 8NOS) ) ModelDass MNo ratings yet

- Job No. 25800: Quebrada Blanca Fase 2Document1 pageJob No. 25800: Quebrada Blanca Fase 2Benjamín Muñoz MuñozNo ratings yet

- Singapore Expansion Project: BillofmaterialsketchlistDocument4 pagesSingapore Expansion Project: BillofmaterialsketchlistLocus Jhun MichaelNo ratings yet

- Singapore Expansion Project: BillofmaterialsketchlistDocument3 pagesSingapore Expansion Project: BillofmaterialsketchlistLocus Jhun MichaelNo ratings yet

- Abts Uqair-B.2Document1 pageAbts Uqair-B.2Anonymous BZQOJwWIh6No ratings yet

- Job No. 26418: CollahuasiDocument1 pageJob No. 26418: Collahuasicutcnc.concepcionNo ratings yet

- Job No. 25800: Quebrada Blanca Fase 2Document1 pageJob No. 25800: Quebrada Blanca Fase 2Ricardo Alberto Zapata BalcazarNo ratings yet

- Top View Cable Stub-Up Plan: 117mm (TYP 2)Document1 pageTop View Cable Stub-Up Plan: 117mm (TYP 2)salman1111aNo ratings yet

- Sound PowerDocument12 pagesSound Powerkulov1592No ratings yet

- ECA Course FileDocument154 pagesECA Course FilebinduscribdNo ratings yet

- Formglas FRP Specification V Sept 2011Document4 pagesFormglas FRP Specification V Sept 2011Srdjan KosoricNo ratings yet

- CLT Guidebook 2019.03Document18 pagesCLT Guidebook 2019.03dopolinaNo ratings yet

- WMM SheetDocument6 pagesWMM SheetManiteja Reddy TatipallyNo ratings yet

- Q235BDocument2 pagesQ235BGoh Boon TiongNo ratings yet

- List of Welding CodesDocument10 pagesList of Welding CodesVijayakumar Samy0% (2)

- National Project Implementation UnitDocument6 pagesNational Project Implementation UnitMallikarjunBhiradeNo ratings yet

- Elec BOQ As Per Price Schedule (138150) After TB 0 1 Rev.1Document627 pagesElec BOQ As Per Price Schedule (138150) After TB 0 1 Rev.1Farhan KhanNo ratings yet

- Calculate Reactive Power of The Capacitor Bank and Improve Power FactorDocument4 pagesCalculate Reactive Power of The Capacitor Bank and Improve Power FactornagarajaNo ratings yet

- FE/Pipe: Finite Element AnalysisDocument2 pagesFE/Pipe: Finite Element AnalysisChirag ShahNo ratings yet

- P614059 PDFDocument5 pagesP614059 PDFAreeb AbbasNo ratings yet

- CT CalculationDocument13 pagesCT CalculationMuhammad Ibad AlamNo ratings yet

- List of C.P.D Programs Attended 2016 - 21 Category: Professional Engineer (P.e)Document63 pagesList of C.P.D Programs Attended 2016 - 21 Category: Professional Engineer (P.e)rohitNo ratings yet

- Mechanical Integrity Inspections For Ammonia Refrigeration SystemsDocument3 pagesMechanical Integrity Inspections For Ammonia Refrigeration Systemsعزت عبد المنعمNo ratings yet

- Engineering EconomyDocument272 pagesEngineering EconomyErrol John Reyes50% (8)

- CCN Manual - FinalDocument58 pagesCCN Manual - Finalvrunda1664No ratings yet

- B01 Documentation: Standard TitleDocument34 pagesB01 Documentation: Standard TitleAkbar ShaikNo ratings yet

- Chapter One: Munir SH Abdullah MARCH-2016Document30 pagesChapter One: Munir SH Abdullah MARCH-2016Abdifatah SaidNo ratings yet

- Chapter 4 Motorola R56!09!01 05Document100 pagesChapter 4 Motorola R56!09!01 05gomozalipanNo ratings yet

- Prestress Concrete TankDocument267 pagesPrestress Concrete TankanandswarupNo ratings yet

- Accreditation & ChallengesDocument54 pagesAccreditation & ChallengestarikNo ratings yet

- SE Module 1Document25 pagesSE Module 1Satya GeethikaNo ratings yet

- Cc206 - IBSDocument25 pagesCc206 - IBSikazuo800% (1)

- Industrial Training Letter June 2020Document1 pageIndustrial Training Letter June 2020Rohit Vasudeva100% (1)

- Ishrae PDFDocument39 pagesIshrae PDFShivraj SawantNo ratings yet

- Decking Specification SheetDocument4 pagesDecking Specification Sheetdarebusi1No ratings yet