Professional Documents

Culture Documents

Method Statement

Method Statement

Uploaded by

Sagar SharmaCopyright:

Available Formats

You might also like

- Helicon x3Document140 pagesHelicon x3TarasenkoNo ratings yet

- Aeg 8.33 UpsDocument110 pagesAeg 8.33 UpsThomas Irwin Dsouza100% (1)

- Successful Instrumentation and Control Systems Design, Second EditionFrom EverandSuccessful Instrumentation and Control Systems Design, Second EditionRating: 4.5 out of 5 stars4.5/5 (10)

- Safe Work Procedure-Set Up RigsDocument4 pagesSafe Work Procedure-Set Up RigsAsif KhanzadaNo ratings yet

- Method Statement - MHI Installation of Utility PoleDocument7 pagesMethod Statement - MHI Installation of Utility PoleJohn DoeNo ratings yet

- Method Statement For Geophysical SurveyDocument7 pagesMethod Statement For Geophysical SurveyvinodhyperNo ratings yet

- Industry Study Activities Industrial Technology HSCDocument3 pagesIndustry Study Activities Industrial Technology HSCapi-320830582100% (1)

- Occupational Health and SafetyDocument8 pagesOccupational Health and Safetygroup oneNo ratings yet

- Temp Fencing & GateDocument12 pagesTemp Fencing & GateMark Fash0% (1)

- CCTV Method Statement GN 3 (V1) February 2009Document5 pagesCCTV Method Statement GN 3 (V1) February 2009Gyanendra Singh0% (1)

- 4A dm253461 Project Premobilization Safety Meeting Checklist PDFDocument19 pages4A dm253461 Project Premobilization Safety Meeting Checklist PDFRheNo ratings yet

- JSA For Welding GrindingDocument7 pagesJSA For Welding GrindingBabar78% (9)

- Performance Indicators MSQH Hospital Accreditation Standards 5th EditionDocument215 pagesPerformance Indicators MSQH Hospital Accreditation Standards 5th EditionMuhammad Khairol Omar100% (2)

- I150 Peristaltic Pump Operating ManualDocument20 pagesI150 Peristaltic Pump Operating ManualPunit PurshotamNo ratings yet

- Asbestos TEMPLATE Asbestos Management PlanDocument6 pagesAsbestos TEMPLATE Asbestos Management PlanIhor100% (1)

- Toolbox Talk - Workshop Safety General RulesDocument3 pagesToolbox Talk - Workshop Safety General Rules260380sdNo ratings yet

- Maledives Airport Scope of Work PDFDocument10 pagesMaledives Airport Scope of Work PDFakanagesNo ratings yet

- Method Statement: Company: Naseem & Son Project: Date: 21/05/2022 1. Description of WorksDocument3 pagesMethod Statement: Company: Naseem & Son Project: Date: 21/05/2022 1. Description of WorksSagar SharmaNo ratings yet

- MS SKP-08 For Internal Grit BlastingDocument9 pagesMS SKP-08 For Internal Grit BlastingSagar SharmaNo ratings yet

- MS - VDU Exention & BLA Installation at KMRDocument5 pagesMS - VDU Exention & BLA Installation at KMRNaseemandson TeamNo ratings yet

- QTC - Safety Permit-InstructionDocument11 pagesQTC - Safety Permit-InstructionQueenie FloresNo ratings yet

- Method Statement (DKi 2024)Document2 pagesMethod Statement (DKi 2024)Noman AliNo ratings yet

- Scope of Work PR 2500366865 - 464-KL1 Repair at Feed End Pfister - HPHI - La Union PlantDocument3 pagesScope of Work PR 2500366865 - 464-KL1 Repair at Feed End Pfister - HPHI - La Union PlantJuancho PaduaNo ratings yet

- TS-406 - Method Statement For Cable Tray InstallationDocument16 pagesTS-406 - Method Statement For Cable Tray InstallationsindalisindiNo ratings yet

- Work Permit SystemDocument5 pagesWork Permit SystemSuresh PasumarthiNo ratings yet

- S-PCM Minutes of Meeting: Produce Water Tank 001/002Document5 pagesS-PCM Minutes of Meeting: Produce Water Tank 001/002sudeesh kumarNo ratings yet

- 10 - WMS - Turpentine - Tie BeamDocument6 pages10 - WMS - Turpentine - Tie BeamVikramaditya NayakNo ratings yet

- Method Statement For MV Panels and Accessories Unloading.: Project NameDocument12 pagesMethod Statement For MV Panels and Accessories Unloading.: Project NameSatish SharmaNo ratings yet

- MSOG-M2014-C-JMS-001 - For Grating Cover InstallationDocument9 pagesMSOG-M2014-C-JMS-001 - For Grating Cover Installationshaiful annuarNo ratings yet

- Jsa Lifting of PitsDocument8 pagesJsa Lifting of PitseslamNo ratings yet

- 11 - WMS - Turpentine - Plaster WorksDocument5 pages11 - WMS - Turpentine - Plaster WorksVikramaditya NayakNo ratings yet

- Work Permit Safety Standard Training PackDocument24 pagesWork Permit Safety Standard Training PackAtma Prakash Sinha100% (1)

- MS For Grounding and Cadwelding WorkDocument34 pagesMS For Grounding and Cadwelding WorkGanga Daran100% (2)

- OHS Work PermitsDocument17 pagesOHS Work PermitsNadaNo ratings yet

- Method Statement For Hydro TestDocument3 pagesMethod Statement For Hydro TestSandeep kumar100% (1)

- 742 Method Statement 2011Document20 pages742 Method Statement 2011kikokiko KarimNo ratings yet

- Permit To WorkDocument3 pagesPermit To WorkPrinterHaapcolNo ratings yet

- Method Statement - IT CablingDocument12 pagesMethod Statement - IT CablingmmcsolutionsystemNo ratings yet

- StatementDocument8 pagesStatementMrProlyfeNo ratings yet

- SMM 12 Hot Work PermitDocument4 pagesSMM 12 Hot Work PermitPavan mylapalliNo ratings yet

- MS Boiler & CalorifierDocument14 pagesMS Boiler & CalorifierSanto ENo ratings yet

- Agenda-HSE 28.02.24Document1 pageAgenda-HSE 28.02.24Pradeep SahuNo ratings yet

- Scope of Work PR 2500366866 - 363-RM1 VRM Int. Repairs & False Air Cor - HPHI - La Union PlantDocument3 pagesScope of Work PR 2500366866 - 363-RM1 VRM Int. Repairs & False Air Cor - HPHI - La Union PlantJuancho PaduaNo ratings yet

- Excavation & BackfillingDocument6 pagesExcavation & BackfillingnidhinbobanNo ratings yet

- Electrical Safety RequirementDocument8 pagesElectrical Safety RequirementAnonymous kWfNFb100% (1)

- Work Permit Compliance (Presentation)Document52 pagesWork Permit Compliance (Presentation)Ramzan Nazir100% (1)

- DIAL WORK PERMIT NewDocument5 pagesDIAL WORK PERMIT NewAkshay PotekarNo ratings yet

- 8 - WMS - Turpentine - Plinth BeamDocument4 pages8 - WMS - Turpentine - Plinth BeamVikramaditya NayakNo ratings yet

- Method Statement For Hard Barrication InstallationDocument10 pagesMethod Statement For Hard Barrication Installationshamshad ahamedNo ratings yet

- Wap2 Cp05a MS 0008 01 - Installation of PanelDocument6 pagesWap2 Cp05a MS 0008 01 - Installation of PanelElisco Pher SalmasanNo ratings yet

- Confined Spaces: Procedures and Use of PermitsDocument28 pagesConfined Spaces: Procedures and Use of PermitsTom BellNo ratings yet

- Method Statement - CCTVDocument7 pagesMethod Statement - CCTVamenmohd100% (1)

- OutlineDocument11 pagesOutlineKadita RogerNo ratings yet

- Method of StatementDocument5 pagesMethod of Statementdaddy coolNo ratings yet

- Editable Health and Safety FormsDocument32 pagesEditable Health and Safety FormsFlavia Rodrigo Guedes100% (1)

- 11 - WMS - Turpentine - Brick WallDocument5 pages11 - WMS - Turpentine - Brick WallVikramaditya NayakNo ratings yet

- Method Statement SampleDocument3 pagesMethod Statement SampleAmrith RajNo ratings yet

- 8 Permit To Work ProcedureDocument7 pages8 Permit To Work Procedurekhurram100% (1)

- METH 00005 A 330 SQUH Method Statement Vinyl FloorDocument3 pagesMETH 00005 A 330 SQUH Method Statement Vinyl Floormohd arshadNo ratings yet

- MS For SKP Tank T-0402Document8 pagesMS For SKP Tank T-0402Sagar SharmaNo ratings yet

- DM001 ENM ALL FO 01076 A2 Worksite Check Tool Box Talk PICDocument2 pagesDM001 ENM ALL FO 01076 A2 Worksite Check Tool Box Talk PICmkashkooli_scribd100% (1)

- General Work Permit: Work Should Not Commence Until Stages 1 To 5 Are CompletedDocument2 pagesGeneral Work Permit: Work Should Not Commence Until Stages 1 To 5 Are CompletedIonian TribeNo ratings yet

- JSA For KAHSDocument6 pagesJSA For KAHSFrancis Enriquez TanNo ratings yet

- Method Statement: Departmental Representative Contractors RepresentativeDocument1 pageMethod Statement: Departmental Representative Contractors RepresentativePranabesh MallickNo ratings yet

- Method Statement DraftDocument9 pagesMethod Statement DraftJAMES neelNo ratings yet

- Facility/Plant Location: Description of Work: Contractor:: PCD Project: Water Treatment Facilities - 3Document8 pagesFacility/Plant Location: Description of Work: Contractor:: PCD Project: Water Treatment Facilities - 3AldrinNo ratings yet

- 20.interior Refurbishment Method Statement GN 20 PDFDocument5 pages20.interior Refurbishment Method Statement GN 20 PDFleebankNo ratings yet

- Ilovepdf MergedDocument8 pagesIlovepdf MergedSagar SharmaNo ratings yet

- B ShackleDocument1 pageB ShackleSagar SharmaNo ratings yet

- Permit Number P240-00-6761810 State Waiting For Verification Lifetime Expires OnDocument47 pagesPermit Number P240-00-6761810 State Waiting For Verification Lifetime Expires OnSagar SharmaNo ratings yet

- Permit Number P289-00-6723327 State Waiting For Verification Lifetime Expires OnDocument53 pagesPermit Number P289-00-6723327 State Waiting For Verification Lifetime Expires OnSagar SharmaNo ratings yet

- Angle Grinder BG-01Document1 pageAngle Grinder BG-01Sagar SharmaNo ratings yet

- D ShackleDocument1 pageD ShackleSagar SharmaNo ratings yet

- Chain Block CB NS.010 2T - 2Document1 pageChain Block CB NS.010 2T - 2Sagar SharmaNo ratings yet

- Permit Number P240-00-6693635 State Live (16 Mar 09:31 - 16 Mar 19:00) Lifetime Expires On 20-03-2024Document4 pagesPermit Number P240-00-6693635 State Live (16 Mar 09:31 - 16 Mar 19:00) Lifetime Expires On 20-03-2024Sagar SharmaNo ratings yet

- Manual Lifting PlanDocument2 pagesManual Lifting PlanSagar SharmaNo ratings yet

- Rescue Plan Working at HeightDocument2 pagesRescue Plan Working at HeightSagar SharmaNo ratings yet

- New EntryDocument1 pageNew EntrySagar SharmaNo ratings yet

- Progress Report 32Document2 pagesProgress Report 32Sagar SharmaNo ratings yet

- Progress Report 33Document2 pagesProgress Report 33Sagar SharmaNo ratings yet

- Naseem & Son: Emergency Response PlanDocument7 pagesNaseem & Son: Emergency Response PlanSagar SharmaNo ratings yet

- Emergency Response/ Rescue Plan Forworking at Height: First Aider: Abdul Samad Rescuer: Noman & RaheelDocument1 pageEmergency Response/ Rescue Plan Forworking at Height: First Aider: Abdul Samad Rescuer: Noman & RaheelSagar SharmaNo ratings yet

- JSA For NSE ProjectDocument7 pagesJSA For NSE ProjectSagar SharmaNo ratings yet

- Progress Report 31Document2 pagesProgress Report 31Sagar SharmaNo ratings yet

- MS SKP-08 For Internal Grit BlastingDocument9 pagesMS SKP-08 For Internal Grit BlastingSagar SharmaNo ratings yet

- Safety Walk Report by ClientDocument3 pagesSafety Walk Report by ClientSagar SharmaNo ratings yet

- Work at Height Rescue PlanDocument1 pageWork at Height Rescue PlanSagar SharmaNo ratings yet

- Method Statement: Company: Naseem & Son Project: Date: 21/05/2022 1. Description of WorksDocument3 pagesMethod Statement: Company: Naseem & Son Project: Date: 21/05/2022 1. Description of WorksSagar SharmaNo ratings yet

- Rescue Plan For HeightDocument2 pagesRescue Plan For HeightSagar SharmaNo ratings yet

- Risk Assessment: Corresponding Permit To Work NoDocument4 pagesRisk Assessment: Corresponding Permit To Work NoSagar SharmaNo ratings yet

- SSE-ST-GL-009-11 Routine Lift Plan: Lifting & Hoisting - Loading of SPL-11 Roof Scrap Plates On TruckDocument4 pagesSSE-ST-GL-009-11 Routine Lift Plan: Lifting & Hoisting - Loading of SPL-11 Roof Scrap Plates On TruckSagar SharmaNo ratings yet

- SHELL SMEP Lifting and Hoisting Manual Rev 1 0Document349 pagesSHELL SMEP Lifting and Hoisting Manual Rev 1 0Sagar SharmaNo ratings yet

- Naseem & Son: Report of Internal AuditDocument5 pagesNaseem & Son: Report of Internal AuditSagar SharmaNo ratings yet

- Key Performance Indicator Naseem & SonDocument1 pageKey Performance Indicator Naseem & SonSagar SharmaNo ratings yet

- Assessment Report Naseem & SonDocument2 pagesAssessment Report Naseem & SonSagar SharmaNo ratings yet

- Method Statement: Company: Naseem & Son Project: Maintinance (SKP-09) Date: 05-12-2021 1. Description of WorksDocument2 pagesMethod Statement: Company: Naseem & Son Project: Maintinance (SKP-09) Date: 05-12-2021 1. Description of WorksSagar SharmaNo ratings yet

- All Safety Inspection ChecklistsDocument30 pagesAll Safety Inspection ChecklistsSagar Sharma50% (2)

- Material Safety Data Sheet: Section 1 - Product and Company IdentificationDocument4 pagesMaterial Safety Data Sheet: Section 1 - Product and Company IdentificationdnmuleNo ratings yet

- BSR455 - Group 9 - Building Inspection - 3aDocument22 pagesBSR455 - Group 9 - Building Inspection - 3aMuhammad IdzhamNo ratings yet

- Msds-En Shell Rimula r3Document9 pagesMsds-En Shell Rimula r3Clement Ayobami OladejoNo ratings yet

- Safety Data Sheet: Exxon Mobil CorporationDocument9 pagesSafety Data Sheet: Exxon Mobil CorporationHpnoteNo ratings yet

- Code of Practice For Access and Working ScaffoldsDocument124 pagesCode of Practice For Access and Working ScaffoldsMohammad Irshad AlamNo ratings yet

- Safety Geremew TarekegnDocument110 pagesSafety Geremew TarekegnTariku NigussieNo ratings yet

- Labour Welfare in India and Its Role in Industrial RelatonsDocument23 pagesLabour Welfare in India and Its Role in Industrial RelatonsPragya ChakshooNo ratings yet

- +CPCCWHS2001 Assessment - Theory AMBDocument34 pages+CPCCWHS2001 Assessment - Theory AMBH .SNo ratings yet

- MSDS Wall & Pier CopingsDocument2 pagesMSDS Wall & Pier Copingsaditarian .pNo ratings yet

- Manage Operational PlanDocument20 pagesManage Operational Planneha100% (2)

- WRAP Audit Checklist Uploaded by Compliance BangladeshDocument1 pageWRAP Audit Checklist Uploaded by Compliance Bangladeshkrishna.greenhrNo ratings yet

- Progesterone Formulation: Safety Data SheetDocument12 pagesProgesterone Formulation: Safety Data SheetMohamedSaid100% (1)

- Safety Data Sheet: AlamineDocument13 pagesSafety Data Sheet: AlamineIbnu BakriNo ratings yet

- Bread and PastryTLE Enrichment ActivityDocument7 pagesBread and PastryTLE Enrichment ActivityalyssaNo ratings yet

- Ali Resume LATESTDocument3 pagesAli Resume LATESTabogadieNo ratings yet

- Copper Foil Shielding TapeDocument2 pagesCopper Foil Shielding TapeEngr. Mehadi Hassan NahidNo ratings yet

- L2RA-Personnel TransferDocument10 pagesL2RA-Personnel TransferSam Delo-deloNo ratings yet

- 3m-5n11-n95-technical-infoDocument2 pages3m-5n11-n95-technical-infoAwal JaNuary SaragiNo ratings yet

- Contractor Safety Managment ProgramDocument19 pagesContractor Safety Managment Programsanjeev kumarNo ratings yet

- Ihsec Nebosh Igc Flyer - GeneralDocument4 pagesIhsec Nebosh Igc Flyer - GeneralJows Magtoto-DavidNo ratings yet

- Safety Data Sheet - EN - (43805315) SODIUM SILICATE SOLUTION (WATER GLASS) (1344-09-8)Document8 pagesSafety Data Sheet - EN - (43805315) SODIUM SILICATE SOLUTION (WATER GLASS) (1344-09-8)Mahdi BelhechmiNo ratings yet

Method Statement

Method Statement

Uploaded by

Sagar SharmaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement

Method Statement

Uploaded by

Sagar SharmaCopyright:

Available Formats

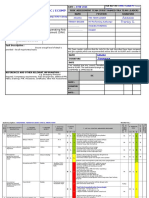

Method Statement Corresponding Permit to Work No.

F P289-00-3795976

The Permit Issuer, when developing the respective Permit forms, will use the Method Statement supplied.

Company: Naseem & Son Project: Mobilization and Hard Date: 14/04/2022

Barrication around Tank SKP-06

1. Description of works

What the work entails?

Mobilization and Hard Barrication around Tank SKP-06

How is it going to be completed? Summarise the operation

Mobilization and Hard Barricade around Tank SKP-06

I. Site Induction

II. Mobilization of Material and manpower to site

III. Stacking of Material on racks.

IV. Hard Barrication around SKP-06

V. Housekeeping

Where is the work going to be completed? (Summary – more details on section 5)

See detail in section 5

Duration of the work? (Stating any times when access to the Terminal will not be required.)

25 Days.

Include site location drawings if appropriate?

NA

Are there any restrictions e.g. overhead power lines?

Nil

Are local permits required (Local regulations)?

Yes

Any other details

NA

2. Names of Responsible persons

Who is going to be working on the project?

Sagar Sharma

Sheraz Ahmed

Who will be in charge?

Sheraz Ahmed

Who has specific responsibilities? e.g. Plant, personnel, materials, etc.

Sheraz Ahmed ,MTehseen Khan

Who is to make contact with local authorities?

Sheraz Ahmed

Any other details

3. Plant and Equipment

What plant equipment and tools are required to do the job?

Tools Wheel barrow, scaffolding pipes ,scaffolding joints and other general hand Tools

Scaffolding

Yes

Loading of materials

Nil

Others, specify

Yes( GI sheets, Fire Extingusher, water cooler etc)

Form F – Method of Statement Distribution Permit to Work

Version 3.0 May 2007 Page 1 of 2

Procedure System

What certificates, if any, are required for plant or equipment?

What training, if any, is required for operatives?

Safety Orientation

4. Communications with the workforce

How are the procedures, hazards to be communicated to the workforce ?

After getting desired work permits, a group communication meeting shall be conducted to

convey the action plan in case of any change in condition, like bad weather (rain/ storm etc) or

any change in plant/process area in the form of fire, leak of gas/oil/water etc. and also in case

of fire alarm/hooter

In case of any emergency and where alarm goes on, all personnel must be evacuated

immediately from the work place and must be report to muster point. Extreme care should be

considered to avoid any unlikely injury caused by panic

In case of any injury occurred then rescue team shell be called up at the scene with all safety

precautions and take out the injured person using the stretcher and shift him at safe place to

provide him first aid or in case of severe injury the team should rush to nearest

hospital/medical centre

The incident shall be reported verbely to permit issuer and later incident report shall be

prepared and submit to client accordingly

Toolbox talks, safety meetings etc.

Toolbox meeting at the start of work regarding safe work.

Include records of any such meetings and record attendance.

Yes, toolbox form shall be filled on daily basis.

Other, specify.

PROPER HOUSE KEEPING.

5. How will the work be completed, i.e. Procedure step by step

Proposed Start date

11/04/2022

Step 1 : Mobilization of Tools, Equipment and Manpower to Site.

Site induction by terminal

Entry inside Terminal

Equipment and tool will be mobilized at site according to requirement by

using truck

Visual inspection of tools and equipment.

All the Equipment shall be third party certified.

Trained and competent resources must be deployed.

Step 2 : Stacking Of Material

Material will be Stacked manually following LITE formula

with manpower

Rack will be prepared for proper stacking of material

Material will be segregated such as joints, planks, scaffolding

pipes, GI sheets, Wheel barrow, gas cutter and other hand tools

will be stacked properly

Do not lift, lower, push, pull, or carry a load greater than 25 kg.

Use correct posture and lifting technique

Wear appropriate hand protection suitable for task

Ensure PPEs suitable for task

Step 3: Hard Baricade Area around SKP-06

Clean the working area

Erect Scaffolding pipes for GI sheets on base

plate

GI sheets will install on Scaffolding

Tank SKP-06 will be hard barricade from all

foursides

Walkways for operation working will not disturbed

Wear appropriate hand protection suitable for task

Flogging spanners are prohibited from use

The use of knives is prohibited

Inspection should be done before use

Always keep clean.

Never take shortcuts.

Never use damage tools and equipments

Step 4: Housekeeping.

Housekeeping of the working area will be done during and after job.

Form F – Method of Statement Distribution Permit to Work

Version 3.0 May 2007 Page 2 of 2

Procedure System

You might also like

- Helicon x3Document140 pagesHelicon x3TarasenkoNo ratings yet

- Aeg 8.33 UpsDocument110 pagesAeg 8.33 UpsThomas Irwin Dsouza100% (1)

- Successful Instrumentation and Control Systems Design, Second EditionFrom EverandSuccessful Instrumentation and Control Systems Design, Second EditionRating: 4.5 out of 5 stars4.5/5 (10)

- Safe Work Procedure-Set Up RigsDocument4 pagesSafe Work Procedure-Set Up RigsAsif KhanzadaNo ratings yet

- Method Statement - MHI Installation of Utility PoleDocument7 pagesMethod Statement - MHI Installation of Utility PoleJohn DoeNo ratings yet

- Method Statement For Geophysical SurveyDocument7 pagesMethod Statement For Geophysical SurveyvinodhyperNo ratings yet

- Industry Study Activities Industrial Technology HSCDocument3 pagesIndustry Study Activities Industrial Technology HSCapi-320830582100% (1)

- Occupational Health and SafetyDocument8 pagesOccupational Health and Safetygroup oneNo ratings yet

- Temp Fencing & GateDocument12 pagesTemp Fencing & GateMark Fash0% (1)

- CCTV Method Statement GN 3 (V1) February 2009Document5 pagesCCTV Method Statement GN 3 (V1) February 2009Gyanendra Singh0% (1)

- 4A dm253461 Project Premobilization Safety Meeting Checklist PDFDocument19 pages4A dm253461 Project Premobilization Safety Meeting Checklist PDFRheNo ratings yet

- JSA For Welding GrindingDocument7 pagesJSA For Welding GrindingBabar78% (9)

- Performance Indicators MSQH Hospital Accreditation Standards 5th EditionDocument215 pagesPerformance Indicators MSQH Hospital Accreditation Standards 5th EditionMuhammad Khairol Omar100% (2)

- I150 Peristaltic Pump Operating ManualDocument20 pagesI150 Peristaltic Pump Operating ManualPunit PurshotamNo ratings yet

- Asbestos TEMPLATE Asbestos Management PlanDocument6 pagesAsbestos TEMPLATE Asbestos Management PlanIhor100% (1)

- Toolbox Talk - Workshop Safety General RulesDocument3 pagesToolbox Talk - Workshop Safety General Rules260380sdNo ratings yet

- Maledives Airport Scope of Work PDFDocument10 pagesMaledives Airport Scope of Work PDFakanagesNo ratings yet

- Method Statement: Company: Naseem & Son Project: Date: 21/05/2022 1. Description of WorksDocument3 pagesMethod Statement: Company: Naseem & Son Project: Date: 21/05/2022 1. Description of WorksSagar SharmaNo ratings yet

- MS SKP-08 For Internal Grit BlastingDocument9 pagesMS SKP-08 For Internal Grit BlastingSagar SharmaNo ratings yet

- MS - VDU Exention & BLA Installation at KMRDocument5 pagesMS - VDU Exention & BLA Installation at KMRNaseemandson TeamNo ratings yet

- QTC - Safety Permit-InstructionDocument11 pagesQTC - Safety Permit-InstructionQueenie FloresNo ratings yet

- Method Statement (DKi 2024)Document2 pagesMethod Statement (DKi 2024)Noman AliNo ratings yet

- Scope of Work PR 2500366865 - 464-KL1 Repair at Feed End Pfister - HPHI - La Union PlantDocument3 pagesScope of Work PR 2500366865 - 464-KL1 Repair at Feed End Pfister - HPHI - La Union PlantJuancho PaduaNo ratings yet

- TS-406 - Method Statement For Cable Tray InstallationDocument16 pagesTS-406 - Method Statement For Cable Tray InstallationsindalisindiNo ratings yet

- Work Permit SystemDocument5 pagesWork Permit SystemSuresh PasumarthiNo ratings yet

- S-PCM Minutes of Meeting: Produce Water Tank 001/002Document5 pagesS-PCM Minutes of Meeting: Produce Water Tank 001/002sudeesh kumarNo ratings yet

- 10 - WMS - Turpentine - Tie BeamDocument6 pages10 - WMS - Turpentine - Tie BeamVikramaditya NayakNo ratings yet

- Method Statement For MV Panels and Accessories Unloading.: Project NameDocument12 pagesMethod Statement For MV Panels and Accessories Unloading.: Project NameSatish SharmaNo ratings yet

- MSOG-M2014-C-JMS-001 - For Grating Cover InstallationDocument9 pagesMSOG-M2014-C-JMS-001 - For Grating Cover Installationshaiful annuarNo ratings yet

- Jsa Lifting of PitsDocument8 pagesJsa Lifting of PitseslamNo ratings yet

- 11 - WMS - Turpentine - Plaster WorksDocument5 pages11 - WMS - Turpentine - Plaster WorksVikramaditya NayakNo ratings yet

- Work Permit Safety Standard Training PackDocument24 pagesWork Permit Safety Standard Training PackAtma Prakash Sinha100% (1)

- MS For Grounding and Cadwelding WorkDocument34 pagesMS For Grounding and Cadwelding WorkGanga Daran100% (2)

- OHS Work PermitsDocument17 pagesOHS Work PermitsNadaNo ratings yet

- Method Statement For Hydro TestDocument3 pagesMethod Statement For Hydro TestSandeep kumar100% (1)

- 742 Method Statement 2011Document20 pages742 Method Statement 2011kikokiko KarimNo ratings yet

- Permit To WorkDocument3 pagesPermit To WorkPrinterHaapcolNo ratings yet

- Method Statement - IT CablingDocument12 pagesMethod Statement - IT CablingmmcsolutionsystemNo ratings yet

- StatementDocument8 pagesStatementMrProlyfeNo ratings yet

- SMM 12 Hot Work PermitDocument4 pagesSMM 12 Hot Work PermitPavan mylapalliNo ratings yet

- MS Boiler & CalorifierDocument14 pagesMS Boiler & CalorifierSanto ENo ratings yet

- Agenda-HSE 28.02.24Document1 pageAgenda-HSE 28.02.24Pradeep SahuNo ratings yet

- Scope of Work PR 2500366866 - 363-RM1 VRM Int. Repairs & False Air Cor - HPHI - La Union PlantDocument3 pagesScope of Work PR 2500366866 - 363-RM1 VRM Int. Repairs & False Air Cor - HPHI - La Union PlantJuancho PaduaNo ratings yet

- Excavation & BackfillingDocument6 pagesExcavation & BackfillingnidhinbobanNo ratings yet

- Electrical Safety RequirementDocument8 pagesElectrical Safety RequirementAnonymous kWfNFb100% (1)

- Work Permit Compliance (Presentation)Document52 pagesWork Permit Compliance (Presentation)Ramzan Nazir100% (1)

- DIAL WORK PERMIT NewDocument5 pagesDIAL WORK PERMIT NewAkshay PotekarNo ratings yet

- 8 - WMS - Turpentine - Plinth BeamDocument4 pages8 - WMS - Turpentine - Plinth BeamVikramaditya NayakNo ratings yet

- Method Statement For Hard Barrication InstallationDocument10 pagesMethod Statement For Hard Barrication Installationshamshad ahamedNo ratings yet

- Wap2 Cp05a MS 0008 01 - Installation of PanelDocument6 pagesWap2 Cp05a MS 0008 01 - Installation of PanelElisco Pher SalmasanNo ratings yet

- Confined Spaces: Procedures and Use of PermitsDocument28 pagesConfined Spaces: Procedures and Use of PermitsTom BellNo ratings yet

- Method Statement - CCTVDocument7 pagesMethod Statement - CCTVamenmohd100% (1)

- OutlineDocument11 pagesOutlineKadita RogerNo ratings yet

- Method of StatementDocument5 pagesMethod of Statementdaddy coolNo ratings yet

- Editable Health and Safety FormsDocument32 pagesEditable Health and Safety FormsFlavia Rodrigo Guedes100% (1)

- 11 - WMS - Turpentine - Brick WallDocument5 pages11 - WMS - Turpentine - Brick WallVikramaditya NayakNo ratings yet

- Method Statement SampleDocument3 pagesMethod Statement SampleAmrith RajNo ratings yet

- 8 Permit To Work ProcedureDocument7 pages8 Permit To Work Procedurekhurram100% (1)

- METH 00005 A 330 SQUH Method Statement Vinyl FloorDocument3 pagesMETH 00005 A 330 SQUH Method Statement Vinyl Floormohd arshadNo ratings yet

- MS For SKP Tank T-0402Document8 pagesMS For SKP Tank T-0402Sagar SharmaNo ratings yet

- DM001 ENM ALL FO 01076 A2 Worksite Check Tool Box Talk PICDocument2 pagesDM001 ENM ALL FO 01076 A2 Worksite Check Tool Box Talk PICmkashkooli_scribd100% (1)

- General Work Permit: Work Should Not Commence Until Stages 1 To 5 Are CompletedDocument2 pagesGeneral Work Permit: Work Should Not Commence Until Stages 1 To 5 Are CompletedIonian TribeNo ratings yet

- JSA For KAHSDocument6 pagesJSA For KAHSFrancis Enriquez TanNo ratings yet

- Method Statement: Departmental Representative Contractors RepresentativeDocument1 pageMethod Statement: Departmental Representative Contractors RepresentativePranabesh MallickNo ratings yet

- Method Statement DraftDocument9 pagesMethod Statement DraftJAMES neelNo ratings yet

- Facility/Plant Location: Description of Work: Contractor:: PCD Project: Water Treatment Facilities - 3Document8 pagesFacility/Plant Location: Description of Work: Contractor:: PCD Project: Water Treatment Facilities - 3AldrinNo ratings yet

- 20.interior Refurbishment Method Statement GN 20 PDFDocument5 pages20.interior Refurbishment Method Statement GN 20 PDFleebankNo ratings yet

- Ilovepdf MergedDocument8 pagesIlovepdf MergedSagar SharmaNo ratings yet

- B ShackleDocument1 pageB ShackleSagar SharmaNo ratings yet

- Permit Number P240-00-6761810 State Waiting For Verification Lifetime Expires OnDocument47 pagesPermit Number P240-00-6761810 State Waiting For Verification Lifetime Expires OnSagar SharmaNo ratings yet

- Permit Number P289-00-6723327 State Waiting For Verification Lifetime Expires OnDocument53 pagesPermit Number P289-00-6723327 State Waiting For Verification Lifetime Expires OnSagar SharmaNo ratings yet

- Angle Grinder BG-01Document1 pageAngle Grinder BG-01Sagar SharmaNo ratings yet

- D ShackleDocument1 pageD ShackleSagar SharmaNo ratings yet

- Chain Block CB NS.010 2T - 2Document1 pageChain Block CB NS.010 2T - 2Sagar SharmaNo ratings yet

- Permit Number P240-00-6693635 State Live (16 Mar 09:31 - 16 Mar 19:00) Lifetime Expires On 20-03-2024Document4 pagesPermit Number P240-00-6693635 State Live (16 Mar 09:31 - 16 Mar 19:00) Lifetime Expires On 20-03-2024Sagar SharmaNo ratings yet

- Manual Lifting PlanDocument2 pagesManual Lifting PlanSagar SharmaNo ratings yet

- Rescue Plan Working at HeightDocument2 pagesRescue Plan Working at HeightSagar SharmaNo ratings yet

- New EntryDocument1 pageNew EntrySagar SharmaNo ratings yet

- Progress Report 32Document2 pagesProgress Report 32Sagar SharmaNo ratings yet

- Progress Report 33Document2 pagesProgress Report 33Sagar SharmaNo ratings yet

- Naseem & Son: Emergency Response PlanDocument7 pagesNaseem & Son: Emergency Response PlanSagar SharmaNo ratings yet

- Emergency Response/ Rescue Plan Forworking at Height: First Aider: Abdul Samad Rescuer: Noman & RaheelDocument1 pageEmergency Response/ Rescue Plan Forworking at Height: First Aider: Abdul Samad Rescuer: Noman & RaheelSagar SharmaNo ratings yet

- JSA For NSE ProjectDocument7 pagesJSA For NSE ProjectSagar SharmaNo ratings yet

- Progress Report 31Document2 pagesProgress Report 31Sagar SharmaNo ratings yet

- MS SKP-08 For Internal Grit BlastingDocument9 pagesMS SKP-08 For Internal Grit BlastingSagar SharmaNo ratings yet

- Safety Walk Report by ClientDocument3 pagesSafety Walk Report by ClientSagar SharmaNo ratings yet

- Work at Height Rescue PlanDocument1 pageWork at Height Rescue PlanSagar SharmaNo ratings yet

- Method Statement: Company: Naseem & Son Project: Date: 21/05/2022 1. Description of WorksDocument3 pagesMethod Statement: Company: Naseem & Son Project: Date: 21/05/2022 1. Description of WorksSagar SharmaNo ratings yet

- Rescue Plan For HeightDocument2 pagesRescue Plan For HeightSagar SharmaNo ratings yet

- Risk Assessment: Corresponding Permit To Work NoDocument4 pagesRisk Assessment: Corresponding Permit To Work NoSagar SharmaNo ratings yet

- SSE-ST-GL-009-11 Routine Lift Plan: Lifting & Hoisting - Loading of SPL-11 Roof Scrap Plates On TruckDocument4 pagesSSE-ST-GL-009-11 Routine Lift Plan: Lifting & Hoisting - Loading of SPL-11 Roof Scrap Plates On TruckSagar SharmaNo ratings yet

- SHELL SMEP Lifting and Hoisting Manual Rev 1 0Document349 pagesSHELL SMEP Lifting and Hoisting Manual Rev 1 0Sagar SharmaNo ratings yet

- Naseem & Son: Report of Internal AuditDocument5 pagesNaseem & Son: Report of Internal AuditSagar SharmaNo ratings yet

- Key Performance Indicator Naseem & SonDocument1 pageKey Performance Indicator Naseem & SonSagar SharmaNo ratings yet

- Assessment Report Naseem & SonDocument2 pagesAssessment Report Naseem & SonSagar SharmaNo ratings yet

- Method Statement: Company: Naseem & Son Project: Maintinance (SKP-09) Date: 05-12-2021 1. Description of WorksDocument2 pagesMethod Statement: Company: Naseem & Son Project: Maintinance (SKP-09) Date: 05-12-2021 1. Description of WorksSagar SharmaNo ratings yet

- All Safety Inspection ChecklistsDocument30 pagesAll Safety Inspection ChecklistsSagar Sharma50% (2)

- Material Safety Data Sheet: Section 1 - Product and Company IdentificationDocument4 pagesMaterial Safety Data Sheet: Section 1 - Product and Company IdentificationdnmuleNo ratings yet

- BSR455 - Group 9 - Building Inspection - 3aDocument22 pagesBSR455 - Group 9 - Building Inspection - 3aMuhammad IdzhamNo ratings yet

- Msds-En Shell Rimula r3Document9 pagesMsds-En Shell Rimula r3Clement Ayobami OladejoNo ratings yet

- Safety Data Sheet: Exxon Mobil CorporationDocument9 pagesSafety Data Sheet: Exxon Mobil CorporationHpnoteNo ratings yet

- Code of Practice For Access and Working ScaffoldsDocument124 pagesCode of Practice For Access and Working ScaffoldsMohammad Irshad AlamNo ratings yet

- Safety Geremew TarekegnDocument110 pagesSafety Geremew TarekegnTariku NigussieNo ratings yet

- Labour Welfare in India and Its Role in Industrial RelatonsDocument23 pagesLabour Welfare in India and Its Role in Industrial RelatonsPragya ChakshooNo ratings yet

- +CPCCWHS2001 Assessment - Theory AMBDocument34 pages+CPCCWHS2001 Assessment - Theory AMBH .SNo ratings yet

- MSDS Wall & Pier CopingsDocument2 pagesMSDS Wall & Pier Copingsaditarian .pNo ratings yet

- Manage Operational PlanDocument20 pagesManage Operational Planneha100% (2)

- WRAP Audit Checklist Uploaded by Compliance BangladeshDocument1 pageWRAP Audit Checklist Uploaded by Compliance Bangladeshkrishna.greenhrNo ratings yet

- Progesterone Formulation: Safety Data SheetDocument12 pagesProgesterone Formulation: Safety Data SheetMohamedSaid100% (1)

- Safety Data Sheet: AlamineDocument13 pagesSafety Data Sheet: AlamineIbnu BakriNo ratings yet

- Bread and PastryTLE Enrichment ActivityDocument7 pagesBread and PastryTLE Enrichment ActivityalyssaNo ratings yet

- Ali Resume LATESTDocument3 pagesAli Resume LATESTabogadieNo ratings yet

- Copper Foil Shielding TapeDocument2 pagesCopper Foil Shielding TapeEngr. Mehadi Hassan NahidNo ratings yet

- L2RA-Personnel TransferDocument10 pagesL2RA-Personnel TransferSam Delo-deloNo ratings yet

- 3m-5n11-n95-technical-infoDocument2 pages3m-5n11-n95-technical-infoAwal JaNuary SaragiNo ratings yet

- Contractor Safety Managment ProgramDocument19 pagesContractor Safety Managment Programsanjeev kumarNo ratings yet

- Ihsec Nebosh Igc Flyer - GeneralDocument4 pagesIhsec Nebosh Igc Flyer - GeneralJows Magtoto-DavidNo ratings yet

- Safety Data Sheet - EN - (43805315) SODIUM SILICATE SOLUTION (WATER GLASS) (1344-09-8)Document8 pagesSafety Data Sheet - EN - (43805315) SODIUM SILICATE SOLUTION (WATER GLASS) (1344-09-8)Mahdi BelhechmiNo ratings yet