Professional Documents

Culture Documents

IMG - 0115 PSME Code 2008 106

IMG - 0115 PSME Code 2008 106

Uploaded by

ricky fluor50Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IMG - 0115 PSME Code 2008 106

IMG - 0115 PSME Code 2008 106

Uploaded by

ricky fluor50Copyright:

Available Formats

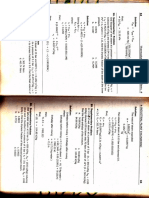

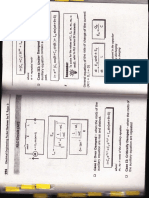

CHAPTER 6 - ELEVATORS, DUMBWAITERS, ESCALATORS AND MOVING WALKS

450 10.00 8.9

500 1.25 9.15 a. By individual tapered babbitted rope

600 1.7 9.5 sockets; or

700 11.0 9.8

1000 11.55 10.3 b. By other tytes of rope fastening, if approved

1s00 11.9 10.55 by the enferrcing authority, on the basis of

adequate tensile'and fatigue tests made by

NOTE:

a qualified laboratory provided that:

m/s' = fpmx0.00508

1. such fastenings conform to the

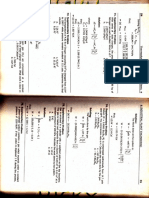

6.4.13.10 Suspension Rope Equalizers. Suspension

rope equalizers, where provided, shall be of

requirement of Section 6.4'13'15

and 6.4.13.16.

the individual-compression spring type.

Exception: Equalizers of other types may

2. the rope socketing shall be such as

to develoP at least 80% of the

be used with traction elevators provided the

ultimate breaking strength to the

equalizers and their fastenings are approved

strongest roPe to be used in such

by the enforcing authority on the basis of

fastenings,; and

adequate tensile and fatigue tests made by

a qualified laboratory. Such tests shall show

the ultimate strength of the equalizer and its

3. U-bolt type rope clips (clamps) shall

not be used for such fastenings.

fastenings in its several pahs and assembly,

which shall be not less than 10% in excess

6.4.13.15 Adiustable Shackle Rods. The car ends,

of the strength of suspension ropes as or the car or counterweight dead ends

required by Sec. 6.4.13.8, provided that

equalizers of the single-bar type, or springs

where multiple roping is used, of all

in tension, shall not be used to attach suspension wire ropes of traction type

elevators shall be provided with shackle

suspension ropes to cars or counterweights

rods of a design which will permit individual

or to deadened hitchPlates.

adjustment of the rope lengths. Similar

of Suspension Wire Ropes to shackle rods shall be provided on the car or

6.4.13.11 Securing

Drums. Suspension wire ropes of counterweight ends of compensating ropes.

Winding

winding-drurn machines shall have the drum

6.4.13.16 General Design Requirements. Wire rope

ends of the ropes secured on the inside of

fastenings shall conform to the following:

the drum by clamps or by tapered babbitted

sockets, or by.other means approved by the

enforcing authbrity.

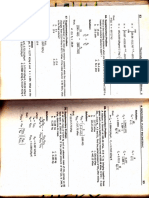

The portion of the rope fastenings which

holds the wire rope (rope socket) and the

t'

6.4.13.12Spare rope-Turns on Winding Drums. shackle rod may be in one piece (unit

construction), or they may be separate.

Suspension wire ropes of winding-drum

machines shall have not less than one turn

of the rope on the drum when the car is b. The rope socket shall be either cast or

resting on the fully compressed buffers.

forged steel provided that where the rope

socket and the shackle rod are in one piece

(unit construction), the entire fastening shal

6.4.13.13 Splicing and Replacement of Suspension

Ropes. Suspension wire ropes shall not be be of forged steel.

lengthened or repaired by splicing. lf one

rope of a set is worn or damaged and c. Where the shackle rod and rope socket are

required replacement, the entire set of roPes, not in one piece, the shackle rod shall be d

forged or rolled steel.

shall be replaced.

6.4.13.14 Type of Rope Fastenings. The car and d. Cast of forged steel rope sockets, shackle

countenrveight ends of suspension wire rods and their connections shall be made d

ropes, or the stationary hitch-ends where unwelded steel, having an elongation of nd

multiple roping is used, shall be fastened in less than 20% in a length of 51 mm,

such a manner that all portions of the rope conforming to ANSI/ASTM A668, Class B

except the portion inside the rope sockets

for forged steel and ANSI/ASTM M7,

shall be readily visible. Fastening shall be:

106

You might also like

- Concrete Mechanics and Design - Solution ManualDocument277 pagesConcrete Mechanics and Design - Solution Manualramya_an241167% (3)

- Mooring Hawser Conoco PhiliphinDocument15 pagesMooring Hawser Conoco PhiliphinhaitacvietnamNo ratings yet

- SPMT Stability of Hydraulic EngDocument4 pagesSPMT Stability of Hydraulic Engparamarthasom1974No ratings yet

- Manual For EOT CranesDocument39 pagesManual For EOT CranesManish Jha67% (12)

- IMG - 0069 PSME Code 2008 58Document1 pageIMG - 0069 PSME Code 2008 58Arwyn BermasNo ratings yet

- IMG - 0095 PSME Code 2008 86Document1 pageIMG - 0095 PSME Code 2008 86Arwyn BermasNo ratings yet

- IMG - 0107 PSME Code 2008 98Document1 pageIMG - 0107 PSME Code 2008 98Master JaguarNo ratings yet

- IMG - 0097 PSME Code 2008 88Document1 pageIMG - 0097 PSME Code 2008 88Arwyn BermasNo ratings yet

- IMG - 0119 PSME Code 2008 110Document1 pageIMG - 0119 PSME Code 2008 110ricky fluor50No ratings yet

- IMG - 0124 PSME Code 2008 115Document1 pageIMG - 0124 PSME Code 2008 115Bugoy2023No ratings yet

- Tabla Tension Correas Gates PDFDocument4 pagesTabla Tension Correas Gates PDFHarold BurgosNo ratings yet

- Use and CareDocument4 pagesUse and CarechannarongNo ratings yet

- BKI Vol3 - Section04Document6 pagesBKI Vol3 - Section04Iwan BopengNo ratings yet

- Differential & DrivelineDocument138 pagesDifferential & DrivelineRocky SNo ratings yet

- Survey Guidelines - Emergency Towing Arrangements No.40: Initial InstallationDocument3 pagesSurvey Guidelines - Emergency Towing Arrangements No.40: Initial Installationnaing kyawNo ratings yet

- Retificador e ReguladorDocument6 pagesRetificador e ReguladorArtur ValNo ratings yet

- Wire Rope Users Manual-2Document13 pagesWire Rope Users Manual-2Kathrin KatsNo ratings yet

- Mooring Assessment FormDocument4 pagesMooring Assessment FormSAGAMINo ratings yet

- IMG - 0136 PSME Code 2008 128Document1 pageIMG - 0136 PSME Code 2008 128Arwyn BermasNo ratings yet

- Specification No. 1 United Kingdom Civil Aviation Authority: Issue: 6 Date: 12 March 2004Document5 pagesSpecification No. 1 United Kingdom Civil Aviation Authority: Issue: 6 Date: 12 March 2004Kaung MyatToeNo ratings yet

- Business Class M2 Workshop Manual-8Document289 pagesBusiness Class M2 Workshop Manual-8Dinator CortésNo ratings yet

- Wood Propellers: Installation, Operation, & Maintenance Integral Flange CrankshaftsDocument4 pagesWood Propellers: Installation, Operation, & Maintenance Integral Flange CrankshaftsPOUETNo ratings yet

- PT Bhaita Wire Rope Inspection ProcedureDocument4 pagesPT Bhaita Wire Rope Inspection ProcedureSugianto TanNo ratings yet

- Asme-B30.22 - 02Document41 pagesAsme-B30.22 - 02Brayan Montalban GarciaNo ratings yet

- Local Buckling: C RveDocument1 pageLocal Buckling: C RveprateekmuleNo ratings yet

- Agitated VF - Ssel!I: Yz,) 'RoDocument1 pageAgitated VF - Ssel!I: Yz,) 'RoprateekmuleNo ratings yet

- RT440B ENG Rev.01 - 2007 (1) (099-248)Document150 pagesRT440B ENG Rev.01 - 2007 (1) (099-248)Valmaq Prestação Serviço LdaNo ratings yet

- Mooring Line Care MaintenanceDocument2 pagesMooring Line Care MaintenanceMehmet Ali100% (1)

- Wire Rope Hoist Wire Rope Hoist: Lift & Connect SafelyDocument20 pagesWire Rope Hoist Wire Rope Hoist: Lift & Connect SafelyFiroz PawaskarNo ratings yet

- Pre-Stressed ConcreteDocument23 pagesPre-Stressed ConcreteShabbar Abbas MalikNo ratings yet

- Health: & Safety AdvisoryDocument2 pagesHealth: & Safety AdvisorykrissregionNo ratings yet

- Higher Pole Number Synchronous Reluctance Machines With Fractional Slot Concentrated WindingsDocument6 pagesHigher Pole Number Synchronous Reluctance Machines With Fractional Slot Concentrated WindingsELL750 MEMNo ratings yet

- 6.5. Bolt Installation: 5.1. What Can Be Done To Prevent The Nut From Loosening?Document3 pages6.5. Bolt Installation: 5.1. What Can Be Done To Prevent The Nut From Loosening?Ahmed LepdaNo ratings yet

- Couplings and BuffersDocument11 pagesCouplings and BuffersSinter PlanningNo ratings yet

- H4212 Spread 3Document1 pageH4212 Spread 3Dimitris76No ratings yet

- Dsaeda000140584 PDFDocument2 pagesDsaeda000140584 PDFchrisNo ratings yet

- Spun Pile MosDocument5 pagesSpun Pile MosTinesh K RamanNo ratings yet

- w"I/1I4 Ec: 408.6 Modulus of ElasticityDocument1 pagew"I/1I4 Ec: 408.6 Modulus of ElasticityAlskduiNo ratings yet

- L.electrically Travelling: (E.O.T) CraneDocument38 pagesL.electrically Travelling: (E.O.T) CraneFiroz PawaskarNo ratings yet

- Gunite Slack Adjuster: Service ManualDocument16 pagesGunite Slack Adjuster: Service ManualMarlon MontenegroNo ratings yet

- Pre-Starting Checks: Avertissement DangerDocument2 pagesPre-Starting Checks: Avertissement DangerAquino ArviNo ratings yet

- Anchor Bolt Pretension - SummaryDocument4 pagesAnchor Bolt Pretension - SummaryFWICIPNo ratings yet

- Cat 09a en Spring Operated Cable ReelsDocument40 pagesCat 09a en Spring Operated Cable ReelssonNo ratings yet

- 9.2.3 Sag Adjusters: Dhofar Power Company SAOGDocument1 page9.2.3 Sag Adjusters: Dhofar Power Company SAOG54045114No ratings yet

- Operating Inst DR 10 - Versi Holding BrakeDocument20 pagesOperating Inst DR 10 - Versi Holding Brakefatchur rochmanNo ratings yet

- AASHTO LRFD Bridge Design Specifications 7th Ed. 2014 CL 5.11.5.3Document3 pagesAASHTO LRFD Bridge Design Specifications 7th Ed. 2014 CL 5.11.5.3JohnNo ratings yet

- S&C XSDocument1 pageS&C XSAnonymous qDCftTW5MNo ratings yet

- 01 - I-Line II Catalogue 2020 PDFDocument3 pages01 - I-Line II Catalogue 2020 PDFsajeevi piumikaNo ratings yet

- Scanned by CamscannerDocument10 pagesScanned by CamscannerChandrashekhar KalyankarNo ratings yet

- AASHTO BoltsDocument5 pagesAASHTO BoltsCyrilNo ratings yet

- BS 6210Document16 pagesBS 6210Fatima JawadNo ratings yet

- Chain Installation: Safety PrecautionsDocument16 pagesChain Installation: Safety PrecautionsAlejandro RodriguezNo ratings yet

- CFR 2011 Title49 Vol3 Sec179 200Document1 pageCFR 2011 Title49 Vol3 Sec179 200AssemNo ratings yet

- ER288-Bearing Test PlanDocument3 pagesER288-Bearing Test PlanalfieNo ratings yet

- Design of Journal Bearing Supports To Be Used in Fiber Reinforced Concrete Beam TestsDocument7 pagesDesign of Journal Bearing Supports To Be Used in Fiber Reinforced Concrete Beam TestsConnieNo ratings yet

- Anchor HandlingDocument3 pagesAnchor HandlingSaptarshi BasuNo ratings yet

- ASTM F1911-2005 (2010) - 4375 - Razor Barbed WireDocument3 pagesASTM F1911-2005 (2010) - 4375 - Razor Barbed WireOlivia WangNo ratings yet

- Bridge Joints: Code of PracticeDocument3 pagesBridge Joints: Code of PracticePaulNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Understanding Your Boats Systems and Choices.From EverandUnderstanding Your Boats Systems and Choices.Rating: 3 out of 5 stars3/5 (1)

- Img - 0036 MCQ For Power & Ipe 63aDocument1 pageImg - 0036 MCQ For Power & Ipe 63aricky fluor50No ratings yet

- Img - 0034 MCQ For Power & Ipe 59aDocument1 pageImg - 0034 MCQ For Power & Ipe 59aricky fluor50No ratings yet

- Img - 0033 MCQ For Power & Ipe 57aDocument1 pageImg - 0033 MCQ For Power & Ipe 57aricky fluor50No ratings yet

- Img - 0037 MCQ For Power & Ipe 65Document1 pageImg - 0037 MCQ For Power & Ipe 65ricky fluor50No ratings yet

- Img - 0032 MCQ For Power & Ipe 55Document1 pageImg - 0032 MCQ For Power & Ipe 55ricky fluor50No ratings yet

- Img - 0038 MCQ For Power & Ipe 67Document1 pageImg - 0038 MCQ For Power & Ipe 67ricky fluor50No ratings yet

- Img - 0039 MCQ For Power & Ipe 69Document1 pageImg - 0039 MCQ For Power & Ipe 69ricky fluor50No ratings yet

- IMG - 0117 PSME Code 2008 108Document1 pageIMG - 0117 PSME Code 2008 108ricky fluor50No ratings yet

- Img - 0040 MCQ For Power & Ipe 71Document1 pageImg - 0040 MCQ For Power & Ipe 71ricky fluor50No ratings yet

- Img - 0031 MCQ For Power & Ipe 53Document1 pageImg - 0031 MCQ For Power & Ipe 53ricky fluor50No ratings yet

- IMG - 0119 PSME Code 2008 110Document1 pageIMG - 0119 PSME Code 2008 110ricky fluor50No ratings yet

- IMG - 0111 PSME Code 2008 102Document1 pageIMG - 0111 PSME Code 2008 102ricky fluor50No ratings yet

- IMG - 0078 PSME Code 2012 77Document1 pageIMG - 0078 PSME Code 2012 77ricky fluor50No ratings yet

- IMG - 0113 PSME Code 2008 104Document1 pageIMG - 0113 PSME Code 2008 104ricky fluor50No ratings yet

- IMG - 0118 ESAS 2001 Solved Problem Objectives 21-47Document1 pageIMG - 0118 ESAS 2001 Solved Problem Objectives 21-47ricky fluor50No ratings yet

- IMG - 0076 PSME Code 2012 75Document1 pageIMG - 0076 PSME Code 2012 75ricky fluor50No ratings yet

- Img - 0085 MCQ Ece Board Exam 157Document1 pageImg - 0085 MCQ Ece Board Exam 157ricky fluor50No ratings yet

- Img - 0082 MCQ Ece Board Exam 151Document1 pageImg - 0082 MCQ Ece Board Exam 151ricky fluor50No ratings yet

- IMG - 0080 PSME Code 2012 79Document1 pageIMG - 0080 PSME Code 2012 79ricky fluor50No ratings yet

- IMG - 0074 PSME Code 2012 73Document1 pageIMG - 0074 PSME Code 2012 73ricky fluor50No ratings yet

- IMG - 0072 PSME Code 2012 71Document1 pageIMG - 0072 PSME Code 2012 71ricky fluor50No ratings yet

- IMG - 0071 PSME Code 2012 70Document1 pageIMG - 0071 PSME Code 2012 70ricky fluor50No ratings yet

- Img - 0086 MCQ Ece Board Exam 159Document1 pageImg - 0086 MCQ Ece Board Exam 159ricky fluor50No ratings yet

- Img - 0087 MCQ Ece Board Exam 161Document1 pageImg - 0087 MCQ Ece Board Exam 161ricky fluor50No ratings yet

- Img - 0096 MCQ Ree Board Exam 185Document1 pageImg - 0096 MCQ Ree Board Exam 185ricky fluor50No ratings yet

- Img - 0098 MCQ Ree Board Exam 189Document1 pageImg - 0098 MCQ Ree Board Exam 189ricky fluor50No ratings yet

- Img - 0083 MCQ Ece Board Exam 153Document1 pageImg - 0083 MCQ Ece Board Exam 153ricky fluor50No ratings yet

- Img - 0094 MCQ Ree Board Exam 181Document1 pageImg - 0094 MCQ Ree Board Exam 181ricky fluor50No ratings yet

- Img - 0100 MCQ Ree Board Exam 193Document1 pageImg - 0100 MCQ Ree Board Exam 193ricky fluor50No ratings yet

- Img - 0101 MCQ Ree Board Exam 195Document1 pageImg - 0101 MCQ Ree Board Exam 195ricky fluor50No ratings yet

- Heat Pumps Planning File 2012Document399 pagesHeat Pumps Planning File 2012szaszdeziderNo ratings yet

- C-FC-01-Liquid Tightness Design of LNG Storage Tank Incorporating Cryogenic Temperature-Induced StressesDocument8 pagesC-FC-01-Liquid Tightness Design of LNG Storage Tank Incorporating Cryogenic Temperature-Induced StressesManoj KanadiaNo ratings yet

- TRM37 Basements - Design For Watertightness Rev6Document6 pagesTRM37 Basements - Design For Watertightness Rev6TuanNo ratings yet

- Upcoming Code Changes ASME CSD-1, NFPA 85, and NFPA 87: Prepared ForDocument39 pagesUpcoming Code Changes ASME CSD-1, NFPA 85, and NFPA 87: Prepared ForHimanshu PatelNo ratings yet

- Bearing Piles and GroupsDocument36 pagesBearing Piles and Groupsjologscresencia100% (1)

- Fire Fighting SpecificationDocument23 pagesFire Fighting SpecificationsurendramaharjanNo ratings yet

- GARDENA MygardenDocument22 pagesGARDENA MygardengrecuvaliNo ratings yet

- 10P87-D0003-046-R0-WHRU by TEPLDocument23 pages10P87-D0003-046-R0-WHRU by TEPLjigarNo ratings yet

- Washers: 1.0. ScopeDocument3 pagesWashers: 1.0. ScopehendrexNo ratings yet

- Muvtons Wheel DetailsDocument2 pagesMuvtons Wheel Detailsvivek jayswalNo ratings yet

- EX037 Report by Penny Taylor - Factual Report - September 2008 PDFDocument46 pagesEX037 Report by Penny Taylor - Factual Report - September 2008 PDFagitentNo ratings yet

- Entrances Storefronts Window Walls Curtain Walls (PDFDrive)Document226 pagesEntrances Storefronts Window Walls Curtain Walls (PDFDrive)liquid snakeNo ratings yet

- Section 7 GposDocument62 pagesSection 7 GposDangolNo ratings yet

- QCM-001 2023 Comment PeriodDocument187 pagesQCM-001 2023 Comment PeriodemlNo ratings yet

- Edt Has Bearings For All Areas of Baked Goods and Snack ProcessingDocument4 pagesEdt Has Bearings For All Areas of Baked Goods and Snack ProcessingLeroy AraoNo ratings yet

- PR PYR P06-17 v1 How To Improve Fan EfficiencyDocument8 pagesPR PYR P06-17 v1 How To Improve Fan EfficiencyTamer FathyNo ratings yet

- Pipe and Pipe Fittings in Hydraulic SystemDocument11 pagesPipe and Pipe Fittings in Hydraulic SystemAaryan Pawar100% (1)

- Bederina Et Al. - 2007 - Effect of The Addition of Wood Shavings On ThermalDocument8 pagesBederina Et Al. - 2007 - Effect of The Addition of Wood Shavings On ThermalsalvadorNo ratings yet

- Lab Report Sheet-2 - 0Document11 pagesLab Report Sheet-2 - 0I-zad MJNo ratings yet

- Τιμοκαταλογοσ Price ListDocument108 pagesΤιμοκαταλογοσ Price ListBambas FrostNo ratings yet

- Manual Bcjad Bermo 472Document7 pagesManual Bcjad Bermo 472MarcosGobbiNo ratings yet

- Die CastDocument7 pagesDie CastLokesh BaviskarNo ratings yet

- Manufacturing Technology-1: Course Code: 15ME1106 L T P C 3 0 0 3Document2 pagesManufacturing Technology-1: Course Code: 15ME1106 L T P C 3 0 0 3Madduri HemantNo ratings yet

- Spontaneously Not Vice Versa: Second-Law - PPT Modified 10/9/02Document10 pagesSpontaneously Not Vice Versa: Second-Law - PPT Modified 10/9/02Sapari VelNo ratings yet

- UNIT 20 PRINCIPLES OF STRUCTURAL DESIGN Assignment Dineth Sankalpa 65574 Batch 04 PDFDocument32 pagesUNIT 20 PRINCIPLES OF STRUCTURAL DESIGN Assignment Dineth Sankalpa 65574 Batch 04 PDFShaikh Farha100% (2)

- Defence Research Proposal Slide PresentationDocument25 pagesDefence Research Proposal Slide PresentationAmira DzulkifliNo ratings yet

- Flexural Member DesignDocument50 pagesFlexural Member DesignremedanNo ratings yet

- HWDP 3.5 03Document2 pagesHWDP 3.5 03km1790No ratings yet