Professional Documents

Culture Documents

Brochure D GT 800 en

Brochure D GT 800 en

Uploaded by

William WhittleCopyright:

Available Formats

You might also like

- Kohler Model 45rz 45kw Natural Gas Generator SetDocument4 pagesKohler Model 45rz 45kw Natural Gas Generator SetRebecca Winfrey100% (1)

- Ed5lfs2 ST22V1Document24 pagesEd5lfs2 ST22V1Matheus BorgesNo ratings yet

- Iso - 3093 - 2009 - Edicion 4 PDFDocument18 pagesIso - 3093 - 2009 - Edicion 4 PDFJovany rojanoNo ratings yet

- 30XW-VZE/30XWHVZE: Water-Cooled Variable-Speed Screw Chillers Water-Sourced Variable-Speed Screw Heat PumpsDocument19 pages30XW-VZE/30XWHVZE: Water-Cooled Variable-Speed Screw Chillers Water-Sourced Variable-Speed Screw Heat PumpsMechanical PowerNo ratings yet

- EICO 147A Signal TracerDocument43 pagesEICO 147A Signal Tracerbhaidri100% (1)

- Bro Dle603 enDocument1 pageBro Dle603 enMohammad MalekiNo ratings yet

- Durag HG 400 72x PDFDocument1 pageDurag HG 400 72x PDFRKVSK1No ratings yet

- Bro Flare Pilot Burner enDocument3 pagesBro Flare Pilot Burner endebasish bhowmickNo ratings yet

- 7522 Eurol Protence 5w 30 GN IIDocument1 page7522 Eurol Protence 5w 30 GN IIВиталийNo ratings yet

- Optical Opacity / Dust Monitor: New GenerationDocument4 pagesOptical Opacity / Dust Monitor: New GenerationTito Saul PerezNo ratings yet

- Catalogue and Technical DDocument5 pagesCatalogue and Technical DmohdtakrimiNo ratings yet

- Bro Dhg400 enDocument1 pageBro Dhg400 enAzkha EsaNo ratings yet

- Durag D-LX 200 Flame ScannerDocument4 pagesDurag D-LX 200 Flame Scannersojo josephNo ratings yet

- AI240686442008en 000505Document5 pagesAI240686442008en 000505Ernesto OrihuelaNo ratings yet

- Multispectrum Ir Flame Detector X3301: Description HighlightsDocument2 pagesMultispectrum Ir Flame Detector X3301: Description Highlightsdo quangNo ratings yet

- 3.1-Ht-X3301a4n13t1 Detector Multiespectro Triple RDocument2 pages3.1-Ht-X3301a4n13t1 Detector Multiespectro Triple Rerick valenciaNo ratings yet

- In-Line Detonation Flame Arrester: For Stable Detonations and Defl Agrations in A Straight Through Design, BidirectionalDocument4 pagesIn-Line Detonation Flame Arrester: For Stable Detonations and Defl Agrations in A Straight Through Design, BidirectionalkaramullahrasheedNo ratings yet

- 231-Damper Actuator PDFDocument20 pages231-Damper Actuator PDFChakib AutomationNo ratings yet

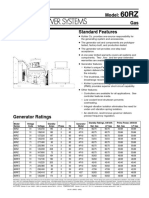

- Kohler 60RZ Spec SheetDocument4 pagesKohler 60RZ Spec SheetRomanvi1980No ratings yet

- Kta19 G3aDocument2 pagesKta19 G3aHoracio LafuenteNo ratings yet

- HazardousDocument2 pagesHazardousMarco AquinoNo ratings yet

- Spectracool Indoor/Outdoor (S-284623) : Industry StandardsDocument24 pagesSpectracool Indoor/Outdoor (S-284623) : Industry Standardsclint kendrickNo ratings yet

- Brochure D-R 290 enDocument1 pageBrochure D-R 290 enDandy Harris FirdiandaNo ratings yet

- Z Powder: Permissible Extra Gelatin Nitroglycerin DynamiteDocument2 pagesZ Powder: Permissible Extra Gelatin Nitroglycerin Dynamitecarllos as5No ratings yet

- Gst108a DS10105778Document3 pagesGst108a DS10105778Thein TunNo ratings yet

- Diaphragm Type Vacuum Pumps: OutlineDocument3 pagesDiaphragm Type Vacuum Pumps: OutlineMursyid YazidNo ratings yet

- Model Cgo Model Cgo HTD Forced Draft Burners GAS Light Oil 98,000 - 19,100,000 Btu/HrDocument2 pagesModel Cgo Model Cgo HTD Forced Draft Burners GAS Light Oil 98,000 - 19,100,000 Btu/HrRafael CalleNo ratings yet

- VinayDocument28 pagesVinayyugendraraoknNo ratings yet

- Ecoline GT 40: Gate ValveDocument14 pagesEcoline GT 40: Gate ValveCristhian Niño MartinezNo ratings yet

- Fiche Technique Hyd Pump H01-1008-010Document16 pagesFiche Technique Hyd Pump H01-1008-010Abdellah AbdellahNo ratings yet

- N 4 Iluxridg 8 CT 0 Npkvjge 1 U 6 F 2 Xa 2 S 42Document40 pagesN 4 Iluxridg 8 CT 0 Npkvjge 1 U 6 F 2 Xa 2 S 42hadetab10No ratings yet

- TSURUMI TPG-series Portable GeneratorsDocument1 pageTSURUMI TPG-series Portable GeneratorsWinson LamNo ratings yet

- Technical Data: BCMU 1760S-60 T2/F BCMU 1600P-60 T2/FDocument3 pagesTechnical Data: BCMU 1760S-60 T2/F BCMU 1600P-60 T2/FmaherNo ratings yet

- Product Data: Titanpro For ThermoformingDocument1 pageProduct Data: Titanpro For ThermoformingFarah99hanNo ratings yet

- JDN Air Hoists ProfiDocument8 pagesJDN Air Hoists ProfiRichard EVNo ratings yet

- Model AG168 Standard Response Upright Sprinkler (SIN AG1124)Document4 pagesModel AG168 Standard Response Upright Sprinkler (SIN AG1124)arieNo ratings yet

- Technical Data: BCY 13-60SPDocument4 pagesTechnical Data: BCY 13-60SPJunior EspinalNo ratings yet

- Atlas Copco Leaflet Portable Zone2 R3Document2 pagesAtlas Copco Leaflet Portable Zone2 R3KunalanNo ratings yet

- D39ex PX-22 Cen00321-02Document12 pagesD39ex PX-22 Cen00321-02Yosytha Parissing100% (1)

- DRONE Pressure - RegulatorDocument4 pagesDRONE Pressure - RegulatorAbhinav SinghNo ratings yet

- AirTop-2000-STC Datasheet ENDocument2 pagesAirTop-2000-STC Datasheet ENmadalinenescu30No ratings yet

- D39ex PX 22 KLTD BrochureDocument12 pagesD39ex PX 22 KLTD BrochureIGNACIONo ratings yet

- CP 191-enUS-ASTMDocument1 pageCP 191-enUS-ASTMAndersonNo ratings yet

- CM20200320 39552 31fa9Document4 pagesCM20200320 39552 31fa9johnward19951995No ratings yet

- Bar Pneumatic Actuators GT ENG BET O BW GT EnglischDocument28 pagesBar Pneumatic Actuators GT ENG BET O BW GT EnglischMỹ Anh 3B-PhạmNo ratings yet

- Specifications: GAO-A4, GMH-A4, and GML-A4 Gas Pressure Switch Installation InstructionsDocument4 pagesSpecifications: GAO-A4, GMH-A4, and GML-A4 Gas Pressure Switch Installation InstructionsPablo MartinezNo ratings yet

- Super Udt: Specifications and ApprovalsDocument1 pageSuper Udt: Specifications and ApprovalsMichaelNo ratings yet

- Ir109 1 DSDocument2 pagesIr109 1 DSbondsivamaniNo ratings yet

- MWM-G-2007 (Draft) MWM-G-2007 (Draft)Document131 pagesMWM-G-2007 (Draft) MWM-G-2007 (Draft)Ricardo Molina SánchezNo ratings yet

- Roto-Glyd-ring CatalogueDocument34 pagesRoto-Glyd-ring CatalogueMuthukumar RadhakrishnanNo ratings yet

- Bro Dr220 enDocument4 pagesBro Dr220 enPaun AlNo ratings yet

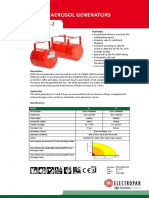

- DSPA 8-1 8-2 Aerosol Generator Data SheetDocument1 pageDSPA 8-1 8-2 Aerosol Generator Data SheetMohammed HussainNo ratings yet

- Honeywell Digital Burner Controller - TBC2800 Series Product HandbookDocument4 pagesHoneywell Digital Burner Controller - TBC2800 Series Product HandbookOSAMANo ratings yet

- RMX-JZVMB DatabookDocument35 pagesRMX-JZVMB DatabookUbaldo BritoNo ratings yet

- Periflex PS r11Document2 pagesPeriflex PS r11OrshanetzNo ratings yet

- TS12CLR ExDocument3 pagesTS12CLR ExSwapnil SangodkarNo ratings yet

- Ge10 1Document4 pagesGe10 1Groover Contreras100% (2)

- JOHN-DEERE-GENERATOR-BCJD23-60SPiT4 (1F)Document4 pagesJOHN-DEERE-GENERATOR-BCJD23-60SPiT4 (1F)Samuel J. GamezNo ratings yet

- 30 KW John Deere Generator Bcjd30 60it4Document4 pages30 KW John Deere Generator Bcjd30 60it4Juan Leonardo Fonseca ValderramaNo ratings yet

- Digital Pressure Gages: 0.25% or 0.5% FS Accuracy, NEMA 4X (IP66) Aluminum HousingDocument1 pageDigital Pressure Gages: 0.25% or 0.5% FS Accuracy, NEMA 4X (IP66) Aluminum HousingBrigitteNo ratings yet

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualFrom EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNo ratings yet

- Cat Dcs Sis ControllerDocument2 pagesCat Dcs Sis Controllerroestatom50% (2)

- Design and Implementation of Microstrip Patch Antenna ArrayDocument4 pagesDesign and Implementation of Microstrip Patch Antenna ArrayPriscilaNo ratings yet

- SKM .Catalog SeriesDocument23 pagesSKM .Catalog SeriesMohamedAhmedFawzyNo ratings yet

- YGMOD756Document31 pagesYGMOD756Márcio Martins da SilvaNo ratings yet

- 1 2Document65 pages1 2AQEESHA NUWAIRA BINTI USMAN BN21110154No ratings yet

- 4000 Manual PDFDocument17 pages4000 Manual PDFJose Daniel MartinezNo ratings yet

- Demonstration Equipment of Expansion ProcessesDocument3 pagesDemonstration Equipment of Expansion ProcessesMehtab AhmadNo ratings yet

- Strand Cable Stay Damping SystemDocument8 pagesStrand Cable Stay Damping SystemZakee MohamedNo ratings yet

- Optical CommunicationDocument25 pagesOptical CommunicationKlNo ratings yet

- Acid BaseDocument36 pagesAcid Baseবিল গেটসNo ratings yet

- M230HGE-L20 C2 Ver.2.0-6 Approval SpecificationDocument17 pagesM230HGE-L20 C2 Ver.2.0-6 Approval SpecificationpasmanteriabellaNo ratings yet

- Siemens 5sy62017Document4 pagesSiemens 5sy62017Kleiber OrtegaNo ratings yet

- ITBP Assistant Commandant Previous PapersDocument5 pagesITBP Assistant Commandant Previous PapersSenthilNo ratings yet

- Ex. 3 - Aeroelastic Static Stability 16-19/10/2018: Ex. 3a - Divergence Analysis With 1 DOFDocument2 pagesEx. 3 - Aeroelastic Static Stability 16-19/10/2018: Ex. 3a - Divergence Analysis With 1 DOFjacazio.brischettoNo ratings yet

- Private Pilot Licence Learning ObjectivesDocument39 pagesPrivate Pilot Licence Learning ObjectivesKrit RattanaratNo ratings yet

- Open Circuit Characteristics of Self Excited DC Shunt GeneratorDocument5 pagesOpen Circuit Characteristics of Self Excited DC Shunt Generatorramniwas123No ratings yet

- MICROMERITICSDocument30 pagesMICROMERITICSNoorul AlamNo ratings yet

- STD-INSP-0024 Procedure For Radiographic TestDocument13 pagesSTD-INSP-0024 Procedure For Radiographic TestTeam SpiderNo ratings yet

- 1 Sheet Fundamentals of Heat TransferDocument3 pages1 Sheet Fundamentals of Heat TransferManju MuruhanNo ratings yet

- Steam DistributionDocument16 pagesSteam DistributionHaris PrawotoNo ratings yet

- HV Circuit Breaker TestingDocument5 pagesHV Circuit Breaker TestingVelitinelNo ratings yet

- Compressed Air System For Thermal Power ProjectsDocument21 pagesCompressed Air System For Thermal Power Projectsjkhan_7243840% (1)

- f607 Chauvin PDFDocument4 pagesf607 Chauvin PDFsilveriserNo ratings yet

- Control Systems Course OutlineDocument3 pagesControl Systems Course OutlineWaqar AliNo ratings yet

- Operation Manual For Transmission Monitor RSUK0919: ORSUK0919Document31 pagesOperation Manual For Transmission Monitor RSUK0919: ORSUK0919Baena75No ratings yet

- Enggzc112 May05 An PDFDocument3 pagesEnggzc112 May05 An PDFdharmendra_kanthariaNo ratings yet

- Lab Report 5Document6 pagesLab Report 5Rajput JanjuaNo ratings yet

- Physics Lab:Coefficient of Linear ExpansionDocument3 pagesPhysics Lab:Coefficient of Linear ExpansionNatalie Sherwood100% (1)

Brochure D GT 800 en

Brochure D GT 800 en

Uploaded by

William WhittleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brochure D GT 800 en

Brochure D GT 800 en

Uploaded by

William WhittleCopyright:

Available Formats

D-GT 800

Flame sensor

Flame sensor for monitoring gas

and oil flames, primarily in gas

turbines or in particularly harsh

environments

D-GT 800-P

Features Functional description Models

●● Self-monitoring and fail-safe in conjunction With its combination of a highly sensitive photo ●● Cable gland connection (-Ex)

with a control unit/ burner control element and sturdy design, the D-GT 800/801 ●● Axial plug (-P)

●● Deployable with high combustion chamber flame sensors are ideal for use in harsh environ- ●● Available with air or water cooling for very

overpressure and with strong vibrations ments such as in gas turbines. The photodiode high temperatures (D-GT 800)

●● Connection to the D-UG 120, D-UG 660 used can detect almost all blue burning flames,

control units and the D-GF 150 (-MB) burner such as gas flames having only a low radiation Accessories

control component in the visible range.

●● Optionally available with air/water cooling The D-GT 800/801 is available with different ●● UV-A, UV-B and IR test light source

●● Compliant to general safety regulations photo elements for optimal selectivity when 230 V/ 50 Hz (D-ZS 093)

●● Flame monitoring in the UV-range from 190 using different fuels. ●● Terminal box for connecting the flame

to 570 nm sensor (D-ZS 140, D-ZS 141)

●● ATEX-approved (D-GT 800/801../Ex) Flame sensor selection

Flame sensor Suitability for Features

Applications Gas Oil

D-GT 800/801 UAF o ++ with intensive ambient light (neighbouring burners)

●● Burners with difficult installation conditions

D-GT 800/801 UA + ++ at low NOx component

for conventional flame sensors or on those

++ ideally suited + well suited o conditional suited ! not permitted (from experience)

where ambient temperature near the

sighting tube is very high

●● Power stations

●● Chemical industry

●● Refineries

●● Cement plants

●● Waste incinerators Control unit/

Burner control

●● Steam generators

●● Heating plants D-UG 120

D-UG 660

●● Gas turbines D-GF 150

Certifications (only D-GT 800/801)

D-GT 800/ Ex

●● DVGW

●● EAC Control unit/

Burner control

●● ATEX

D-UG 120

D-UG 660

D-GF 150

D-GT 801/ Ex (without cooling jacket)

©DURAG GROUP 08/2016 · Subject to change without notice

Operational mode Intermittent operation, continuous Perm. ambient Without cooling: -20 °C to +120 °C

D-GT 800/801 operation and 72-hour operation temperature Air cooling: -20 °C to +200 °C

without permanent supervision Water cooling: -20 °C to +300 °C

Safety Self-monitoring and fail-safe in Vibration 10 g

conjunction with a control unit/

burner control Dimensions Ø 100 mm; length approx. 190 mm

Protection With cable gland Weight Without cooling: approx. 1.5 kg

(D-GT 800/801 -P) IP67 with cooling: approx. 2.0 kg

Ex-Version

(D-GT 800/801 .../Ex) IP66

Ex-Protection II 2G Ex d T4/T5/T6 Max combustion 30 bar

(D-GT 800/801../ chamber

Ex) overpressure

Spectral range UV Sighting tube ¾“ NPT (F)

connection

Viewing angle 6° Cooling ½“ NPT (F)

connection

DURAG GmbH Tel. +49 (40) 554 218-0 · Fax +49 (40) 584 154

Kollaustrasse 105 · 22453 Hamburg · Germany E-Mail: info@durag.de www.durag.com

You might also like

- Kohler Model 45rz 45kw Natural Gas Generator SetDocument4 pagesKohler Model 45rz 45kw Natural Gas Generator SetRebecca Winfrey100% (1)

- Ed5lfs2 ST22V1Document24 pagesEd5lfs2 ST22V1Matheus BorgesNo ratings yet

- Iso - 3093 - 2009 - Edicion 4 PDFDocument18 pagesIso - 3093 - 2009 - Edicion 4 PDFJovany rojanoNo ratings yet

- 30XW-VZE/30XWHVZE: Water-Cooled Variable-Speed Screw Chillers Water-Sourced Variable-Speed Screw Heat PumpsDocument19 pages30XW-VZE/30XWHVZE: Water-Cooled Variable-Speed Screw Chillers Water-Sourced Variable-Speed Screw Heat PumpsMechanical PowerNo ratings yet

- EICO 147A Signal TracerDocument43 pagesEICO 147A Signal Tracerbhaidri100% (1)

- Bro Dle603 enDocument1 pageBro Dle603 enMohammad MalekiNo ratings yet

- Durag HG 400 72x PDFDocument1 pageDurag HG 400 72x PDFRKVSK1No ratings yet

- Bro Flare Pilot Burner enDocument3 pagesBro Flare Pilot Burner endebasish bhowmickNo ratings yet

- 7522 Eurol Protence 5w 30 GN IIDocument1 page7522 Eurol Protence 5w 30 GN IIВиталийNo ratings yet

- Optical Opacity / Dust Monitor: New GenerationDocument4 pagesOptical Opacity / Dust Monitor: New GenerationTito Saul PerezNo ratings yet

- Catalogue and Technical DDocument5 pagesCatalogue and Technical DmohdtakrimiNo ratings yet

- Bro Dhg400 enDocument1 pageBro Dhg400 enAzkha EsaNo ratings yet

- Durag D-LX 200 Flame ScannerDocument4 pagesDurag D-LX 200 Flame Scannersojo josephNo ratings yet

- AI240686442008en 000505Document5 pagesAI240686442008en 000505Ernesto OrihuelaNo ratings yet

- Multispectrum Ir Flame Detector X3301: Description HighlightsDocument2 pagesMultispectrum Ir Flame Detector X3301: Description Highlightsdo quangNo ratings yet

- 3.1-Ht-X3301a4n13t1 Detector Multiespectro Triple RDocument2 pages3.1-Ht-X3301a4n13t1 Detector Multiespectro Triple Rerick valenciaNo ratings yet

- In-Line Detonation Flame Arrester: For Stable Detonations and Defl Agrations in A Straight Through Design, BidirectionalDocument4 pagesIn-Line Detonation Flame Arrester: For Stable Detonations and Defl Agrations in A Straight Through Design, BidirectionalkaramullahrasheedNo ratings yet

- 231-Damper Actuator PDFDocument20 pages231-Damper Actuator PDFChakib AutomationNo ratings yet

- Kohler 60RZ Spec SheetDocument4 pagesKohler 60RZ Spec SheetRomanvi1980No ratings yet

- Kta19 G3aDocument2 pagesKta19 G3aHoracio LafuenteNo ratings yet

- HazardousDocument2 pagesHazardousMarco AquinoNo ratings yet

- Spectracool Indoor/Outdoor (S-284623) : Industry StandardsDocument24 pagesSpectracool Indoor/Outdoor (S-284623) : Industry Standardsclint kendrickNo ratings yet

- Brochure D-R 290 enDocument1 pageBrochure D-R 290 enDandy Harris FirdiandaNo ratings yet

- Z Powder: Permissible Extra Gelatin Nitroglycerin DynamiteDocument2 pagesZ Powder: Permissible Extra Gelatin Nitroglycerin Dynamitecarllos as5No ratings yet

- Gst108a DS10105778Document3 pagesGst108a DS10105778Thein TunNo ratings yet

- Diaphragm Type Vacuum Pumps: OutlineDocument3 pagesDiaphragm Type Vacuum Pumps: OutlineMursyid YazidNo ratings yet

- Model Cgo Model Cgo HTD Forced Draft Burners GAS Light Oil 98,000 - 19,100,000 Btu/HrDocument2 pagesModel Cgo Model Cgo HTD Forced Draft Burners GAS Light Oil 98,000 - 19,100,000 Btu/HrRafael CalleNo ratings yet

- VinayDocument28 pagesVinayyugendraraoknNo ratings yet

- Ecoline GT 40: Gate ValveDocument14 pagesEcoline GT 40: Gate ValveCristhian Niño MartinezNo ratings yet

- Fiche Technique Hyd Pump H01-1008-010Document16 pagesFiche Technique Hyd Pump H01-1008-010Abdellah AbdellahNo ratings yet

- N 4 Iluxridg 8 CT 0 Npkvjge 1 U 6 F 2 Xa 2 S 42Document40 pagesN 4 Iluxridg 8 CT 0 Npkvjge 1 U 6 F 2 Xa 2 S 42hadetab10No ratings yet

- TSURUMI TPG-series Portable GeneratorsDocument1 pageTSURUMI TPG-series Portable GeneratorsWinson LamNo ratings yet

- Technical Data: BCMU 1760S-60 T2/F BCMU 1600P-60 T2/FDocument3 pagesTechnical Data: BCMU 1760S-60 T2/F BCMU 1600P-60 T2/FmaherNo ratings yet

- Product Data: Titanpro For ThermoformingDocument1 pageProduct Data: Titanpro For ThermoformingFarah99hanNo ratings yet

- JDN Air Hoists ProfiDocument8 pagesJDN Air Hoists ProfiRichard EVNo ratings yet

- Model AG168 Standard Response Upright Sprinkler (SIN AG1124)Document4 pagesModel AG168 Standard Response Upright Sprinkler (SIN AG1124)arieNo ratings yet

- Technical Data: BCY 13-60SPDocument4 pagesTechnical Data: BCY 13-60SPJunior EspinalNo ratings yet

- Atlas Copco Leaflet Portable Zone2 R3Document2 pagesAtlas Copco Leaflet Portable Zone2 R3KunalanNo ratings yet

- D39ex PX-22 Cen00321-02Document12 pagesD39ex PX-22 Cen00321-02Yosytha Parissing100% (1)

- DRONE Pressure - RegulatorDocument4 pagesDRONE Pressure - RegulatorAbhinav SinghNo ratings yet

- AirTop-2000-STC Datasheet ENDocument2 pagesAirTop-2000-STC Datasheet ENmadalinenescu30No ratings yet

- D39ex PX 22 KLTD BrochureDocument12 pagesD39ex PX 22 KLTD BrochureIGNACIONo ratings yet

- CP 191-enUS-ASTMDocument1 pageCP 191-enUS-ASTMAndersonNo ratings yet

- CM20200320 39552 31fa9Document4 pagesCM20200320 39552 31fa9johnward19951995No ratings yet

- Bar Pneumatic Actuators GT ENG BET O BW GT EnglischDocument28 pagesBar Pneumatic Actuators GT ENG BET O BW GT EnglischMỹ Anh 3B-PhạmNo ratings yet

- Specifications: GAO-A4, GMH-A4, and GML-A4 Gas Pressure Switch Installation InstructionsDocument4 pagesSpecifications: GAO-A4, GMH-A4, and GML-A4 Gas Pressure Switch Installation InstructionsPablo MartinezNo ratings yet

- Super Udt: Specifications and ApprovalsDocument1 pageSuper Udt: Specifications and ApprovalsMichaelNo ratings yet

- Ir109 1 DSDocument2 pagesIr109 1 DSbondsivamaniNo ratings yet

- MWM-G-2007 (Draft) MWM-G-2007 (Draft)Document131 pagesMWM-G-2007 (Draft) MWM-G-2007 (Draft)Ricardo Molina SánchezNo ratings yet

- Roto-Glyd-ring CatalogueDocument34 pagesRoto-Glyd-ring CatalogueMuthukumar RadhakrishnanNo ratings yet

- Bro Dr220 enDocument4 pagesBro Dr220 enPaun AlNo ratings yet

- DSPA 8-1 8-2 Aerosol Generator Data SheetDocument1 pageDSPA 8-1 8-2 Aerosol Generator Data SheetMohammed HussainNo ratings yet

- Honeywell Digital Burner Controller - TBC2800 Series Product HandbookDocument4 pagesHoneywell Digital Burner Controller - TBC2800 Series Product HandbookOSAMANo ratings yet

- RMX-JZVMB DatabookDocument35 pagesRMX-JZVMB DatabookUbaldo BritoNo ratings yet

- Periflex PS r11Document2 pagesPeriflex PS r11OrshanetzNo ratings yet

- TS12CLR ExDocument3 pagesTS12CLR ExSwapnil SangodkarNo ratings yet

- Ge10 1Document4 pagesGe10 1Groover Contreras100% (2)

- JOHN-DEERE-GENERATOR-BCJD23-60SPiT4 (1F)Document4 pagesJOHN-DEERE-GENERATOR-BCJD23-60SPiT4 (1F)Samuel J. GamezNo ratings yet

- 30 KW John Deere Generator Bcjd30 60it4Document4 pages30 KW John Deere Generator Bcjd30 60it4Juan Leonardo Fonseca ValderramaNo ratings yet

- Digital Pressure Gages: 0.25% or 0.5% FS Accuracy, NEMA 4X (IP66) Aluminum HousingDocument1 pageDigital Pressure Gages: 0.25% or 0.5% FS Accuracy, NEMA 4X (IP66) Aluminum HousingBrigitteNo ratings yet

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualFrom EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNo ratings yet

- Cat Dcs Sis ControllerDocument2 pagesCat Dcs Sis Controllerroestatom50% (2)

- Design and Implementation of Microstrip Patch Antenna ArrayDocument4 pagesDesign and Implementation of Microstrip Patch Antenna ArrayPriscilaNo ratings yet

- SKM .Catalog SeriesDocument23 pagesSKM .Catalog SeriesMohamedAhmedFawzyNo ratings yet

- YGMOD756Document31 pagesYGMOD756Márcio Martins da SilvaNo ratings yet

- 1 2Document65 pages1 2AQEESHA NUWAIRA BINTI USMAN BN21110154No ratings yet

- 4000 Manual PDFDocument17 pages4000 Manual PDFJose Daniel MartinezNo ratings yet

- Demonstration Equipment of Expansion ProcessesDocument3 pagesDemonstration Equipment of Expansion ProcessesMehtab AhmadNo ratings yet

- Strand Cable Stay Damping SystemDocument8 pagesStrand Cable Stay Damping SystemZakee MohamedNo ratings yet

- Optical CommunicationDocument25 pagesOptical CommunicationKlNo ratings yet

- Acid BaseDocument36 pagesAcid Baseবিল গেটসNo ratings yet

- M230HGE-L20 C2 Ver.2.0-6 Approval SpecificationDocument17 pagesM230HGE-L20 C2 Ver.2.0-6 Approval SpecificationpasmanteriabellaNo ratings yet

- Siemens 5sy62017Document4 pagesSiemens 5sy62017Kleiber OrtegaNo ratings yet

- ITBP Assistant Commandant Previous PapersDocument5 pagesITBP Assistant Commandant Previous PapersSenthilNo ratings yet

- Ex. 3 - Aeroelastic Static Stability 16-19/10/2018: Ex. 3a - Divergence Analysis With 1 DOFDocument2 pagesEx. 3 - Aeroelastic Static Stability 16-19/10/2018: Ex. 3a - Divergence Analysis With 1 DOFjacazio.brischettoNo ratings yet

- Private Pilot Licence Learning ObjectivesDocument39 pagesPrivate Pilot Licence Learning ObjectivesKrit RattanaratNo ratings yet

- Open Circuit Characteristics of Self Excited DC Shunt GeneratorDocument5 pagesOpen Circuit Characteristics of Self Excited DC Shunt Generatorramniwas123No ratings yet

- MICROMERITICSDocument30 pagesMICROMERITICSNoorul AlamNo ratings yet

- STD-INSP-0024 Procedure For Radiographic TestDocument13 pagesSTD-INSP-0024 Procedure For Radiographic TestTeam SpiderNo ratings yet

- 1 Sheet Fundamentals of Heat TransferDocument3 pages1 Sheet Fundamentals of Heat TransferManju MuruhanNo ratings yet

- Steam DistributionDocument16 pagesSteam DistributionHaris PrawotoNo ratings yet

- HV Circuit Breaker TestingDocument5 pagesHV Circuit Breaker TestingVelitinelNo ratings yet

- Compressed Air System For Thermal Power ProjectsDocument21 pagesCompressed Air System For Thermal Power Projectsjkhan_7243840% (1)

- f607 Chauvin PDFDocument4 pagesf607 Chauvin PDFsilveriserNo ratings yet

- Control Systems Course OutlineDocument3 pagesControl Systems Course OutlineWaqar AliNo ratings yet

- Operation Manual For Transmission Monitor RSUK0919: ORSUK0919Document31 pagesOperation Manual For Transmission Monitor RSUK0919: ORSUK0919Baena75No ratings yet

- Enggzc112 May05 An PDFDocument3 pagesEnggzc112 May05 An PDFdharmendra_kanthariaNo ratings yet

- Lab Report 5Document6 pagesLab Report 5Rajput JanjuaNo ratings yet

- Physics Lab:Coefficient of Linear ExpansionDocument3 pagesPhysics Lab:Coefficient of Linear ExpansionNatalie Sherwood100% (1)