Professional Documents

Culture Documents

California Bearing Ratio Test: (As Per IS 2720 (Part-16) )

California Bearing Ratio Test: (As Per IS 2720 (Part-16) )

Uploaded by

ஆதித்தன்Copyright:

Available Formats

You might also like

- Environmental Geology 2nd Edition Reichard Test BankDocument35 pagesEnvironmental Geology 2nd Edition Reichard Test Bankjohnevansixtcwzmoey100% (18)

- VSDC LAC Test Keys v4 - 8Document2 pagesVSDC LAC Test Keys v4 - 8Nirvana Munar Meneses100% (2)

- Theories of Crime CausationDocument59 pagesTheories of Crime CausationRey John Dizon88% (32)

- Occupational Health and Safety ReportDocument6 pagesOccupational Health and Safety Reportخالد نسیمNo ratings yet

- AP.1901 Inventories.Document8 pagesAP.1901 Inventories.Erlinda Esguerra Guiang100% (9)

- Bridge Design Format For Rural Road NQM Project AssamDocument35 pagesBridge Design Format For Rural Road NQM Project Assamarif ahmedNo ratings yet

- Amendment No. 1 November 2019 TO Is 16715: 2018 Ultrafine Ground Granulated Blast Furnace Slag - SpecificationDocument2 pagesAmendment No. 1 November 2019 TO Is 16715: 2018 Ultrafine Ground Granulated Blast Furnace Slag - SpecificationdivithNo ratings yet

- WMM Calibration 05.01.2016Document8 pagesWMM Calibration 05.01.2016SRR QAQCNo ratings yet

- Blank Format Extraction and GradationDocument2 pagesBlank Format Extraction and GradationMohammed AyazNo ratings yet

- Slump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45Document37 pagesSlump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45ChManikumarNo ratings yet

- Self Compacting Concrete-Ce19s015 PDFDocument13 pagesSelf Compacting Concrete-Ce19s015 PDFmamthaNo ratings yet

- Test Result: Acceptance Criteria As Per IS: 456 - 2000 (RA: 2011)Document1 pageTest Result: Acceptance Criteria As Per IS: 456 - 2000 (RA: 2011)Sainath AmudaNo ratings yet

- Field Density Test Sand Replacement Method: Employer: Chennai Metro Rail Limited Project: CMRL C4 ECV02Document1 pageField Density Test Sand Replacement Method: Employer: Chennai Metro Rail Limited Project: CMRL C4 ECV02zealbalaNo ratings yet

- FDT Part 1Document1 pageFDT Part 1bilalNo ratings yet

- Sika Grout Vhs QacDocument1 pageSika Grout Vhs QacSushil RajakNo ratings yet

- Blank Quality Plan PAGE-2 TG 60663Document15 pagesBlank Quality Plan PAGE-2 TG 60663NEERAJ JINDALNo ratings yet

- Moisture Correction Sheet Date-04-11-2020Document7 pagesMoisture Correction Sheet Date-04-11-2020SandeepNo ratings yet

- Mix Design M-25 GradeDocument9 pagesMix Design M-25 Gradeenjoy begening lifeNo ratings yet

- Ultratech PPC 53 Grade CementDocument1 pageUltratech PPC 53 Grade CementGovind SharmaNo ratings yet

- Quality TestDocument22 pagesQuality TestUmair Shaikh100% (1)

- Determination of Field Density of Soil by Core Cutter MethodDocument3 pagesDetermination of Field Density of Soil by Core Cutter MethodsiddiqueakbarNo ratings yet

- CRM Opc BlainesDocument2 pagesCRM Opc BlainesVara Prasad PaluriNo ratings yet

- Pile Integrity Test2 PDFDocument3 pagesPile Integrity Test2 PDFSima Datta Deb100% (1)

- Apcotrak: Technical DataDocument1 pageApcotrak: Technical DatahafsalNo ratings yet

- RMM CalibrationDocument18 pagesRMM CalibrationPrasanna S KulkarniNo ratings yet

- Is 16720 Product Manual Fuel AshDocument7 pagesIs 16720 Product Manual Fuel AshKolkata PIUNo ratings yet

- WMM Mix DesignDocument23 pagesWMM Mix DesignEnd EndNo ratings yet

- Fine Sieve Analysis RegisterDocument2 pagesFine Sieve Analysis RegisterRicha YadavNo ratings yet

- Annexure 2 Form 72 (Scope) Annexure IDocument4 pagesAnnexure 2 Form 72 (Scope) Annexure IVaghasiyaBipinNo ratings yet

- RCPT SopDocument2 pagesRCPT SopAbraham Henry BernardNo ratings yet

- Basf Masterpolyheed 8118 TdsDocument2 pagesBasf Masterpolyheed 8118 Tdsaji arafat100% (2)

- Test Method - Soil2Document25 pagesTest Method - Soil2jitendraNo ratings yet

- Bitumen (Ext)Document1 pageBitumen (Ext)venkateswara rao PothinaNo ratings yet

- GSB Trial Patch-3Document2 pagesGSB Trial Patch-3Md YasinNo ratings yet

- Is 16651-2017Document18 pagesIs 16651-2017Assistant Coordinator Business DevelopmentNo ratings yet

- Sew Infrastructutre LTD: Calibration of Sand Pouring CylinderDocument1 pageSew Infrastructutre LTD: Calibration of Sand Pouring CylinderRayudu VVSNo ratings yet

- Danta - Lateral Load Test Report Final-05.01.24Document18 pagesDanta - Lateral Load Test Report Final-05.01.24Deepak avinashNo ratings yet

- Is 2720 29 1975Document14 pagesIs 2720 29 1975biswashree10No ratings yet

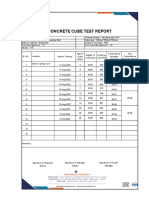

- Cube Test ReportDocument1 pageCube Test ReportSurajit SahaNo ratings yet

- Is 383 (1970) Grading ZonesDocument2 pagesIs 383 (1970) Grading ZonesAnonymous 2RduvkjgZNo ratings yet

- Mix Design FormatDocument3 pagesMix Design FormatAkshay MitraNo ratings yet

- Cube Test ReportDocument1 pageCube Test ReportShubham MareNo ratings yet

- Compaction Test by Core Cutter (Is: 2720, Part 29)Document2 pagesCompaction Test by Core Cutter (Is: 2720, Part 29)Francis Aw Soon LeeNo ratings yet

- Test Reports PDFDocument25 pagesTest Reports PDFAbdelhamid ElgasaierNo ratings yet

- Is 1195-1978 Specification For Bitumen Mastic For FlooringDocument20 pagesIs 1195-1978 Specification For Bitumen Mastic For FlooringVijayakrishna Singamsetti100% (1)

- FT003 - Aggregate Impact Value TestDocument15 pagesFT003 - Aggregate Impact Value Testjjksite voyantsNo ratings yet

- Grain Size Analysis For SoilsDocument11 pagesGrain Size Analysis For SoilsyogananthanNo ratings yet

- Mix Design of DLCDocument8 pagesMix Design of DLCSasanka SekharNo ratings yet

- M 40 PQC With GGBS 340-60Document6 pagesM 40 PQC With GGBS 340-60Er Dnyaneshwar PatilNo ratings yet

- Test Report: M/S Pcil & MBPCL Joint VentureDocument7 pagesTest Report: M/S Pcil & MBPCL Joint VentureImran KhanNo ratings yet

- Andhra Pradesh Class 1 Registration Certificate FormatDocument2 pagesAndhra Pradesh Class 1 Registration Certificate Formatgsatyasrikanth0% (3)

- BR 32 Water, Aggregate & Cement Test ReportDocument4 pagesBR 32 Water, Aggregate & Cement Test ReportSravan KuppiliNo ratings yet

- ASTM D2041 aashto T209 ефект процент битума PDFDocument4 pagesASTM D2041 aashto T209 ефект процент битума PDFanon_711474514No ratings yet

- FT004 - FLAKINESS & ELONGATION INDICESdDocument23 pagesFT004 - FLAKINESS & ELONGATION INDICESdjjksite voyantsNo ratings yet

- Fine Aggregate - M-SandDocument1 pageFine Aggregate - M-SandSudhir Mishra100% (1)

- Soil Report Sec-155Document16 pagesSoil Report Sec-155Sandeep SainiNo ratings yet

- Sector Project-Package A:Mahua-Chuwahi RoadDocument6 pagesSector Project-Package A:Mahua-Chuwahi RoadVIMAL TIWARINo ratings yet

- Ultratech Cement Limited: Sieve Analysis of Coarse Aggregate For Concrete (As Per Is: 383 - 1970)Document24 pagesUltratech Cement Limited: Sieve Analysis of Coarse Aggregate For Concrete (As Per Is: 383 - 1970)Mamata BhangaleNo ratings yet

- Laboratory Manual FinalDocument57 pagesLaboratory Manual Finalrohit kumarNo ratings yet

- Road Bitumen Work QAP No 02Document2 pagesRoad Bitumen Work QAP No 02Sasanka SekharNo ratings yet

- SC - Panel Test PDFDocument1 pageSC - Panel Test PDFjitendraNo ratings yet

- Observation Sheet For Bitumen Extraction Test: Name of Division Name of Sub DivisionDocument2 pagesObservation Sheet For Bitumen Extraction Test: Name of Division Name of Sub DivisionramNo ratings yet

- Ravi Sir DLC PresentationDocument13 pagesRavi Sir DLC Presentationসৌগত রায় ঘটকNo ratings yet

- Concrete Lab ManualDocument42 pagesConcrete Lab ManualVENKATA RANGANADHNo ratings yet

- CBR Ba-9 - 2Document2 pagesCBR Ba-9 - 2Prakash budhaniNo ratings yet

- TED Taiye SelasiDocument4 pagesTED Taiye SelasiMinh ThuNo ratings yet

- Negara Hukum-5-1-Juni-2014Document99 pagesNegara Hukum-5-1-Juni-2014haekalnashvilleNo ratings yet

- Operation EPSOM: To The Odon!: Mission H3Document3 pagesOperation EPSOM: To The Odon!: Mission H3PaoloViarengoNo ratings yet

- Indian Institute of Information Technology, Surat: SVNIT Campus, Ichchanath, Surat - 395007Document1 pageIndian Institute of Information Technology, Surat: SVNIT Campus, Ichchanath, Surat - 395007gopalgeniusNo ratings yet

- EWRFDocument1 pageEWRFHarini Sybel CullenNo ratings yet

- Lecture Notes On Vat As AmendedDocument7 pagesLecture Notes On Vat As Amendedbubblingbrook100% (1)

- CH 3Document41 pagesCH 3Diana BaRobNo ratings yet

- The Effectiveness of Bilingual Program and Policy in The Academic Performance and Engagement of StudentsDocument10 pagesThe Effectiveness of Bilingual Program and Policy in The Academic Performance and Engagement of StudentsJoshua LagonoyNo ratings yet

- Milvik ProposalDocument29 pagesMilvik ProposalMin HajNo ratings yet

- Two Versions PDFDocument70 pagesTwo Versions PDFkamilghoshalNo ratings yet

- Alex. Hamilton Vs Thomas JeffersonDocument4 pagesAlex. Hamilton Vs Thomas JeffersonRhett Hunt100% (1)

- The Blood PDFDocument4 pagesThe Blood PDFAdeNo ratings yet

- Chapters 1-5: Task No. 6 Process QuestionsDocument4 pagesChapters 1-5: Task No. 6 Process QuestionsFarNo ratings yet

- Report On Rosemary Chiavetta in Harrisburg PA From NuwberDocument82 pagesReport On Rosemary Chiavetta in Harrisburg PA From Nuwbermaria-bellaNo ratings yet

- Financial and Managerial Accounting: Wild, Shaw, and Chiappetta Fifth EditionDocument41 pagesFinancial and Managerial Accounting: Wild, Shaw, and Chiappetta Fifth EditionryoguNo ratings yet

- Global WarmingDocument50 pagesGlobal WarmingLeah Oljol RualesNo ratings yet

- Module MAPEH 8 4thDocument21 pagesModule MAPEH 8 4thEdnell VelascoNo ratings yet

- Lecture 03 - ECO 209 - W2013 PDFDocument69 pagesLecture 03 - ECO 209 - W2013 PDF123No ratings yet

- Answers Unit 2 IMK Part 1Document8 pagesAnswers Unit 2 IMK Part 1Vivi SamaniegoNo ratings yet

- Kurt LewinDocument6 pagesKurt Lewinfotiadis100% (2)

- WogManual 022408 AVAGDUDocument315 pagesWogManual 022408 AVAGDUhellishteethNo ratings yet

- Malankara Catholic Church Sui Iuris: Juridical Status and Power of GovernanceDocument26 pagesMalankara Catholic Church Sui Iuris: Juridical Status and Power of GovernanceDr. Thomas Kuzhinapurath100% (6)

- Current Trends Issues and Problems in Education SystemDocument49 pagesCurrent Trends Issues and Problems in Education SystemfuellasjericNo ratings yet

- Unit 7 Exercises To StsDocument7 pagesUnit 7 Exercises To StsHưng TrầnNo ratings yet

- Narrative Report On SGC ASSEMBLYDocument3 pagesNarrative Report On SGC ASSEMBLYcathy93No ratings yet

California Bearing Ratio Test: (As Per IS 2720 (Part-16) )

California Bearing Ratio Test: (As Per IS 2720 (Part-16) )

Uploaded by

ஆதித்தன்Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

California Bearing Ratio Test: (As Per IS 2720 (Part-16) )

California Bearing Ratio Test: (As Per IS 2720 (Part-16) )

Uploaded by

ஆதித்தன்Copyright:

Available Formats

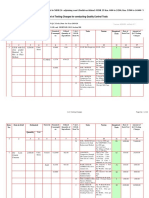

Rehabilitation And Up-Gradation Of Existing 2 Lane With Paved Shoulder Configuration of Wardha-Arvi from Km.

0+000 (Wardha) to Km. 53+708 (Arvi) NH-647 in the State of Maharastra On Engineering Procurment & Construction

(EPC)Basic Contract.

Format No.:T/F 7 Rev no: 0

Client National Highways Public Work Department Of Maharashtra

Contractor RPP Infra Project's Ltd

Authority Engineer TPF ENGINEERING PVT LTD

CALIFORNIA BEARING RATIO TEST

[As per IS 2720(Part-16)]

Laboratory job no. Date of Sampling 2/27/2019

Type of material Soil Date of Casting 3/6/2019

Source/Location OGL - 26+500 Date of Testing 3/10/2019

MDD of Sample (gm/cc) 1.695 Sampled by Jointly

OMC of Sample (%) 15.5 Tested by Jointly

Proposed use Emb.Bottom

MOISTURE CONTENT AND UNIT WEIGHT OF TEST SAMPLES

S.No Description Mould No. 13 Mould No. 14 Mould No. 15

A. No.Of layers 5 5 5

B. No.Of blows per layer 56 56 56

C. Condition of sample while SOAKING Before After Before After Before After

D. Wt.of mould(gm) 6960 6482 6408

E. Wt.of wet sample+mould(gm) 11263 11337 10832 10883 10732 10772

F. Wt.of wet sample(E-D)(gm) 4303 4377 4350 4401 4324 4364

G. Volume of mould/sample (cc) 2250 2250 2250 2250 2250 2250

H. Wet density (F/G)(gm/cc) 1.912 1.945 1.933 1.956 1.922 1.940

J. Moisture determination

K. Container no. 21 23 22 27 26 25

L. Wt.of container(gm) 35.62 35.4 34.9 35.19 34.23 34.95

M. Wt.of wet sample+cont.(gm) 93.12 95.02 93.71 91.98 89.2 92.16

N. Wt.of dry sample+cont.(gm) 85.61 86.51 85.98 84.03 81.93 84.26

P. Wt.of water(M-N)(gm) 7.51 8.51 7.73 7.95 7.27 7.9

Q. Wt.of dry sample(N-L)(gm) 49.99 51.11 51.08 48.84 47.7 49.31

R. Water content[(P/Q)x100](%) 15.02 16.65 15.13 16.28 15.24 16.02

S. Dry density{H/[1+(R/100)]}(gm/cc) 1.663 1.668 1.679 1.682 1.668 1.672

LOAD PENETRATION TEST DATA

Penetratio Proving ring Proving ring Proving ring

GENERAL INFORMATION

n (mm) reading

Load(kgf)

reading

Load(kgf)

reading

Load(kgf)

0.0 0 0 0 0 0 0

Type of compaction used: Static/ Dynamic

0.5 2 12.94 4 25.88 3 19.41

1.0 4 25.88 6 38.82 5 32.35

Period of soaking : 04 days

1.5 5 32.35 8 51.76 6 38.82

2.0 6 38.82 9 58.23 7 45.29

Wt.of surcharge used (kg) : 5kg

2.5 7 45.29 10 64.7 8 51.76

4.0 9 58.23 13 84.11 10 64.7

Proving ring Number & capacity : 50KN

5.0 10 64.7 14 90.58 11 71.17

7.5 12 77.64 16 103.52 13 84.11

Proving Ring Load Factor 6.47

10.0

12.5

Corrected unit load from graph(kg) for 2.5mm 3.31 4.72 3.78

Corrected unit load from graph(kg) for 5.0mm 3.15 4.41 3.46

CBR at 2.5mm (%) 3.31 4.72 3.78

CBR at 5.0mm (%) 3.15 4.41 3.46

CBR reported (%) 3.94

For Contractor(RPP) For Authority Engineer For Client/NHPWD

Name: Name: Name:

Designation: Designation: Designation:

Date: Date: Date:

Rehabilitation And Up-Gradation Of Existing 2 Lane With Paved Shoulder Configuration of Wardha-Arvi from

Km. 0+000 (Wardha) to Km. 53+708 (Arvi) NH-647 in the State of Maharastra On Engineering Procurment &

Construction (EPC)Basic Contract.

Format No.:T/F 7 Rev no: 0

Client National Highways Public Work Department

Contractor RPP Infra Project's Ltd

Authority Engineer TPF ENGINEERING PVT LTD

C B R TEST

Laboratory job no. Date of sampling 2/27/2019

Type of material Soil Sampled by Jointly

Source OGL Date of testing 3/10/2019

Location 26+500 Tested by Jointly

Proposed use Emb.Bottom

LOAD vsLOAD

PENETRATION GRAPH

vs PENETRATION (56 Blows)

GRAPH

100

400

90

350

80

300

70

250

60

(Kg)

Load(Kg)

50

200

Load

40

150

30

100

20

50

10

00

12.5

13.0

14.5

0.5

1.0

2.0

2.5

3.5

4.0

5.0

5.5

6.5

7.0

8.0

8.5

9.5

10.0

10.5

11.0

11.5

12.0

13.5

14.0

15.0

0.0

1.5

3.0

4.5

6.0

7.5

9.0

0.5

1.0

2.5

3.0

3.5

5.0

5.5

6.0

7.5

9.0

9.5

10.0

12.5

0.0

1.5

2.0

4.0

4.5

6.5

7.0

8.0

8.5

10.5

11.0

11.5

12.0

13.0

13.5

14.0

14.5

15.0

Penetration

Penetration(mm)

(mm)

Results:-

Mould no. 13

CBR at 2.5mm Penetration

CBR at 5.0mm Penetration

Corrected CBR at 2.5mm Penetration

Corrected CBR at 5.0mm Penetration

CBR reported as (%)=

For Contractor(RPP) For Authority Engineer For Client/NHPWD

Name: Name: Name:

Designation: Designation: Designation:

Date: Date: Date:

Rehabilitation And Up-Gradation Of Existing 2 Lane With Paved Shoulder Configuration of Wardha-Arvi from

Km. 0+000 (Wardha) to Km. 53+708 (Arvi) NH-647 in the State of Maharastra On Engineering Procurment &

Construction (EPC)Basic Contract.

Format No.:T/F 7 Rev no: 0

Client National Highways Public Work Department

Contractor RPP Infra Project's Ltd

Authority Engineer TPF ENGINEERING PVT LTD

C B R TEST

Laboratory job no. Date of sampling 2/27/2019

Type of material Soil Sampled by Jointly

Source OGL Date of testing 3/10/2019

Location 26+500 Tested by Jointly

Proposed use Emb.Bottom

LOAD vs PENETRATION GRAPH (56 Blows)

140

120

100

80

Load (Kg)

60

40

20

0

0.5

1.0

2.5

3.0

3.5

5.0

5.5

6.0

7.5

9.0

9.5

10.0

12.5

0.0

1.5

2.0

4.0

4.5

6.5

7.0

8.0

8.5

10.5

11.0

11.5

12.0

13.0

13.5

14.0

14.5

15.0

Penetration (mm)

Results:-

Mould no. 14

CBR at 2.5mm Penetration

CBR at 5.0mm Penetration

Corrected CBR at 2.5mm Penetration

Corrected CBR at 5.0mm Penetration

CBR reported as (%)=

For Contractor(L&T) For Authority Engineer For Client/NHPWD

Name: Name: Name:

Designation: Designation: Designation:

Date: Date: Date:

Rehabilitation And Up-Gradation Of Existing 2 Lane With Paved Shoulder Configuration of Wardha-Arvi from

Km. 0+000 (Wardha) to Km. 53+708 (Arvi) NH-647 in the State of Maharastra On Engineering Procurment &

Construction (EPC)Basic Contract.

Format No.:T/F 7 Rev no: 0

Client National Highways Public Work Department

Contractor RPP Infra Project's Ltd

Authority Engineer TPF ENGINEERING PVT LTD

C B R TEST

Laboratory job no. Date of sampling 2/27/2019

Type of material Soil Sampled by Jointly

Source OGL Date of testing 3/10/2019

Location 26+500 Tested by Jointly

Proposed use Emb.Bottom

LOAD vs PENETRATION GRAPH (56 Blows)

100

90

80

70

60

Load (Kg)

50

40

30

20

10

0

0.5

1.0

2.5

3.0

3.5

5.0

5.5

6.0

7.5

9.0

9.5

10.0

12.5

0.0

1.5

2.0

4.0

4.5

6.5

7.0

8.0

8.5

10.5

11.0

11.5

12.0

13.0

13.5

14.0

14.5

15.0

Penetration (mm)

Results:-

Mould no. 15

CBR at 2.5mm Penetration

CBR at 5.0mm Penetration

Corrected CBR at 2.5mm Penetration

Corrected CBR at 5.0mm Penetration

CBR reported as (%)=

For Contractor(L&T) For Authority Engineer For Client/NHPWD

Name: Name: Name:

Designation: Designation: Designation:

Date: Date: Date:

Dry Density Vs CBR Graph

15

10

CBR (%)

0

1.80 1.85 1.90 1.95

Dry Density (g/cc)

Maximum Dry Density (g/cc) 1.70

97% of MDD (g/cc) 1.64

CBR at 97% of MDD (%) 1.64

You might also like

- Environmental Geology 2nd Edition Reichard Test BankDocument35 pagesEnvironmental Geology 2nd Edition Reichard Test Bankjohnevansixtcwzmoey100% (18)

- VSDC LAC Test Keys v4 - 8Document2 pagesVSDC LAC Test Keys v4 - 8Nirvana Munar Meneses100% (2)

- Theories of Crime CausationDocument59 pagesTheories of Crime CausationRey John Dizon88% (32)

- Occupational Health and Safety ReportDocument6 pagesOccupational Health and Safety Reportخالد نسیمNo ratings yet

- AP.1901 Inventories.Document8 pagesAP.1901 Inventories.Erlinda Esguerra Guiang100% (9)

- Bridge Design Format For Rural Road NQM Project AssamDocument35 pagesBridge Design Format For Rural Road NQM Project Assamarif ahmedNo ratings yet

- Amendment No. 1 November 2019 TO Is 16715: 2018 Ultrafine Ground Granulated Blast Furnace Slag - SpecificationDocument2 pagesAmendment No. 1 November 2019 TO Is 16715: 2018 Ultrafine Ground Granulated Blast Furnace Slag - SpecificationdivithNo ratings yet

- WMM Calibration 05.01.2016Document8 pagesWMM Calibration 05.01.2016SRR QAQCNo ratings yet

- Blank Format Extraction and GradationDocument2 pagesBlank Format Extraction and GradationMohammed AyazNo ratings yet

- Slump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45Document37 pagesSlump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45ChManikumarNo ratings yet

- Self Compacting Concrete-Ce19s015 PDFDocument13 pagesSelf Compacting Concrete-Ce19s015 PDFmamthaNo ratings yet

- Test Result: Acceptance Criteria As Per IS: 456 - 2000 (RA: 2011)Document1 pageTest Result: Acceptance Criteria As Per IS: 456 - 2000 (RA: 2011)Sainath AmudaNo ratings yet

- Field Density Test Sand Replacement Method: Employer: Chennai Metro Rail Limited Project: CMRL C4 ECV02Document1 pageField Density Test Sand Replacement Method: Employer: Chennai Metro Rail Limited Project: CMRL C4 ECV02zealbalaNo ratings yet

- FDT Part 1Document1 pageFDT Part 1bilalNo ratings yet

- Sika Grout Vhs QacDocument1 pageSika Grout Vhs QacSushil RajakNo ratings yet

- Blank Quality Plan PAGE-2 TG 60663Document15 pagesBlank Quality Plan PAGE-2 TG 60663NEERAJ JINDALNo ratings yet

- Moisture Correction Sheet Date-04-11-2020Document7 pagesMoisture Correction Sheet Date-04-11-2020SandeepNo ratings yet

- Mix Design M-25 GradeDocument9 pagesMix Design M-25 Gradeenjoy begening lifeNo ratings yet

- Ultratech PPC 53 Grade CementDocument1 pageUltratech PPC 53 Grade CementGovind SharmaNo ratings yet

- Quality TestDocument22 pagesQuality TestUmair Shaikh100% (1)

- Determination of Field Density of Soil by Core Cutter MethodDocument3 pagesDetermination of Field Density of Soil by Core Cutter MethodsiddiqueakbarNo ratings yet

- CRM Opc BlainesDocument2 pagesCRM Opc BlainesVara Prasad PaluriNo ratings yet

- Pile Integrity Test2 PDFDocument3 pagesPile Integrity Test2 PDFSima Datta Deb100% (1)

- Apcotrak: Technical DataDocument1 pageApcotrak: Technical DatahafsalNo ratings yet

- RMM CalibrationDocument18 pagesRMM CalibrationPrasanna S KulkarniNo ratings yet

- Is 16720 Product Manual Fuel AshDocument7 pagesIs 16720 Product Manual Fuel AshKolkata PIUNo ratings yet

- WMM Mix DesignDocument23 pagesWMM Mix DesignEnd EndNo ratings yet

- Fine Sieve Analysis RegisterDocument2 pagesFine Sieve Analysis RegisterRicha YadavNo ratings yet

- Annexure 2 Form 72 (Scope) Annexure IDocument4 pagesAnnexure 2 Form 72 (Scope) Annexure IVaghasiyaBipinNo ratings yet

- RCPT SopDocument2 pagesRCPT SopAbraham Henry BernardNo ratings yet

- Basf Masterpolyheed 8118 TdsDocument2 pagesBasf Masterpolyheed 8118 Tdsaji arafat100% (2)

- Test Method - Soil2Document25 pagesTest Method - Soil2jitendraNo ratings yet

- Bitumen (Ext)Document1 pageBitumen (Ext)venkateswara rao PothinaNo ratings yet

- GSB Trial Patch-3Document2 pagesGSB Trial Patch-3Md YasinNo ratings yet

- Is 16651-2017Document18 pagesIs 16651-2017Assistant Coordinator Business DevelopmentNo ratings yet

- Sew Infrastructutre LTD: Calibration of Sand Pouring CylinderDocument1 pageSew Infrastructutre LTD: Calibration of Sand Pouring CylinderRayudu VVSNo ratings yet

- Danta - Lateral Load Test Report Final-05.01.24Document18 pagesDanta - Lateral Load Test Report Final-05.01.24Deepak avinashNo ratings yet

- Is 2720 29 1975Document14 pagesIs 2720 29 1975biswashree10No ratings yet

- Cube Test ReportDocument1 pageCube Test ReportSurajit SahaNo ratings yet

- Is 383 (1970) Grading ZonesDocument2 pagesIs 383 (1970) Grading ZonesAnonymous 2RduvkjgZNo ratings yet

- Mix Design FormatDocument3 pagesMix Design FormatAkshay MitraNo ratings yet

- Cube Test ReportDocument1 pageCube Test ReportShubham MareNo ratings yet

- Compaction Test by Core Cutter (Is: 2720, Part 29)Document2 pagesCompaction Test by Core Cutter (Is: 2720, Part 29)Francis Aw Soon LeeNo ratings yet

- Test Reports PDFDocument25 pagesTest Reports PDFAbdelhamid ElgasaierNo ratings yet

- Is 1195-1978 Specification For Bitumen Mastic For FlooringDocument20 pagesIs 1195-1978 Specification For Bitumen Mastic For FlooringVijayakrishna Singamsetti100% (1)

- FT003 - Aggregate Impact Value TestDocument15 pagesFT003 - Aggregate Impact Value Testjjksite voyantsNo ratings yet

- Grain Size Analysis For SoilsDocument11 pagesGrain Size Analysis For SoilsyogananthanNo ratings yet

- Mix Design of DLCDocument8 pagesMix Design of DLCSasanka SekharNo ratings yet

- M 40 PQC With GGBS 340-60Document6 pagesM 40 PQC With GGBS 340-60Er Dnyaneshwar PatilNo ratings yet

- Test Report: M/S Pcil & MBPCL Joint VentureDocument7 pagesTest Report: M/S Pcil & MBPCL Joint VentureImran KhanNo ratings yet

- Andhra Pradesh Class 1 Registration Certificate FormatDocument2 pagesAndhra Pradesh Class 1 Registration Certificate Formatgsatyasrikanth0% (3)

- BR 32 Water, Aggregate & Cement Test ReportDocument4 pagesBR 32 Water, Aggregate & Cement Test ReportSravan KuppiliNo ratings yet

- ASTM D2041 aashto T209 ефект процент битума PDFDocument4 pagesASTM D2041 aashto T209 ефект процент битума PDFanon_711474514No ratings yet

- FT004 - FLAKINESS & ELONGATION INDICESdDocument23 pagesFT004 - FLAKINESS & ELONGATION INDICESdjjksite voyantsNo ratings yet

- Fine Aggregate - M-SandDocument1 pageFine Aggregate - M-SandSudhir Mishra100% (1)

- Soil Report Sec-155Document16 pagesSoil Report Sec-155Sandeep SainiNo ratings yet

- Sector Project-Package A:Mahua-Chuwahi RoadDocument6 pagesSector Project-Package A:Mahua-Chuwahi RoadVIMAL TIWARINo ratings yet

- Ultratech Cement Limited: Sieve Analysis of Coarse Aggregate For Concrete (As Per Is: 383 - 1970)Document24 pagesUltratech Cement Limited: Sieve Analysis of Coarse Aggregate For Concrete (As Per Is: 383 - 1970)Mamata BhangaleNo ratings yet

- Laboratory Manual FinalDocument57 pagesLaboratory Manual Finalrohit kumarNo ratings yet

- Road Bitumen Work QAP No 02Document2 pagesRoad Bitumen Work QAP No 02Sasanka SekharNo ratings yet

- SC - Panel Test PDFDocument1 pageSC - Panel Test PDFjitendraNo ratings yet

- Observation Sheet For Bitumen Extraction Test: Name of Division Name of Sub DivisionDocument2 pagesObservation Sheet For Bitumen Extraction Test: Name of Division Name of Sub DivisionramNo ratings yet

- Ravi Sir DLC PresentationDocument13 pagesRavi Sir DLC Presentationসৌগত রায় ঘটকNo ratings yet

- Concrete Lab ManualDocument42 pagesConcrete Lab ManualVENKATA RANGANADHNo ratings yet

- CBR Ba-9 - 2Document2 pagesCBR Ba-9 - 2Prakash budhaniNo ratings yet

- TED Taiye SelasiDocument4 pagesTED Taiye SelasiMinh ThuNo ratings yet

- Negara Hukum-5-1-Juni-2014Document99 pagesNegara Hukum-5-1-Juni-2014haekalnashvilleNo ratings yet

- Operation EPSOM: To The Odon!: Mission H3Document3 pagesOperation EPSOM: To The Odon!: Mission H3PaoloViarengoNo ratings yet

- Indian Institute of Information Technology, Surat: SVNIT Campus, Ichchanath, Surat - 395007Document1 pageIndian Institute of Information Technology, Surat: SVNIT Campus, Ichchanath, Surat - 395007gopalgeniusNo ratings yet

- EWRFDocument1 pageEWRFHarini Sybel CullenNo ratings yet

- Lecture Notes On Vat As AmendedDocument7 pagesLecture Notes On Vat As Amendedbubblingbrook100% (1)

- CH 3Document41 pagesCH 3Diana BaRobNo ratings yet

- The Effectiveness of Bilingual Program and Policy in The Academic Performance and Engagement of StudentsDocument10 pagesThe Effectiveness of Bilingual Program and Policy in The Academic Performance and Engagement of StudentsJoshua LagonoyNo ratings yet

- Milvik ProposalDocument29 pagesMilvik ProposalMin HajNo ratings yet

- Two Versions PDFDocument70 pagesTwo Versions PDFkamilghoshalNo ratings yet

- Alex. Hamilton Vs Thomas JeffersonDocument4 pagesAlex. Hamilton Vs Thomas JeffersonRhett Hunt100% (1)

- The Blood PDFDocument4 pagesThe Blood PDFAdeNo ratings yet

- Chapters 1-5: Task No. 6 Process QuestionsDocument4 pagesChapters 1-5: Task No. 6 Process QuestionsFarNo ratings yet

- Report On Rosemary Chiavetta in Harrisburg PA From NuwberDocument82 pagesReport On Rosemary Chiavetta in Harrisburg PA From Nuwbermaria-bellaNo ratings yet

- Financial and Managerial Accounting: Wild, Shaw, and Chiappetta Fifth EditionDocument41 pagesFinancial and Managerial Accounting: Wild, Shaw, and Chiappetta Fifth EditionryoguNo ratings yet

- Global WarmingDocument50 pagesGlobal WarmingLeah Oljol RualesNo ratings yet

- Module MAPEH 8 4thDocument21 pagesModule MAPEH 8 4thEdnell VelascoNo ratings yet

- Lecture 03 - ECO 209 - W2013 PDFDocument69 pagesLecture 03 - ECO 209 - W2013 PDF123No ratings yet

- Answers Unit 2 IMK Part 1Document8 pagesAnswers Unit 2 IMK Part 1Vivi SamaniegoNo ratings yet

- Kurt LewinDocument6 pagesKurt Lewinfotiadis100% (2)

- WogManual 022408 AVAGDUDocument315 pagesWogManual 022408 AVAGDUhellishteethNo ratings yet

- Malankara Catholic Church Sui Iuris: Juridical Status and Power of GovernanceDocument26 pagesMalankara Catholic Church Sui Iuris: Juridical Status and Power of GovernanceDr. Thomas Kuzhinapurath100% (6)

- Current Trends Issues and Problems in Education SystemDocument49 pagesCurrent Trends Issues and Problems in Education SystemfuellasjericNo ratings yet

- Unit 7 Exercises To StsDocument7 pagesUnit 7 Exercises To StsHưng TrầnNo ratings yet

- Narrative Report On SGC ASSEMBLYDocument3 pagesNarrative Report On SGC ASSEMBLYcathy93No ratings yet