Professional Documents

Culture Documents

Bilstein Rear E4-WM5-Y764A00

Bilstein Rear E4-WM5-Y764A00

Uploaded by

AlzieOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bilstein Rear E4-WM5-Y764A00

Bilstein Rear E4-WM5-Y764A00

Uploaded by

AlzieCopyright:

Available Formats

E4-WM5-Y764A00

MOUNTING INSTRUCTION

IMPORTANT! READ THIS FIRST!

Installation of shock absorbers requires special tools and expert knowledge. Accordingly, installation of all BILSTEIN

products must be performed by a professional automotive suspension technician.

When replacing other brands, BILSTEIN shock absorbers should always be installed as a set. All BILSTEIN products must

only be used for the specific, intended application as indicated in the application guide. Any use of any BILSTEIN product

other than for its intended use may result in serious bodily injury or death.

Always use a chassis hoist for the installation of BILSTEIN products and make certain that the raised vehicle is securely

attached to the hoist and/or supported to prevent the vehicle from slipping, falling, or moving during the installation process.

If you install any BILSTEIN product without the necessary special tools, expertise, and chassis hoist, you may

subject yourself to the risk of serious bodily injury or death.

BILSTEIN shock absorbers are gas-filled and are highly pressurized.

Never place any BILSTEIN product in a vise or use a clamp on any BILSTEIN product.

Never apply heat near any BILSTEIN product.

Never attempt to open or repair any BILSTEIN product, in order to prevent serious bodily injury or death.

Any attempt to misuse, misapply, modify, or tamper with any BILSTEIN suspension product voids any warranty and may result

in serious bodily injury or death.

While installing any BILSTEIN product:

Do not use impact tools for loosening or tightening fasteners, because this may destroy the screw threads.

Self-locking fasteners must only be used once!

Reuse original equipment components only if they are in good condition, otherwise replace them with new components.

Never remove the slight film of oil on the piston rod and seal.

All mounting fasteners for shocks and struts must be securely tightened before tension is placed on the suspension

system, unless otherwise specified in the manufacturer’s service manual or in this instruction.

After installing any BILSTEIN product:

The suspension caster and camber must be checked and/or adjusted to comply with the vehicle manufacturer’s

specifications.

The (load dependent) brake compensator and the anti-lock brake system must be checked and/or reset to comply with

the vehicle manufacturer’s specifications.

The headlight aim must be checked and adjusted.

created: 08.24.21 E4-WM5-Y764A00_0 Page 1 of 15 latest revision:

E4-WM5-Y764A00

MOUNTING INSTRUCTION

Ø22.3mm

[7/8"]

Ø24.75mm

[31/32"]

Items in this box are

bagged separately.

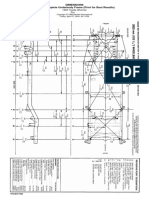

Bill of Materials

Item # Description Qty

1 Anti Rotation Pin 1

2 Washer; 1/4" ID x 3/4" OD 1

3 Nylock; M6x1 1

4 Anti Rotation Plate 1

5 Bushing; Lower 1

6 Alignment Washer; '10- 1

7 Alignment Washer; '03-'09 1

8 Bushing; Upper 1

9 Concave Washer 1

10 Flange Locknut; M12X1.25 1

11 Reservoir Bracket Adapter 1

12 Reservoir Bracket 1

13 M8x1.25 x 25mm SHCS 3

14 Split Lock Washer (for M8x1.25 x 25 SHCS) 3

15 M6x1 x 25mm SHCS 1

16 Nylon, 8mm, Washer 1

17 Stud, Right-Angle 1

18 Nylon Retaining Washer 1

19 Split Washer; ¼” 2

20 Hex nut, 1/4”-20 1

21 Snapring 1

22 Hex Head Cap Screw, 1/4”-20, L=1.25” 1

23 Washer 1

24 Serrated Flange Nut 1

25 Threaded Insert 1

26 SHCS ¼”-20, L=3/4" 1

created: 08.24.21 E4-WM5-Y764A00_0 Page 2 of 15 latest revision:

E4-WM5-Y764A00

MOUNTING INSTRUCTION

B8 5160 reservoir shock installation procedure:

B8 5160 reservoir shocks are corner specific. The step by step procedure is shown with pictures below. See pages

14 and 15 for the end result.

A. Remove the existing shock from the vehicle following all procedures in the vehicle manufacturer’s service manual.

Inspect the OE lower shock bolt/washer for any damage or excessive wear. If these components are in good condition,

save them for reuse later. If damage or excessive wear is present on any of these components, purchase the required

replacement OE components.

B. Find the Reservoir Bracket and appropriate hardware shown in Figure 1 below.

o Note: The Reservoir Bracket orientation is different for the Left (Driver) and Right (Passenger) side. Refer to

Figure 1 below.

Snapring

(BOM item #21)

Reservoir Bracket, Right Side

Reservoir Bracket, Left Side (BOM item #12)

(BOM item #12)

M6x1 x 25 SHCS

(BOM item #15)

M6x1 x 25 SHCS

(BOM item #15)

Reservoir Tube Reservoir Tube

Figure 1: Reservoir

tube/bracket assembly

C. Slide Reservoir Bracket (BOM item #12) down over the Reservoir Tube and install the Snapring (BOM item #21) into

the groove as shown in Figure 2.

Snapring

(BOM item

#21)

Figure 2: Reservoir tube Snapring installation. Right (Passenger) side depicted

created: 08.24.21 E4-WM5-Y764A00_0 Page 3 of 15 latest revision:

E4-WM5-Y764A00

MOUNTING INSTRUCTION

D. Slide the Reservoir Bracket up over the Snapring until it bottoms out. Verify the Reservoir Brackets are oriented on each

side as shown below in Figure 3.

Figure 3: Reservoir tube bracket

M6x1 x 25 SHCS

(BOM item #15)

Left (Driver) Side Right (Passenger) Side

E. Apply non-permanent thread locker to the M6x1 x 25 SHCS (BOM item #15).

F. Screw in the M6x1 SHCS using a 5mm hex driver.

o Torque: 5 ft·lb (7 Nm)

G. Figure 4 shows the vehicle frame rail on the driver side toward the front of the wheel well. There are two existing

holes in the frame rail that will be used to secure the reservoir bracket. The upper hole has a M8x1.25 thread, the

lower hole is oval and has no threads. For vehicles not equipped with the M8x1.25 thread in the upper mounting

hole, refer to steps H through N below. If the M8x1.25 threaded hole is present, skip to step O and BOM items in

the dotted box on page 2 can be discarded (BOM items #19 and #22 through #26).

Upper

hole-

M8x1.25

thread

Oval hole

Figure 4

created: 08.24.21 E4-WM5-Y764A00_0 Page 4 of 15 latest revision:

E4-WM5-Y764A00

MOUNTING INSTRUCTION

Process for installing Threaded Inserts into frame

H. Discard quantity 1 of the M8 hardware shown here in Figure 5:

Split Lock Washer (for Nylon 8mm

M8x1.25 x 25 SHCS) Washer

(BOM item #14) (BOM item #16)

M8x1.25 SHCS –

BOM item #13

Figure 5

I. Use the following hardware in exchange for the discarded M8 hardware shown above in step H. See Figure 6.

¼”-20 SHCS – BOM

Split Washer, ¼”

item #26

– BOM item #19

Figure 6

J. The upper hole on the frame is 0.35” in diameter. It must be drilled out to 0.39” using a 25/64" drill bit (not

provided).

K. If you have access to a threaded Insert gun or pliers, that may be preferable to set the provided threaded inserts.

Otherwise, using the BOM items shown below and a ½” box end wrench, arrange them as shown and turn the ¼”-

20 hex head cap screw by hand until it is snug. Refer to Figure 7 and Figure 8.

Note that the screw will pass through the serrated flange nut without engaging the threads. The threads will instead

engage the threaded insert. The serrations on the flange nut prevent the threaded insert from rotating while setting

it.

created: 08.24.21 E4-WM5-Y764A00_0 Page 5 of 15 latest revision:

E4-WM5-Y764A00

MOUNTING INSTRUCTION

Hex Head Cap screw, ¼”-20 x 1 ¼” (BOM item #22)

Washer, ¼”ID x ¾” OD (BOM item #23)

½” box end wrench

Serrated Flange Nut, 5/16”-18

(BOM item #24)

Threaded Insert, 1/4”-20

(BOM item #25)

Figure 7

½” box end wrench

7/16” wrench

Hex Head Cap screw, ¼”-20 x 1 ¼” (BOM item #22)

Washer, ¼”ID x ¾” OD (BOM item #23)

Serrated Flange Nut, 5/16”-18 (BOM item #24)

Threaded Insert, 1/4”-20 (BOM item #25) Figure 8

L. Insert the threaded insert into the drilled out hole.

Figure 9

M. While keeping the threaded insert flange firm and parallel against the frame rail, tighten the screw using a 7/16”

box end wrench or socket. Turn it 2.5 rotations to set the threaded insert. Tightening in ¼ turn increments tends to

work well.

created: 08.24.21 E4-WM5-Y764A00_0 Page 6 of 15 latest revision:

E4-WM5-Y764A00

MOUNTING INSTRUCTION

Figure 10

N. Remove the screw, washer, and flange nut. The threaded insert should now be rigidly fixed in the hole as shown

below.

Figure 11

created: 08.24.21 E4-WM5-Y764A00_0 Page 7 of 15 latest revision:

E4-WM5-Y764A00

MOUNTING INSTRUCTION

O. Find the Reservoir Bracket Adapter and appropriate hardware for each side. Refer to Figure 12:

Split Lock Washer for

M8x1.25 x 25 SHCS -

BOM item #14 (or Split

Washer, ¼” – BOM item

M8x1.25 x 25 SHCS - #19 if the threaded

BOM item #13 (or ¼”- insert is being used) Nylon 8mm

20 SHCS – BOM item Washer

#26 if the Threaded (BOM item #16)

insert is being used)

Nylon Retaining

Washer

Reservoir Bracket (BOM item #18)

Adapter

(BOM item #11)

Right Angle

Stud

(BOM item #17)

Hex nut, ¼”-20

(BOM item #20)

Split Washer; ¼”

(BOM item #19) Figure 12: Reservoir

bracket adapter hardware

P. Slide the Nylon Retaining Washer over the Right Angle Stud, and then insert the threaded end of the stud into the

back of the Reservoir Bracket Adapter as shown in Figure 13.

Q. From the other side, slide the Split Washer over the Right Angle Stud threads, and then thread on the Hex nut,

1/4”-20 by hand until snug. Refer to Figure 13.

Figure 13: Reservoir

bracket adapter

R. Insert the Right Angle Stud into the hole as shown in Figure 14. With the Reservoir Bracket Adapter hanging

upside down, slide the M8x1.25 SHCS through a Split Lock Washer (for M8x1.25 SHCS), and then into the

remaining counter bored hole. Then slide the Nylon Washer over the exposed threads of the M8. Refer to Figure

14. If the threaded inserts were installed, discard the M8x1.25 SHCS (BOM item #13), Split Lock Washer (BOM

item #14), and Nylon 8mm washer (BOM item #16). Instead use the SHCS ¼”-20, L=3/4” (BOM item #26) and ¼”

Split Washer (BOM item #19), refer to steps H and I.

created: 08.24.21 E4-WM5-Y764A00_0 Page 8 of 15 latest revision:

E4-WM5-Y764A00

MOUNTING INSTRUCTION

Nylon, 8mm,

M8x1.25 SHCS – BOM washer (BOM

item #13 (or ¼”-20 item #16)

SHCS if the Threaded

insert is being used -

Figure 14: Reservoir bracket adapter installation BOM item #26)

S. Apply non-permanent thread locker to the remaining exposed M8 or ¼-20 threads.

T. Swing the Reservoir Bracket Adapter right side up and screw the M8x1.25 (or ¼”-20) SHCS into the threaded

hole in the chassis. Use a 6mm hex driver (or 3/16 hex driver if using the ¼”-20 SHCS). Using a 7/16” socket,

tighten the Hex nut, ¼”-20. Refer to Figure 15.

Note: The tab on the stud will catch on an interior feature of the frame which will prevent it from rotating and

allow the nut to be tightened. (In the event that the bracket ever needs to be removed from the vehicle, the nylon

retaining washer will prevent the stud from falling into the frame when the nut is removed).

Torque for M8x1.25 SHCS or SHCS ¼”-20, L=3/4”: 10 ft·lb (13.6 Nm)

Torque for Hex nut, ¼”-20: 8 ft·lb (10.9 Nm)

Figure 15:

Reservoir bracket

adapter

installation

U. Place the Anti-Rotation Pin (BOM item #1) into the frame hole circled in white below. This hole is towards the

front of the shock mount hole. Refer to Figure 16.

Figure 16: Anti-Rotation pin installation

Left (driver) side depicted. Right (passenger) side is a mirror image.

created: 08.24.21 E4-WM5-Y764A00_0 Page 9 of 15 latest revision:

E4-WM5-Y764A00

MOUNTING INSTRUCTION

V. Hold the Anti Rotation Pin with a ½” or 13mm deep socket. Place the Washer (BOM item #2) over the threaded stem

from the top side of the frame. Thread the Nylock; M6x1 (BOM item #3) onto the stem. Then, hold the Anti Rotation Pin

assembly towards the rear of the vehicle and tighten the Nylock with a 10mm ratcheting wrench. Refer to Figure 17.

Torque the Nylock; M6x1 to 7 ft-lb (10 Nm).

Figure 17: Anti-Rotation pin installation complete

Left (Driver) side Right (Passenger) side

W. Slide the Anti Rotation Plate (BOM item #4) over the threaded pin and onto the shock body as shown in Figure 18.

Verify the D-ring hole in the plate seats over the D-ring boss at the base of the pin. Failure to lock this D-ring into place

as shown below may cause your shock to rotate which could create interference issues.

Threaded Pin

Anti Rotation Plate

(BOM item #4)

Figure 18: Anti-Rotation plate installation

created: 08.24.21 E4-WM5-Y764A00_0 Page 10 of 15 latest revision:

E4-WM5-Y764A00

MOUNTING INSTRUCTION

X. Slide the Lower Bushing (BOM item #5) and the appropriate Alignment Washer for your vehicle (BOM item #6 or #7

depending on year; see BOM on page 2) over the threaded pin on the shock body as shown in Figure 19.

Alignment Washer

(BOM item #6 or #7)

Lower Bushing

(BOM item #5)

Figure 19: Anti-Rotation plate, bushing, and washer installation

complete

Y. Place the threaded pin on the shock body through the chassis mount. Guide the Anti Rotation Plate (BOM item #4) so

it captures the Anti Rotation Pin (BOM item #1) and carefully center the Alignment Washer (BOM item #6 or #7) in the

chassis mount hole. Refer to Figure 20.

Figure 20: Top mount/stem parts installation

Left side depicted. Right side is a mirror image.

Z. Slide the Upper Bushing (BOM item #8) over the threaded pin, followed by the Concave Washer (BOM item #9). Verify

the Concave Washer is installed concave side up as shown in Figure 21 and Figure 22. Then thread the Flange

Locknut (BOM item #10) onto the threaded pin on the shock body. Tighten the Flange Locknut using an 18mm ratcheting

wrench.

Torque the Flange Locknut to 20 ft-lb (27 Nm).

created: 08.24.21 E4-WM5-Y764A00_0 Page 11 of 15 latest revision:

E4-WM5-Y764A00

MOUNTING INSTRUCTION

You should now have the following, refer to Figure 21 and Figure 22:

Flange Locknut

(BOM item #10)

Concave Washer

(BOM item #9)

*Note: Verify

concave side up

Upper Bushing

(BOM item #8)

Figure 21: Top mount/stem parts installation complete

Left Side

Figure 22: Top mount/stem parts installation complete

Right Side

created: 08.24.21 E4-WM5-Y764A00_0 Page 12 of 15 latest revision:

E4-WM5-Y764A00

MOUNTING INSTRUCTION

AA. With the upper shock mount secured, install the lower shock mount using bolt/washer removed in step A. Thread until

hand tight (bolt will be torqued at a later step). Refer to Figure 23.

Figure 23: Lower mount installation

Left Side Shown

BB. With the rear suspension drooped out, make sure the Anti-Rotation Pin is not contacting the Anti-Rotation Plate. If it is

contacting, loosen the Nylock; M6x1 (BOM item #3) and slide the Anti-Rotation Pin forward slightly until there is a small

gap (~1/16”). Re-torque Nylock; M6x1 according to step V.

CC. With the main shock body in place, route the reservoir and reservoir hose toward the center of the vehicle, and then in

front of the main shock body. Refer to Figure 24.

Figure 24: Reservoir hose routing

Left (Driver) Side Right (Passenger) Side

created: 08.24.21 E4-WM5-Y764A00_0 Page 13 of 15 latest revision:

E4-WM5-Y764A00

MOUNTING INSTRUCTION

DD. Slide the two M8x1.25 SHCS (BOM item #13) through two Split Lock Washers (BOM item #14), then through the two

holes in the Reservoir Bracket.

EE. Apply non-permanent thread locker to the remaining exposed M8x1.25 threads.

FF. Secure the Reservoir Bracket to the Reservoir Bracket Adapter by screwing both M8x1.25 SHCS into the Reservoir

Bracket Adapter using a 6mm hex driver. Refer to Figure 25.

Torque: 12.5 ft-lb (17 Nm)

Figure 25: Reservoir bracket torque

Left Side Right Side

Final left rear (driver) B8 5160 reservoir shock installed on vehicle, refer to Figure 26.

Figure 26: Final Installation (left side)

Note: The shocks depicted herein may differ slightly in appearance from the supplied components.

created: 08.24.21 E4-WM5-Y764A00_0 Page 14 of 15 latest revision:

E4-WM5-Y764A00

MOUNTING INSTRUCTION

Final right rear (passenger) B8 5160 reservoir shock installed on vehicle, refer to Figure 27.

Figure 27: Final Installation (right side)

GG. Be sure to lower the vehicle such that its full weight is on the suspension prior to fully tightening the lower mount

fasteners to the vehicle manufacturer’s service manual torque specification.

Anti Rotation component service:

The Anti Rotation Pin (BOM item #1) and Anti Rotation Plate (BOM item #4) are wear items and will need to be replaced

periodically depending on usage. Check for wear every 20,000 miles and replace components if they show excessive signs

of wear.

To purchase new Anti Rotation components, please contact:

THYSSENKRUPP BILSTEIN OF AMERICA

Toll Free: 1-800-537-1085

bilsteinus.com

created: 08.24.21 E4-WM5-Y764A00_0 Page 15 of 15 latest revision:

You might also like

- Bloque R9MDocument20 pagesBloque R9M80140067% (3)

- Land Rover Range Rover L320-11My Sport Wiring Diagram-21215L400013Document158 pagesLand Rover Range Rover L320-11My Sport Wiring Diagram-21215L400013Carlos Lopez100% (1)

- Manual Minicargador Caterpillar bh27 y bh30Document5 pagesManual Minicargador Caterpillar bh27 y bh30Pedro BarriosNo ratings yet

- Instructions Lefty DLR2 - EXCELLENTDocument27 pagesInstructions Lefty DLR2 - EXCELLENTleftyrider86% (7)

- T ISS PX01 Instruction Manual Rev.01Document9 pagesT ISS PX01 Instruction Manual Rev.01Louis Marino100% (1)

- Thermo Accela 1250 - Pump - Service Training - ManualDocument90 pagesThermo Accela 1250 - Pump - Service Training - ManualOliver MüllerNo ratings yet

- Strada 2001-2009 PDFDocument309 pagesStrada 2001-2009 PDFFernando MorenoNo ratings yet

- Piaggio Fly 125-150 I.E. MY 2012 (EN)Document252 pagesPiaggio Fly 125-150 I.E. MY 2012 (EN)Manualles67% (6)

- Soosan Servicemanual SB GBDocument10 pagesSoosan Servicemanual SB GBvanNo ratings yet

- TK-50 Installation Manual Rev 1.1 - EVO1 PDFDocument147 pagesTK-50 Installation Manual Rev 1.1 - EVO1 PDFanh trong100% (7)

- 2008 Marin XC120 Service ManualDocument14 pages2008 Marin XC120 Service Manualsastusbulbas100% (1)

- Diagrama de Parachoques DelanteroDocument9 pagesDiagrama de Parachoques DelanteroAbel Mario ArévaloNo ratings yet

- AspxDocument27 pagesAspxBrayan Sánchez ParedesNo ratings yet

- TowHaul SM1645 Main Lift Cross-Port Relief Kit Install Procedure-9354Document8 pagesTowHaul SM1645 Main Lift Cross-Port Relief Kit Install Procedure-9354lusiNo ratings yet

- Motorcycle Assembly & Preparation ManualDocument36 pagesMotorcycle Assembly & Preparation ManualsamellveeNo ratings yet

- Yarway Blow Off Valves Operation ManualDocument4 pagesYarway Blow Off Valves Operation ManualLeoNo ratings yet

- Installation Instructions: Automotive Products, IncDocument6 pagesInstallation Instructions: Automotive Products, IncLuis BaracchiNo ratings yet

- Instructions For The Safe Use of P-Quip Liner Retention Systems - Pt. No. 80000111 Revision Date August 9, 2006Document7 pagesInstructions For The Safe Use of P-Quip Liner Retention Systems - Pt. No. 80000111 Revision Date August 9, 2006Heri VillaNo ratings yet

- Part No. Description Qty. Part No. Description QtyDocument2 pagesPart No. Description Qty. Part No. Description QtyRiyaz SiddiqueNo ratings yet

- 6.38 10M EH Single Shear Seal BOPDocument19 pages6.38 10M EH Single Shear Seal BOPpramodptvpm_65797156No ratings yet

- Contractor Truck Rack Instruction ManualDocument9 pagesContractor Truck Rack Instruction Manualramses9No ratings yet

- Use and Maintenance Manual: Pneumatic L SealerDocument20 pagesUse and Maintenance Manual: Pneumatic L SealerYoslen NuñezNo ratings yet

- Kit de Instalación 1250RO-4 para OL500 SeriesDocument1 pageKit de Instalación 1250RO-4 para OL500 SeriesHarold VasquezNo ratings yet

- Manual de Reparacion Bomba Eaton Modelo 33 A 64Document28 pagesManual de Reparacion Bomba Eaton Modelo 33 A 64Jose Luis Grupo LeivaNo ratings yet

- ENT50131 INstall Sienna HitchDocument1 pageENT50131 INstall Sienna Hitchkimu takuNo ratings yet

- Api 623 Cast Steel Globe Valve: Installation, Operation and Maintenance ManualDocument20 pagesApi 623 Cast Steel Globe Valve: Installation, Operation and Maintenance ManualFahmi HaidiNo ratings yet

- Spring Manual: V3.3 EnglishDocument32 pagesSpring Manual: V3.3 EnglishSinca LucianNo ratings yet

- Maintenance Instruction For The WB Valves: Spare PartsDocument7 pagesMaintenance Instruction For The WB Valves: Spare PartsagrovadoNo ratings yet

- IOM API 623 Globe ValveDocument21 pagesIOM API 623 Globe Valvedesign04No ratings yet

- Service Manual Hino Dutro 1999 DemoDocument15 pagesService Manual Hino Dutro 1999 DemoMe YouNo ratings yet

- 99939-1334-03 EJ800AD EnglishDocument28 pages99939-1334-03 EJ800AD EnglishNAUTI SURNo ratings yet

- Lista de Partes de Suspension HendricsonDocument4 pagesLista de Partes de Suspension HendricsonLEO100% (1)

- RWYL34BTDocument20 pagesRWYL34BTbifok96010No ratings yet

- AJ401Document36 pagesAJ401luis javier munoz berdugoNo ratings yet

- Remove RockerDocument16 pagesRemove RockerjeremyNo ratings yet

- HydroLeducM MA MSI - RepairDocument23 pagesHydroLeducM MA MSI - RepairJUAN CARLOS BERMUDEZNo ratings yet

- (04-02) - AlternatorDocument3 pages(04-02) - AlternatoreduardoNo ratings yet

- Installation Instructions: CascadeDocument4 pagesInstallation Instructions: CascadeSARAMQRNo ratings yet

- Chillersapikhubdocuments5wpq Iw7UC NV6ZJjGVizgcontentDocument18 pagesChillersapikhubdocuments5wpq Iw7UC NV6ZJjGVizgcontentsyhnhpc7qmNo ratings yet

- Bondura Bolt - Assembly ProcedureDocument5 pagesBondura Bolt - Assembly ProceduresamersurfNo ratings yet

- 31 5310 GMC Sierra Installation Instructions CaridDocument4 pages31 5310 GMC Sierra Installation Instructions CaridenthonytopmakNo ratings yet

- Continental PC125-RCD SHOP-IN-A-BOX Quick Start Guide 05142020Document4 pagesContinental PC125-RCD SHOP-IN-A-BOX Quick Start Guide 05142020miguel.angel.garcia.011295No ratings yet

- YoshimuraDocument4 pagesYoshimuramovistarfacil55No ratings yet

- 11 Crankcase CrankshaftDocument7 pages11 Crankcase CrankshaftSaraNo ratings yet

- Service Bulletin Trucks: Unit Injectors, ReplacementDocument23 pagesService Bulletin Trucks: Unit Injectors, ReplacementbabyNo ratings yet

- Desarme Parking Brake Wa600-6Document2 pagesDesarme Parking Brake Wa600-6Oliver ArcosNo ratings yet

- AR26.60-Y-6510A Disassembling, Assembling Shift Shaft 06.09.2021 Transmission 400.720 in Model 400.216/241/243/262/281/300Document3 pagesAR26.60-Y-6510A Disassembling, Assembling Shift Shaft 06.09.2021 Transmission 400.720 in Model 400.216/241/243/262/281/300Faiz CeboolNo ratings yet

- Tech 1183 Man StripperDocument19 pagesTech 1183 Man StripperDonna Gray100% (1)

- Mini Stepper Weemsm17930Document2 pagesMini Stepper Weemsm17930Dolores RmzNo ratings yet

- J05074 - Roda Raiada Sem CameraDocument2 pagesJ05074 - Roda Raiada Sem CamerahugoNo ratings yet

- Auxiliary Valve Kit For NEW HOLLAND NEW MODEL HARRITAGE 3600 3230 3037 4710 1Document2 pagesAuxiliary Valve Kit For NEW HOLLAND NEW MODEL HARRITAGE 3600 3230 3037 4710 1Manoj YadavNo ratings yet

- Forward Upper Nacelle Camlocs: Applicability: Q400Document4 pagesForward Upper Nacelle Camlocs: Applicability: Q400Raj Kumar DepalliNo ratings yet

- Weld Power SupplyDocument1 pageWeld Power SupplyK PNo ratings yet

- Yoshimura Fender Kit KTM 390Document4 pagesYoshimura Fender Kit KTM 390Rodrigo CamperoNo ratings yet

- Piston Valve User ManualDocument20 pagesPiston Valve User ManualqaramanNo ratings yet

- CM2 Amt100 2001 03Document66 pagesCM2 Amt100 2001 03Arun VijilanNo ratings yet

- Contents:: Choke Valve Installation & Maintenance ManualDocument10 pagesContents:: Choke Valve Installation & Maintenance Manualimam susantoNo ratings yet

- RCP19 Nissan X-Trail - Heavy Duty Removable 2 Bar System: LayoutDocument4 pagesRCP19 Nissan X-Trail - Heavy Duty Removable 2 Bar System: Layoutwaterlife70No ratings yet

- Level Glass Gauge Tightening ProcedureDocument2 pagesLevel Glass Gauge Tightening ProcedureUsman Aslam100% (1)

- MH Hyd Tac Tm-353!01!3Document6 pagesMH Hyd Tac Tm-353!01!3David MannNo ratings yet

- Sasiu2 Suzuki VL800Document20 pagesSasiu2 Suzuki VL800Crisan SorinNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- MAJOR TECHNICAL SPECIFICATIONS 70 SeriesDocument7 pagesMAJOR TECHNICAL SPECIFICATIONS 70 SeriesAlzieNo ratings yet

- 4runner93 FrameDocument2 pages4runner93 FrameAlzieNo ratings yet

- Parts CatalogueDocument44 pagesParts CatalogueAlzieNo ratings yet

- Japan Auctions GradesDocument5 pagesJapan Auctions GradesAlzieNo ratings yet

- TECHSTREAM 1VD-FTV параметрыDocument46 pagesTECHSTREAM 1VD-FTV параметрыAlzie100% (1)

- A 5421100 ARB Skid PlateDocument8 pagesA 5421100 ARB Skid PlateAlzieNo ratings yet

- Rukovodstvo A750E 2Document41 pagesRukovodstvo A750E 2AlzieNo ratings yet

- Hanse 470 Polar DiagramDocument1 pageHanse 470 Polar DiagramAlzieNo ratings yet

- Bilstein E4-WM5-Y690A00Document7 pagesBilstein E4-WM5-Y690A00AlzieNo ratings yet

- VF4BM Transfer Service ManualDocument59 pagesVF4BM Transfer Service ManualAlzieNo ratings yet

- Ome 46 August 2021Document212 pagesOme 46 August 2021AlzieNo ratings yet

- Rail Vehicle Dynamic Performance (Product Re-Engineering For Improving Safety and Ride Comfort)Document116 pagesRail Vehicle Dynamic Performance (Product Re-Engineering For Improving Safety and Ride Comfort)Bhargav BhargavNo ratings yet

- DX55Document842 pagesDX55Teknik Makina100% (2)

- TATT 100Level1Manual3 15 PDFDocument670 pagesTATT 100Level1Manual3 15 PDFFauziah67% (3)

- National 1879Document20 pagesNational 1879Paula PlataNo ratings yet

- Colorado High Country LeafletDocument2 pagesColorado High Country LeafletDanangAjiPrasetiaNo ratings yet

- Partes Transporter 4Document276 pagesPartes Transporter 4Oscar PinzonNo ratings yet

- Baja Saeindia 2022 DVP&R + Dfmea TemplateDocument10 pagesBaja Saeindia 2022 DVP&R + Dfmea TemplateTinu MawaleNo ratings yet

- Captura de Pantalla 2022-04-14 A La(s) 2.46.12 P. M.Document210 pagesCaptura de Pantalla 2022-04-14 A La(s) 2.46.12 P. M.Oscar GomezNo ratings yet

- A Tool For Rapid Vehicle Suspension Design PDFDocument10 pagesA Tool For Rapid Vehicle Suspension Design PDFmikael bezerra cotias dos santosNo ratings yet

- APTA PR-CS-RP-003-98 Recommended Practice For Developing A Clearance Diagram For Passenger EquipmentDocument26 pagesAPTA PR-CS-RP-003-98 Recommended Practice For Developing A Clearance Diagram For Passenger EquipmentdiablopapanatasNo ratings yet

- Chevrolet SAIL3 Parts CatalogueDocument3 pagesChevrolet SAIL3 Parts Cataloguecifer.xiongNo ratings yet

- Find Your Roll CenterDocument20 pagesFind Your Roll CenterchainplatesNo ratings yet

- Brosur Alessa MotorDocument2 pagesBrosur Alessa MotorEka Purwarahayu NFNo ratings yet

- Introduction To LHB CoachDocument68 pagesIntroduction To LHB Coachkr_abhijeet72356587100% (4)

- Parts List: Replacement Parts Composilite™ SC Steerable Suspension SystemsDocument8 pagesParts List: Replacement Parts Composilite™ SC Steerable Suspension SystemsFilip FaustNo ratings yet

- Vzwkuawpwai1huldterex-Demag Ac 50-1 All Terrain Crane NetworkDocument14 pagesVzwkuawpwai1huldterex-Demag Ac 50-1 All Terrain Crane NetworkSameh MohamedNo ratings yet

- OptimumKinematics - Help FileDocument95 pagesOptimumKinematics - Help FileRajan SwamiNo ratings yet

- Piaggio MP3 400 User ManualDocument100 pagesPiaggio MP3 400 User Manuallynhaven1100% (3)

- Ohlins - DTC - Einbauanleitung Oehlins Motorrad DMX 0301Document4 pagesOhlins - DTC - Einbauanleitung Oehlins Motorrad DMX 0301AlbertoNo ratings yet

- Terminal Tractor SpecificationDocument4 pagesTerminal Tractor Specification徐磊No ratings yet

- Suspension SystemsDocument85 pagesSuspension SystemsWalter Tapfumanei MhosvahNo ratings yet

- Racing BrandsDocument13 pagesRacing Brandsricky villa moralesNo ratings yet

- Background Service Solution: Ti 04-11 11 21 en-GB Technical InformationDocument13 pagesBackground Service Solution: Ti 04-11 11 21 en-GB Technical InformationRuanNo ratings yet

- Suspension Catalogue & Price ListDocument98 pagesSuspension Catalogue & Price ListDusan KNo ratings yet

- Tiger Tractor TC-50 PDFDocument692 pagesTiger Tractor TC-50 PDFCarlos SolisNo ratings yet

- Renault KWID Brochure Mar2018Document13 pagesRenault KWID Brochure Mar2018Ryan GovindsamyNo ratings yet