Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

19 viewsEn 2832-1993

En 2832-1993

Uploaded by

Sainath AmudaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Central Institute of Petrochemical & Engineering TechnologiesDocument1 pageCentral Institute of Petrochemical & Engineering TechnologiesSainath AmudaNo ratings yet

- No:RGPO-2223-00466, Dt:08/11/2022: M/S.Voith Turbo Private LTDDocument1 pageNo:RGPO-2223-00466, Dt:08/11/2022: M/S.Voith Turbo Private LTDSainath AmudaNo ratings yet

- Extensometer CalibrationDocument2 pagesExtensometer CalibrationSainath AmudaNo ratings yet

- Nabl Assesment July 2021Document2 pagesNabl Assesment July 2021Sainath AmudaNo ratings yet

- Plot No: 48, Sy - No: 302/3, EC Extension, ECIL X Roads, Kushaiguda, Hyderabad - 500062, TelanganaDocument5 pagesPlot No: 48, Sy - No: 302/3, EC Extension, ECIL X Roads, Kushaiguda, Hyderabad - 500062, TelanganaSainath AmudaNo ratings yet

- Nabl Assesment July 2021: Drying ShrinkageDocument2 pagesNabl Assesment July 2021: Drying ShrinkageSainath AmudaNo ratings yet

- Nabl Assesment July 2021: End ReportDocument1 pageNabl Assesment July 2021: End ReportSainath AmudaNo ratings yet

- Test Result: Acceptance Criteria As Per IS: 456 - 2000 (RA: 2011)Document1 pageTest Result: Acceptance Criteria As Per IS: 456 - 2000 (RA: 2011)Sainath AmudaNo ratings yet

- Test Result: For Sanray Laboratories PVT LTDDocument1 pageTest Result: For Sanray Laboratories PVT LTDSainath AmudaNo ratings yet

- Test Result: Acceptance Criteria As Per IS: 456 - 2000 (RA: 2011)Document2 pagesTest Result: Acceptance Criteria As Per IS: 456 - 2000 (RA: 2011)Sainath AmudaNo ratings yet

- 20.00mm 16.00mm 12.50mm 10.00mm 4.75mm: Test ResultDocument2 pages20.00mm 16.00mm 12.50mm 10.00mm 4.75mm: Test ResultSainath AmudaNo ratings yet

- Test Result: M/S.Machine Tool Aids (India)Document2 pagesTest Result: M/S.Machine Tool Aids (India)Sainath AmudaNo ratings yet

- Raw Data Work Sheet: Compresion Strength of Concrete CubesDocument3 pagesRaw Data Work Sheet: Compresion Strength of Concrete CubesSainath AmudaNo ratings yet

- BS en 10137-1-1996Document20 pagesBS en 10137-1-1996Sainath AmudaNo ratings yet

- 0 RebondDocument1 page0 RebondSainath AmudaNo ratings yet

- Software Design DocumentDocument3 pagesSoftware Design DocumentSainath AmudaNo ratings yet

- Test Result: M/s.Hyderabad Engineering LabsDocument1 pageTest Result: M/s.Hyderabad Engineering LabsSainath AmudaNo ratings yet

- SL - No. Rec - Date Batch No. Test Required Due Date Reg - No. Project Name LocationDocument14 pagesSL - No. Rec - Date Batch No. Test Required Due Date Reg - No. Project Name LocationSainath AmudaNo ratings yet

En 2832-1993

En 2832-1993

Uploaded by

Sainath Amuda0 ratings0% found this document useful (0 votes)

19 views4 pagesOriginal Title

EN 2832-1993

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

19 views4 pagesEn 2832-1993

En 2832-1993

Uploaded by

Sainath AmudaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 4

EUROPEAN STANDARD EN 2832

NORME EUROPEENNE

EUROPAISCHE NORM nian

UDE 669. 14:621,793794:620.172.629.7

Descriptors: Aireraft industry, steels, hydrogen embrittlement, tests, test specimens

English version

Aerospace series — Hydrogen embrittlement of steels —

Notched specimen test

Série aérospatiale — Fragilisation des aciers —_ Luft- und Raumfahrt —

par l'hydrogéne — Essai par éprouvette Wasserstoffversprédung von Stihlen

entaillée Kerbzugversuch

‘This European Standard was approved by CEN on 1993-02-19. CEN members

are bound to comply with the CEN/CENELEC Internal Regulations which

stipulate the conditions for giving this European Standard the status of a

national standard without any alteration.

Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the Central Secretariat or to any

CEN member.

‘This European Standard exists in three official versions (English, French,

German). A version in any other language made by translation under the

responsibility of a CEN member into its own language and notified to the

Central Secretariat has the same status as the official versions,

CEN members are the national standards organizations of Austria, Belgium,

Denmark, Finland, France, Germany, Greece, Iceland, Ireland, Italy,

Luxembourg, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and

United Kingdom.

CEN

European Committee for Standardization

Comité Européen de Normalisation

Europaisches Komitee fiir Normung

Central Secretariat: rue de Stassart 36, B-1050 Brussels

© 1993 Copyright reserved to CEN members

Ref. No. EN 2832:1993 E

EN 2832:1993

Foreword

This Buropean Standard has been prepared by the

European Association of Aerospace Manufacturers

(AECMA),

After inquiries and votes carried out in accordance

with the rules of this Association, this standard has

successively received the approval of the National

Associations and the Official Services of the member

countries of ARCMA, prior to its presentation to

CEN.

‘This European Standard shall be given the status of,

a national standard, either by publication of an

identical text or by endorsement, at the latest by

August 1993, and conflicting national standards

shall be withdrawn at the latest by August 1993,

According to the CENICENELEC Internal

Regulations, the following countries are bound to

implement this European Standard:

Austria, Belgium, Denmark, Finland, France,

Germany, Greece, Iceland, Ireland, Italy,

Luxembourg, Netherlands, Norway, Portugal,

Spain, Sweden, Switzerland and United Kingdom,

Contents

Foreword

1 Scope

2 Apparatus

3 Tost specimens

4 Procedure

5 Fault sanction

6 Test report

Figure 1

Table 1

Page

eRe

EN 2832:1993

1 Scope

‘This standard specifies the method for the notched

specimen test, which is used to assess the hydrogen

embrittlement of steels during chemical or

electrolytic surface treatments.

It is applicable whenever referenced.

2 Apparatus

Any device allowing a constant load to be applied to

the test specimens may be used, i.e. direct load

machines, dynamometric rings, ete.

3 Test specimens

3.1 Material and heat treatment

They shall be identical with those of the parts.

However, the purchaser may require to use a

reference material and heat treatment.

3.2 Dimensions

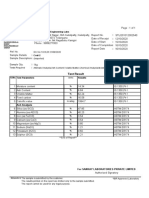

See Figure 1 and Table 1

3.3 Surface treatment

It shall be carried out as on the parts and ensure

that the thickness of the deposit at the notch root is,

the same as that specified for the parts.

3.4 De-embrittlement

It shall be carried out as for the parts,

4 Procedure

‘The test specimens shall be subjected for 200 h, at

ambient temperature, to an axial load equal

to (75+ 2) % of the tensile strength of a notched

uncoated specimen.

5 Fault sanction

No fracture is permissible before 200 h.

6 Test report

It shall include the following:

— reference to this standard;

— reference numbers and types of the test

specimens;

— nature of the coating;

— thickness of the coating;

— test result.

EN 2832:1993

Length not specified

BF 6 6 2F ;

Ry R

T J y x

5 a | ee ee |

,

Ww

la

©] 0.03

Ato

1) The value is not specified however, the diameter of the thread root shall be greater than E.

2) Other head types compatibles with the tensile test may be used.

3) The notch (side and root) shall have the same roughness.

Figure 1

Table 1

D E ¢ R R

55 | esom [evn | som [oto | nom [o/c [lee | tal

T 6A0 307 [Fi [ais [635 [02s

0

3 +0,018

z apr —]* °°? Teas —* 98 FT O13

0

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Central Institute of Petrochemical & Engineering TechnologiesDocument1 pageCentral Institute of Petrochemical & Engineering TechnologiesSainath AmudaNo ratings yet

- No:RGPO-2223-00466, Dt:08/11/2022: M/S.Voith Turbo Private LTDDocument1 pageNo:RGPO-2223-00466, Dt:08/11/2022: M/S.Voith Turbo Private LTDSainath AmudaNo ratings yet

- Extensometer CalibrationDocument2 pagesExtensometer CalibrationSainath AmudaNo ratings yet

- Nabl Assesment July 2021Document2 pagesNabl Assesment July 2021Sainath AmudaNo ratings yet

- Plot No: 48, Sy - No: 302/3, EC Extension, ECIL X Roads, Kushaiguda, Hyderabad - 500062, TelanganaDocument5 pagesPlot No: 48, Sy - No: 302/3, EC Extension, ECIL X Roads, Kushaiguda, Hyderabad - 500062, TelanganaSainath AmudaNo ratings yet

- Nabl Assesment July 2021: Drying ShrinkageDocument2 pagesNabl Assesment July 2021: Drying ShrinkageSainath AmudaNo ratings yet

- Nabl Assesment July 2021: End ReportDocument1 pageNabl Assesment July 2021: End ReportSainath AmudaNo ratings yet

- Test Result: Acceptance Criteria As Per IS: 456 - 2000 (RA: 2011)Document1 pageTest Result: Acceptance Criteria As Per IS: 456 - 2000 (RA: 2011)Sainath AmudaNo ratings yet

- Test Result: For Sanray Laboratories PVT LTDDocument1 pageTest Result: For Sanray Laboratories PVT LTDSainath AmudaNo ratings yet

- Test Result: Acceptance Criteria As Per IS: 456 - 2000 (RA: 2011)Document2 pagesTest Result: Acceptance Criteria As Per IS: 456 - 2000 (RA: 2011)Sainath AmudaNo ratings yet

- 20.00mm 16.00mm 12.50mm 10.00mm 4.75mm: Test ResultDocument2 pages20.00mm 16.00mm 12.50mm 10.00mm 4.75mm: Test ResultSainath AmudaNo ratings yet

- Test Result: M/S.Machine Tool Aids (India)Document2 pagesTest Result: M/S.Machine Tool Aids (India)Sainath AmudaNo ratings yet

- Raw Data Work Sheet: Compresion Strength of Concrete CubesDocument3 pagesRaw Data Work Sheet: Compresion Strength of Concrete CubesSainath AmudaNo ratings yet

- BS en 10137-1-1996Document20 pagesBS en 10137-1-1996Sainath AmudaNo ratings yet

- 0 RebondDocument1 page0 RebondSainath AmudaNo ratings yet

- Software Design DocumentDocument3 pagesSoftware Design DocumentSainath AmudaNo ratings yet

- Test Result: M/s.Hyderabad Engineering LabsDocument1 pageTest Result: M/s.Hyderabad Engineering LabsSainath AmudaNo ratings yet

- SL - No. Rec - Date Batch No. Test Required Due Date Reg - No. Project Name LocationDocument14 pagesSL - No. Rec - Date Batch No. Test Required Due Date Reg - No. Project Name LocationSainath AmudaNo ratings yet