Professional Documents

Culture Documents

Verif EPI Poulies Procedure EN

Verif EPI Poulies Procedure EN

Uploaded by

aliya azharOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Verif EPI Poulies Procedure EN

Verif EPI Poulies Procedure EN

Uploaded by

aliya azharCopyright:

Available Formats

PPE Inspection

Inspection procedure

• In addition to routine checks for each use, PPE should regularly undergo a detailed inspection by a competent

person. Petzl recommends an inspection every 12 months and after any exceptional event in the life of the product.

• PPE inspection should be conducted with the manufacturer’s Instructions for Use.

Download the Instructions at PETZL.COM

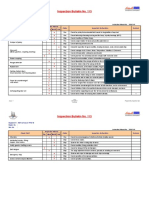

PULLEYS

1. Known product history

Any PPE showing unexpected degradation should be quarantined, pending a detailed inspection.

The user should:

- Provide precise information on the usage conditions.

- Report any exceptional event regarding his/her PPE.

(Examples: fall or fall arrest, use or storage at extreme temperatures, modification outside manufacturer’s

facilities...)

2. Preliminary observations

Verify the presence and legibility of the serial number and the CE mark.

Note: the serial number code on our products is evolving. Two types of code will coexist.

See below for details on each serial number code.

Code A: Code B:

00 000 AA 0000 00 A 0000000 000

Year of manufacture Year of manufacture

Day of manufacture Month of manufacture

Name of Inspector Batch number

Incrementation Incrementation

Verify that the product lifetime has not been exceeded.

Compare with a new product to verify there are no modifications or missing parts.

PPE INSPECTION - Inspection procedure - Pulleys (060121) 1/3

3. Checking the condition of the side plates

• Check the condition of the side plates (marks, deformation, cracks, wear, • Check the condition of the attachment holes (marks, deformation, cracks,

corrosion). wear, corrosion...).

• For pulleys with moving side plates, verify that the • Check the condition of the rivets • Check the condition (marks,

side plates rotate properly. (marks, deformation, cracks, deformation, cracks, wear,

corrosion, absence of play...). corrosion) and the rotation of the

swivel in both directions.

4. Checking the condition of the sheave(s)

• Check the condition of the sheave • Verify that the sheave turns freely

(marks, deformation, cracks, wear, in both directions.

corrosion, absence of foreign

bodies...).

PPE INSPECTION - Inspection procedure - Pulleys (060121) 2/3

Sheave on ratcheting wheel, SPIN L1D

• Check the condition of • Count the number of clicks

the ratcheting wheel (marks, of the ratcheting wheel. You

deformation, cracks, wear, must hear 12 clicks during one

corrosion...). Verify that the complete rotation.

sheave turns in the desired

direction and blocks in the other

direction.

5. Checking the side plates’ opening and locking systems

1. 2. 3. 4. 5.

PUSH ! CLIC !

• Check the condition and function of the locking system (marks, deformation, dirt, effectiveness of the return spring(s)).

6. Function check

• Install your pulley on an anchor and install a compatible rope around the

sheave.

• Circulate the rope in both directions.

PPE INSPECTION - Inspection procedure - Pulleys (060121) 3/3

You might also like

- Community Health Education Methods A Practical Guide PDFDocument2 pagesCommunity Health Education Methods A Practical Guide PDFLaura0% (4)

- LY38 Ops Manual PDFDocument36 pagesLY38 Ops Manual PDForlando chullo llave100% (1)

- SOP Overhead Crane-Rev.1Document5 pagesSOP Overhead Crane-Rev.1RonniNo ratings yet

- REE SPAC Presentation 2021Document41 pagesREE SPAC Presentation 2021Ramon Ramirez TijerinaNo ratings yet

- Verif EPI GRIGRI Procedure enDocument3 pagesVerif EPI GRIGRI Procedure eninternetNo ratings yet

- Verif Epi Protraxion Procedure enDocument4 pagesVerif Epi Protraxion Procedure eninternetNo ratings yet

- Inspection Procedure: Grillon LanyardDocument5 pagesInspection Procedure: Grillon LanyardUlviyye ElesgerovaNo ratings yet

- Verif EPI Harnais SPORT Procedure enDocument4 pagesVerif EPI Harnais SPORT Procedure enisacc palacios gamarraNo ratings yet

- Inspection Procedure: Professional HarnessesDocument9 pagesInspection Procedure: Professional Harnesseschanks498No ratings yet

- Inspection Procedure: Zig ZagDocument3 pagesInspection Procedure: Zig ZagAli Ben AmorNo ratings yet

- Verif EPI Sangleamarrage Procedure FRDocument2 pagesVerif EPI Sangleamarrage Procedure FRinternetNo ratings yet

- Verif EPI Bloqueur Procedure EN PDFDocument6 pagesVerif EPI Bloqueur Procedure EN PDFdsn_sarmaNo ratings yet

- Verif EPI-ASAP-procedure-ENDocument4 pagesVerif EPI-ASAP-procedure-ENAditya GandhiNo ratings yet

- Verif EPI Degaines Procedure enDocument2 pagesVerif EPI Degaines Procedure eninternetNo ratings yet

- PRO12 2P621CT - Rev 7 - 09 19Document24 pagesPRO12 2P621CT - Rev 7 - 09 19Edwin Montenegro MurilloNo ratings yet

- SOP Mobile Crane-Rev.1Document7 pagesSOP Mobile Crane-Rev.1RonniNo ratings yet

- Verif EPI IDS IDL RIG Procedure enDocument5 pagesVerif EPI IDS IDL RIG Procedure enAldisley OliveiraNo ratings yet

- Belt Conveyor RT45-BDocument2 pagesBelt Conveyor RT45-BMahmoud HanafyNo ratings yet

- SRL Inspection ChecklistDocument1 pageSRL Inspection ChecklistLtqt FdrzmNo ratings yet

- Checklist - Backup Device - Petzl ASAP-LOCKDocument1 pageChecklist - Backup Device - Petzl ASAP-LOCKMax BeeksNo ratings yet

- Eot Ibl Crane Yearly ChecksheetDocument3 pagesEot Ibl Crane Yearly ChecksheetAmit ThakurNo ratings yet

- Checklist - Ascenders - Petzl Hand & Chest - 050717Document1 pageChecklist - Ascenders - Petzl Hand & Chest - 050717Max BeeksNo ratings yet

- Travelling Block AdaptorDocument1 pageTravelling Block AdaptormhmdtrainingNo ratings yet

- Eot Crane Monthly ChecksheetDocument4 pagesEot Crane Monthly ChecksheetAmit ThakurNo ratings yet

- LH Sust Mee - FinalDocument45 pagesLH Sust Mee - Finalapi-506314450No ratings yet

- Belt Conveyor RFBE-B1800 X 9.7Document2 pagesBelt Conveyor RFBE-B1800 X 9.7Mahmoud HanafyNo ratings yet

- Time Limits/Maintenance Checks Unscheduled Maintenance Checks Inspection/CheckDocument17 pagesTime Limits/Maintenance Checks Unscheduled Maintenance Checks Inspection/CheckWalter TorenaNo ratings yet

- Miller Lanyard Inspection and Maintenance Proceedure PDFDocument2 pagesMiller Lanyard Inspection and Maintenance Proceedure PDFUlviyye ElesgerovaNo ratings yet

- Full-Body Harnesses: Inspection ChecklistDocument1 pageFull-Body Harnesses: Inspection ChecklistMark Israel DirectoNo ratings yet

- Inspection Form: Frame-Loaded Rope ClampDocument1 pageInspection Form: Frame-Loaded Rope ClampDimasDianaFerreiraNo ratings yet

- ZHENJIANG MARINE AUXILIARY MACHINERY WORKS - Ops & Maint - SH70 - 16Document19 pagesZHENJIANG MARINE AUXILIARY MACHINERY WORKS - Ops & Maint - SH70 - 16Amanda ViverosNo ratings yet

- 6-1d - Maintenance For Control EquipmentDocument84 pages6-1d - Maintenance For Control EquipmentDangolNo ratings yet

- System and Work Methodology For Casting Final 2Document6 pagesSystem and Work Methodology For Casting Final 2Dan GoNo ratings yet

- Weekly Maintenance On Hydra RackerDocument4 pagesWeekly Maintenance On Hydra Rackermohamed hamedNo ratings yet

- CBC AuditDocument4 pagesCBC Auditfrenz2kiranNo ratings yet

- Verif EPI Casque PRO Suivi enDocument1 pageVerif EPI Casque PRO Suivi eneastNo ratings yet

- Fall Protection Equipment Inspection ChecklistDocument1 pageFall Protection Equipment Inspection Checklistأبو خالد الأثرىNo ratings yet

- V30ZMUDocument26 pagesV30ZMUmanuelsaenzNo ratings yet

- 3 Month Maintenance On Hydra RackerDocument2 pages3 Month Maintenance On Hydra Rackermohamed hamedNo ratings yet

- Mechanical Integrity Inspection ExchangerDocument7 pagesMechanical Integrity Inspection ExchangerSyed Faraz Raza100% (1)

- GM 002 AccessoriesDocument45 pagesGM 002 AccessoriesJohn DareNo ratings yet

- Inspeccion de Mantenimiento Por Vida Limite.Document11 pagesInspeccion de Mantenimiento Por Vida Limite.francisco ybarra blancoNo ratings yet

- Pre Operational InspectionDocument89 pagesPre Operational InspectionGustavo ArancibiaNo ratings yet

- 5-Year Maintenance On Hydra RackerDocument2 pages5-Year Maintenance On Hydra Rackermohamed hamedNo ratings yet

- Fall Protection Equipment Inspection ChecklistDocument2 pagesFall Protection Equipment Inspection ChecklistCristinaNo ratings yet

- T48. Annexure - 11 RFT Check SheetDocument11 pagesT48. Annexure - 11 RFT Check SheetarissaNo ratings yet

- 6-Rupture Disc Inspection ChecklistDocument2 pages6-Rupture Disc Inspection ChecklistMAT-LIONNo ratings yet

- Inspection Bulletin No. 103: Impact Crusher IM - 13RDocument1 pageInspection Bulletin No. 103: Impact Crusher IM - 13RMahmoud HanafyNo ratings yet

- A5e39789602ak en 72Document2 pagesA5e39789602ak en 72Mina IsaacNo ratings yet

- Chapter 5: Checking and Maintaining Ultrasound EquipmentDocument8 pagesChapter 5: Checking and Maintaining Ultrasound EquipmentUmar DhaniNo ratings yet

- Of in Service Storage Tank Inspection and Verification ChecklistDocument16 pagesOf in Service Storage Tank Inspection and Verification Checklistkevin RichNo ratings yet

- How To Analyze Gear FailuresDocument6 pagesHow To Analyze Gear FailuresHossein100% (1)

- CS76 Before OperationDocument4 pagesCS76 Before OperationJosé Carlos CarvalhoNo ratings yet

- MM y ServicioDocument82 pagesMM y Serviciojesus francoNo ratings yet

- Group 2 Major Component: 1. Main PumpDocument11 pagesGroup 2 Major Component: 1. Main PumpChristian VicenteNo ratings yet

- Checklist - Lanyard - Petzl ABSORBICA-I-YDocument1 pageChecklist - Lanyard - Petzl ABSORBICA-I-YMax BeeksNo ratings yet

- Swivel & Main ShaftDocument2 pagesSwivel & Main ShaftmhmdtrainingNo ratings yet

- Crankcase Inspection Safety & Procedure MMD Favourite QuestionsDocument1 pageCrankcase Inspection Safety & Procedure MMD Favourite QuestionsAnkit ChatterjeeNo ratings yet

- JSA - Replace Grinding Wheel From Bench GrinderDocument2 pagesJSA - Replace Grinding Wheel From Bench GrinderAshok Suresh100% (1)

- Excavator Instructors NotesDocument31 pagesExcavator Instructors NotesWALTER EMMANUEL FLORES COSCONo ratings yet

- Copy of in Service Storage Tank Inspection and Verification ChecklistDocument9 pagesCopy of in Service Storage Tank Inspection and Verification ChecklistZohaib AlamNo ratings yet

- Activation PDFDocument270 pagesActivation PDFPedro Ruiz MedianeroNo ratings yet

- CompassDocument15 pagesCompassozkan toprakNo ratings yet

- LLM Placement Brochure 2021 22 V15Document24 pagesLLM Placement Brochure 2021 22 V15Bala KumaranNo ratings yet

- Social Media Changed The Nature of Indian Education SystemDocument9 pagesSocial Media Changed The Nature of Indian Education SystemHiteshNo ratings yet

- Active and Passive VoiceDocument3 pagesActive and Passive VoiceCray CrayNo ratings yet

- HigginsBaumfieldHall07 - LearningSkills Tech OnlineDocument52 pagesHigginsBaumfieldHall07 - LearningSkills Tech OnlineattiqbakhtawarNo ratings yet

- Csec It Mock ExamDocument10 pagesCsec It Mock Examvidur_talreja100% (1)

- 4 P's of RolexDocument27 pages4 P's of RolexDaniel Carroll50% (10)

- Comparative Study Between Public and Private InsuranceDocument21 pagesComparative Study Between Public and Private InsuranceNadeemNo ratings yet

- Basic Concepts in Nursing (Report)Document101 pagesBasic Concepts in Nursing (Report)NDJNo ratings yet

- TrashDocument106 pagesTrashMakBuckNo ratings yet

- Anatomy of The Lymphatic SystemDocument76 pagesAnatomy of The Lymphatic SystemManisha RaoNo ratings yet

- SOPs River Sand and Stone Mining ActivitiesDocument64 pagesSOPs River Sand and Stone Mining ActivitiesAliffIrhamMohdHashimNo ratings yet

- C.H. Robinson Contract Addendum and Carrier Load Confirmation - #349533259Document3 pagesC.H. Robinson Contract Addendum and Carrier Load Confirmation - #349533259terry72imlNo ratings yet

- OET SpeakingDocument92 pagesOET SpeakingAnwaarNo ratings yet

- Inv - 1124003027 - Po - 407097662 - VR - 407097662 - (Top Synthetic Rubber)Document1 pageInv - 1124003027 - Po - 407097662 - VR - 407097662 - (Top Synthetic Rubber)shamirah98No ratings yet

- Rural Development: 14.1. Rural Scenario in Tamil NaduDocument17 pagesRural Development: 14.1. Rural Scenario in Tamil NaduhinduNo ratings yet

- Incident Investigation Report - Fire Incedent - 04-11-2018 Swati InteriorsDocument4 pagesIncident Investigation Report - Fire Incedent - 04-11-2018 Swati InteriorsMobin Thomas AbrahamNo ratings yet

- Welcome To Everest Insurance CoDocument2 pagesWelcome To Everest Insurance Cosrijan consultancyNo ratings yet

- Lec 3Document32 pagesLec 3wjeelaniNo ratings yet

- Lock Out-Tag OutDocument40 pagesLock Out-Tag OutMurali DharNo ratings yet

- Miles High Cycles Katherine Roland and John ConnorsDocument4 pagesMiles High Cycles Katherine Roland and John ConnorsvivekNo ratings yet

- OvernutritionDocument4 pagesOvernutritionBleedalNo ratings yet

- Saudi Publication Law (2003/1421)Document11 pagesSaudi Publication Law (2003/1421)Social Media Exchange AssociationNo ratings yet

- Kubernetes CKA 0100 Core Concepts PDFDocument77 pagesKubernetes CKA 0100 Core Concepts PDFShobhit SrivastavaNo ratings yet

- Save The TigerDocument5 pagesSave The TigerChiranjit Saha100% (1)

- SponsorsDocument17 pagesSponsorsGergely TóthNo ratings yet

- Consultants/Contractors Confirmation Check List: Consultant/Contractor UndertakingDocument1 pageConsultants/Contractors Confirmation Check List: Consultant/Contractor Undertakingom_23123062No ratings yet