Professional Documents

Culture Documents

Arz 104 Wood 125143

Arz 104 Wood 125143

Uploaded by

youcef islaCopyright:

Available Formats

You might also like

- Pig Receiver Data Sheet 91303 - 8 InchDocument4 pagesPig Receiver Data Sheet 91303 - 8 InchSinaNo ratings yet

- 강도계산프로그램Document16 pages강도계산프로그램심판자No ratings yet

- AAG Fire Water Cum Foam Monitor 100mmDocument2 pagesAAG Fire Water Cum Foam Monitor 100mmMitul Patel100% (1)

- ChemLab Use Density To Date A CoinDocument7 pagesChemLab Use Density To Date A Coindstaines100% (1)

- Arz 104 Wood 125141Document1 pageArz 104 Wood 125141youcef islaNo ratings yet

- Eq Das 8020 0001Document10 pagesEq Das 8020 0001pradeep yadavNo ratings yet

- 8) Tss-Glycol Surge DrumDocument1 page8) Tss-Glycol Surge DrumKiran KumarNo ratings yet

- DWG 00001Document4 pagesDWG 00001ariyaNo ratings yet

- Pig Launcher Data Sheet 91303 - 8 InchDocument4 pagesPig Launcher Data Sheet 91303 - 8 InchSina100% (1)

- D 1 1Document956 pagesD 1 1karthi82887100% (1)

- VMS - 5Document1 pageVMS - 5ritoh8657No ratings yet

- 15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Document4 pages15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Umair A. KhanNo ratings yet

- Activated Carbon Filter VesselDocument5 pagesActivated Carbon Filter VesselShaaban NoamanNo ratings yet

- VB 536 Ag DR: TypeDocument1 pageVB 536 Ag DR: TypeMaffone NumerounoNo ratings yet

- P/N 25G130R040 P/N 25G130R050 P/N 25G130R060 P/N 25G130R070 P/N 25G130R080 P/N 25G130R090 P/N 25G130R100Document17 pagesP/N 25G130R040 P/N 25G130R050 P/N 25G130R060 P/N 25G130R070 P/N 25G130R080 P/N 25G130R090 P/N 25G130R100carmenNo ratings yet

- Pressure VesselDocument6 pagesPressure VesselKiranNo ratings yet

- Design Data Sheet: Insulating JointsDocument1 pageDesign Data Sheet: Insulating Jointsibra benaNo ratings yet

- 501abcde 016Document30 pages501abcde 016husen123 alhusadaNo ratings yet

- Air Surge VesselDocument1 pageAir Surge Vesselsushant_jhawerNo ratings yet

- VMS PDFDocument1 pageVMS PDFritoh8657No ratings yet

- Hav HKN 219001 Gas Me DS 0017Document5 pagesHav HKN 219001 Gas Me DS 0017bkm dizaynNo ratings yet

- Data Sheet Residue Gas Scrubber (V-1110)Document2 pagesData Sheet Residue Gas Scrubber (V-1110)Elias EliasNo ratings yet

- Data Sheets PDFDocument7 pagesData Sheets PDFshareyhouNo ratings yet

- Data Sheet Amine Contactor (V-1040)Document2 pagesData Sheet Amine Contactor (V-1040)Elias EliasNo ratings yet

- 06-GR60-T-007.001 of 03Document3 pages06-GR60-T-007.001 of 03carrei JohnNo ratings yet

- Equipment Data Sheet: Type: Doc No: Mds-Pv-01Document3 pagesEquipment Data Sheet: Type: Doc No: Mds-Pv-01Waqas WaqasNo ratings yet

- Design Calculation-Spacer SpoolDocument8 pagesDesign Calculation-Spacer SpoolHasmukh Dave100% (1)

- 1A P220 WHD Data Sheet PDFDocument5 pages1A P220 WHD Data Sheet PDFAhmed MusallamNo ratings yet

- Datasheet TankDocument1 pageDatasheet TankAnonymous lQiANQusxiNo ratings yet

- Coalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Document2 pagesCoalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Elias EliasNo ratings yet

- Bectel ASME Process Cal R2Document21 pagesBectel ASME Process Cal R2Sivakumar SelvarajNo ratings yet

- Data Sheet TEG Contactor (V-1100)Document2 pagesData Sheet TEG Contactor (V-1100)Elias EliasNo ratings yet

- Equipment Definition: Component LiteratureDocument4 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- NotesDocument26 pagesNotesBSK entertainmentNo ratings yet

- Vaporizer Specification SR No. Description Unit Design ParametersDocument1 pageVaporizer Specification SR No. Description Unit Design ParametersVenkatesan ManikandanNo ratings yet

- Weight CalculatorDocument75 pagesWeight CalculatorRakshit KumarNo ratings yet

- Vacuum Catch PotDocument1 pageVacuum Catch Potsushant_jhawerNo ratings yet

- G225iexm08-Srp-M-Dwg-0003 - Rev A4Document55 pagesG225iexm08-Srp-M-Dwg-0003 - Rev A4BALASUBRAMANIAM MEGHANADHNo ratings yet

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument14 pagesStorage Tank Design Calculation - Api 650: Close Floating Roofhgagselim2012No ratings yet

- Best Tank Calculation SheetDocument88 pagesBest Tank Calculation Sheetchriscivil12No ratings yet

- Strainer PDFDocument7 pagesStrainer PDFvinoj chandranNo ratings yet

- Data Sheet Basket Filter-ATF R2Document4 pagesData Sheet Basket Filter-ATF R2Suaib VCSNo ratings yet

- BB4-Catalogue 2015Document11 pagesBB4-Catalogue 2015nima hasanzadehNo ratings yet

- Wellhead Dual Cyclone DesanderDocument2 pagesWellhead Dual Cyclone DesanderAhmed MusallamNo ratings yet

- Technical Specification For Furnace Pressure Switch High SL - No Description Unit Specification Model No. Range Tag NumberDocument4 pagesTechnical Specification For Furnace Pressure Switch High SL - No Description Unit Specification Model No. Range Tag NumberflowdewiceNo ratings yet

- Treehouse, Waiheke Island: Structural Steelwork NotesDocument12 pagesTreehouse, Waiheke Island: Structural Steelwork NotesKesavan DhuraiNo ratings yet

- GA of ACCDocument5 pagesGA of ACCshashinaganurNo ratings yet

- THAI TAFFETA SW-111,2,3,4 - Rev02 - 20240403Document10 pagesTHAI TAFFETA SW-111,2,3,4 - Rev02 - 20240403Việt QuốcNo ratings yet

- Intial Visual Inspection Gs-Asme-035 16 V006aDocument1 pageIntial Visual Inspection Gs-Asme-035 16 V006aSam RajaNo ratings yet

- Data Sheet-Vacuum Stripper Tower 11-T-1102: Nombre Del ProyectoDocument7 pagesData Sheet-Vacuum Stripper Tower 11-T-1102: Nombre Del ProyectoAARON HERRERANo ratings yet

- 1416 MC MDS V 104 - Rev.0Document5 pages1416 MC MDS V 104 - Rev.0KrunalNo ratings yet

- Eil PMSDocument7 pagesEil PMSKRUNAL SHAHNo ratings yet

- 2A P220 Accumulator Process Data Sheet PDFDocument3 pages2A P220 Accumulator Process Data Sheet PDFAhmed MusallamNo ratings yet

- Doc. Title Document No. Phase Area Unit Disc. Doc. Seq. Rev. Blow Down Valve Data SheetDocument4 pagesDoc. Title Document No. Phase Area Unit Disc. Doc. Seq. Rev. Blow Down Valve Data SheetHoomanrrNo ratings yet

- 3-77-06 Field Weld Ends Pumps& Valves Conrolled Circulation & CC UnitsDocument10 pages3-77-06 Field Weld Ends Pumps& Valves Conrolled Circulation & CC UnitsJKKNo ratings yet

- Hci634w 312Document9 pagesHci634w 312GUZMAN05No ratings yet

- Valve DatasheetDocument9 pagesValve DatasheetArunkumarNo ratings yet

- Data Sheet Basket Filter-ATF R1Document3 pagesData Sheet Basket Filter-ATF R1Suaib VCSNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Advances in High Voltage Insulation and Arc Interruption in SF6 and VacuumFrom EverandAdvances in High Voltage Insulation and Arc Interruption in SF6 and VacuumNo ratings yet

- Permanent-Magnet Synchronous Machines With Non-Overlapping Concentrated Windings For Low-Speed Direct-Drive Applications.Document177 pagesPermanent-Magnet Synchronous Machines With Non-Overlapping Concentrated Windings For Low-Speed Direct-Drive Applications.briscabarombiNo ratings yet

- Engineering Mechanics: StaticsDocument45 pagesEngineering Mechanics: StaticsDaya AhmadNo ratings yet

- STH Poster Winter 2013Document2 pagesSTH Poster Winter 2013SakuragiNo ratings yet

- Impact of Occupant Autonomy On Satisfaction and Building Energy EffciencyDocument9 pagesImpact of Occupant Autonomy On Satisfaction and Building Energy EffciencyAngelica ElboNo ratings yet

- Aluminum RF Power Splitters Under TestDocument7 pagesAluminum RF Power Splitters Under TesttomasNo ratings yet

- Coil-Type Heat Exchanger PDFDocument2 pagesCoil-Type Heat Exchanger PDFRuben100% (1)

- (2091) Lecture Notes Electrochemistry E.pdf - TMPDocument43 pages(2091) Lecture Notes Electrochemistry E.pdf - TMPRamJiPandeyNo ratings yet

- CBSE NCERT Solutions For Class 11 Mathematics Chapter 01: Back of Chapter QuestionsDocument72 pagesCBSE NCERT Solutions For Class 11 Mathematics Chapter 01: Back of Chapter QuestionsMridula PriyaNo ratings yet

- Lecture 5: Capacitors (Cont.), Circuits, Current, and ResistanceDocument6 pagesLecture 5: Capacitors (Cont.), Circuits, Current, and ResistanceAmir YonanNo ratings yet

- 03 IPv6 RoutingDocument74 pages03 IPv6 Routingguido.martiniNo ratings yet

- Davis Et Al., 2005 (IMP)Document10 pagesDavis Et Al., 2005 (IMP)Xenon ArgonNo ratings yet

- Conditional Probability and Bayes TheoremDocument68 pagesConditional Probability and Bayes TheoremLipi Ghosh100% (1)

- Thermoeconomic Modeling and Analysis of sCO2 Brayton CycleDocument21 pagesThermoeconomic Modeling and Analysis of sCO2 Brayton Cycley_durNo ratings yet

- DLP Finding Volume of Cube and Rectangular PrismDocument10 pagesDLP Finding Volume of Cube and Rectangular PrismDom MartinezNo ratings yet

- Ansys Known Issues and LimitationsDocument44 pagesAnsys Known Issues and Limitationstalabiz0% (1)

- Solid Object: Ce 102: Civil Engineering Drawing IDocument27 pagesSolid Object: Ce 102: Civil Engineering Drawing INazmul HaqueNo ratings yet

- HP 4100 Part.Document32 pagesHP 4100 Part.marecalinNo ratings yet

- Difference Between IPv4 and IPv6Document5 pagesDifference Between IPv4 and IPv6Ardit Mezini100% (1)

- Unit Test 1Document2 pagesUnit Test 1Maria Monica Mae MirandaNo ratings yet

- Haptics Seminar ReportDocument38 pagesHaptics Seminar Reportmonty083No ratings yet

- 50481C, Analog Devices 3B Backplane Power Supplies AEROJETDocument7 pages50481C, Analog Devices 3B Backplane Power Supplies AEROJETenticoNo ratings yet

- Hydram PDFDocument6 pagesHydram PDFDedi SatriyawanNo ratings yet

- Dbms Lab File FormatDocument11 pagesDbms Lab File Formatshagunverma039No ratings yet

- Ethyl Benzene Plant Design PDFDocument31 pagesEthyl Benzene Plant Design PDFKaul PatrickNo ratings yet

- Ruby Concurrency ExplainedDocument7 pagesRuby Concurrency ExplainedachhuNo ratings yet

- CaretDocument5 pagesCareternarajaNo ratings yet

- GNU Sed Cheat Sheet: CommandsDocument2 pagesGNU Sed Cheat Sheet: CommandsRonaldMartinezNo ratings yet

- Varian Chapter28 Game TheoryDocument94 pagesVarian Chapter28 Game TheoryBongani TutaniNo ratings yet

- ChatGPT What Do Know About TelepathyDocument6 pagesChatGPT What Do Know About TelepathyBruce WilliamsNo ratings yet

Arz 104 Wood 125143

Arz 104 Wood 125143

Uploaded by

youcef islaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Arz 104 Wood 125143

Arz 104 Wood 125143

Uploaded by

youcef islaCopyright:

Available Formats

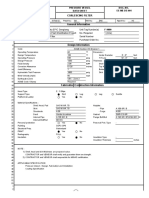

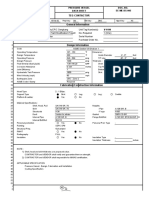

GENERAL NOTES VESSEL DESIGN DATA

1 - FOR NOTES, DESIGN DATA, NOZZLES AND INTERNALS NOT SHOWN ON MECHANICAL DATA SHEET CODE: ASME VIII, DIV. 1, Latest Ed. STAMPED: 'U' PLATE SHELL : SA 516 Gr. 60

REFER TO PROCESS DATA SHEET N° BD1149A-104-PRS-DS-194143 LATEST REVISION. DESIGN PRESSURE (INT./EXT) : 0.7 / - barg PLATE HEAD : SA 516 Gr. 60

2 - ALL DIMENSIONS ARE IN MILLIMETERS UNLESS OTHERWISE INDICATED. DESIGN TEMPERATURE (INT./EXT) : 425 / - °C FORGINGS : SA 105 N

MAX. OPERATING PRESSURE : 0.05 barg PIPES : SA 106 Gr. B

3 - SW SS316L WITH INNER ANTI CRUSHING RING SS316 AND EXTERNAL CENTRE RING IN CS.

MAX. OPERATING TEMPERATURE : 93 °C PLATE SUPPORTS : SA 516 Gr. 60 / SA 285 Gr. C

4 - THICKNESSES TO BE CONFIRMED BY VENDOR DURING EPC / DETAILED DESIGN PHASE.

STRESS RELIEVED : AS PER SPEC / CODE TYPE OF HEADS : 2:1 ELLIPTICAL (TOP) / CONICAL (BOTTOM)

5 - PERSONNEL PROTECTION SHALL BE PROVIDED BY THE USE OF OPEN GUARD, SHIELDS OR RAILINGS.

RADIOGRAPHED : RT3 EXTERNAL BOLTING : SA 193 Gr. B7 / SA 194 Gr. 2H

INSULATION SHALL NOT BE USED. SHELL : 0.85 CS

6 - C.O.G. 2385 mm FROM BOTTOM TAN LINE FOR A NORMAL OPERATING WEIGHT OF 43700 kg. JOINT EFFICIENCY INTERNALS :

HEAD : 1.0

7 - ALL INTERIOR SURFACES TO BE SMOOTH AND FREE OF WELDING SLAG AND BURRS. AVOID INTERIOR SHELL : 3.0 mm GASKET : NOTE 3

LEDGES AND SHARP DISCONTINUITIES IN INSIDE DIAMETER. CORROSION ALLOWANCE

HEAD : 3.0 mm FLANGE BOLT HOLES : TO STRADDLE MAIN VESSEL ℄

8 - VESSEL TO BE DESIGNED AS FULL OF GRANULAR SOLIDS HAVING A BULK DENSITY OF 675 kg/m³. FLUID CONTAINED: CATALYST (CA) + NITROGEN (NG) S.G.: NOTE 8 PAINT : AS PER GS RC COR 001 & BD1149A-000-83A1

DESIGN PRESSURE DOES NOT INCLUDE SOLIDS STATIC HEAD. M.D.M.T. : 0 °C INSULATION : NOTE 5

9 - SUPPORTS DESIGN SHALL BE CONFIRMED BY EPC CONTRACTOR AFTER STRESS ANALYSIS OF THE CONNECTED PIPES. REQUESTED QUANTITY : 1 No. SHIPMENT : ONE PIECE

10 - SRWN NOZZLE DESIGN SHALL BE IN ACCORDANCE WITH "ASME VIII Div. 1, FIGURE UW-16.1 (f-1) OR (f-4)". NOZZLES CHART WEIGHTS

11 - FOR LOCAL LAW / MAIN DESIGN / WIND AND SEISMIC REQUIREMENTS, REFER TO ALGERIAN DECREE 90-245/246 PROJECTION MIN. FABRICATED : 9600 kg

AND LATEST REVISIONS OF GS RC PVE 001, BD1149A-000-10A1, BD1149A-000-40A2. FROM NECK. CONN. RATING N° WATER ONLY : 50500 kg

12 - FOR ENGINEERING STANDARD DRAWINGS REFER TO BD1149A-000-11-100 LATEST REVISION. EQUIPMENT ℄ SIZE SERVICE

TO FLANGE THK. N° (ANSI) REQ'D TRAYS : - kg

13 - FOR EQUIPMENT CRITICALITY RATING REFER TO EQUIPMENT LIST LATEST REVISION. FACE (SCH.) INTERNALS : 1000 kg

14 - NOZZLES "A1" AND "B1" TO BE BUILT-UP CONSTRUCTION USING SCH. 80 PIPE AND WELDING NECK FLANGE SEE DWG. NOTE 14 A1 4" 300# SRWN-RF CATALYST INLET 1 INSULATION : - kg

BORED TO SCH. 80. SEE DWG. - A2 4" 300# SRWN-RF CATALYST ADDITION 1 FIREPROOFING : - kg

15 - MR STANDS FOR MANUFACTURER OR EPC CONTRACTOR RESPONSIBILITY. SEE DWG. NOTE 14 B1 6" 300# SRWN-RF CATALYST OUTLET 1 PLATs AND LADDERS (ESTIMATED) : - kg

16 - IN CASE OF CONFLICT BETWEEN STEP GS AND UOP APPLICABLE SPECIFICATIONS, THE MOST STRINGENT SEE DWG. - E1 2" 300# LWN-RF ANALYZER CONNECTION 1 CAPACITY : 50.5 m3

REQUIREMENT APPLIES. 1810 - K1-K36 1" 3000# COUPLING COOLING WATER 36

17 - INSTRUMENTATION NOZZLES SIZE / RATING ARE PRELIMINARY, TO BE CONFIRMED BY EPC CONTRACTOR. SEE DWG. - P1 2" 300# LWN-RF GAUGING HATCH 1

SEE DWG. - V1 2" 300# LWN-RF EQUALIZATION VENT 1

TAPER BORE SEE DWG. - V2 6" 300# SRWN-RF VENTILATION w/BLIND 1

V1

A2 45° F3 SEE DWG. - W1 6"(*) 300# LWN-RF RELIEF 1

A1 V2 W1 E1 1910 - M1 24" 300# SRWN-RF MANWAY w/BLIND & DAVIT 1

P1

F3 (*)= PSV NOZZLE SIZE TO BE CONFIRMED DURING EPC/DETAILED DESIGN PHASE Digitally signed by mirko.colombo

Date: 2021.09.23 14:56:30 +02'00'

pietro.ciniero

460 2:1 ELLIPTICAL HEAD

1020

14 THK. MIN. A.F. F3 23-Sept-21 IFD ISSUED FOR DESIGN PCO MCO DMI

1070

TAN LINE F2 11-May-21 IFD ISSUED FOR DESIGN SOR PSR DMI

BRACKET FOR NUCLEAR

LEVEL INSTRUMENT Y1 22-Feb-21 IFR ISSUED FOR REVIEW SOR PSR DMI

(AS PER PROJECT SPECIFICATION 613)

X0 19-Jan-21 IFR ISSUED FOR REVIEW SOR NNK DMI

Rev. Date Status Revision Description Iss. Check. Appr.

M1

~7870 OVERALL LENGTH

PROJECT NAME & LOGO CONTRACTOR NAME & LOGO

N°4 LUG SUPPORT FOR

M30 DIA. ANCHOR BOLTS

PDH PP PROJECT

5000

3520 B.C.D

MR

10 THK. 3200 I.D.

This document is the property of the STEP and it shall not be disclosed to third parties or reproduced without the express written

460 WIDE permission of the STEP.

This document has been generated by an Electronic Document Management System. When printed it shall be considered as "for

PLATECOILS

2000

information only". The controlled copy is the EDMS version and it is document holder's responsibility to make sure that latest version is

in use.

K1-36

Affiliate: - Site: ARZ Project Phase: FEED

485

MR

BD1149A-104-TEC-DS-125143

TAN LINE SURGE HOPPER

300 KNUCKLE

840

RADIUS

MECHANICAL DATASHEET

1700

1850

HATCHED AREA DEFINES

10 PLATE 100-V-403

CATALYST FLOW ZONE

CONE ON

NOTE 7

10 THK. VESSEL CL.

CONE Discipline: PVE Doc. Type: DSH Sector: 104 System: -

Company Doc. N°: - Class: 2 Scale: -

150

B1

B.S: add "flange Contractor Doc. N°: BD1149A-104-TEC-DS-125143 Format: A3 Folio: 1 of 1

face", according to

UOP drawing BD1149A-104-TEC-DS-125143.DWG

You might also like

- Pig Receiver Data Sheet 91303 - 8 InchDocument4 pagesPig Receiver Data Sheet 91303 - 8 InchSinaNo ratings yet

- 강도계산프로그램Document16 pages강도계산프로그램심판자No ratings yet

- AAG Fire Water Cum Foam Monitor 100mmDocument2 pagesAAG Fire Water Cum Foam Monitor 100mmMitul Patel100% (1)

- ChemLab Use Density To Date A CoinDocument7 pagesChemLab Use Density To Date A Coindstaines100% (1)

- Arz 104 Wood 125141Document1 pageArz 104 Wood 125141youcef islaNo ratings yet

- Eq Das 8020 0001Document10 pagesEq Das 8020 0001pradeep yadavNo ratings yet

- 8) Tss-Glycol Surge DrumDocument1 page8) Tss-Glycol Surge DrumKiran KumarNo ratings yet

- DWG 00001Document4 pagesDWG 00001ariyaNo ratings yet

- Pig Launcher Data Sheet 91303 - 8 InchDocument4 pagesPig Launcher Data Sheet 91303 - 8 InchSina100% (1)

- D 1 1Document956 pagesD 1 1karthi82887100% (1)

- VMS - 5Document1 pageVMS - 5ritoh8657No ratings yet

- 15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Document4 pages15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Umair A. KhanNo ratings yet

- Activated Carbon Filter VesselDocument5 pagesActivated Carbon Filter VesselShaaban NoamanNo ratings yet

- VB 536 Ag DR: TypeDocument1 pageVB 536 Ag DR: TypeMaffone NumerounoNo ratings yet

- P/N 25G130R040 P/N 25G130R050 P/N 25G130R060 P/N 25G130R070 P/N 25G130R080 P/N 25G130R090 P/N 25G130R100Document17 pagesP/N 25G130R040 P/N 25G130R050 P/N 25G130R060 P/N 25G130R070 P/N 25G130R080 P/N 25G130R090 P/N 25G130R100carmenNo ratings yet

- Pressure VesselDocument6 pagesPressure VesselKiranNo ratings yet

- Design Data Sheet: Insulating JointsDocument1 pageDesign Data Sheet: Insulating Jointsibra benaNo ratings yet

- 501abcde 016Document30 pages501abcde 016husen123 alhusadaNo ratings yet

- Air Surge VesselDocument1 pageAir Surge Vesselsushant_jhawerNo ratings yet

- VMS PDFDocument1 pageVMS PDFritoh8657No ratings yet

- Hav HKN 219001 Gas Me DS 0017Document5 pagesHav HKN 219001 Gas Me DS 0017bkm dizaynNo ratings yet

- Data Sheet Residue Gas Scrubber (V-1110)Document2 pagesData Sheet Residue Gas Scrubber (V-1110)Elias EliasNo ratings yet

- Data Sheets PDFDocument7 pagesData Sheets PDFshareyhouNo ratings yet

- Data Sheet Amine Contactor (V-1040)Document2 pagesData Sheet Amine Contactor (V-1040)Elias EliasNo ratings yet

- 06-GR60-T-007.001 of 03Document3 pages06-GR60-T-007.001 of 03carrei JohnNo ratings yet

- Equipment Data Sheet: Type: Doc No: Mds-Pv-01Document3 pagesEquipment Data Sheet: Type: Doc No: Mds-Pv-01Waqas WaqasNo ratings yet

- Design Calculation-Spacer SpoolDocument8 pagesDesign Calculation-Spacer SpoolHasmukh Dave100% (1)

- 1A P220 WHD Data Sheet PDFDocument5 pages1A P220 WHD Data Sheet PDFAhmed MusallamNo ratings yet

- Datasheet TankDocument1 pageDatasheet TankAnonymous lQiANQusxiNo ratings yet

- Coalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Document2 pagesCoalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Elias EliasNo ratings yet

- Bectel ASME Process Cal R2Document21 pagesBectel ASME Process Cal R2Sivakumar SelvarajNo ratings yet

- Data Sheet TEG Contactor (V-1100)Document2 pagesData Sheet TEG Contactor (V-1100)Elias EliasNo ratings yet

- Equipment Definition: Component LiteratureDocument4 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- NotesDocument26 pagesNotesBSK entertainmentNo ratings yet

- Vaporizer Specification SR No. Description Unit Design ParametersDocument1 pageVaporizer Specification SR No. Description Unit Design ParametersVenkatesan ManikandanNo ratings yet

- Weight CalculatorDocument75 pagesWeight CalculatorRakshit KumarNo ratings yet

- Vacuum Catch PotDocument1 pageVacuum Catch Potsushant_jhawerNo ratings yet

- G225iexm08-Srp-M-Dwg-0003 - Rev A4Document55 pagesG225iexm08-Srp-M-Dwg-0003 - Rev A4BALASUBRAMANIAM MEGHANADHNo ratings yet

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument14 pagesStorage Tank Design Calculation - Api 650: Close Floating Roofhgagselim2012No ratings yet

- Best Tank Calculation SheetDocument88 pagesBest Tank Calculation Sheetchriscivil12No ratings yet

- Strainer PDFDocument7 pagesStrainer PDFvinoj chandranNo ratings yet

- Data Sheet Basket Filter-ATF R2Document4 pagesData Sheet Basket Filter-ATF R2Suaib VCSNo ratings yet

- BB4-Catalogue 2015Document11 pagesBB4-Catalogue 2015nima hasanzadehNo ratings yet

- Wellhead Dual Cyclone DesanderDocument2 pagesWellhead Dual Cyclone DesanderAhmed MusallamNo ratings yet

- Technical Specification For Furnace Pressure Switch High SL - No Description Unit Specification Model No. Range Tag NumberDocument4 pagesTechnical Specification For Furnace Pressure Switch High SL - No Description Unit Specification Model No. Range Tag NumberflowdewiceNo ratings yet

- Treehouse, Waiheke Island: Structural Steelwork NotesDocument12 pagesTreehouse, Waiheke Island: Structural Steelwork NotesKesavan DhuraiNo ratings yet

- GA of ACCDocument5 pagesGA of ACCshashinaganurNo ratings yet

- THAI TAFFETA SW-111,2,3,4 - Rev02 - 20240403Document10 pagesTHAI TAFFETA SW-111,2,3,4 - Rev02 - 20240403Việt QuốcNo ratings yet

- Intial Visual Inspection Gs-Asme-035 16 V006aDocument1 pageIntial Visual Inspection Gs-Asme-035 16 V006aSam RajaNo ratings yet

- Data Sheet-Vacuum Stripper Tower 11-T-1102: Nombre Del ProyectoDocument7 pagesData Sheet-Vacuum Stripper Tower 11-T-1102: Nombre Del ProyectoAARON HERRERANo ratings yet

- 1416 MC MDS V 104 - Rev.0Document5 pages1416 MC MDS V 104 - Rev.0KrunalNo ratings yet

- Eil PMSDocument7 pagesEil PMSKRUNAL SHAHNo ratings yet

- 2A P220 Accumulator Process Data Sheet PDFDocument3 pages2A P220 Accumulator Process Data Sheet PDFAhmed MusallamNo ratings yet

- Doc. Title Document No. Phase Area Unit Disc. Doc. Seq. Rev. Blow Down Valve Data SheetDocument4 pagesDoc. Title Document No. Phase Area Unit Disc. Doc. Seq. Rev. Blow Down Valve Data SheetHoomanrrNo ratings yet

- 3-77-06 Field Weld Ends Pumps& Valves Conrolled Circulation & CC UnitsDocument10 pages3-77-06 Field Weld Ends Pumps& Valves Conrolled Circulation & CC UnitsJKKNo ratings yet

- Hci634w 312Document9 pagesHci634w 312GUZMAN05No ratings yet

- Valve DatasheetDocument9 pagesValve DatasheetArunkumarNo ratings yet

- Data Sheet Basket Filter-ATF R1Document3 pagesData Sheet Basket Filter-ATF R1Suaib VCSNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Advances in High Voltage Insulation and Arc Interruption in SF6 and VacuumFrom EverandAdvances in High Voltage Insulation and Arc Interruption in SF6 and VacuumNo ratings yet

- Permanent-Magnet Synchronous Machines With Non-Overlapping Concentrated Windings For Low-Speed Direct-Drive Applications.Document177 pagesPermanent-Magnet Synchronous Machines With Non-Overlapping Concentrated Windings For Low-Speed Direct-Drive Applications.briscabarombiNo ratings yet

- Engineering Mechanics: StaticsDocument45 pagesEngineering Mechanics: StaticsDaya AhmadNo ratings yet

- STH Poster Winter 2013Document2 pagesSTH Poster Winter 2013SakuragiNo ratings yet

- Impact of Occupant Autonomy On Satisfaction and Building Energy EffciencyDocument9 pagesImpact of Occupant Autonomy On Satisfaction and Building Energy EffciencyAngelica ElboNo ratings yet

- Aluminum RF Power Splitters Under TestDocument7 pagesAluminum RF Power Splitters Under TesttomasNo ratings yet

- Coil-Type Heat Exchanger PDFDocument2 pagesCoil-Type Heat Exchanger PDFRuben100% (1)

- (2091) Lecture Notes Electrochemistry E.pdf - TMPDocument43 pages(2091) Lecture Notes Electrochemistry E.pdf - TMPRamJiPandeyNo ratings yet

- CBSE NCERT Solutions For Class 11 Mathematics Chapter 01: Back of Chapter QuestionsDocument72 pagesCBSE NCERT Solutions For Class 11 Mathematics Chapter 01: Back of Chapter QuestionsMridula PriyaNo ratings yet

- Lecture 5: Capacitors (Cont.), Circuits, Current, and ResistanceDocument6 pagesLecture 5: Capacitors (Cont.), Circuits, Current, and ResistanceAmir YonanNo ratings yet

- 03 IPv6 RoutingDocument74 pages03 IPv6 Routingguido.martiniNo ratings yet

- Davis Et Al., 2005 (IMP)Document10 pagesDavis Et Al., 2005 (IMP)Xenon ArgonNo ratings yet

- Conditional Probability and Bayes TheoremDocument68 pagesConditional Probability and Bayes TheoremLipi Ghosh100% (1)

- Thermoeconomic Modeling and Analysis of sCO2 Brayton CycleDocument21 pagesThermoeconomic Modeling and Analysis of sCO2 Brayton Cycley_durNo ratings yet

- DLP Finding Volume of Cube and Rectangular PrismDocument10 pagesDLP Finding Volume of Cube and Rectangular PrismDom MartinezNo ratings yet

- Ansys Known Issues and LimitationsDocument44 pagesAnsys Known Issues and Limitationstalabiz0% (1)

- Solid Object: Ce 102: Civil Engineering Drawing IDocument27 pagesSolid Object: Ce 102: Civil Engineering Drawing INazmul HaqueNo ratings yet

- HP 4100 Part.Document32 pagesHP 4100 Part.marecalinNo ratings yet

- Difference Between IPv4 and IPv6Document5 pagesDifference Between IPv4 and IPv6Ardit Mezini100% (1)

- Unit Test 1Document2 pagesUnit Test 1Maria Monica Mae MirandaNo ratings yet

- Haptics Seminar ReportDocument38 pagesHaptics Seminar Reportmonty083No ratings yet

- 50481C, Analog Devices 3B Backplane Power Supplies AEROJETDocument7 pages50481C, Analog Devices 3B Backplane Power Supplies AEROJETenticoNo ratings yet

- Hydram PDFDocument6 pagesHydram PDFDedi SatriyawanNo ratings yet

- Dbms Lab File FormatDocument11 pagesDbms Lab File Formatshagunverma039No ratings yet

- Ethyl Benzene Plant Design PDFDocument31 pagesEthyl Benzene Plant Design PDFKaul PatrickNo ratings yet

- Ruby Concurrency ExplainedDocument7 pagesRuby Concurrency ExplainedachhuNo ratings yet

- CaretDocument5 pagesCareternarajaNo ratings yet

- GNU Sed Cheat Sheet: CommandsDocument2 pagesGNU Sed Cheat Sheet: CommandsRonaldMartinezNo ratings yet

- Varian Chapter28 Game TheoryDocument94 pagesVarian Chapter28 Game TheoryBongani TutaniNo ratings yet

- ChatGPT What Do Know About TelepathyDocument6 pagesChatGPT What Do Know About TelepathyBruce WilliamsNo ratings yet