Professional Documents

Culture Documents

OEE Report Template: 10 May 2019 / Vertical Milling Machine / Rosa Shelly

OEE Report Template: 10 May 2019 / Vertical Milling Machine / Rosa Shelly

Uploaded by

ALBERTO ALVARADO CARRILLOCopyright:

Available Formats

You might also like

- 8D Human Error Root Cause Analysis Worksheet Revision Date: 4/3/2018 Revision #: 1Document1 page8D Human Error Root Cause Analysis Worksheet Revision Date: 4/3/2018 Revision #: 1Thee Bouyy100% (1)

- Factory Acceptance Test New Sample ReportDocument13 pagesFactory Acceptance Test New Sample ReportJafarov VuqarNo ratings yet

- Exercise Workbook 19 AisDocument93 pagesExercise Workbook 19 AisKenneth PimentelNo ratings yet

- 8D Problem Solving Worksheet - Long FormDocument7 pages8D Problem Solving Worksheet - Long FormdanielonnarNo ratings yet

- Zero Defects With Poka-Yoke - Mistake ProofingDocument249 pagesZero Defects With Poka-Yoke - Mistake Proofingmagudeesh100% (2)

- 5Y Cheat SheetDocument21 pages5Y Cheat SheetManik ChowdharyNo ratings yet

- Jisu Hozen PillarDocument98 pagesJisu Hozen PillarAndrei MarinNo ratings yet

- College Notes GalleryDocument29 pagesCollege Notes GalleryAbhishek Singh57% (21)

- Kaizen Report Template Sample PDF ReportDocument8 pagesKaizen Report Template Sample PDF ReportMkrKhairulChappuisNo ratings yet

- Alveya Incorporated: General Toolbox Meeting ChecklistDocument6 pagesAlveya Incorporated: General Toolbox Meeting ChecklistBhanu PrakashNo ratings yet

- Supplier Self Audit FormDocument5 pagesSupplier Self Audit FormAllison Porter100% (2)

- Manufacturing Quality Control Checklist 2022Document7 pagesManufacturing Quality Control Checklist 2022nafis2uNo ratings yet

- SHE Inspection-General - SafetyCultureDocument36 pagesSHE Inspection-General - SafetyCulturematthew kagurabadzaNo ratings yet

- Vigilance Squad Report For Mscit Exam (Sept 2018) : Yes / NoDocument1 pageVigilance Squad Report For Mscit Exam (Sept 2018) : Yes / NoYogesh ChaudhariNo ratings yet

- Office Safety Checklist Sample PDF ReportDocument16 pagesOffice Safety Checklist Sample PDF ReportMarcelo RamírezNo ratings yet

- 3.2. Programme of Work - Spillage Management - Black Couture 2023Document2 pages3.2. Programme of Work - Spillage Management - Black Couture 2023blackcoutureconsultationsNo ratings yet

- 2C - Reacting To Quality ProblemDocument23 pages2C - Reacting To Quality ProblemDevarsh KakaNo ratings yet

- 8D Problem Solving Analysis: MinorDocument2 pages8D Problem Solving Analysis: MinorK K MaharanaNo ratings yet

- A. General Information On Company, Product and Quality ManagementDocument10 pagesA. General Information On Company, Product and Quality ManagementsutharitesshNo ratings yet

- 5-Whys AnalysisDocument12 pages5-Whys AnalysisVinh TranNo ratings yet

- CCTV Maintenance Checklist Log ReportDocument5 pagesCCTV Maintenance Checklist Log Reportali ahmedNo ratings yet

- Guideline Supplier Qualification - Dec09FINALDocument10 pagesGuideline Supplier Qualification - Dec09FINALflongNo ratings yet

- GMP Quality Supplier Audit Questionnaire 1663569818Document15 pagesGMP Quality Supplier Audit Questionnaire 1663569818Cyclone Pharmaceuticals Pvt Ltd PuneNo ratings yet

- Incident Report Template Sample PDF ReportDocument5 pagesIncident Report Template Sample PDF ReportBelbaraka AbdoNo ratings yet

- Presentation Poka YokeDocument34 pagesPresentation Poka YokeRiadh JellaliNo ratings yet

- General Cleaning Checklist Sample PDF ReportDocument8 pagesGeneral Cleaning Checklist Sample PDF Reportelianamabel10No ratings yet

- Answering Calls From RecruitersDocument10 pagesAnswering Calls From RecruitersPhu Cong LeNo ratings yet

- SOPQC0019EDocument212 pagesSOPQC0019Eh.boukhelfrosasNo ratings yet

- Tle 8 Week 6Document7 pagesTle 8 Week 6Jhon Jomarie Adlawon RobasNo ratings yet

- Accident Form V1Document6 pagesAccident Form V1Dimitrios NikolaidisNo ratings yet

- LEA - 5 WhysDocument1 pageLEA - 5 WhysJasser KandumeNo ratings yet

- Working Effectively in An IT Environment - Presentation OutlineDocument1 pageWorking Effectively in An IT Environment - Presentation OutlinejejemonbusterNo ratings yet

- 8D Presentation ASQDocument29 pages8D Presentation ASQpradeep100% (1)

- Afa 1 Module 6 ActivitiesDocument3 pagesAfa 1 Module 6 ActivitiesJulius BalbinNo ratings yet

- Problem Solution - 5 Why's Analysis Worksheet: Be Sure The 5 Why's Is Grounded in Observation Not DeductionDocument2 pagesProblem Solution - 5 Why's Analysis Worksheet: Be Sure The 5 Why's Is Grounded in Observation Not DeductionSyafiq Sulaiman100% (1)

- BWD Equipment Failure Report - TemplateDocument1 pageBWD Equipment Failure Report - TemplateAbdallah ElhendyNo ratings yet

- Root - Cause - Corrective Action PDFDocument31 pagesRoot - Cause - Corrective Action PDFBeste Ardıç Arslan100% (1)

- Task - Create Survey QuestionsDocument4 pagesTask - Create Survey QuestionsLiam JoseNo ratings yet

- General Solar Panel Maintenance Checklist Sample ReportDocument5 pagesGeneral Solar Panel Maintenance Checklist Sample Reportasmaaabdelkreem71No ratings yet

- Flevy 52Document5 pagesFlevy 52Karina BlancoNo ratings yet

- Lecture 8 - Poka-YokeDocument9 pagesLecture 8 - Poka-YokeCherie DiazNo ratings yet

- RubricDocument2 pagesRubricTan QuimNo ratings yet

- Planned Job Observation Report: ELEMENT 5.20bDocument1 pagePlanned Job Observation Report: ELEMENT 5.20bShafie ZubierNo ratings yet

- Visual Inspection Checklist Sample PDF ReportDocument7 pagesVisual Inspection Checklist Sample PDF Reporthamzachebbi43No ratings yet

- Jcecf Qms 1st Internal Audit PlanDocument3 pagesJcecf Qms 1st Internal Audit PlanteNo ratings yet

- Root Cause AnalysisDocument4 pagesRoot Cause AnalysisGreature Tana VareNo ratings yet

- 04 Auto MaintenanceDocument486 pages04 Auto Maintenanceanderson pariz100% (1)

- Mistake Proofing TechniquesDocument28 pagesMistake Proofing TechniquesRamasubramanian SankaranarayananNo ratings yet

- What Is Poka-YokeDocument114 pagesWhat Is Poka-YokeAdriano CarlosNo ratings yet

- 5 Whys: Basic Technique For Finding Root CausesDocument8 pages5 Whys: Basic Technique For Finding Root CausesFran JimenezNo ratings yet

- Six Sigma Analyze PhaseDocument13 pagesSix Sigma Analyze PhaseerinelNo ratings yet

- Heavy Lifting Permit VERY PERMIT - ContohDocument1 pageHeavy Lifting Permit VERY PERMIT - ContohOctaviary Bintan FamilyNo ratings yet

- RCA FormatDocument293 pagesRCA FormatONMPlanning EngineerPT. GPOSKPSiteNo ratings yet

- Poka YokeDocument11 pagesPoka YokecutepiyaNo ratings yet

- QC Book of Standards: Topic: 7 Steps of Human Error (Including Human Nature)Document8 pagesQC Book of Standards: Topic: 7 Steps of Human Error (Including Human Nature)wagnerqualidNo ratings yet

- Sample of Report Factory VisitingDocument10 pagesSample of Report Factory VisitingSang ThanhNo ratings yet

- 14.04.2018 - LS - Basic - Asking For Leave of Absence Huyendt9 PDFDocument10 pages14.04.2018 - LS - Basic - Asking For Leave of Absence Huyendt9 PDFPhu Cong LeNo ratings yet

- QACinemas Risk Log MatrixDocument9 pagesQACinemas Risk Log MatrixMustafa NyazNo ratings yet

- Training On 5 Why: Magneti Marelli Talbros Chassis Systems PVT - LTDDocument24 pagesTraining On 5 Why: Magneti Marelli Talbros Chassis Systems PVT - LTDGirish60No ratings yet

- F01 (OCP-005) & OHS Vehicle Inspection FormDocument1 pageF01 (OCP-005) & OHS Vehicle Inspection FormDeepakNo ratings yet

- Teach Pendant KeysDocument6 pagesTeach Pendant KeysALBERTO ALVARADO CARRILLONo ratings yet

- A3 Problem Solve ExcelDocument2 pagesA3 Problem Solve ExcelALBERTO ALVARADO CARRILLONo ratings yet

- Class Observation Tool 2022Document5 pagesClass Observation Tool 2022ALBERTO ALVARADO CARRILLONo ratings yet

- Layered Process Audit Checklist (LPA)Document5 pagesLayered Process Audit Checklist (LPA)ALBERTO ALVARADO CARRILLONo ratings yet

- ISCOM5508 (B) Configuration Guide (Rel - 03)Document491 pagesISCOM5508 (B) Configuration Guide (Rel - 03)glebegNo ratings yet

- Deloitte Uk Oracle Fusion Financials UnearthedDocument6 pagesDeloitte Uk Oracle Fusion Financials Unearthedzeeshan78No ratings yet

- Text Book of Organic Chemistry For Medical Students - Bunge 1912 PDFDocument283 pagesText Book of Organic Chemistry For Medical Students - Bunge 1912 PDFbabithyNo ratings yet

- We MediaDocument66 pagesWe MediaArtur AraujoNo ratings yet

- Lokesh Technical SeminarDocument26 pagesLokesh Technical SeminarSree AdithyaNo ratings yet

- VivaDocument16 pagesVivaRahulPrasadNo ratings yet

- Insulation Co-Ordination For Gas-Insulated Transmission LineDocument9 pagesInsulation Co-Ordination For Gas-Insulated Transmission LinewetrfdfdfweeNo ratings yet

- Quick Start GuideDocument5 pagesQuick Start GuideShaun PhelpsNo ratings yet

- Sr. No Question A B C D Correct AnswerDocument7 pagesSr. No Question A B C D Correct AnswerSagar DaradeNo ratings yet

- Study On Cbs With Tcs - SBIDocument22 pagesStudy On Cbs With Tcs - SBIvarghese.mathewNo ratings yet

- RJ45 C6 Toolless STP: Ordering Information Part Number E-Number DescriptionDocument1 pageRJ45 C6 Toolless STP: Ordering Information Part Number E-Number Descriptionov.ei.clerk1No ratings yet

- Resume FormatDocument3 pagesResume FormatarunNo ratings yet

- IEEE Writing FormatDocument4 pagesIEEE Writing FormatJerome JeremiasNo ratings yet

- What Is IC SubstrateDocument20 pagesWhat Is IC SubstratejackNo ratings yet

- 08 Scheme of StudiesDocument47 pages08 Scheme of StudieszeeshizeesheNo ratings yet

- Bus Reservation SystemDocument7 pagesBus Reservation SystemPreetham Gowda50% (2)

- Cit 3100 Introduction To Computer TechnologyDocument3 pagesCit 3100 Introduction To Computer TechnologyOUMA GORDONNo ratings yet

- 11 SQL Config SP3DDocument39 pages11 SQL Config SP3DgoodmorningfredNo ratings yet

- ECC Online System EIS and RequirementsDocument53 pagesECC Online System EIS and RequirementsMira AbisoNo ratings yet

- TempDocument76 pagesTempIanNo ratings yet

- Android NotesDocument24 pagesAndroid NotesAdit KadakiaNo ratings yet

- Amazon Web Services HyderabadDocument6 pagesAmazon Web Services Hyderabadraghava KNo ratings yet

- RHCSA Practice Exam D: General NotesDocument2 pagesRHCSA Practice Exam D: General NotesMaher MechiNo ratings yet

- EnglishDocument8 pagesEnglishNguyễn KhoaNo ratings yet

- Fox 1HDocument2 pagesFox 1HYen BaoNo ratings yet

- How To Use Windows Server 2016 - HandoutDocument7 pagesHow To Use Windows Server 2016 - Handoutquang nguyengocNo ratings yet

- 0916 02 EDEM StudentwebinarDocument32 pages0916 02 EDEM StudentwebinarJesse DANNo ratings yet

- DS-7700NI-K4 Series NVR: Key FeatureDocument4 pagesDS-7700NI-K4 Series NVR: Key FeatureNhẫn Nguyễn NgọcNo ratings yet

OEE Report Template: 10 May 2019 / Vertical Milling Machine / Rosa Shelly

OEE Report Template: 10 May 2019 / Vertical Milling Machine / Rosa Shelly

Uploaded by

ALBERTO ALVARADO CARRILLOOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OEE Report Template: 10 May 2019 / Vertical Milling Machine / Rosa Shelly

OEE Report Template: 10 May 2019 / Vertical Milling Machine / Rosa Shelly

Uploaded by

ALBERTO ALVARADO CARRILLOCopyright:

Available Formats

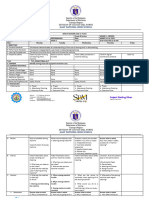

OEE Report Template

10 May 2019 / Vertical Milling Machine / Rosa Shelly Complete

Score 46.67% Failed items 8

Site Sydney

Company

Primo Manufacturing Co.

Manufacturing Facility 4245 Jessie St., Coltington OH 43085

Equipment/Production Process

Vertical Milling Machine

Machine Operator Rosa Shelly

Conducted on 10 May 2019 12:14 PST

Private & confidential 1/6

Failed Items 8 failed

OEE Report Template / Unplanned Downtime

Were there equipment breakdowns/failures? Yes

Photo 1

OEE Report Template / Unplanned Downtime

Were unplanned repairs made? Yes

Photo 2 Photo 3

OEE Report Template / Planned Downtime

Was the equipment set up too long? Yes

53 minutes longer than usual

OEE Report Template / Planned Downtime

Did the changeovers take too long? Yes

The next production run was on hold for an hour and 24 minutes

Photo 4

OEE Report Template / Slow Cycles

Was there a lack of maintenance? Yes

OEE Report Template / Slow Cycles

Was there wear and tear on the equipment? Yes

Photo 5 Photo 6 Photo 7

Private & confidential 2/6

OEE Report Template / Production Rejects

Were there products that had to be reworked to be usable? Yes

OEE Report Template / Start-up Rejects

Were there start-up losses during ramp up of production? Yes

Photo 8

Private & confidential 3/6

OEE Report Template 8 failed, 46.67%

Unplanned Downtime 2 failed, 50%

Were there equipment breakdowns/failures? Yes

Photo 1

Were unplanned repairs made? Yes

Photo 2 Photo 3

Was there a lack of material? No

Was there a lack of transport for completed goods? No

Planned Downtime 2 failed, 33.33%

Was the equipment set up too long? Yes

53 minutes longer than usual

Did the changeovers take too long? Yes

The next production run was on hold for an hour and 24 minutes

Photo 4

Was the operator frequently absent? (e.g. breaks, comfort room time, etc.) No

Small Stops 100%

Was there minor idling? No

Was an incorrect operation done on the equipment? No

The operator is experienced and properly trained

Slow Cycles 2 failed, 33.33%

Private & confidential 4/6

Was there a lack of maintenance? Yes

Was there wear and tear on the equipment? Yes

Photo 5 Photo 6 Photo 7

Were wrong settings applied to the equipment? (e.g. set speed slower than

No

possible)

Production Rejects 1 failed, 50%

Were there products that cannot be salvaged at all? No

Were there products that had to be reworked to be usable? Yes

Start-up Rejects 1 failed, 0%

Were there start-up losses during ramp up of production? Yes

Photo 8

Completion

Additional Observations

46.67% OEE is below industry standard. Let’s keep on using iAuditor for our maintenance checks and quality assurance

inspections to increase our overall equipment effectiveness.

Machine Operator Name & Signature

Rosa Shelly

10 May 2019 12:51 PST

Quality Manager Name & Signature

Frank Gene

10 May 2019 12:50 PST

Private & confidential 5/6

Appendix

Photo 2

Photo 1

Photo 4

Photo 3

Photo 6

Photo 5

Photo 7

Photo 8

Private & confidential 6/6

You might also like

- 8D Human Error Root Cause Analysis Worksheet Revision Date: 4/3/2018 Revision #: 1Document1 page8D Human Error Root Cause Analysis Worksheet Revision Date: 4/3/2018 Revision #: 1Thee Bouyy100% (1)

- Factory Acceptance Test New Sample ReportDocument13 pagesFactory Acceptance Test New Sample ReportJafarov VuqarNo ratings yet

- Exercise Workbook 19 AisDocument93 pagesExercise Workbook 19 AisKenneth PimentelNo ratings yet

- 8D Problem Solving Worksheet - Long FormDocument7 pages8D Problem Solving Worksheet - Long FormdanielonnarNo ratings yet

- Zero Defects With Poka-Yoke - Mistake ProofingDocument249 pagesZero Defects With Poka-Yoke - Mistake Proofingmagudeesh100% (2)

- 5Y Cheat SheetDocument21 pages5Y Cheat SheetManik ChowdharyNo ratings yet

- Jisu Hozen PillarDocument98 pagesJisu Hozen PillarAndrei MarinNo ratings yet

- College Notes GalleryDocument29 pagesCollege Notes GalleryAbhishek Singh57% (21)

- Kaizen Report Template Sample PDF ReportDocument8 pagesKaizen Report Template Sample PDF ReportMkrKhairulChappuisNo ratings yet

- Alveya Incorporated: General Toolbox Meeting ChecklistDocument6 pagesAlveya Incorporated: General Toolbox Meeting ChecklistBhanu PrakashNo ratings yet

- Supplier Self Audit FormDocument5 pagesSupplier Self Audit FormAllison Porter100% (2)

- Manufacturing Quality Control Checklist 2022Document7 pagesManufacturing Quality Control Checklist 2022nafis2uNo ratings yet

- SHE Inspection-General - SafetyCultureDocument36 pagesSHE Inspection-General - SafetyCulturematthew kagurabadzaNo ratings yet

- Vigilance Squad Report For Mscit Exam (Sept 2018) : Yes / NoDocument1 pageVigilance Squad Report For Mscit Exam (Sept 2018) : Yes / NoYogesh ChaudhariNo ratings yet

- Office Safety Checklist Sample PDF ReportDocument16 pagesOffice Safety Checklist Sample PDF ReportMarcelo RamírezNo ratings yet

- 3.2. Programme of Work - Spillage Management - Black Couture 2023Document2 pages3.2. Programme of Work - Spillage Management - Black Couture 2023blackcoutureconsultationsNo ratings yet

- 2C - Reacting To Quality ProblemDocument23 pages2C - Reacting To Quality ProblemDevarsh KakaNo ratings yet

- 8D Problem Solving Analysis: MinorDocument2 pages8D Problem Solving Analysis: MinorK K MaharanaNo ratings yet

- A. General Information On Company, Product and Quality ManagementDocument10 pagesA. General Information On Company, Product and Quality ManagementsutharitesshNo ratings yet

- 5-Whys AnalysisDocument12 pages5-Whys AnalysisVinh TranNo ratings yet

- CCTV Maintenance Checklist Log ReportDocument5 pagesCCTV Maintenance Checklist Log Reportali ahmedNo ratings yet

- Guideline Supplier Qualification - Dec09FINALDocument10 pagesGuideline Supplier Qualification - Dec09FINALflongNo ratings yet

- GMP Quality Supplier Audit Questionnaire 1663569818Document15 pagesGMP Quality Supplier Audit Questionnaire 1663569818Cyclone Pharmaceuticals Pvt Ltd PuneNo ratings yet

- Incident Report Template Sample PDF ReportDocument5 pagesIncident Report Template Sample PDF ReportBelbaraka AbdoNo ratings yet

- Presentation Poka YokeDocument34 pagesPresentation Poka YokeRiadh JellaliNo ratings yet

- General Cleaning Checklist Sample PDF ReportDocument8 pagesGeneral Cleaning Checklist Sample PDF Reportelianamabel10No ratings yet

- Answering Calls From RecruitersDocument10 pagesAnswering Calls From RecruitersPhu Cong LeNo ratings yet

- SOPQC0019EDocument212 pagesSOPQC0019Eh.boukhelfrosasNo ratings yet

- Tle 8 Week 6Document7 pagesTle 8 Week 6Jhon Jomarie Adlawon RobasNo ratings yet

- Accident Form V1Document6 pagesAccident Form V1Dimitrios NikolaidisNo ratings yet

- LEA - 5 WhysDocument1 pageLEA - 5 WhysJasser KandumeNo ratings yet

- Working Effectively in An IT Environment - Presentation OutlineDocument1 pageWorking Effectively in An IT Environment - Presentation OutlinejejemonbusterNo ratings yet

- 8D Presentation ASQDocument29 pages8D Presentation ASQpradeep100% (1)

- Afa 1 Module 6 ActivitiesDocument3 pagesAfa 1 Module 6 ActivitiesJulius BalbinNo ratings yet

- Problem Solution - 5 Why's Analysis Worksheet: Be Sure The 5 Why's Is Grounded in Observation Not DeductionDocument2 pagesProblem Solution - 5 Why's Analysis Worksheet: Be Sure The 5 Why's Is Grounded in Observation Not DeductionSyafiq Sulaiman100% (1)

- BWD Equipment Failure Report - TemplateDocument1 pageBWD Equipment Failure Report - TemplateAbdallah ElhendyNo ratings yet

- Root - Cause - Corrective Action PDFDocument31 pagesRoot - Cause - Corrective Action PDFBeste Ardıç Arslan100% (1)

- Task - Create Survey QuestionsDocument4 pagesTask - Create Survey QuestionsLiam JoseNo ratings yet

- General Solar Panel Maintenance Checklist Sample ReportDocument5 pagesGeneral Solar Panel Maintenance Checklist Sample Reportasmaaabdelkreem71No ratings yet

- Flevy 52Document5 pagesFlevy 52Karina BlancoNo ratings yet

- Lecture 8 - Poka-YokeDocument9 pagesLecture 8 - Poka-YokeCherie DiazNo ratings yet

- RubricDocument2 pagesRubricTan QuimNo ratings yet

- Planned Job Observation Report: ELEMENT 5.20bDocument1 pagePlanned Job Observation Report: ELEMENT 5.20bShafie ZubierNo ratings yet

- Visual Inspection Checklist Sample PDF ReportDocument7 pagesVisual Inspection Checklist Sample PDF Reporthamzachebbi43No ratings yet

- Jcecf Qms 1st Internal Audit PlanDocument3 pagesJcecf Qms 1st Internal Audit PlanteNo ratings yet

- Root Cause AnalysisDocument4 pagesRoot Cause AnalysisGreature Tana VareNo ratings yet

- 04 Auto MaintenanceDocument486 pages04 Auto Maintenanceanderson pariz100% (1)

- Mistake Proofing TechniquesDocument28 pagesMistake Proofing TechniquesRamasubramanian SankaranarayananNo ratings yet

- What Is Poka-YokeDocument114 pagesWhat Is Poka-YokeAdriano CarlosNo ratings yet

- 5 Whys: Basic Technique For Finding Root CausesDocument8 pages5 Whys: Basic Technique For Finding Root CausesFran JimenezNo ratings yet

- Six Sigma Analyze PhaseDocument13 pagesSix Sigma Analyze PhaseerinelNo ratings yet

- Heavy Lifting Permit VERY PERMIT - ContohDocument1 pageHeavy Lifting Permit VERY PERMIT - ContohOctaviary Bintan FamilyNo ratings yet

- RCA FormatDocument293 pagesRCA FormatONMPlanning EngineerPT. GPOSKPSiteNo ratings yet

- Poka YokeDocument11 pagesPoka YokecutepiyaNo ratings yet

- QC Book of Standards: Topic: 7 Steps of Human Error (Including Human Nature)Document8 pagesQC Book of Standards: Topic: 7 Steps of Human Error (Including Human Nature)wagnerqualidNo ratings yet

- Sample of Report Factory VisitingDocument10 pagesSample of Report Factory VisitingSang ThanhNo ratings yet

- 14.04.2018 - LS - Basic - Asking For Leave of Absence Huyendt9 PDFDocument10 pages14.04.2018 - LS - Basic - Asking For Leave of Absence Huyendt9 PDFPhu Cong LeNo ratings yet

- QACinemas Risk Log MatrixDocument9 pagesQACinemas Risk Log MatrixMustafa NyazNo ratings yet

- Training On 5 Why: Magneti Marelli Talbros Chassis Systems PVT - LTDDocument24 pagesTraining On 5 Why: Magneti Marelli Talbros Chassis Systems PVT - LTDGirish60No ratings yet

- F01 (OCP-005) & OHS Vehicle Inspection FormDocument1 pageF01 (OCP-005) & OHS Vehicle Inspection FormDeepakNo ratings yet

- Teach Pendant KeysDocument6 pagesTeach Pendant KeysALBERTO ALVARADO CARRILLONo ratings yet

- A3 Problem Solve ExcelDocument2 pagesA3 Problem Solve ExcelALBERTO ALVARADO CARRILLONo ratings yet

- Class Observation Tool 2022Document5 pagesClass Observation Tool 2022ALBERTO ALVARADO CARRILLONo ratings yet

- Layered Process Audit Checklist (LPA)Document5 pagesLayered Process Audit Checklist (LPA)ALBERTO ALVARADO CARRILLONo ratings yet

- ISCOM5508 (B) Configuration Guide (Rel - 03)Document491 pagesISCOM5508 (B) Configuration Guide (Rel - 03)glebegNo ratings yet

- Deloitte Uk Oracle Fusion Financials UnearthedDocument6 pagesDeloitte Uk Oracle Fusion Financials Unearthedzeeshan78No ratings yet

- Text Book of Organic Chemistry For Medical Students - Bunge 1912 PDFDocument283 pagesText Book of Organic Chemistry For Medical Students - Bunge 1912 PDFbabithyNo ratings yet

- We MediaDocument66 pagesWe MediaArtur AraujoNo ratings yet

- Lokesh Technical SeminarDocument26 pagesLokesh Technical SeminarSree AdithyaNo ratings yet

- VivaDocument16 pagesVivaRahulPrasadNo ratings yet

- Insulation Co-Ordination For Gas-Insulated Transmission LineDocument9 pagesInsulation Co-Ordination For Gas-Insulated Transmission LinewetrfdfdfweeNo ratings yet

- Quick Start GuideDocument5 pagesQuick Start GuideShaun PhelpsNo ratings yet

- Sr. No Question A B C D Correct AnswerDocument7 pagesSr. No Question A B C D Correct AnswerSagar DaradeNo ratings yet

- Study On Cbs With Tcs - SBIDocument22 pagesStudy On Cbs With Tcs - SBIvarghese.mathewNo ratings yet

- RJ45 C6 Toolless STP: Ordering Information Part Number E-Number DescriptionDocument1 pageRJ45 C6 Toolless STP: Ordering Information Part Number E-Number Descriptionov.ei.clerk1No ratings yet

- Resume FormatDocument3 pagesResume FormatarunNo ratings yet

- IEEE Writing FormatDocument4 pagesIEEE Writing FormatJerome JeremiasNo ratings yet

- What Is IC SubstrateDocument20 pagesWhat Is IC SubstratejackNo ratings yet

- 08 Scheme of StudiesDocument47 pages08 Scheme of StudieszeeshizeesheNo ratings yet

- Bus Reservation SystemDocument7 pagesBus Reservation SystemPreetham Gowda50% (2)

- Cit 3100 Introduction To Computer TechnologyDocument3 pagesCit 3100 Introduction To Computer TechnologyOUMA GORDONNo ratings yet

- 11 SQL Config SP3DDocument39 pages11 SQL Config SP3DgoodmorningfredNo ratings yet

- ECC Online System EIS and RequirementsDocument53 pagesECC Online System EIS and RequirementsMira AbisoNo ratings yet

- TempDocument76 pagesTempIanNo ratings yet

- Android NotesDocument24 pagesAndroid NotesAdit KadakiaNo ratings yet

- Amazon Web Services HyderabadDocument6 pagesAmazon Web Services Hyderabadraghava KNo ratings yet

- RHCSA Practice Exam D: General NotesDocument2 pagesRHCSA Practice Exam D: General NotesMaher MechiNo ratings yet

- EnglishDocument8 pagesEnglishNguyễn KhoaNo ratings yet

- Fox 1HDocument2 pagesFox 1HYen BaoNo ratings yet

- How To Use Windows Server 2016 - HandoutDocument7 pagesHow To Use Windows Server 2016 - Handoutquang nguyengocNo ratings yet

- 0916 02 EDEM StudentwebinarDocument32 pages0916 02 EDEM StudentwebinarJesse DANNo ratings yet

- DS-7700NI-K4 Series NVR: Key FeatureDocument4 pagesDS-7700NI-K4 Series NVR: Key FeatureNhẫn Nguyễn NgọcNo ratings yet