Professional Documents

Culture Documents

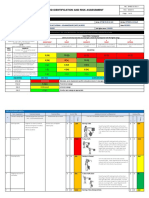

Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazard

Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazard

Uploaded by

SaravanaCopyright:

Available Formats

You might also like

- Excavation Risk AssessmentDocument3 pagesExcavation Risk Assessmentkhalef100% (2)

- Risk Assessment Guidance: Hazard Severity Likelihood of OccurrenceDocument10 pagesRisk Assessment Guidance: Hazard Severity Likelihood of OccurrenceSaleem AkhtarNo ratings yet

- Risk Assessment - HV 11kV Cable, Joint & TerminationDocument90 pagesRisk Assessment - HV 11kV Cable, Joint & TerminationJobish PK0% (2)

- Checklist WeldingDocument5 pagesChecklist WeldingMarko RisticNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazardshaibaz chafekarNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument3 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazardshaibaz chafekarNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazardshaibaz chafekarNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardPRASAD6219No ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardAffin RoyNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument6 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardPearl TeresaNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Confined Space WorkingDocument1 pageRisk Assessment: Act/Hse/Ra 001: Confined Space WorkingbrandedwahidNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument3 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazardshaibaz chafekarNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use of Suspended Access Cradles and Platforms (Temporary Works)Document2 pagesRisk Assessment: Act/Hse/Ra 001: Use of Suspended Access Cradles and Platforms (Temporary Works)Saravana0% (1)

- JB Pumping Pty LTDDocument2 pagesJB Pumping Pty LTDJB PumpingNo ratings yet

- 13initialprojectsiteofficeset Upriskassessmenttemplates 200616093558Document6 pages13initialprojectsiteofficeset Upriskassessmenttemplates 200616093558test fypNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Lifting Operations With Tower CraneDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Lifting Operations With Tower CraneM ShahzadNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Lifting Operations With Mobile CraneDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Lifting Operations With Mobile CraneKhalid KhalidNo ratings yet

- 17trafficoperations Workingonliveroadsriskassessmenttemplates 230419084508 3275aa2bDocument2 pages17trafficoperations Workingonliveroadsriskassessmenttemplates 230419084508 3275aa2bM ShahzadNo ratings yet

- ScaffoldingDocument2 pagesScaffoldingLheo PaduaNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Laying Blockwork With Access ScaffoldingDocument3 pagesRisk Assessment: Act/Hse/Ra 001: Laying Blockwork With Access ScaffoldingEdwin MofokengNo ratings yet

- 31.0.11 ALR - Temporary Electrical InstallationDocument3 pages31.0.11 ALR - Temporary Electrical InstallationGerritNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Sheet Piling Operations (Temporary Works)Document2 pagesRisk Assessment: Act/Hse/Ra 001: Sheet Piling Operations (Temporary Works)M ShahzadNo ratings yet

- 31.0.9 ALR - Loading & Off-Loading TruckDocument5 pages31.0.9 ALR - Loading & Off-Loading TruckGerrit100% (1)

- 31.0.10 LLA - Manual HandlingDocument4 pages31.0.10 LLA - Manual HandlingGerrit100% (1)

- Risk Assessment P3 Permanent Power Provision at IthraDocument2 pagesRisk Assessment P3 Permanent Power Provision at Ithraghazi4uNo ratings yet

- 31.0.12 ALR - Traffic Control by FlagmanDocument3 pages31.0.12 ALR - Traffic Control by FlagmanGerrit100% (1)

- Rev-01-Mariner WorkDocument40 pagesRev-01-Mariner Workrohit kumarNo ratings yet

- Jsa For Installation, Testing and Commissioning of Sewer and Strom Water Drainage System at 14 Nos. of Alijarah Warehouse.Document67 pagesJsa For Installation, Testing and Commissioning of Sewer and Strom Water Drainage System at 14 Nos. of Alijarah Warehouse.jafar mohdNo ratings yet

- Risk Assessment Guidance: Hazard Severity (A) Likelihood of Occurrence (B)Document3 pagesRisk Assessment Guidance: Hazard Severity (A) Likelihood of Occurrence (B)Ahmad Syauqi SuhairiNo ratings yet

- 1 - R.A. - 003 - CompactionDocument2 pages1 - R.A. - 003 - CompactionmahmoudabidaliNo ratings yet

- SF 011 Hazard Risk AseessmentDocument3 pagesSF 011 Hazard Risk AseessmentShahid RazaNo ratings yet

- Risk Assessment For Structural Concretes Works at Birkat Al Awamer Logistic ParkDocument22 pagesRisk Assessment For Structural Concretes Works at Birkat Al Awamer Logistic ParkAshir RIZNo ratings yet

- Risk Assessment Fitout SalonDocument19 pagesRisk Assessment Fitout SalonVision ConceptNo ratings yet

- Risk Assessment For Runway Beams 1Document10 pagesRisk Assessment For Runway Beams 1Subbu AbuNo ratings yet

- RA Excessive Noise .Vibration.Document11 pagesRA Excessive Noise .Vibration.Ndifor Dinho0% (1)

- EFS-SLB-SRA-002 Risk Assessment For Carpet Cleaning Vacuum & ShampooDocument4 pagesEFS-SLB-SRA-002 Risk Assessment For Carpet Cleaning Vacuum & Shampoomohammed ayazNo ratings yet

- Risk Assessment 004 NGSCHDocument2 pagesRisk Assessment 004 NGSCHsheraaz87100% (1)

- Context - General Risk AssessmentDocument14 pagesContext - General Risk AssessmentAngeloNo ratings yet

- Welcome To TÜV Rheinland Vietnam: Risk AssessmentDocument50 pagesWelcome To TÜV Rheinland Vietnam: Risk AssessmentTruong Quang HuyNo ratings yet

- Risk Assement UpdatedDocument10 pagesRisk Assement Updatedashwin0% (1)

- Hazard Identification and Risk Assessment FormDocument4 pagesHazard Identification and Risk Assessment FormAli Al-GhamghamNo ratings yet

- Site Mobilization Risk Assessment at Birkat Al Awamer Logistic ParkDocument26 pagesSite Mobilization Risk Assessment at Birkat Al Awamer Logistic ParkAshir RIZNo ratings yet

- Blank Risk Assessment TemplateDocument4 pagesBlank Risk Assessment TemplateMNo ratings yet

- Sample of JHA - Roofing Top Installation Rev 2Document5 pagesSample of JHA - Roofing Top Installation Rev 2vajiravel407No ratings yet

- Ra Concrete Chipping 7514Document5 pagesRa Concrete Chipping 7514Charles DoriaNo ratings yet

- Risk Assesment Generic Tender Despatch Electrical DepotDocument10 pagesRisk Assesment Generic Tender Despatch Electrical DepotanishavanloggerenbergNo ratings yet

- Instructions For Using OHS Risk Assessment Template: Only Complete The Unshaded Cells All Others Are Locked 1. 2Document4 pagesInstructions For Using OHS Risk Assessment Template: Only Complete The Unshaded Cells All Others Are Locked 1. 2Abdelrahman N. Ali100% (1)

- Safety at OffshoreDocument51 pagesSafety at OffshoreRavi Kant TripathiNo ratings yet

- Risk Assesment Fab - Rev-07Document71 pagesRisk Assesment Fab - Rev-07Nikhil PuthiryNo ratings yet

- International Building Systems Factory Co. LTDDocument6 pagesInternational Building Systems Factory Co. LTDMohammad Imtiaz AliNo ratings yet

- Risk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Document6 pagesRisk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Bulent AkNo ratings yet

- Ra Concrete Chipping Pic R 7514Document6 pagesRa Concrete Chipping Pic R 7514Charles DoriaNo ratings yet

- Generic RA FSDocument5 pagesGeneric RA FSStephenNo ratings yet

- Risk Assessment 2 PDFDocument15 pagesRisk Assessment 2 PDFarunNo ratings yet

- Risk Assessment ContDocument4 pagesRisk Assessment Contdevnraj 09No ratings yet

- Job Risk Asessment. Excavation 8-6-22Document3 pagesJob Risk Asessment. Excavation 8-6-22Mohammed Ali Qazi100% (1)

- Baseline Risk Assessment1 PDFDocument25 pagesBaseline Risk Assessment1 PDFRico100% (2)

- HIRARC TemplateDocument2 pagesHIRARC TemplateIzham ZainalNo ratings yet

- Risk Assessment & Control Module 3Document38 pagesRisk Assessment & Control Module 3Marvin ReggieNo ratings yet

- Triple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsFrom EverandTriple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsNo ratings yet

- Fixturenote 2Document4 pagesFixturenote 2George Bryan PatalinghugNo ratings yet

- Common Traffic Ordinance Violations and Traffic Accidents in Iriga CityDocument59 pagesCommon Traffic Ordinance Violations and Traffic Accidents in Iriga CityJulius PrimaNo ratings yet

- Case Studies On MV CarmelaDocument2 pagesCase Studies On MV CarmelaResearch DevelopmentNo ratings yet

- Risky Zones in Urban Area - An Analysis Using Fault Tree and Risk Matrix MethodDocument11 pagesRisky Zones in Urban Area - An Analysis Using Fault Tree and Risk Matrix MethodbahugunaNo ratings yet

- Carec Manual 1 Rsa English FinDocument51 pagesCarec Manual 1 Rsa English FinIlie BricicaruNo ratings yet

- Fasika MekonnenDocument101 pagesFasika MekonnenEmmanuel CristobalNo ratings yet

- DANGWA TRANSPORTATION CO v. CADocument3 pagesDANGWA TRANSPORTATION CO v. CAGrant GratedNo ratings yet

- NTP Irr - SignedDocument24 pagesNTP Irr - SignedPalanas A. VinceNo ratings yet

- Science 8 - Q1 - M1Document16 pagesScience 8 - Q1 - M1Rhea Abegail Ramos CejasNo ratings yet

- 2007 370 XTNDocument384 pages2007 370 XTNAung Hlaing Min MyanmarNo ratings yet

- Changes in The Transporation of Fruits and VegetablesDocument18 pagesChanges in The Transporation of Fruits and VegetablesStiloflexindia EnterpriseNo ratings yet

- Enhancing Maritime Domain Awareness in The Indo Pacific and The Eastern Mediterranean Regions NMF HMSDocument29 pagesEnhancing Maritime Domain Awareness in The Indo Pacific and The Eastern Mediterranean Regions NMF HMSPranav Painuly100% (1)

- Pabna University of Science and TechnologyDocument6 pagesPabna University of Science and TechnologyBadhon ChatterjeeNo ratings yet

- Loose Wheel Nuts - Causes and Effects, News ArticlesDocument2 pagesLoose Wheel Nuts - Causes and Effects, News Articleshassan eijyNo ratings yet

- 35 Cacho v. ManahanDocument3 pages35 Cacho v. ManahanGabrielle Adine SantosNo ratings yet

- Hitachi Hydraulic Excavator Zx400r 400lch 3 Technical Manual TroubleshootingDocument20 pagesHitachi Hydraulic Excavator Zx400r 400lch 3 Technical Manual Troubleshootingsara100% (58)

- Airplane Flyght Manual KGP-560Document22 pagesAirplane Flyght Manual KGP-560DanielLobatoBernardesNo ratings yet

- Examples of HIRARC 3Document3 pagesExamples of HIRARC 3fairus100% (1)

- Minimum Fuel SituationDocument6 pagesMinimum Fuel SituationTariq khosoNo ratings yet

- Crash of Air France ConcordeDocument11 pagesCrash of Air France ConcordeAhmad Aimi SafuanNo ratings yet

- Oic Engine - Oic Ew C17Document26 pagesOic Engine - Oic Ew C17joseph bmahusay0% (1)

- Vishal NepalDocument3 pagesVishal NepalBhoomika & shaurya KannoujiyaNo ratings yet

- Failure of Titanic PDFDocument26 pagesFailure of Titanic PDFAkshay BhaleraoNo ratings yet

- School of Engineering: Assignment Cover SheetDocument4 pagesSchool of Engineering: Assignment Cover Sheettahmid ahsanNo ratings yet

- Affidavit of Damage To Vehicle - SampleDocument2 pagesAffidavit of Damage To Vehicle - SampleReese OguisNo ratings yet

- Highway and Bridge MaintenanceDocument34 pagesHighway and Bridge MaintenanceProkopNo ratings yet

- GULDBORGDocument10 pagesGULDBORGLyubomir IvanovNo ratings yet

- Exam EssayDocument3 pagesExam EssayMa. Angelica ValleNo ratings yet

- Call For Paper of EASTS2021Document5 pagesCall For Paper of EASTS2021Puzy PrawiraNo ratings yet

- NTSB ReportDocument2 pagesNTSB ReportAlbuquerque JournalNo ratings yet

Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazard

Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazard

Uploaded by

SaravanaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazard

Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazard

Uploaded by

SaravanaCopyright:

Available Formats

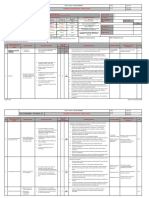

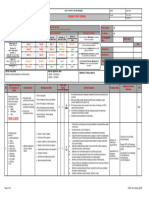

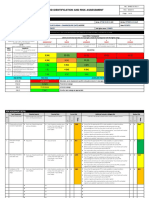

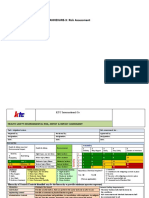

HEALTH SAFETY AND ENVIRONMENT Author: Approved:

Issued: Rev. Date:

RISK ASSESSMENT: ACT/HSE/RA 001 Lifting Operations with Tower crane

Revision: 0

RISK SCORE CALCULATOR Project Name: xxx

Use the Risk Score Calculator to Determine the Level of Risk of each Hazard

What is the LIKELIHOOD of an occurrence? Hierarchy of Controls RA Ref No.: xxx

What w ould be the

CONSEQUENCE Frequent/Almost certain (5) Rarely (1) Can the hazard be Elim inated or removed

Continuous or will happen

Often (4) Likely (3) Possible (2) Less than once every 5 RA compilation

of an occurrence be? 6 to 12 times a year 1 to 5 times a year Once every 5 years from the w ork place? Review date:

frequently years Date:

Catastrophic (5) Can the product or process be substituted for Date:

High 25 High 20 High 15 Medium 10 Medium 5

Multiple Fatalities a less hazardous alternative?

Serious (4) Can the hazard be engineered aw ay w ith

High 20 High 16 High 12 Medium 8 Low 4 Compiled by:

Class 1 single fatality guards or barriers?

Moderate (3)

Can Adm inistration Controls be adopted

Class2 (AWI or LTI) or Class 1 High 15 High 12 Medium 9 Medium 6 Low 3 Reviewed by:

Permanently disabling effects

I.e. procedures, job rotation etc.

Minor (2)

Medical attention needed, no work Medium 10 Medium 8 Medium 6 Low 4 Low 2 Can Personal Protective Equipm ent & Approved by:

restrictions. MTI Clothing be w orn to safe guard against

Insignificant (1) hazards?

FAI

Medium 10 Medium 4 Low 3 Low 2 Low 1

Overall Task Details Relevant Applicable MAS:

Additional Training required: NOC’s Required for task:

01412 – Lifting Operations;

Lifting operations using Tower crane within site boundary

00941 – Lifting equipment Riggers / Slingers As applicable

Specific Task Step Initial Risk

Additional Control

No (In sequence of Hazard Details Consequence/Risk Rating Control Measures Residual Risks RR

Measures

works) P S RR

i. Worker pedestrian routes to be designed and implemented with clear

Collision with plant or vehicles and

signage to provide segregation;

live traffic;

Access of Tower crane Plant and workers in ii. Instruction to workers at induction on use of access routes around the Workers not

Workers struck by plant, very high 12

1 sections to work areas same working area 3 4 project; complying with Regular topic in TBT’s Low

risk of fatality; High

as delivery truck; flagmen

iii. Flagmen to be used to control crane movements;

Uncontrolled crane reversing;

iv. The Logistics plan shall clearly illustrate crane access and egress points;

Excavations; See Risk Assessment 010 –

i. Crane foundations to be designed by approved persons, to clear design

Use of plant – Excavations;

criteria;

excavators etc.; 20

2 Tower crane See Risk Assessment 014 – use of 4 5 Low

foundations High ii. Foundations given adequate curing time before crane erection;

Use of concrete; Mobile Concrete pump;

iii. Temporary Works Coordinator to control excavations and concrete pours;

Temporary Works; Failure due to incorrect design;

i. Ensure crane is erected to standards by trained competent erection

personnel;

Fall from height; ii. No crane erection in adverse weather or high wind speed;

Falling materials from height; iii. Concise erection Method Statement compiled and available in work area

for review;

Use of untrained erectors;

iv. Area below works cleared and barriers implemented;

Works at Height; Erection in adverse weather; v. Solid barriers should be situated, where practicable, to protect erected

Siting, setting up and 12 crane from traffic routes; Failure of crash Crane quarantined until

3 Working in proximity Collision with overhead services; 3 4

High detector

Low

testing of Tower crane to existing structures vi. Consideration given to overhead services and existing structures when repaired and tested

Blocking access routes; siting tower crane;

and services;

Load striking moving and/or

vii. All Tower cranes to be Third Party Certificated by a DM approved

stationary structures; inspector prior to use, documentation available on arrival to site;

Use of untested crane;

viii. Load tests undertaken prior to use and available for review;

Use of unqualified operator;

ix. Operators to have in-date Third Party certificate by approved body,

available for review;

x. Crane load indicator to be installed and functioning correctly;

Page 1 of 2 HSEQ -Rev-01(Aug-2018)

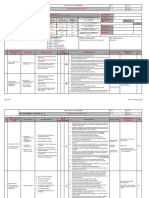

HEALTH SAFETY AND ENVIRONMENT Author: Approved:

Issued: Rev. Date:

RISK ASSESSMENT: ACT/HSE/RA 001 Lifting Operations with Tower crane

Revision: 0

xi. Crash detectors installed and functioning correctly;

i. HLG Minimum Acceptable Standard HLG/OHS/MAS/00941 to be adhered

to at all times;

ii. Lift Plan to be completed prior to any lift taking place by crane supervisor

and engineer;

Incident due to use of defective Machine

lifting gear / equipment; iii. Ensure all lifting tackle and equipment have valid test certificate before breakdown

Operator competency use (6 monthly 3 rd party inspections); Machine isolated and

Lifting of equipment Crane collapse due to lifting loads

and health; quarantined until repaired.

and material beyond SWL; 20 iv. Method statements and risk assessments to be submitted and adhered to

4 4 5 Low

Lift planning; HIGH for technical and/or non-routine lifts; Hydraulic fluid spill

(Tower crane Operator) No crane documentation in place; Spoil removed and treated as

v. Crane load indicator to be functioning correctly, and not to be overridden hazardous waste

Tower crane operator collapse whilst under any circumstances;

in cab; Operator deemed

vi. Operator to adhere to crane safe working load limits , weight of load and Removed from operation

unfit to operate

COG established before lifting; crane

vii. Tower crane operator subject to regular health checks;

i. Lift controlled by designated trained rigger/banks man using approved

hand signals only;

Persons underneath load struck by

ii. No personnel situated or walking under elevated loads, avoid over-

materials;

sailing of personnel if practicable;

Load swinging / spinning

Lifting operations iii. No over-sailing of loads over live traffic routes without road closure; Work stopped, area cleared

uncontrolled;

around workers; iv. No lifts undertaken when wind speed exceeds 40kph; Incident – falling and full investigation

Tower Crane Falling materials; 20 materials undertaken

5 Workers in crane 4 5 v. No blind lifts without visual and communication aids, radios etc.; Low

supervision

operating radius; Damage to lifting slings from sharp High

edges; vi. Tag lines shall be used to guide materials while lifting, 2 lines minimum

10m in length;

Over-sailing of material over live

vii. Slings protected from sharp edges with rubber etc.;

traffic routes;

viii. Riggers to undertake visual inspection of all lifting equipment daily;

High winds – adverse weather;

ix. Tower crane allowed to ‘weather vane’ in high winds;

i. Ensure crane is jumped or dismantled to standards by trained competent

Fall from height; erection personnel;

Falling materials from height; ii. No dismantling or jumping in adverse weather or high winds;

Jumping and Works at Height; 20

Storage of Designated area established

6 dismantling of Tower Use of untrained personnel; 4 5 iii. Concise Dismantling Method Statement compiled and available in work dismantled Low

High clear of access routes

Crane area for review; material

Dismantling in adverse weather;

iv. Area below works cleared and barriers implemented during jumping or

dismantling;

Page 2 of 2 HSEQ -Rev-01(Aug-2018)

You might also like

- Excavation Risk AssessmentDocument3 pagesExcavation Risk Assessmentkhalef100% (2)

- Risk Assessment Guidance: Hazard Severity Likelihood of OccurrenceDocument10 pagesRisk Assessment Guidance: Hazard Severity Likelihood of OccurrenceSaleem AkhtarNo ratings yet

- Risk Assessment - HV 11kV Cable, Joint & TerminationDocument90 pagesRisk Assessment - HV 11kV Cable, Joint & TerminationJobish PK0% (2)

- Checklist WeldingDocument5 pagesChecklist WeldingMarko RisticNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazardshaibaz chafekarNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument3 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazardshaibaz chafekarNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazardshaibaz chafekarNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardPRASAD6219No ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardAffin RoyNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument6 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardPearl TeresaNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Confined Space WorkingDocument1 pageRisk Assessment: Act/Hse/Ra 001: Confined Space WorkingbrandedwahidNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument3 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazardshaibaz chafekarNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use of Suspended Access Cradles and Platforms (Temporary Works)Document2 pagesRisk Assessment: Act/Hse/Ra 001: Use of Suspended Access Cradles and Platforms (Temporary Works)Saravana0% (1)

- JB Pumping Pty LTDDocument2 pagesJB Pumping Pty LTDJB PumpingNo ratings yet

- 13initialprojectsiteofficeset Upriskassessmenttemplates 200616093558Document6 pages13initialprojectsiteofficeset Upriskassessmenttemplates 200616093558test fypNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Lifting Operations With Tower CraneDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Lifting Operations With Tower CraneM ShahzadNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Lifting Operations With Mobile CraneDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Lifting Operations With Mobile CraneKhalid KhalidNo ratings yet

- 17trafficoperations Workingonliveroadsriskassessmenttemplates 230419084508 3275aa2bDocument2 pages17trafficoperations Workingonliveroadsriskassessmenttemplates 230419084508 3275aa2bM ShahzadNo ratings yet

- ScaffoldingDocument2 pagesScaffoldingLheo PaduaNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Laying Blockwork With Access ScaffoldingDocument3 pagesRisk Assessment: Act/Hse/Ra 001: Laying Blockwork With Access ScaffoldingEdwin MofokengNo ratings yet

- 31.0.11 ALR - Temporary Electrical InstallationDocument3 pages31.0.11 ALR - Temporary Electrical InstallationGerritNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Sheet Piling Operations (Temporary Works)Document2 pagesRisk Assessment: Act/Hse/Ra 001: Sheet Piling Operations (Temporary Works)M ShahzadNo ratings yet

- 31.0.9 ALR - Loading & Off-Loading TruckDocument5 pages31.0.9 ALR - Loading & Off-Loading TruckGerrit100% (1)

- 31.0.10 LLA - Manual HandlingDocument4 pages31.0.10 LLA - Manual HandlingGerrit100% (1)

- Risk Assessment P3 Permanent Power Provision at IthraDocument2 pagesRisk Assessment P3 Permanent Power Provision at Ithraghazi4uNo ratings yet

- 31.0.12 ALR - Traffic Control by FlagmanDocument3 pages31.0.12 ALR - Traffic Control by FlagmanGerrit100% (1)

- Rev-01-Mariner WorkDocument40 pagesRev-01-Mariner Workrohit kumarNo ratings yet

- Jsa For Installation, Testing and Commissioning of Sewer and Strom Water Drainage System at 14 Nos. of Alijarah Warehouse.Document67 pagesJsa For Installation, Testing and Commissioning of Sewer and Strom Water Drainage System at 14 Nos. of Alijarah Warehouse.jafar mohdNo ratings yet

- Risk Assessment Guidance: Hazard Severity (A) Likelihood of Occurrence (B)Document3 pagesRisk Assessment Guidance: Hazard Severity (A) Likelihood of Occurrence (B)Ahmad Syauqi SuhairiNo ratings yet

- 1 - R.A. - 003 - CompactionDocument2 pages1 - R.A. - 003 - CompactionmahmoudabidaliNo ratings yet

- SF 011 Hazard Risk AseessmentDocument3 pagesSF 011 Hazard Risk AseessmentShahid RazaNo ratings yet

- Risk Assessment For Structural Concretes Works at Birkat Al Awamer Logistic ParkDocument22 pagesRisk Assessment For Structural Concretes Works at Birkat Al Awamer Logistic ParkAshir RIZNo ratings yet

- Risk Assessment Fitout SalonDocument19 pagesRisk Assessment Fitout SalonVision ConceptNo ratings yet

- Risk Assessment For Runway Beams 1Document10 pagesRisk Assessment For Runway Beams 1Subbu AbuNo ratings yet

- RA Excessive Noise .Vibration.Document11 pagesRA Excessive Noise .Vibration.Ndifor Dinho0% (1)

- EFS-SLB-SRA-002 Risk Assessment For Carpet Cleaning Vacuum & ShampooDocument4 pagesEFS-SLB-SRA-002 Risk Assessment For Carpet Cleaning Vacuum & Shampoomohammed ayazNo ratings yet

- Risk Assessment 004 NGSCHDocument2 pagesRisk Assessment 004 NGSCHsheraaz87100% (1)

- Context - General Risk AssessmentDocument14 pagesContext - General Risk AssessmentAngeloNo ratings yet

- Welcome To TÜV Rheinland Vietnam: Risk AssessmentDocument50 pagesWelcome To TÜV Rheinland Vietnam: Risk AssessmentTruong Quang HuyNo ratings yet

- Risk Assement UpdatedDocument10 pagesRisk Assement Updatedashwin0% (1)

- Hazard Identification and Risk Assessment FormDocument4 pagesHazard Identification and Risk Assessment FormAli Al-GhamghamNo ratings yet

- Site Mobilization Risk Assessment at Birkat Al Awamer Logistic ParkDocument26 pagesSite Mobilization Risk Assessment at Birkat Al Awamer Logistic ParkAshir RIZNo ratings yet

- Blank Risk Assessment TemplateDocument4 pagesBlank Risk Assessment TemplateMNo ratings yet

- Sample of JHA - Roofing Top Installation Rev 2Document5 pagesSample of JHA - Roofing Top Installation Rev 2vajiravel407No ratings yet

- Ra Concrete Chipping 7514Document5 pagesRa Concrete Chipping 7514Charles DoriaNo ratings yet

- Risk Assesment Generic Tender Despatch Electrical DepotDocument10 pagesRisk Assesment Generic Tender Despatch Electrical DepotanishavanloggerenbergNo ratings yet

- Instructions For Using OHS Risk Assessment Template: Only Complete The Unshaded Cells All Others Are Locked 1. 2Document4 pagesInstructions For Using OHS Risk Assessment Template: Only Complete The Unshaded Cells All Others Are Locked 1. 2Abdelrahman N. Ali100% (1)

- Safety at OffshoreDocument51 pagesSafety at OffshoreRavi Kant TripathiNo ratings yet

- Risk Assesment Fab - Rev-07Document71 pagesRisk Assesment Fab - Rev-07Nikhil PuthiryNo ratings yet

- International Building Systems Factory Co. LTDDocument6 pagesInternational Building Systems Factory Co. LTDMohammad Imtiaz AliNo ratings yet

- Risk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Document6 pagesRisk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Bulent AkNo ratings yet

- Ra Concrete Chipping Pic R 7514Document6 pagesRa Concrete Chipping Pic R 7514Charles DoriaNo ratings yet

- Generic RA FSDocument5 pagesGeneric RA FSStephenNo ratings yet

- Risk Assessment 2 PDFDocument15 pagesRisk Assessment 2 PDFarunNo ratings yet

- Risk Assessment ContDocument4 pagesRisk Assessment Contdevnraj 09No ratings yet

- Job Risk Asessment. Excavation 8-6-22Document3 pagesJob Risk Asessment. Excavation 8-6-22Mohammed Ali Qazi100% (1)

- Baseline Risk Assessment1 PDFDocument25 pagesBaseline Risk Assessment1 PDFRico100% (2)

- HIRARC TemplateDocument2 pagesHIRARC TemplateIzham ZainalNo ratings yet

- Risk Assessment & Control Module 3Document38 pagesRisk Assessment & Control Module 3Marvin ReggieNo ratings yet

- Triple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsFrom EverandTriple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsNo ratings yet

- Fixturenote 2Document4 pagesFixturenote 2George Bryan PatalinghugNo ratings yet

- Common Traffic Ordinance Violations and Traffic Accidents in Iriga CityDocument59 pagesCommon Traffic Ordinance Violations and Traffic Accidents in Iriga CityJulius PrimaNo ratings yet

- Case Studies On MV CarmelaDocument2 pagesCase Studies On MV CarmelaResearch DevelopmentNo ratings yet

- Risky Zones in Urban Area - An Analysis Using Fault Tree and Risk Matrix MethodDocument11 pagesRisky Zones in Urban Area - An Analysis Using Fault Tree and Risk Matrix MethodbahugunaNo ratings yet

- Carec Manual 1 Rsa English FinDocument51 pagesCarec Manual 1 Rsa English FinIlie BricicaruNo ratings yet

- Fasika MekonnenDocument101 pagesFasika MekonnenEmmanuel CristobalNo ratings yet

- DANGWA TRANSPORTATION CO v. CADocument3 pagesDANGWA TRANSPORTATION CO v. CAGrant GratedNo ratings yet

- NTP Irr - SignedDocument24 pagesNTP Irr - SignedPalanas A. VinceNo ratings yet

- Science 8 - Q1 - M1Document16 pagesScience 8 - Q1 - M1Rhea Abegail Ramos CejasNo ratings yet

- 2007 370 XTNDocument384 pages2007 370 XTNAung Hlaing Min MyanmarNo ratings yet

- Changes in The Transporation of Fruits and VegetablesDocument18 pagesChanges in The Transporation of Fruits and VegetablesStiloflexindia EnterpriseNo ratings yet

- Enhancing Maritime Domain Awareness in The Indo Pacific and The Eastern Mediterranean Regions NMF HMSDocument29 pagesEnhancing Maritime Domain Awareness in The Indo Pacific and The Eastern Mediterranean Regions NMF HMSPranav Painuly100% (1)

- Pabna University of Science and TechnologyDocument6 pagesPabna University of Science and TechnologyBadhon ChatterjeeNo ratings yet

- Loose Wheel Nuts - Causes and Effects, News ArticlesDocument2 pagesLoose Wheel Nuts - Causes and Effects, News Articleshassan eijyNo ratings yet

- 35 Cacho v. ManahanDocument3 pages35 Cacho v. ManahanGabrielle Adine SantosNo ratings yet

- Hitachi Hydraulic Excavator Zx400r 400lch 3 Technical Manual TroubleshootingDocument20 pagesHitachi Hydraulic Excavator Zx400r 400lch 3 Technical Manual Troubleshootingsara100% (58)

- Airplane Flyght Manual KGP-560Document22 pagesAirplane Flyght Manual KGP-560DanielLobatoBernardesNo ratings yet

- Examples of HIRARC 3Document3 pagesExamples of HIRARC 3fairus100% (1)

- Minimum Fuel SituationDocument6 pagesMinimum Fuel SituationTariq khosoNo ratings yet

- Crash of Air France ConcordeDocument11 pagesCrash of Air France ConcordeAhmad Aimi SafuanNo ratings yet

- Oic Engine - Oic Ew C17Document26 pagesOic Engine - Oic Ew C17joseph bmahusay0% (1)

- Vishal NepalDocument3 pagesVishal NepalBhoomika & shaurya KannoujiyaNo ratings yet

- Failure of Titanic PDFDocument26 pagesFailure of Titanic PDFAkshay BhaleraoNo ratings yet

- School of Engineering: Assignment Cover SheetDocument4 pagesSchool of Engineering: Assignment Cover Sheettahmid ahsanNo ratings yet

- Affidavit of Damage To Vehicle - SampleDocument2 pagesAffidavit of Damage To Vehicle - SampleReese OguisNo ratings yet

- Highway and Bridge MaintenanceDocument34 pagesHighway and Bridge MaintenanceProkopNo ratings yet

- GULDBORGDocument10 pagesGULDBORGLyubomir IvanovNo ratings yet

- Exam EssayDocument3 pagesExam EssayMa. Angelica ValleNo ratings yet

- Call For Paper of EASTS2021Document5 pagesCall For Paper of EASTS2021Puzy PrawiraNo ratings yet

- NTSB ReportDocument2 pagesNTSB ReportAlbuquerque JournalNo ratings yet