Professional Documents

Culture Documents

Nitofill EPLV

Nitofill EPLV

Uploaded by

Santhosh ParanjothiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nitofill EPLV

Nitofill EPLV

Uploaded by

Santhosh ParanjothiCopyright:

Available Formats

Fosroc Nitofill EPLV constructive solutions

Low viscosity epoxy injection resin system

Uses Properties

For injecting into cracks in concrete or masonry, to form a The following properties were obtained at a temperature of

permanent bond or seal. 35ºC and at 7 days unless otherwise specified.

Test method Typical results

Advantages

Compressive strength : Tolerance (±10%)

Low viscosity allows penetration into the finest cracks (BS 6319) : 70.0 N/mm2 @ 20ºC

Formulated for hot climates 93.0 N/mm2 @ 35ºC

Tensile strength : 26.0 N/mm2 @ 35ºC

Suitable for structural repairs

(BS 6319)

Excellent bond to concrete, brick and masonry

Flexural strength : 63.0 N/mm2 @ 35ºC

Minimum creep under sustained load (BS 6319)

Resistant to wide range of chemicals Youngs modulus in

Non-shrink, adheres with no loss of bond compression : 16 GPa

Pot life : 90 minutes @ 20°C

Description 40 minutes @ 35°C

Specific gravity : 1.04

Nitofill EPLV two part, solvent-free, low viscosity epoxy resin Mixed viscosity : 1.0 poise @ 35°C

system is mixed in the proportions supplied to form a strong

permanent bond and seal in cracks in concrete and masonry. Instructions for use

Nitofill EPLV is designed to be injected into cracks using

suitable resin injection equipment. Nitofill EPLV can be applied using either injection packers

fixed into holes drilled directly into the crack or drilled

Design criteria diagonally from concrete adjacent to the crack or by the

fixing of injection nipples bonded to the surface using

Nitofill EPLV is designed to seal and bond cracks in concrete Nitomortar FC*†.

and masonry. Crack widths of between 0.1 mm and 9 mm

can be treated. Consult the local Fosroc office for further Preparation

details. Clean the surface and remove any dust, unsound or contam-

inated material, plaster, oil, paint, grease, corrosion deposits

Specification or algae.

The epoxy crack injection resin system shall be Nitofill The surface should preferably be prepared using high

EPLV, a two part solvent-free low viscosity, epoxy. When pressure water jetting or light abrasive blasting, followed by

mixed in the proportions supplied and injected into cracks in thorough washing to remove dust and remaining particles.

concrete, the resin shall form a permanent bond to seal in Dirt alone may be removed with wire brushes or similar

dry conditions. mechanical means.

Oil and grease deposits should be removed by steam

cleaning, detergent scrubbing or the use of a proprietary

degreaser. The effectiveness of decontamination should be

assessed by a pull-off test.

Blow the cracks and treated surface with oil free air to ensure

complete removal of all dust and loose particles. Ensure that

the surfaces are blown dry.

In the presence of running water the flow must be

stopped using Nitofill WS60*† which produces a rapid setting

water-stopping foam. When the water is stopped the cracks

Nitofill EPLV

are re-injected with Nitofill UR63*†.

Fosroc Nitofill EPLV

Fixing injection packers Application in Horizontal cracks

The injection packers shall be inserted into pre-drilled holes at In case of horizontal cracks in excess of 2mm Nitofil EPLV

intervals along the length of each crack. The distance be- can be applied through gravity flow, without the use of

tween each packer will depend upon the width and depth of injection packers. However such appliction need to be verified

the crack. Spacing shall be close enough to ensure that the for suitability through a site trial.

resin will penetrate along the crack to the next point of

Cleaning

injection.

Nitofill EPLV and Nitomortar FC should be removed from

The surface of the cracks between the packers shall be

tools, equipment and mixers with Fosroc Solvent 102*

sealed with a band of Nitomortar FC, 30 to 40mm wide and 2

immediately after use. Hardened material can only be

to 3 mm thick. Both sides of any cracks which go all the way

removed mechanically.

through a wall or slab shall be sealed in this way. In the case

of a wall or slab cracked all the way through, packers shall be

Limitations

located on both sides with those at the back placed at midway

points between those at the front. Nitofill EPLV is only to be used in dry.

The Nitomortar FC shall be allowed to cure for 8 hours at Nitofill EPLV should not be used on live cracks or where

35°C. At low ambient temperatures (5°C to 12°C) the curing further movement is expected. In these cases contact the

time will be extended and the applicator shall ensure that the local Fosroc office.

surface sealant has adequately cured prior to continuing. One

Nitofill EPLV should not be used in the presence of

end of the injection hose shall be attached to the lowest

running water. In these cases Nitofill WS60 or Nitofill

packer on vertical cracks or to either end of the horizontal

UR63 should be used.

cracks.

If any doubts arise concerning temperature, application or

Alternative methods of resin injection are currently in use, they

substrate conditions, consult the local Fosroc office.

include the system where injection nipples are bonded to the

substrate. High temperature working

Nitofill EPLV application It is suggested that, for temperatures above 35°C, the

following guidelines are adopted as good working practice:

Thoroughly mix the entire hardener and base resin contents

until the liquid becomes clear. (i) Store unmixed material in a cool (preferably temperature

controlled) environment, avoiding exposure to direct

Nitofill EPLV should be used with standard injection equip-

sunlight.

ment having closed containers. The injection pressure should

be at least 0.4N/mm2 (4 bar). (ii) Keep equipment cool, arranging shade protection if

necessary. It is especially important to keep cool those

Only mix sufficient resin that can be used within the pot life of

surfaces of the equipment which will come into direct

the material.

contact with the material itself.

Following completion of the injection works the injection

(iii) Try to eliminate application during the hottest times of the

system shall be allowed to cure for 24 hours and shall be left

day and in direct sunlight.

undisturbed for this time.

(iv) Make sufficient material, plant and labour available to

Making good

ensure that application is a continuous process.

Remove the packers and make good any holes or voids with

Nitomortar FC and allow to cure. The Nitomortar FC can be Technical support

ground off or softened with a blow lamp and peeled off. Do not

Fosroc offers a comprehensive technical support service to

allow to burn.

specifiers, end users and contractors. It is also able to offer

on-site technical assistance, an AutoCAD facility and

dedicated specification assistance in locations all over the

world.

Nitofill EPLV - Page 2 of 4

Fosroc Nitofill EPLV

Estimating Precautions

Supply Health and safety

Nitofill EPLV : 1 litre pack

Nitofill EPLV contains resins which may cause sensitisation

Nitomortar FC : 1 and 4 litre packs

by skin contact. During use of Nitofill EPLV, Nitomortar FC

Fosroc Solvent 102 : 5 litre packs

and Fosroc Solvent 102 avoid contact with skin and eyes.

Ensure adequate ventilation and avoid inhalation of vapours.

Storage

Some people are sensitive to resins, hardeners and solvents.

Shelf life

Wear suitable protective clothing, gloves and eye/face protec-

12 months, when Stored in warehouse conditions below 35 tion. Use only in well ventilated areas. If working in confined

degree C. areas or in cases of insufficient ventilation, suitable respirato-

ry protective equipment must be used.

Storage conditions

The use of barrier creams provide additional skin protection.

Store in dry conditions in the original, unopened containers. If

Should accidental skin contact occur, remove immediately

stored at high temperatures and/or high humidity conditions

with a resin removing cream followed by soap and water. Do

the shelf life may be reduced to 2 to 3 months.

not use solvent.

In case of contact with eyes, rinse immediately with plenty of

clean water and seek medical advice.

If swallowed seek medical attention immediately - do not

induce vomiting.

Fire

Nitofill EPLV and Nitomortar FC are non-flammable.

Fosroc Solvent 102 is flammable. Keep away from sources of

ignition. No smoking. In the event of fire extinguish with CO2

or foam. Do not use a water jet.

Flash points

Fosroc Solvent 102 : 33ºC

For further information, refer to the Product Material Safety

Data Sheet.

Nitofill EPLV - Page 3 of 4

Fosroc Nitofill EPLV

Additional Information

Fosroc manufactures a wide range of complementary

products which include :

waterproofing membranes & waterstops

joint sealants & filler boards

cementitious & epoxy grouts

specialised flooring materials

Fosroc additionally offers a comprehensive package of

products specifically designed for the repair and refurbish-

ment of damaged concrete. Fosroc’s ‘Systematic Approach’

to concrete repair features the following :

hand-placed repair mortars

spray grade repair mortars

fluid micro-concretes

chemically resistant epoxy mortars

anti-carbonation/anti-chloride protective coatings

chemical and abrasion resistant coatings

For further information on any of the above, please consult

your local Fosroc office - as below.

* Denotes the trademark of Fosroc International Limited

†

See separate data sheet

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions for the Supply of

Goods and Service. All Fosroc datasheets are updated on a regular basis. It is the user’s responsibility to obtain the latest version.

Head Office

telephone: (+9714) 2039699 fax: (+9714) 2859649 email: agf@fosroc.com

Al Gurg Fosroc Co. LLC

Regional offices

Post Box 657, Dubai Abu Dhabi, Al Gurg Fosroc telephone: 673 1779 fax: 673 1449 email: abudhabi@fosroc.com

Bahrain, YBA Kanoo telephone: 17738200 fax: 17732828 email: bahrain@fosroc.com

United Arab Emirates Kuwait, Boodai telephone: 4817618 fax: 4832124 email: kuwait@fosroc.com

www.fosroc.com Oman, Al Amana telephone: 24815080 fax: 24817554 email: oman@fosroc.com

UAE/0298/21/H

You might also like

- SCH4U - Unit 1 - Version C PDFDocument64 pagesSCH4U - Unit 1 - Version C PDFAbdul Mujeeb100% (1)

- Science: Quarter 4 - Module 2: BiomoleculesDocument31 pagesScience: Quarter 4 - Module 2: BiomoleculesMerrie Anne Pascual Bagsic75% (4)

- Nitofill EPLVDocument4 pagesNitofill EPLVMansoor AliNo ratings yet

- FosrocNitofill EPLV PDFDocument4 pagesFosrocNitofill EPLV PDFaahtagoNo ratings yet

- Nitofill Eplv6Document3 pagesNitofill Eplv6mohammad khabibNo ratings yet

- Nitofill EPLVDocument2 pagesNitofill EPLVSean Harsha100% (1)

- Specifications of Nitofill EPLV PDFDocument2 pagesSpecifications of Nitofill EPLV PDFTrung Nguyen ThanhNo ratings yet

- Nitofi LL EPLV: Low Viscous Epoxy Injection Resin GroutDocument2 pagesNitofi LL EPLV: Low Viscous Epoxy Injection Resin Grout8108295484No ratings yet

- Fosroc Nitofill UR63: Flexible Polyurethane Injection Resin SystemDocument4 pagesFosroc Nitofill UR63: Flexible Polyurethane Injection Resin SystemVincent JavateNo ratings yet

- TDS Nitofill EPLV BFLDocument2 pagesTDS Nitofill EPLV BFLanandswarupNo ratings yet

- Nitofill UR63Document4 pagesNitofill UR63Mansoor AliNo ratings yet

- Conbextra EP10TGDocument3 pagesConbextra EP10TGSales PPINo ratings yet

- Nitofill EPLV (M)Document2 pagesNitofill EPLV (M)VaishamNo ratings yet

- Renderoc EP10TGDocument3 pagesRenderoc EP10TGmohammad khabibNo ratings yet

- Fosroc Nitoflor EU10: Constructive SolutionsDocument4 pagesFosroc Nitoflor EU10: Constructive SolutionsVincent JavateNo ratings yet

- TDS Conbextra EP10 LV IndiaDocument2 pagesTDS Conbextra EP10 LV IndiaAnanth KumarNo ratings yet

- Nitofill UR63: Constructive SolutionsDocument3 pagesNitofill UR63: Constructive SolutionsrayNo ratings yet

- TDS Nitobond EP Saudi ArabiaDocument3 pagesTDS Nitobond EP Saudi ArabiaSCCPL UKNo ratings yet

- Nitofill Ur63 PDFDocument3 pagesNitofill Ur63 PDFtalatzahoorNo ratings yet

- TDS Nitobond EP India4Document3 pagesTDS Nitobond EP India4SHIVANSHUNo ratings yet

- Fosroc Nitoflor EU5: Constructive SolutionsDocument3 pagesFosroc Nitoflor EU5: Constructive SolutionsVincent JavateNo ratings yet

- TDS Conbextra EP10M IndiaDocument2 pagesTDS Conbextra EP10M IndiaBabla SNo ratings yet

- TDS Conbextra EP10M IndiaDocument2 pagesTDS Conbextra EP10M Indiasyed AffanNo ratings yet

- Nitofill UR63: Solvent Free, Two Part Polyurethane Resin For Sealing Cracks Application InstructionsDocument2 pagesNitofill UR63: Solvent Free, Two Part Polyurethane Resin For Sealing Cracks Application Instructionsaneesh kapaNo ratings yet

- Nitoflor Levelcrete IndiaDocument4 pagesNitoflor Levelcrete IndiaArun KumarNo ratings yet

- Conbextra STDDocument2 pagesConbextra STDPritha DasNo ratings yet

- Cikopoxy CF: Technical DataDocument2 pagesCikopoxy CF: Technical DataM. KumaranNo ratings yet

- Nitobond EP July20 v2Document2 pagesNitobond EP July20 v2CHNo ratings yet

- Conbextra EP40 UAEDocument2 pagesConbextra EP40 UAEjasonNo ratings yet

- Fosroc Conbextra EP10: Constructive SolutionsDocument2 pagesFosroc Conbextra EP10: Constructive SolutionsVincent JavateNo ratings yet

- Nitoflor EPU100Document4 pagesNitoflor EPU100Allan DerickNo ratings yet

- Nitoseal MS60Document2 pagesNitoseal MS60talatzahoorNo ratings yet

- Fosroc Conbextra EPGP: Constructive SolutionsDocument2 pagesFosroc Conbextra EPGP: Constructive SolutionsVincent JavateNo ratings yet

- Nitobond EP 0608Document2 pagesNitobond EP 0608James PittsNo ratings yet

- Conbextra EP10 : High Strength, Epoxy Resin GroutDocument1 pageConbextra EP10 : High Strength, Epoxy Resin GroutminedataNo ratings yet

- TDS Nitoflor Levelcrete IndiaDocument4 pagesTDS Nitoflor Levelcrete IndiaSHAIK ASIMUDDINNo ratings yet

- NITOKITDocument3 pagesNITOKITquamarsrNo ratings yet

- Nitokit Surface Sealant: Constructive SolutionsDocument2 pagesNitokit Surface Sealant: Constructive SolutionstalatzahoorNo ratings yet

- TDS Conbextra EP10LV IndiaDocument2 pagesTDS Conbextra EP10LV Indiaraahul_nNo ratings yet

- Conbextra EPGPDocument2 pagesConbextra EPGPm.elsanee.cubicNo ratings yet

- Fosroc Nitoflor EU50: High Strength Epoxy UnderlayDocument4 pagesFosroc Nitoflor EU50: High Strength Epoxy UnderlayVincent JavateNo ratings yet

- Conbextra STDDocument2 pagesConbextra STDm.basim.technitalNo ratings yet

- TDS Nitofill UR63 India3Document3 pagesTDS Nitofill UR63 India3chikukar3No ratings yet

- Fosroc Nitoflor Levelcrete: Cementitious Floor Levelling CompoundDocument4 pagesFosroc Nitoflor Levelcrete: Cementitious Floor Levelling CompoundVincent JavateNo ratings yet

- Conbextra EPGPDocument2 pagesConbextra EPGPm.basim.technitalNo ratings yet

- Conbextra EP: T T T T T TDocument4 pagesConbextra EP: T T T T T TFeri Oktara IrawanNo ratings yet

- TDS Nitoproof Damp Protect India2Document2 pagesTDS Nitoproof Damp Protect India2hitesh315No ratings yet

- Nitofill WS60Document4 pagesNitofill WS60Mansoor AliNo ratings yet

- Conbextra EP10 (M) PDFDocument2 pagesConbextra EP10 (M) PDFBinoy Sankar SarkerNo ratings yet

- Nitoflor EU50Document4 pagesNitoflor EU50m.elsanee.cubicNo ratings yet

- Conbextra EP10 (M)Document2 pagesConbextra EP10 (M)abhay_joshi2002No ratings yet

- Nitofill EPLV : Constructive SolutionsDocument4 pagesNitofill EPLV : Constructive SolutionsmilanbrasinaNo ratings yet

- (PDS) Conbextra GPDocument4 pages(PDS) Conbextra GPSheena GardnerNo ratings yet

- TDS Nitocote CM210 BFL3Document4 pagesTDS Nitocote CM210 BFL3ryan wachiraNo ratings yet

- Fosroc Nitocote SN511 TDSDocument2 pagesFosroc Nitocote SN511 TDSmrameshceNo ratings yet

- Decofill PDFDocument2 pagesDecofill PDFArun KumarNo ratings yet

- Fosroc Nitoflor FC550: Constructive SolutionsDocument4 pagesFosroc Nitoflor FC550: Constructive SolutionsVincent JavateNo ratings yet

- Conbextra EP10Document2 pagesConbextra EP10m.elsanee.cubicNo ratings yet

- Nitomortar TC2000Document3 pagesNitomortar TC2000talatzahoorNo ratings yet

- Nitobond EP: Epoxy Resin Concrete Bonding AgentDocument3 pagesNitobond EP: Epoxy Resin Concrete Bonding AgentDinesh HastakNo ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- HTDS 750 SDS - en 06-2017Document7 pagesHTDS 750 SDS - en 06-2017Jean GrégoireNo ratings yet

- Tle 7 - Cookery Week 3Document9 pagesTle 7 - Cookery Week 3Dominic Camacho RotaNo ratings yet

- Amerex Ansul Badger Ul Catalogo Por PartesDocument37 pagesAmerex Ansul Badger Ul Catalogo Por PartesPuma De La Torre ExtintoresNo ratings yet

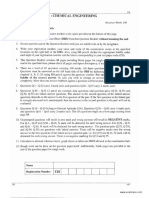

- CH: Chemical Engineering: Duracio11: Three Hours Maximum MarksDocument21 pagesCH: Chemical Engineering: Duracio11: Three Hours Maximum Markspratik rulesNo ratings yet

- Crl-Soil Sampling-Pcapi R4a 2022Document40 pagesCrl-Soil Sampling-Pcapi R4a 2022Marc ChristianNo ratings yet

- KPL - Inv PPT 2020Document24 pagesKPL - Inv PPT 2020himanshuNo ratings yet

- Tablas Metalurgicas 2 PDFDocument40 pagesTablas Metalurgicas 2 PDFAnonymous CNormeuqWpNo ratings yet

- Formic AcidDocument23 pagesFormic AcidAMS100% (1)

- Structure Identification HandoutDocument8 pagesStructure Identification HandoutmikcNo ratings yet

- Assignment in Advance Chemistry (Hydrocarbons) : Frauline C. Tadle IV-Galileo Mr. Romel Condeza S.Y.: 2010-2011Document7 pagesAssignment in Advance Chemistry (Hydrocarbons) : Frauline C. Tadle IV-Galileo Mr. Romel Condeza S.Y.: 2010-2011Fraul TadleNo ratings yet

- 2009-06-15 AB-3P Technical Reference Manual R6Document73 pages2009-06-15 AB-3P Technical Reference Manual R6Faiz SabianNo ratings yet

- Draft Product Manual ToysDocument44 pagesDraft Product Manual ToysShejil BalakrishnanNo ratings yet

- Datasheet Zincalume G550Document2 pagesDatasheet Zincalume G550adihindNo ratings yet

- 2545 PracticalDocument10 pages2545 PracticalYared Genene100% (1)

- Alits-6 Xii Apt 3 - Set-ADocument13 pagesAlits-6 Xii Apt 3 - Set-AashishNo ratings yet

- Food-PackagingDocument48 pagesFood-PackagingTrishitman DasNo ratings yet

- Forensic ChemDocument31 pagesForensic ChemHarrison sajor100% (1)

- 5 EnzymesDocument22 pages5 EnzymeslibanNo ratings yet

- Now Test Yourself Answers: 1 Engineering MaterialsDocument9 pagesNow Test Yourself Answers: 1 Engineering MaterialsSylvesterNo ratings yet

- TNCDA Monthly Journal NovemberDocument36 pagesTNCDA Monthly Journal Novemberrammvr05No ratings yet

- Asparagina 2Document15 pagesAsparagina 2Daniela SepulvedaNo ratings yet

- Ic-0014 Kit Refrifluid B Uc-0020-1700 (En)Document2 pagesIc-0014 Kit Refrifluid B Uc-0020-1700 (En)Lluis Cuevas EstradaNo ratings yet

- 3 LAB ACTIVITY SHEET 3 Precipitation and Solubility 1Document3 pages3 LAB ACTIVITY SHEET 3 Precipitation and Solubility 1Jurel JohnNo ratings yet

- Curriculum Vitae: Academic QualificationsDocument3 pagesCurriculum Vitae: Academic QualificationswongsosoegaliNo ratings yet

- Technical SpecificationDocument10 pagesTechnical SpecificationricardoNo ratings yet

- Manual Service Vitodens 200Document77 pagesManual Service Vitodens 200MariusMNo ratings yet

- Polyaluminium Chloride MSDSDocument6 pagesPolyaluminium Chloride MSDSNandhakumarNo ratings yet

- Bhopal SecurityDocument4 pagesBhopal SecurityAmiraNo ratings yet