Professional Documents

Culture Documents

General: CRUDE OIL / Liquid 313.9 / 313.9

General: CRUDE OIL / Liquid 313.9 / 313.9

Uploaded by

amirCopyright:

Available Formats

You might also like

- Data Sheet For PSVDocument1 pageData Sheet For PSVBABILIN VNo ratings yet

- General: Crude Oil - 219 Crude Oil - 219 1.117 82.6Document1 pageGeneral: Crude Oil - 219 Crude Oil - 219 1.117 82.6amirNo ratings yet

- GeneralDocument1 pageGeneralamirNo ratings yet

- GeneralDocument1 pageGeneralamirNo ratings yet

- GeneralDocument1 pageGeneralamirNo ratings yet

- General: Crude Oil Crude Oil - 219 219 1.117 1.14Document1 pageGeneral: Crude Oil Crude Oil - 219 219 1.117 1.14amirNo ratings yet

- General: Crude Oil Crude Oil - 219 219Document1 pageGeneral: Crude Oil Crude Oil - 219 219amirNo ratings yet

- 2055 Ed 2FGGF7 B1 9Document1 page2055 Ed 2FGGF7 B1 9amirNo ratings yet

- General: Crude Oil - 219 1.117 4.6 Crude Oil - 219Document1 pageGeneral: Crude Oil - 219 1.117 4.6 Crude Oil - 219amirNo ratings yet

- 6-Pressure Safety ValveDocument1 page6-Pressure Safety ValveFari NazariNo ratings yet

- 141014.datasheet For PSV-1323Document2 pages141014.datasheet For PSV-1323ocanhthuNo ratings yet

- File 5Document1 pageFile 5VENKATACHALAM SUBBARAJNo ratings yet

- Ed0581b-1639e 01 Ap1Document5 pagesEd0581b-1639e 01 Ap1Erol DAĞNo ratings yet

- Final End User Data Sheets 15 Valves Tor Deshy Rev1Document15 pagesFinal End User Data Sheets 15 Valves Tor Deshy Rev1Ghofrane HNo ratings yet

- Severn GloconDocument6 pagesSevern GloconAmit Surti0% (1)

- HOJA DATOS PSVDocument9 pagesHOJA DATOS PSVRafael GarciaNo ratings yet

- DELUGE VALVES DATASHEET Rev.01Document1 pageDELUGE VALVES DATASHEET Rev.01moodydoodyNo ratings yet

- SA 980 P 11432 CS Globe Valve Rev T02Document3 pagesSA 980 P 11432 CS Globe Valve Rev T02altipatlar100% (1)

- Data Sheet For PSVDocument9 pagesData Sheet For PSVashams492No ratings yet

- PIC 1 /SIC-1 N/A N/A N/A N2 Secondary Barrier: Exhaust Filter Safety Valve Exhaust Filter Safety Valve ClassificationDocument2 pagesPIC 1 /SIC-1 N/A N/A N/A N2 Secondary Barrier: Exhaust Filter Safety Valve Exhaust Filter Safety Valve ClassificationRanchojiNo ratings yet

- SA 980 P 11433 CS Plug Valve Rev T02Document3 pagesSA 980 P 11433 CS Plug Valve Rev T02altipatlarNo ratings yet

- Severn Glocon Lot2Document5 pagesSevern Glocon Lot2Amit SurtiNo ratings yet

- 42 Mab 191Document5 pages42 Mab 191false mailNo ratings yet

- RFQ-12172 valves datasheetDocument2 pagesRFQ-12172 valves datasheetthillais7feNo ratings yet

- Magnetrol TD2-8D00-032 + Tma-A210-007Document1 pageMagnetrol TD2-8D00-032 + Tma-A210-007BRUNONo ratings yet

- E0805-220-V-903-120-3A (Latihan)Document65 pagesE0805-220-V-903-120-3A (Latihan)Sabrang LorNo ratings yet

- Spec SheetDocument7 pagesSpec SheetPatricia MirandaNo ratings yet

- Ras Gahreb Gas Treatment Plant: EN 10025-2-S355JR EN 10025-2-S355 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JRDocument1 pageRas Gahreb Gas Treatment Plant: EN 10025-2-S355JR EN 10025-2-S355 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JROmar WardehNo ratings yet

- 07-PSV-07 Folha de Dados ValbracDocument1 page07-PSV-07 Folha de Dados ValbracRODRIGO CARDOSONo ratings yet

- A307 Ius Uv DS 1201Document2 pagesA307 Ius Uv DS 1201smartravi222No ratings yet

- Tpp-Abe-Mp-1201-0004 - Data Sheet For Pig Launcher & Receiver - R2 - 13-May-2016Document9 pagesTpp-Abe-Mp-1201-0004 - Data Sheet For Pig Launcher & Receiver - R2 - 13-May-2016OlusayoNo ratings yet

- Datasheet For PSVDocument1 pageDatasheet For PSVlãng duNo ratings yet

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument6 pagesPressure Safety Valve-Preliminary Sizing: Input DataPIDNo ratings yet

- Atlas Copco India LTD.: Gas Process ApplicationDocument4 pagesAtlas Copco India LTD.: Gas Process ApplicationAmit SurtiNo ratings yet

- 01.data SheetDocument1 page01.data SheetBhargav PatelNo ratings yet

- Ps 138 Ma Data SheetDocument4 pagesPs 138 Ma Data SheetRutchelle BrunoNo ratings yet

- Pressure Vessels Data SheetDocument6 pagesPressure Vessels Data SheetPatricio LagosNo ratings yet

- Datasheet For Pressure Safety Valve - IfbDocument66 pagesDatasheet For Pressure Safety Valve - Ifbfathan fathullahNo ratings yet

- LT-401 Remoto RecipienteDocument1 pageLT-401 Remoto RecipienteGabriel CidNo ratings yet

- Booster Pump, 5 HP, 80 GPM X 180 FTDocument4 pagesBooster Pump, 5 HP, 80 GPM X 180 FTRutchelle BrunoNo ratings yet

- FEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0Document14 pagesFEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0ddaalayamoct313024No ratings yet

- Shell & Tube Gas HEATER EXCHANGER (P-1233002) : Srge/EsupDocument3 pagesShell & Tube Gas HEATER EXCHANGER (P-1233002) : Srge/EsupRobles DreschNo ratings yet

- 1-MVCP00116-885PSVr2 20210524100343 852 XDocument4 pages1-MVCP00116-885PSVr2 20210524100343 852 XŁukasz BolewskiNo ratings yet

- Pzem 33H224 3 Pumps 10 HPDocument4 pagesPzem 33H224 3 Pumps 10 HPRutchelle BrunoNo ratings yet

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument5 pagesPressure Safety Valve-Preliminary Sizing: Input DataTun Naing WinNo ratings yet

- Booster Pump Rainwater, 1 HP 1x230v, 60hzDocument4 pagesBooster Pump Rainwater, 1 HP 1x230v, 60hzRutchelle BrunoNo ratings yet

- Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Document3 pagesDs-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Panisa BanimaNo ratings yet

- Ras Gahreb Gas Treatment Plant: EN 10025-2-S275 JR EN 10025-2-S275 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JRDocument1 pageRas Gahreb Gas Treatment Plant: EN 10025-2-S275 JR EN 10025-2-S275 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JROmar WardehNo ratings yet

- Reactor Data Sheet: Sketch (Bundle / Nozzle Orientation) GeneralDocument1 pageReactor Data Sheet: Sketch (Bundle / Nozzle Orientation) GeneralAndrés SepúlvedaNo ratings yet

- KSB MIL Control Valves Specification V0998-SPECDocument36 pagesKSB MIL Control Valves Specification V0998-SPECNutan PowerNo ratings yet

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDocument2 pagesProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanNo ratings yet

- sdv 560Document1 pagesdv 560Charlyss AlfonsoNo ratings yet

- Damper DS - 1196DPR-430Document2 pagesDamper DS - 1196DPR-430harishcsharmaNo ratings yet

- A307 Ius FV DS 1311Document2 pagesA307 Ius FV DS 1311Ravi KumarNo ratings yet

- Strength Calculation Sheet For Item No. C-053-12Document297 pagesStrength Calculation Sheet For Item No. C-053-12Urdian Syah100% (1)

- 15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Document4 pages15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Umair A. KhanNo ratings yet

- Sa 980 P 11434 Cs Swing Check Valve Rev. t02Document3 pagesSa 980 P 11434 Cs Swing Check Valve Rev. t02altipatlar100% (1)

- KSB MIL Controls Limited Valve Specification SheetDocument2 pagesKSB MIL Controls Limited Valve Specification SheetPablo TorresNo ratings yet

- FS22-015-PR-DS-002-Rev A-Datasheets For Pressure Vacuum Safety ValveDocument1 pageFS22-015-PR-DS-002-Rev A-Datasheets For Pressure Vacuum Safety ValveMinh DoNo ratings yet

- Temperature Instruments Temperature InstrumentsDocument1 pageTemperature Instruments Temperature InstrumentsamirNo ratings yet

- Control Valve (Include On/Off Valve) Control Valve (Include On/Off Valve)Document1 pageControl Valve (Include On/Off Valve) Control Valve (Include On/Off Valve)amirNo ratings yet

- Attachment No. 8: Documents: DocumentsDocument1 pageAttachment No. 8: Documents: DocumentsamirNo ratings yet

- Attachment No. 6: Vendor Recommendation To Specifications: Vendor Recommendation To Specifications: Vendor Recommendation To SpecificationsDocument1 pageAttachment No. 6: Vendor Recommendation To Specifications: Vendor Recommendation To Specifications: Vendor Recommendation To SpecificationsamirNo ratings yet

- Safety and Relief Valve Safety and Relief ValveDocument1 pageSafety and Relief Valve Safety and Relief ValveamirNo ratings yet

- Safety Relief Valves Safety Relief ValvesDocument1 pageSafety Relief Valves Safety Relief ValvesamirNo ratings yet

- Attachment No. 7: Spare Part List: Spare Part ListDocument1 pageAttachment No. 7: Spare Part List: Spare Part ListamirNo ratings yet

- Attachment No. 5: Deviations / Exceptions To Specifications: Deviations / Exceptions To Specifications: Deviations / Exceptions To SpecificationsDocument1 pageAttachment No. 5: Deviations / Exceptions To Specifications: Deviations / Exceptions To Specifications: Deviations / Exceptions To SpecificationsamirNo ratings yet

- 2055 Ep 000 in MR 0006 B0 26Document1 page2055 Ep 000 in MR 0006 B0 26amirNo ratings yet

- COORDINATION MEETING (If Applicable) COORDINATION MEETING (If Applicable)Document1 pageCOORDINATION MEETING (If Applicable) COORDINATION MEETING (If Applicable)amirNo ratings yet

- 2055 Ep 000 in MR 0006 B0 35Document1 page2055 Ep 000 in MR 0006 B0 35amirNo ratings yet

- 10.4. Verification VerificationDocument1 page10.4. Verification VerificationamirNo ratings yet

- Attachement No. 1: Material Summary List Attachement No. 1: Material Summary ListDocument1 pageAttachement No. 1: Material Summary List Attachement No. 1: Material Summary ListamirNo ratings yet

- ClarificationDocument1 pageClarificationamirNo ratings yet

- 16.2. Special Tools Special ToolsDocument1 page16.2. Special Tools Special ToolsamirNo ratings yet

- 17.2. Checking of Vendors Documents Checking of Vendors DocumentsDocument1 page17.2. Checking of Vendors Documents Checking of Vendors DocumentsamirNo ratings yet

- 2055 Ep 000 in MR 0006 B0 11Document1 page2055 Ep 000 in MR 0006 B0 11amirNo ratings yet

- Attachement No. 3: Vendor Data Requirement (VDR) 1. Language 3: Vendor Data Requirement (VDR)Document1 pageAttachement No. 3: Vendor Data Requirement (VDR) 1. Language 3: Vendor Data Requirement (VDR)amirNo ratings yet

- Equipment/Materials Equipment/MaterialsDocument1 pageEquipment/Materials Equipment/MaterialsamirNo ratings yet

- Pre-Commissioning, Commissioning and Start Up Ning, Commissioning and Start Up Ning, Commissioning and Start UpDocument1 pagePre-Commissioning, Commissioning and Start Up Ning, Commissioning and Start Up Ning, Commissioning and Start UpamirNo ratings yet

- Comprehensive Descriptive Literature & Catalogue Comprehensive Descriptive Literature & CatalogueDocument1 pageComprehensive Descriptive Literature & Catalogue Comprehensive Descriptive Literature & CatalogueamirNo ratings yet

- Attachement No. 2: Letter of Conformity Attachement No. 2: Letter of ConformityDocument1 pageAttachement No. 2: Letter of Conformity Attachement No. 2: Letter of ConformityamirNo ratings yet

- QuotationDocument1 pageQuotationamirNo ratings yet

- Units: "Safety Relief Valves Safety Relief Valves"Document1 pageUnits: "Safety Relief Valves Safety Relief Valves"amirNo ratings yet

- General Notes 4.1. Design Responsibility Responsibility: "Safety Relief Valves Safety Relief Valves"Document1 pageGeneral Notes 4.1. Design Responsibility Responsibility: "Safety Relief Valves Safety Relief Valves"amirNo ratings yet

- 2055 Ep 000 in MR 0006 B0 25Document1 page2055 Ep 000 in MR 0006 B0 25amirNo ratings yet

- 2055 Ep 000 in MR 0006 B0 4Document1 page2055 Ep 000 in MR 0006 B0 4amirNo ratings yet

- Site ConditionsDocument1 pageSite ConditionsamirNo ratings yet

- General 1.1Document1 pageGeneral 1.1amirNo ratings yet

- 2055 Ep 000 in MR 0006 B0 7Document1 page2055 Ep 000 in MR 0006 B0 7amirNo ratings yet

- Steam Tracing For HfoDocument18 pagesSteam Tracing For HfoTsouki Tsouki0% (1)

- Dual Fuel EngineDocument13 pagesDual Fuel EngineVIKASNo ratings yet

- CONSOLIDATED For Power ServiceDocument20 pagesCONSOLIDATED For Power Servicenico andrew doylay SiahaanNo ratings yet

- 4 WNS Series Horizontal Gas Fired Oil BoilerDocument25 pages4 WNS Series Horizontal Gas Fired Oil Boilerfauzi endra100% (1)

- Fresh Water GeneratorDocument2 pagesFresh Water GeneratorAlberto Ramírez TorrensNo ratings yet

- DongFeng RICH-ZD25TCIDocument3 pagesDongFeng RICH-ZD25TCIEduardo Antonio Barria OjedaNo ratings yet

- Siemens SGen-1000A+Series Nov14Document4 pagesSiemens SGen-1000A+Series Nov14Jaylord CrisostomoNo ratings yet

- Boiler Types and Classifications - WikiDocument21 pagesBoiler Types and Classifications - WikiKarthik ChillaNo ratings yet

- Air Cooled Condensors: General DescriptionDocument7 pagesAir Cooled Condensors: General DescriptionRajeev MaheshwariNo ratings yet

- 5 Star Rated ACDocument3 pages5 Star Rated ACavr8784No ratings yet

- Belajar Kerusakan AlatDocument126 pagesBelajar Kerusakan AlatHijrah Saputro RaharjoNo ratings yet

- 25 CompressorsDocument8 pages25 CompressorsYosephanderNo ratings yet

- BTS Ac SystemDocument40 pagesBTS Ac Systemmohsinaliqureshi02No ratings yet

- ES EasyGrid 5kVA 10kVA 15kVA BrochureDocument4 pagesES EasyGrid 5kVA 10kVA 15kVA Brochuremayssa fadhlaouiNo ratings yet

- Condensate System PresentationDocument24 pagesCondensate System Presentationмing junNo ratings yet

- Seminar On Jet Engine: Submitted To: Submitted byDocument20 pagesSeminar On Jet Engine: Submitted To: Submitted bypavan kalyanNo ratings yet

- MEE Promotional Pages Gas Engine GS16R2PTKDocument2 pagesMEE Promotional Pages Gas Engine GS16R2PTKJusril A HidayatNo ratings yet

- Edc Power Plant FacilitiesDocument32 pagesEdc Power Plant FacilitiesMichael TayactacNo ratings yet

- PEDDocument2 pagesPEDAjay KumarNo ratings yet

- Gujarat Technological University: Project Report ON Scope of Utility Reduction in Chemical IndustryDocument24 pagesGujarat Technological University: Project Report ON Scope of Utility Reduction in Chemical IndustryPradeep SutharNo ratings yet

- 7 Assignment SolutionDocument4 pages7 Assignment SolutionBhavya AnoohyaNo ratings yet

- Case StudiesDocument32 pagesCase StudiesSE Electrical100% (2)

- Four Stroke Petrol EngineDocument12 pagesFour Stroke Petrol EngineSyed Zaheer SajjadNo ratings yet

- Brochure SMA Energy-System Home-En-14Document24 pagesBrochure SMA Energy-System Home-En-14Furqan HamidNo ratings yet

- Kebutuhan Steam Untuk Blowing BoilerDocument3 pagesKebutuhan Steam Untuk Blowing BoilerRizal FauziNo ratings yet

- Lead Smelting Equipments - Aswathi Industries LimitedDocument1 pageLead Smelting Equipments - Aswathi Industries LimitedmOHITNo ratings yet

- KiranDocument16 pagesKiranLokeshNo ratings yet

- Study of Gas Lift MethodsDocument42 pagesStudy of Gas Lift MethodsMahesh100% (2)

- Presentation On Simhadri Unit-2 High VibrationDocument21 pagesPresentation On Simhadri Unit-2 High VibrationVIBHAV100% (1)

- Theoretical CyclesDocument49 pagesTheoretical CyclesMariaEzzaSyUy100% (1)

General: CRUDE OIL / Liquid 313.9 / 313.9

General: CRUDE OIL / Liquid 313.9 / 313.9

Uploaded by

amirOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General: CRUDE OIL / Liquid 313.9 / 313.9

General: CRUDE OIL / Liquid 313.9 / 313.9

Uploaded by

amirCopyright:

Available Formats

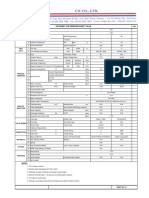

1. TAG No.

PRV-3507(In service)

2. QUANTITY 1

3. SERVICE Station Outlet PRVs

4. P&ID No 2055-ED-233-PR-PI-0001

5. LINE No. CRD-3-042-B7C3-3"-PT

GENERAL

6. BONNET TYPE Close Bonnet, Bolted

7. FULL NOZZLE / SEMI NOZZLE Full Nozzle

8. CONV./ BELLOWS/PILOT Conventional, Direct Spring-Op

9 NACE COMPLIANCE Required (Note 2 )

10 ENCLOSURE PROTECTION Zone 1 , Class IIB , T4

11 FLUID AND STATE CRUDE OIL / Liquid

12 REQUIRED CAPACITY (TOTAL / PER VALVE) 313.9 / 313.9

(M3/h)

13 MOLECULAR WEIGHT (kg/kmol) 218.9

14 SPECIFIC HEAT RATIO (Cp/Cv) 1.132

15 OPERATING PRESSURE (barg) 82.6

PROCESS 16 RELIEVING TEMPERATURE (°C) 10.54

17 NORMAL TEMPERATURE (°C) 10.45

18 SET PRESSURE (barg) 97.6

19 TOTAL BACK PRESSURE (barg) 4.6

20 OVER PRESSURE (barg) 10 %

21 COMPRESSIBILITY FACTOR 1.013

@ RELIEVING COND.

22 SIZE : INLET / OUTLET 3 "× 4"

CONNECTION 23 FLANGED OR SCREWED Flanged

24 RATING : INLET / OUTLET # 900 RTJ / # 150 RF

25 BODY & BONNET CS SA216-WCB

26 SEAT AND DISC AND SPINDLE SS 316

MATERIALS 27 RESILIENT SEAT SEAL VTA

28 GUIDE AND RINGS SS A297-HE

29 SPRING Incoel® X750

30 BELLOWS N/A

31 CAP. SCREWED OR BOLTED Screwed

OPTIONS 32 LEVER: PLAIN OR PACKED Packed

33 TEST GAG Yes

34 LIMIT SWITCH PRVs. 24 VDC , 2A - M 20*1.5 - Eex "d"

35 CODE API 520

BASIS 36 FIRE No

37 BLOCKED OUTLET Yes

38 CALC. AREA SQ. In² 1.271

SPECIFICATION 39 SELECTED AREA SQ. In² 1.453

S

(V.T.A) 40 ORIFICE DESIGNATION J (ASME)

41 MANUFACTURER

42 MODEL NO

Note :

1.According to API 521- (521, Guide for Pressure-Relieving and Depressuring Systems, 6th Edition ) And Design Code is ASME VIII.

2. All wetted parts shall be according to "NACE-MR-01-75-STD"

3.Process information are based on CRUDE OIL.

4. Vendor shall provide calculation (using API520 formula) sheet for each safety relife valve.

5. Multiple VALVE Application

You might also like

- Data Sheet For PSVDocument1 pageData Sheet For PSVBABILIN VNo ratings yet

- General: Crude Oil - 219 Crude Oil - 219 1.117 82.6Document1 pageGeneral: Crude Oil - 219 Crude Oil - 219 1.117 82.6amirNo ratings yet

- GeneralDocument1 pageGeneralamirNo ratings yet

- GeneralDocument1 pageGeneralamirNo ratings yet

- GeneralDocument1 pageGeneralamirNo ratings yet

- General: Crude Oil Crude Oil - 219 219 1.117 1.14Document1 pageGeneral: Crude Oil Crude Oil - 219 219 1.117 1.14amirNo ratings yet

- General: Crude Oil Crude Oil - 219 219Document1 pageGeneral: Crude Oil Crude Oil - 219 219amirNo ratings yet

- 2055 Ed 2FGGF7 B1 9Document1 page2055 Ed 2FGGF7 B1 9amirNo ratings yet

- General: Crude Oil - 219 1.117 4.6 Crude Oil - 219Document1 pageGeneral: Crude Oil - 219 1.117 4.6 Crude Oil - 219amirNo ratings yet

- 6-Pressure Safety ValveDocument1 page6-Pressure Safety ValveFari NazariNo ratings yet

- 141014.datasheet For PSV-1323Document2 pages141014.datasheet For PSV-1323ocanhthuNo ratings yet

- File 5Document1 pageFile 5VENKATACHALAM SUBBARAJNo ratings yet

- Ed0581b-1639e 01 Ap1Document5 pagesEd0581b-1639e 01 Ap1Erol DAĞNo ratings yet

- Final End User Data Sheets 15 Valves Tor Deshy Rev1Document15 pagesFinal End User Data Sheets 15 Valves Tor Deshy Rev1Ghofrane HNo ratings yet

- Severn GloconDocument6 pagesSevern GloconAmit Surti0% (1)

- HOJA DATOS PSVDocument9 pagesHOJA DATOS PSVRafael GarciaNo ratings yet

- DELUGE VALVES DATASHEET Rev.01Document1 pageDELUGE VALVES DATASHEET Rev.01moodydoodyNo ratings yet

- SA 980 P 11432 CS Globe Valve Rev T02Document3 pagesSA 980 P 11432 CS Globe Valve Rev T02altipatlar100% (1)

- Data Sheet For PSVDocument9 pagesData Sheet For PSVashams492No ratings yet

- PIC 1 /SIC-1 N/A N/A N/A N2 Secondary Barrier: Exhaust Filter Safety Valve Exhaust Filter Safety Valve ClassificationDocument2 pagesPIC 1 /SIC-1 N/A N/A N/A N2 Secondary Barrier: Exhaust Filter Safety Valve Exhaust Filter Safety Valve ClassificationRanchojiNo ratings yet

- SA 980 P 11433 CS Plug Valve Rev T02Document3 pagesSA 980 P 11433 CS Plug Valve Rev T02altipatlarNo ratings yet

- Severn Glocon Lot2Document5 pagesSevern Glocon Lot2Amit SurtiNo ratings yet

- 42 Mab 191Document5 pages42 Mab 191false mailNo ratings yet

- RFQ-12172 valves datasheetDocument2 pagesRFQ-12172 valves datasheetthillais7feNo ratings yet

- Magnetrol TD2-8D00-032 + Tma-A210-007Document1 pageMagnetrol TD2-8D00-032 + Tma-A210-007BRUNONo ratings yet

- E0805-220-V-903-120-3A (Latihan)Document65 pagesE0805-220-V-903-120-3A (Latihan)Sabrang LorNo ratings yet

- Spec SheetDocument7 pagesSpec SheetPatricia MirandaNo ratings yet

- Ras Gahreb Gas Treatment Plant: EN 10025-2-S355JR EN 10025-2-S355 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JRDocument1 pageRas Gahreb Gas Treatment Plant: EN 10025-2-S355JR EN 10025-2-S355 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JROmar WardehNo ratings yet

- 07-PSV-07 Folha de Dados ValbracDocument1 page07-PSV-07 Folha de Dados ValbracRODRIGO CARDOSONo ratings yet

- A307 Ius Uv DS 1201Document2 pagesA307 Ius Uv DS 1201smartravi222No ratings yet

- Tpp-Abe-Mp-1201-0004 - Data Sheet For Pig Launcher & Receiver - R2 - 13-May-2016Document9 pagesTpp-Abe-Mp-1201-0004 - Data Sheet For Pig Launcher & Receiver - R2 - 13-May-2016OlusayoNo ratings yet

- Datasheet For PSVDocument1 pageDatasheet For PSVlãng duNo ratings yet

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument6 pagesPressure Safety Valve-Preliminary Sizing: Input DataPIDNo ratings yet

- Atlas Copco India LTD.: Gas Process ApplicationDocument4 pagesAtlas Copco India LTD.: Gas Process ApplicationAmit SurtiNo ratings yet

- 01.data SheetDocument1 page01.data SheetBhargav PatelNo ratings yet

- Ps 138 Ma Data SheetDocument4 pagesPs 138 Ma Data SheetRutchelle BrunoNo ratings yet

- Pressure Vessels Data SheetDocument6 pagesPressure Vessels Data SheetPatricio LagosNo ratings yet

- Datasheet For Pressure Safety Valve - IfbDocument66 pagesDatasheet For Pressure Safety Valve - Ifbfathan fathullahNo ratings yet

- LT-401 Remoto RecipienteDocument1 pageLT-401 Remoto RecipienteGabriel CidNo ratings yet

- Booster Pump, 5 HP, 80 GPM X 180 FTDocument4 pagesBooster Pump, 5 HP, 80 GPM X 180 FTRutchelle BrunoNo ratings yet

- FEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0Document14 pagesFEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0ddaalayamoct313024No ratings yet

- Shell & Tube Gas HEATER EXCHANGER (P-1233002) : Srge/EsupDocument3 pagesShell & Tube Gas HEATER EXCHANGER (P-1233002) : Srge/EsupRobles DreschNo ratings yet

- 1-MVCP00116-885PSVr2 20210524100343 852 XDocument4 pages1-MVCP00116-885PSVr2 20210524100343 852 XŁukasz BolewskiNo ratings yet

- Pzem 33H224 3 Pumps 10 HPDocument4 pagesPzem 33H224 3 Pumps 10 HPRutchelle BrunoNo ratings yet

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument5 pagesPressure Safety Valve-Preliminary Sizing: Input DataTun Naing WinNo ratings yet

- Booster Pump Rainwater, 1 HP 1x230v, 60hzDocument4 pagesBooster Pump Rainwater, 1 HP 1x230v, 60hzRutchelle BrunoNo ratings yet

- Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Document3 pagesDs-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Panisa BanimaNo ratings yet

- Ras Gahreb Gas Treatment Plant: EN 10025-2-S275 JR EN 10025-2-S275 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JRDocument1 pageRas Gahreb Gas Treatment Plant: EN 10025-2-S275 JR EN 10025-2-S275 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JROmar WardehNo ratings yet

- Reactor Data Sheet: Sketch (Bundle / Nozzle Orientation) GeneralDocument1 pageReactor Data Sheet: Sketch (Bundle / Nozzle Orientation) GeneralAndrés SepúlvedaNo ratings yet

- KSB MIL Control Valves Specification V0998-SPECDocument36 pagesKSB MIL Control Valves Specification V0998-SPECNutan PowerNo ratings yet

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDocument2 pagesProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanNo ratings yet

- sdv 560Document1 pagesdv 560Charlyss AlfonsoNo ratings yet

- Damper DS - 1196DPR-430Document2 pagesDamper DS - 1196DPR-430harishcsharmaNo ratings yet

- A307 Ius FV DS 1311Document2 pagesA307 Ius FV DS 1311Ravi KumarNo ratings yet

- Strength Calculation Sheet For Item No. C-053-12Document297 pagesStrength Calculation Sheet For Item No. C-053-12Urdian Syah100% (1)

- 15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Document4 pages15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Umair A. KhanNo ratings yet

- Sa 980 P 11434 Cs Swing Check Valve Rev. t02Document3 pagesSa 980 P 11434 Cs Swing Check Valve Rev. t02altipatlar100% (1)

- KSB MIL Controls Limited Valve Specification SheetDocument2 pagesKSB MIL Controls Limited Valve Specification SheetPablo TorresNo ratings yet

- FS22-015-PR-DS-002-Rev A-Datasheets For Pressure Vacuum Safety ValveDocument1 pageFS22-015-PR-DS-002-Rev A-Datasheets For Pressure Vacuum Safety ValveMinh DoNo ratings yet

- Temperature Instruments Temperature InstrumentsDocument1 pageTemperature Instruments Temperature InstrumentsamirNo ratings yet

- Control Valve (Include On/Off Valve) Control Valve (Include On/Off Valve)Document1 pageControl Valve (Include On/Off Valve) Control Valve (Include On/Off Valve)amirNo ratings yet

- Attachment No. 8: Documents: DocumentsDocument1 pageAttachment No. 8: Documents: DocumentsamirNo ratings yet

- Attachment No. 6: Vendor Recommendation To Specifications: Vendor Recommendation To Specifications: Vendor Recommendation To SpecificationsDocument1 pageAttachment No. 6: Vendor Recommendation To Specifications: Vendor Recommendation To Specifications: Vendor Recommendation To SpecificationsamirNo ratings yet

- Safety and Relief Valve Safety and Relief ValveDocument1 pageSafety and Relief Valve Safety and Relief ValveamirNo ratings yet

- Safety Relief Valves Safety Relief ValvesDocument1 pageSafety Relief Valves Safety Relief ValvesamirNo ratings yet

- Attachment No. 7: Spare Part List: Spare Part ListDocument1 pageAttachment No. 7: Spare Part List: Spare Part ListamirNo ratings yet

- Attachment No. 5: Deviations / Exceptions To Specifications: Deviations / Exceptions To Specifications: Deviations / Exceptions To SpecificationsDocument1 pageAttachment No. 5: Deviations / Exceptions To Specifications: Deviations / Exceptions To Specifications: Deviations / Exceptions To SpecificationsamirNo ratings yet

- 2055 Ep 000 in MR 0006 B0 26Document1 page2055 Ep 000 in MR 0006 B0 26amirNo ratings yet

- COORDINATION MEETING (If Applicable) COORDINATION MEETING (If Applicable)Document1 pageCOORDINATION MEETING (If Applicable) COORDINATION MEETING (If Applicable)amirNo ratings yet

- 2055 Ep 000 in MR 0006 B0 35Document1 page2055 Ep 000 in MR 0006 B0 35amirNo ratings yet

- 10.4. Verification VerificationDocument1 page10.4. Verification VerificationamirNo ratings yet

- Attachement No. 1: Material Summary List Attachement No. 1: Material Summary ListDocument1 pageAttachement No. 1: Material Summary List Attachement No. 1: Material Summary ListamirNo ratings yet

- ClarificationDocument1 pageClarificationamirNo ratings yet

- 16.2. Special Tools Special ToolsDocument1 page16.2. Special Tools Special ToolsamirNo ratings yet

- 17.2. Checking of Vendors Documents Checking of Vendors DocumentsDocument1 page17.2. Checking of Vendors Documents Checking of Vendors DocumentsamirNo ratings yet

- 2055 Ep 000 in MR 0006 B0 11Document1 page2055 Ep 000 in MR 0006 B0 11amirNo ratings yet

- Attachement No. 3: Vendor Data Requirement (VDR) 1. Language 3: Vendor Data Requirement (VDR)Document1 pageAttachement No. 3: Vendor Data Requirement (VDR) 1. Language 3: Vendor Data Requirement (VDR)amirNo ratings yet

- Equipment/Materials Equipment/MaterialsDocument1 pageEquipment/Materials Equipment/MaterialsamirNo ratings yet

- Pre-Commissioning, Commissioning and Start Up Ning, Commissioning and Start Up Ning, Commissioning and Start UpDocument1 pagePre-Commissioning, Commissioning and Start Up Ning, Commissioning and Start Up Ning, Commissioning and Start UpamirNo ratings yet

- Comprehensive Descriptive Literature & Catalogue Comprehensive Descriptive Literature & CatalogueDocument1 pageComprehensive Descriptive Literature & Catalogue Comprehensive Descriptive Literature & CatalogueamirNo ratings yet

- Attachement No. 2: Letter of Conformity Attachement No. 2: Letter of ConformityDocument1 pageAttachement No. 2: Letter of Conformity Attachement No. 2: Letter of ConformityamirNo ratings yet

- QuotationDocument1 pageQuotationamirNo ratings yet

- Units: "Safety Relief Valves Safety Relief Valves"Document1 pageUnits: "Safety Relief Valves Safety Relief Valves"amirNo ratings yet

- General Notes 4.1. Design Responsibility Responsibility: "Safety Relief Valves Safety Relief Valves"Document1 pageGeneral Notes 4.1. Design Responsibility Responsibility: "Safety Relief Valves Safety Relief Valves"amirNo ratings yet

- 2055 Ep 000 in MR 0006 B0 25Document1 page2055 Ep 000 in MR 0006 B0 25amirNo ratings yet

- 2055 Ep 000 in MR 0006 B0 4Document1 page2055 Ep 000 in MR 0006 B0 4amirNo ratings yet

- Site ConditionsDocument1 pageSite ConditionsamirNo ratings yet

- General 1.1Document1 pageGeneral 1.1amirNo ratings yet

- 2055 Ep 000 in MR 0006 B0 7Document1 page2055 Ep 000 in MR 0006 B0 7amirNo ratings yet

- Steam Tracing For HfoDocument18 pagesSteam Tracing For HfoTsouki Tsouki0% (1)

- Dual Fuel EngineDocument13 pagesDual Fuel EngineVIKASNo ratings yet

- CONSOLIDATED For Power ServiceDocument20 pagesCONSOLIDATED For Power Servicenico andrew doylay SiahaanNo ratings yet

- 4 WNS Series Horizontal Gas Fired Oil BoilerDocument25 pages4 WNS Series Horizontal Gas Fired Oil Boilerfauzi endra100% (1)

- Fresh Water GeneratorDocument2 pagesFresh Water GeneratorAlberto Ramírez TorrensNo ratings yet

- DongFeng RICH-ZD25TCIDocument3 pagesDongFeng RICH-ZD25TCIEduardo Antonio Barria OjedaNo ratings yet

- Siemens SGen-1000A+Series Nov14Document4 pagesSiemens SGen-1000A+Series Nov14Jaylord CrisostomoNo ratings yet

- Boiler Types and Classifications - WikiDocument21 pagesBoiler Types and Classifications - WikiKarthik ChillaNo ratings yet

- Air Cooled Condensors: General DescriptionDocument7 pagesAir Cooled Condensors: General DescriptionRajeev MaheshwariNo ratings yet

- 5 Star Rated ACDocument3 pages5 Star Rated ACavr8784No ratings yet

- Belajar Kerusakan AlatDocument126 pagesBelajar Kerusakan AlatHijrah Saputro RaharjoNo ratings yet

- 25 CompressorsDocument8 pages25 CompressorsYosephanderNo ratings yet

- BTS Ac SystemDocument40 pagesBTS Ac Systemmohsinaliqureshi02No ratings yet

- ES EasyGrid 5kVA 10kVA 15kVA BrochureDocument4 pagesES EasyGrid 5kVA 10kVA 15kVA Brochuremayssa fadhlaouiNo ratings yet

- Condensate System PresentationDocument24 pagesCondensate System Presentationмing junNo ratings yet

- Seminar On Jet Engine: Submitted To: Submitted byDocument20 pagesSeminar On Jet Engine: Submitted To: Submitted bypavan kalyanNo ratings yet

- MEE Promotional Pages Gas Engine GS16R2PTKDocument2 pagesMEE Promotional Pages Gas Engine GS16R2PTKJusril A HidayatNo ratings yet

- Edc Power Plant FacilitiesDocument32 pagesEdc Power Plant FacilitiesMichael TayactacNo ratings yet

- PEDDocument2 pagesPEDAjay KumarNo ratings yet

- Gujarat Technological University: Project Report ON Scope of Utility Reduction in Chemical IndustryDocument24 pagesGujarat Technological University: Project Report ON Scope of Utility Reduction in Chemical IndustryPradeep SutharNo ratings yet

- 7 Assignment SolutionDocument4 pages7 Assignment SolutionBhavya AnoohyaNo ratings yet

- Case StudiesDocument32 pagesCase StudiesSE Electrical100% (2)

- Four Stroke Petrol EngineDocument12 pagesFour Stroke Petrol EngineSyed Zaheer SajjadNo ratings yet

- Brochure SMA Energy-System Home-En-14Document24 pagesBrochure SMA Energy-System Home-En-14Furqan HamidNo ratings yet

- Kebutuhan Steam Untuk Blowing BoilerDocument3 pagesKebutuhan Steam Untuk Blowing BoilerRizal FauziNo ratings yet

- Lead Smelting Equipments - Aswathi Industries LimitedDocument1 pageLead Smelting Equipments - Aswathi Industries LimitedmOHITNo ratings yet

- KiranDocument16 pagesKiranLokeshNo ratings yet

- Study of Gas Lift MethodsDocument42 pagesStudy of Gas Lift MethodsMahesh100% (2)

- Presentation On Simhadri Unit-2 High VibrationDocument21 pagesPresentation On Simhadri Unit-2 High VibrationVIBHAV100% (1)

- Theoretical CyclesDocument49 pagesTheoretical CyclesMariaEzzaSyUy100% (1)