Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

63 viewsHSE Assurance Checklist

HSE Assurance Checklist

Uploaded by

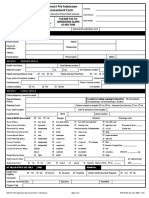

Nibu P ShajiThis document is an inspection checklist for HSE assurance for subcontractors working on a project to retube a cracker furnace. It contains criteria for inspecting scaffolds, power tools, housekeeping, general safety provisions, machinery/equipment, employee communications, personal protective equipment, and accommodation facilities. The inspector is to verify that all criteria are met and note any issues in the comments section.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- NUR 146 MCN2 RLE P2 ExamDocument22 pagesNUR 146 MCN2 RLE P2 ExamMarga WreatheNo ratings yet

- BTME HSE PlanDocument122 pagesBTME HSE PlanNibu P ShajiNo ratings yet

- GC3-NCC2 Practical Workbook Jan 17Document25 pagesGC3-NCC2 Practical Workbook Jan 17mevansmetreelNo ratings yet

- Nursing Documentation Final Course Exam IDocument5 pagesNursing Documentation Final Course Exam Iapi-329063194No ratings yet

- Holistic Treatment of Lyme DiseaseDocument54 pagesHolistic Treatment of Lyme Diseasefrederic9866No ratings yet

- PLU Building Safety Inspection ChecklistDocument5 pagesPLU Building Safety Inspection Checklistwidodo6286No ratings yet

- Workplace Vocabulary for Esl Students: With Exercises and TestsFrom EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsNo ratings yet

- IGC3 - The Health and Safety Practical ApplicationDocument12 pagesIGC3 - The Health and Safety Practical Applicationshaiku shaikhNo ratings yet

- COSHH Assessment Hsg97 HSEDocument57 pagesCOSHH Assessment Hsg97 HSEyasirNo ratings yet

- Sample Igc3 ReportDocument25 pagesSample Igc3 Reportfarhanhussain852100% (1)

- Weekly Progress Report 21 To 27 OCT2017Document2 pagesWeekly Progress Report 21 To 27 OCT2017Mehdi MessNo ratings yet

- Safety Officer Oil and Gas Interview GPT VersionDocument3 pagesSafety Officer Oil and Gas Interview GPT VersionSayeed MalikNo ratings yet

- Machinery Inspection ChecklistDocument3 pagesMachinery Inspection ChecklistrishibarathiNo ratings yet

- Material Handeling OCPDocument1 pageMaterial Handeling OCPAshwani KumarNo ratings yet

- Workplace Inspection Checklist: General Yes No NotesDocument4 pagesWorkplace Inspection Checklist: General Yes No NotesLakshmi BalaNo ratings yet

- Sample Ppe ProgramDocument4 pagesSample Ppe ProgramRizal DaudNo ratings yet

- Portsaid Tunnels Project: Date Project Supervisor LocationDocument8 pagesPortsaid Tunnels Project: Date Project Supervisor LocationMOHNISHKUMARJHANo ratings yet

- Hazards and PrecautionsDocument8 pagesHazards and Precautionsciucalata88No ratings yet

- Di3 0005 Eng QP V1Document7 pagesDi3 0005 Eng QP V1nevinrajtsNo ratings yet

- Confined Spaces CardsDocument1 pageConfined Spaces CardsJafar KhanNo ratings yet

- IOSH Managing SafelyDocument3 pagesIOSH Managing Safelyhsecouncil100% (1)

- IGC3 - Exam TemplateDocument18 pagesIGC3 - Exam TemplateAnas Shoaib50% (2)

- Compliance Assessment ToolsDocument1 pageCompliance Assessment ToolsJohn GriggsNo ratings yet

- Lab Design Guide ChecklistDocument9 pagesLab Design Guide ChecklistTanveer AzizNo ratings yet

- Safety Quiz - Answer PDFDocument1 pageSafety Quiz - Answer PDFRedzwan KadirNo ratings yet

- IMS-FR-016 High Height Work PermitDocument1 pageIMS-FR-016 High Height Work PermitSamsung NetworksNo ratings yet

- JsaDocument7 pagesJsaRiani KanayaNo ratings yet

- IGC3 - Exam TemplateDocument17 pagesIGC3 - Exam Templatevishal_sonari100% (1)

- SPV Contractor Prequalification Questionnaire - Safety AspectDocument3 pagesSPV Contractor Prequalification Questionnaire - Safety AspectdennisjuntakNo ratings yet

- Appendix1: Igc3 - The Health and Safety Practical ApplicationDocument25 pagesAppendix1: Igc3 - The Health and Safety Practical ApplicationAjmal MvNo ratings yet

- Incident Checklist: Other ActionsDocument1 pageIncident Checklist: Other Actionsloveson709No ratings yet

- International General Certificate Assessor's Marking Sheet (2011 Specification) Igc3 - The Health and Safety Practical ApplicationDocument11 pagesInternational General Certificate Assessor's Marking Sheet (2011 Specification) Igc3 - The Health and Safety Practical ApplicationVigneshwaraNo ratings yet

- Completed NGC3 ReportDocument4 pagesCompleted NGC3 ReportTiCu Constantin100% (1)

- Monthly Fire Prevention ChecklistDocument1 pageMonthly Fire Prevention ChecklistgkNo ratings yet

- NEW CL - JLA Steel Hand Tool - SWPDocument3 pagesNEW CL - JLA Steel Hand Tool - SWPAbdul Rafiq100% (1)

- 1.1 Buildings and FloorsDocument4 pages1.1 Buildings and FloorsMohamed Mouner100% (1)

- Igc3-The Health and Safety Practical ApplicationDocument21 pagesIgc3-The Health and Safety Practical ApplicationSamuel P SNo ratings yet

- 25 - Welding, Cutting and Hot WorkDocument16 pages25 - Welding, Cutting and Hot WorkRicardo DalisayNo ratings yet

- M. RPK. Environmental Incident Investigation and Reporting MARCH 2021Document57 pagesM. RPK. Environmental Incident Investigation and Reporting MARCH 2021randell vasquezNo ratings yet

- Environmental, Health & Safety: Methodology For Selecting and Implementing An EHS Management Information System (EMIS)Document50 pagesEnvironmental, Health & Safety: Methodology For Selecting and Implementing An EHS Management Information System (EMIS)Geroldo 'Rollie' L. QuerijeroNo ratings yet

- Creating and Maintaining An Effective CPD AccountDocument37 pagesCreating and Maintaining An Effective CPD AccountMohammed Amer PashaNo ratings yet

- Toolbox MeetingDocument15 pagesToolbox MeetingRich MondNo ratings yet

- Scheduling of Maintenance: Facility Inspection ChecklistDocument2 pagesScheduling of Maintenance: Facility Inspection ChecklistMayuri VarkeyNo ratings yet

- Job Safety Analysis For SupervisorDocument35 pagesJob Safety Analysis For SupervisorSayeed MalikNo ratings yet

- MS B4 - Monthly Report October 2023..Document23 pagesMS B4 - Monthly Report October 2023..safety.nagoor1992No ratings yet

- Ppe ChecklistDocument1 pagePpe ChecklistIvan BaraćNo ratings yet

- Driver Training Assessment ChecklistDocument6 pagesDriver Training Assessment Checklistsantiago morenoNo ratings yet

- Plant and Vicinity Checklists PDFDocument2 pagesPlant and Vicinity Checklists PDFmj santosNo ratings yet

- Chapter 1-Introduction To OshaDocument32 pagesChapter 1-Introduction To OshafettaneNo ratings yet

- Example Risk Assessment For A Bricklaying Company: Setting The SceneDocument9 pagesExample Risk Assessment For A Bricklaying Company: Setting The SceneSorin TecNo ratings yet

- A New GC3Document13 pagesA New GC3Hashim Raza0% (1)

- Description A B C N/A 1 Personal Protective EquipmentDocument3 pagesDescription A B C N/A 1 Personal Protective EquipmentZabidiIbrahimNo ratings yet

- INSP1 MobileCraneDailyInspectionDocument1 pageINSP1 MobileCraneDailyInspectionFuzail Ayaz100% (1)

- Integrated Management System (ISO 9001:2015 - 14001:2015 - ISO 45001:2018)Document2 pagesIntegrated Management System (ISO 9001:2015 - 14001:2015 - ISO 45001:2018)pjosesm100% (1)

- Annexure 9 - Declaration by The Subcontractor For HSE ComplianceDocument1 pageAnnexure 9 - Declaration by The Subcontractor For HSE ComplianceShamim Mahmudur RahmanNo ratings yet

- Permit To Work No.: - 1-General Information - 4 - Additional PrecautionsDocument3 pagesPermit To Work No.: - 1-General Information - 4 - Additional PrecautionsHenry WoartNo ratings yet

- NEBOSH International General Certificate in Occupational Health and SafetyDocument11 pagesNEBOSH International General Certificate in Occupational Health and Safetyananthu.uNo ratings yet

- White Paper Safety 4.0 PDFDocument9 pagesWhite Paper Safety 4.0 PDFAkhtar QuddusNo ratings yet

- Confined Space PlanDocument25 pagesConfined Space PlanPokiko MikotoNo ratings yet

- Fire Extinguisher Training: Firestop EngineersDocument37 pagesFire Extinguisher Training: Firestop Engineersganesha2011No ratings yet

- COSH HousekeepingDocument25 pagesCOSH HousekeepingJeff LugoNo ratings yet

- Training Needs AssessmentDocument5 pagesTraining Needs AssessmentahmadNo ratings yet

- Annotation 2023-02-19 175524Document1 pageAnnotation 2023-02-19 175524Nibu P ShajiNo ratings yet

- Posters A4Document9 pagesPosters A4Nibu P ShajiNo ratings yet

- PM Objectives RevDocument1 pagePM Objectives RevNibu P ShajiNo ratings yet

- Prost HoDocument1 pageProst HoNibu P ShajiNo ratings yet

- (A) PTW System Compliance-Borouge RetubingDocument4 pages(A) PTW System Compliance-Borouge RetubingNibu P ShajiNo ratings yet

- VehicleDocument3 pagesVehicleNibu P ShajiNo ratings yet

- Ad 466 - Emergency Contact Persons - 1Document1 pageAd 466 - Emergency Contact Persons - 1Nibu P ShajiNo ratings yet

- Hot Work in ProgressDocument1 pageHot Work in ProgressNibu P ShajiNo ratings yet

- ScaffoldingDocument1 pageScaffoldingNibu P ShajiNo ratings yet

- Safety Poster - Personal Protective Equipment Is MandatoryDocument1 pageSafety Poster - Personal Protective Equipment Is MandatoryNibu P ShajiNo ratings yet

- High Noise AreaDocument1 pageHigh Noise AreaNibu P ShajiNo ratings yet

- Project Visitor InductionDocument9 pagesProject Visitor InductionNibu P ShajiNo ratings yet

- 02 - 23 - HSEQ - Safety Moment - Moving Vehicles - TEC - Final - ENDocument2 pages02 - 23 - HSEQ - Safety Moment - Moving Vehicles - TEC - Final - ENNibu P ShajiNo ratings yet

- Worker WelfareDocument2 pagesWorker WelfareNibu P ShajiNo ratings yet

- Warning Letter TemplateDocument1 pageWarning Letter TemplateNibu P ShajiNo ratings yet

- Bilfinger Mock DrillDocument2 pagesBilfinger Mock DrillNibu P ShajiNo ratings yet

- FR - HSE - 061 - en Permit To Work Audit ChecklistDocument2 pagesFR - HSE - 061 - en Permit To Work Audit ChecklistNibu P ShajiNo ratings yet

- Blood TransfucionDocument2 pagesBlood TransfucionShreyas WalvekarNo ratings yet

- Suicide Term PaperDocument8 pagesSuicide Term Paperafdtvuzih100% (1)

- Week 5 Nightingale S TheoryDocument72 pagesWeek 5 Nightingale S TheoryAna PimentelNo ratings yet

- Asphalt - MC 800 (Superior) - Superior Refining Company, LLC (Husky Energy)Document11 pagesAsphalt - MC 800 (Superior) - Superior Refining Company, LLC (Husky Energy)Lindsey BondNo ratings yet

- Application Form For Health Intervention and Technology AssessmentDocument3 pagesApplication Form For Health Intervention and Technology AssessmentSonam PhuntshoNo ratings yet

- DSM Diagnostic CodesDocument6 pagesDSM Diagnostic CodesEdward Usca GamarraNo ratings yet

- Childhood Traumatic GriefDocument85 pagesChildhood Traumatic Griefmoi5566No ratings yet

- Pharmacy Practice-I MCQ: A. Nasal CongestionDocument62 pagesPharmacy Practice-I MCQ: A. Nasal CongestionJoyeeta Tahseen KhanNo ratings yet

- PG CQ Phase 1 Collegewise - RevisedDocument54 pagesPG CQ Phase 1 Collegewise - Revisedmanmohansai bacheNo ratings yet

- 2019 Developmentofthe PMGQand Prevalenceof Mobile Gaming Addiction Among Adolescentsin Taiwan Cyberpsychol Behav Soc NetwDocument8 pages2019 Developmentofthe PMGQand Prevalenceof Mobile Gaming Addiction Among Adolescentsin Taiwan Cyberpsychol Behav Soc NetwJr BagaporoNo ratings yet

- Islamic Integrated Cognitive Behavior Therapy: A Shari'ah-Compliant Intervention For Muslims With DepressionDocument10 pagesIslamic Integrated Cognitive Behavior Therapy: A Shari'ah-Compliant Intervention For Muslims With DepressionHANISAH BINTI ABDUL RAHMAN MIC173019No ratings yet

- Medtech Laws and Bioethics MTE 114Document3 pagesMedtech Laws and Bioethics MTE 114Lowin NavarroNo ratings yet

- Presentation 1Document15 pagesPresentation 1Sanjeevini KNo ratings yet

- EA1270 Value Education & EthicsDocument10 pagesEA1270 Value Education & Ethicsraclab sl109No ratings yet

- JSA NEW FORM - Penarikan Kabel FO 37Document6 pagesJSA NEW FORM - Penarikan Kabel FO 37Muchamad SalafudinNo ratings yet

- Sleep Predictors and Sleep Patterns - CarskadonDocument29 pagesSleep Predictors and Sleep Patterns - CarskadonScarlettBlondeNo ratings yet

- Procedures RationaleDocument3 pagesProcedures RationaleJamaica Leslie NovenoNo ratings yet

- Patient Admission Assessment FormDocument1 pagePatient Admission Assessment Formprasanna_326avanthiNo ratings yet

- CXC Social Studies Sba 2023Document27 pagesCXC Social Studies Sba 2023David DillonNo ratings yet

- Suchita Srivastava Chandigarh Case - 35395Document31 pagesSuchita Srivastava Chandigarh Case - 35395Disability Rights AllianceNo ratings yet

- Action Plan in Ok Sa Deped 2023-2024Document5 pagesAction Plan in Ok Sa Deped 2023-2024Evangeline Cansino100% (3)

- Hand Washing LessonDocument6 pagesHand Washing Lessonapi-278856455No ratings yet

- TOPIK 2. Reading Comprehension Tyjpes of NursesDocument6 pagesTOPIK 2. Reading Comprehension Tyjpes of NursesioakasNo ratings yet

- Indian Nutraceutical IndustryDocument64 pagesIndian Nutraceutical Industryhariom100% (2)

- SchizopreniaDocument3 pagesSchizopreniaLillabinNo ratings yet

- Amoebiasis DiseaseDocument10 pagesAmoebiasis Diseaseshruti ghordadeNo ratings yet

- Debretabor Universty: OF Access To ServicesDocument39 pagesDebretabor Universty: OF Access To ServicesGetahun BirhanuNo ratings yet

HSE Assurance Checklist

HSE Assurance Checklist

Uploaded by

Nibu P Shaji0 ratings0% found this document useful (0 votes)

63 views3 pagesThis document is an inspection checklist for HSE assurance for subcontractors working on a project to retube a cracker furnace. It contains criteria for inspecting scaffolds, power tools, housekeeping, general safety provisions, machinery/equipment, employee communications, personal protective equipment, and accommodation facilities. The inspector is to verify that all criteria are met and note any issues in the comments section.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is an inspection checklist for HSE assurance for subcontractors working on a project to retube a cracker furnace. It contains criteria for inspecting scaffolds, power tools, housekeeping, general safety provisions, machinery/equipment, employee communications, personal protective equipment, and accommodation facilities. The inspector is to verify that all criteria are met and note any issues in the comments section.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

63 views3 pagesHSE Assurance Checklist

HSE Assurance Checklist

Uploaded by

Nibu P ShajiThis document is an inspection checklist for HSE assurance for subcontractors working on a project to retube a cracker furnace. It contains criteria for inspecting scaffolds, power tools, housekeeping, general safety provisions, machinery/equipment, employee communications, personal protective equipment, and accommodation facilities. The inspector is to verify that all criteria are met and note any issues in the comments section.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 3

HSE Assurance for Subcontractors

Project: Retubing of Cracker Furnace Date:

Inspection Criteria Yes No Comments

A. Scaffolds

1. All scaffold parts and hardware used as required?

2. All scaffold hardware and parts in good condition?

3. Scaffolds fully planked?

4. All scaffold planks cleaned?

5. Scaffolds have guardrails, midrail and toe boards?

B. Power Tools

1. Power tools have guards in place?

2. Power tools either grounded or double insulated?

3. Power tool cords and plugs in good condition?

4. Impact tools with mushroomed heads dressed as needed?

5. Broken tools repaired or replaced as needed?

C. Housekeeping

1. Walkways kept clear of material and debris?

2. Cords and hoses strung to prevent trip and fall hazard?

3. Are liquid spills cleaned up immediately?

4. Restrooms and eating areas clean?

5. Fabrication and work areas clean and orderly?

6. Trash, scrap, and debris picked up and disposed of?

D. General

1. Emergency phone numbers and procedures posted?

2. First aid supplies readily available?

3. First aid supplies adequate for job manpower?

4. Required posters and signs posted and readable?

5. Valid Health Insurance Card for all employees?

E. Machineries / Equipment / Vehicles

1. Area around machineries/equipment clean

HSE Assurance for Subcontractors

Project: Retubing of Cracker Furnace Date:

2. Machineries/equipment maintained and in good condition

3. Machineries/equipment cannot be operated/accessed when left unattended

4. Emergency stops are working

5. Machine guarding in place

6. Warning labels/procedures on Machines / equipment

7. Power leads in good condition

8. Third Party agency certified machineries/equipment?

9. Vehicles Inspected regularly?

10. Vehicle Insurance, Registration Card, Driver License Available?

11. First Aid Kit, Safety Triangle & Fire Extinguisher Provided in all vehicles?

F. Employee Communications

1. Do foremen communicate with their crews on job methods? (TBT)

2. Do foremen react to employee safety recommendations?

3. Do foremen address unsafe actions and conditions?

4. Are safety meetings held weekly with all employees?

5. Job Specific training given to all employees?

G. Personal Protective Equipment

1. Hard hats worn by all personnel in work areas?

2. Eye and face protection worn as required?

3. Hearing protection worn as required?

4. Respiratory protection worn as required?

5. Safety harnesses and lanyards worn for fall protection?

6. Safety harnesses Inspected?

7. Workers dressed properly for the job?

8. Personal protective equipment in good condition?

9. Safety supplies adequate for job manpower?

I. Accommodation

1. Camp/accommodation buildings are in good condition.

HSE Assurance for Subcontractors

Project: Retubing of Cracker Furnace Date:

2. The electrical supply network and infrastructure has adequate capacity to

safely meet the lighting, power and cooling load, including all reasonable

communal living in the camp/accommodation facilities and services within it.

3. Air conditioning is provided and is fully functional in all accommodation and

recreation areas.

4. Bedrooms are clean, tidy & pest free

5. Appropriate sanitary facilities/appliances provided

Completed By:

Name:

Designation:

Signature:

Date:

You might also like

- NUR 146 MCN2 RLE P2 ExamDocument22 pagesNUR 146 MCN2 RLE P2 ExamMarga WreatheNo ratings yet

- BTME HSE PlanDocument122 pagesBTME HSE PlanNibu P ShajiNo ratings yet

- GC3-NCC2 Practical Workbook Jan 17Document25 pagesGC3-NCC2 Practical Workbook Jan 17mevansmetreelNo ratings yet

- Nursing Documentation Final Course Exam IDocument5 pagesNursing Documentation Final Course Exam Iapi-329063194No ratings yet

- Holistic Treatment of Lyme DiseaseDocument54 pagesHolistic Treatment of Lyme Diseasefrederic9866No ratings yet

- PLU Building Safety Inspection ChecklistDocument5 pagesPLU Building Safety Inspection Checklistwidodo6286No ratings yet

- Workplace Vocabulary for Esl Students: With Exercises and TestsFrom EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsNo ratings yet

- IGC3 - The Health and Safety Practical ApplicationDocument12 pagesIGC3 - The Health and Safety Practical Applicationshaiku shaikhNo ratings yet

- COSHH Assessment Hsg97 HSEDocument57 pagesCOSHH Assessment Hsg97 HSEyasirNo ratings yet

- Sample Igc3 ReportDocument25 pagesSample Igc3 Reportfarhanhussain852100% (1)

- Weekly Progress Report 21 To 27 OCT2017Document2 pagesWeekly Progress Report 21 To 27 OCT2017Mehdi MessNo ratings yet

- Safety Officer Oil and Gas Interview GPT VersionDocument3 pagesSafety Officer Oil and Gas Interview GPT VersionSayeed MalikNo ratings yet

- Machinery Inspection ChecklistDocument3 pagesMachinery Inspection ChecklistrishibarathiNo ratings yet

- Material Handeling OCPDocument1 pageMaterial Handeling OCPAshwani KumarNo ratings yet

- Workplace Inspection Checklist: General Yes No NotesDocument4 pagesWorkplace Inspection Checklist: General Yes No NotesLakshmi BalaNo ratings yet

- Sample Ppe ProgramDocument4 pagesSample Ppe ProgramRizal DaudNo ratings yet

- Portsaid Tunnels Project: Date Project Supervisor LocationDocument8 pagesPortsaid Tunnels Project: Date Project Supervisor LocationMOHNISHKUMARJHANo ratings yet

- Hazards and PrecautionsDocument8 pagesHazards and Precautionsciucalata88No ratings yet

- Di3 0005 Eng QP V1Document7 pagesDi3 0005 Eng QP V1nevinrajtsNo ratings yet

- Confined Spaces CardsDocument1 pageConfined Spaces CardsJafar KhanNo ratings yet

- IOSH Managing SafelyDocument3 pagesIOSH Managing Safelyhsecouncil100% (1)

- IGC3 - Exam TemplateDocument18 pagesIGC3 - Exam TemplateAnas Shoaib50% (2)

- Compliance Assessment ToolsDocument1 pageCompliance Assessment ToolsJohn GriggsNo ratings yet

- Lab Design Guide ChecklistDocument9 pagesLab Design Guide ChecklistTanveer AzizNo ratings yet

- Safety Quiz - Answer PDFDocument1 pageSafety Quiz - Answer PDFRedzwan KadirNo ratings yet

- IMS-FR-016 High Height Work PermitDocument1 pageIMS-FR-016 High Height Work PermitSamsung NetworksNo ratings yet

- JsaDocument7 pagesJsaRiani KanayaNo ratings yet

- IGC3 - Exam TemplateDocument17 pagesIGC3 - Exam Templatevishal_sonari100% (1)

- SPV Contractor Prequalification Questionnaire - Safety AspectDocument3 pagesSPV Contractor Prequalification Questionnaire - Safety AspectdennisjuntakNo ratings yet

- Appendix1: Igc3 - The Health and Safety Practical ApplicationDocument25 pagesAppendix1: Igc3 - The Health and Safety Practical ApplicationAjmal MvNo ratings yet

- Incident Checklist: Other ActionsDocument1 pageIncident Checklist: Other Actionsloveson709No ratings yet

- International General Certificate Assessor's Marking Sheet (2011 Specification) Igc3 - The Health and Safety Practical ApplicationDocument11 pagesInternational General Certificate Assessor's Marking Sheet (2011 Specification) Igc3 - The Health and Safety Practical ApplicationVigneshwaraNo ratings yet

- Completed NGC3 ReportDocument4 pagesCompleted NGC3 ReportTiCu Constantin100% (1)

- Monthly Fire Prevention ChecklistDocument1 pageMonthly Fire Prevention ChecklistgkNo ratings yet

- NEW CL - JLA Steel Hand Tool - SWPDocument3 pagesNEW CL - JLA Steel Hand Tool - SWPAbdul Rafiq100% (1)

- 1.1 Buildings and FloorsDocument4 pages1.1 Buildings and FloorsMohamed Mouner100% (1)

- Igc3-The Health and Safety Practical ApplicationDocument21 pagesIgc3-The Health and Safety Practical ApplicationSamuel P SNo ratings yet

- 25 - Welding, Cutting and Hot WorkDocument16 pages25 - Welding, Cutting and Hot WorkRicardo DalisayNo ratings yet

- M. RPK. Environmental Incident Investigation and Reporting MARCH 2021Document57 pagesM. RPK. Environmental Incident Investigation and Reporting MARCH 2021randell vasquezNo ratings yet

- Environmental, Health & Safety: Methodology For Selecting and Implementing An EHS Management Information System (EMIS)Document50 pagesEnvironmental, Health & Safety: Methodology For Selecting and Implementing An EHS Management Information System (EMIS)Geroldo 'Rollie' L. QuerijeroNo ratings yet

- Creating and Maintaining An Effective CPD AccountDocument37 pagesCreating and Maintaining An Effective CPD AccountMohammed Amer PashaNo ratings yet

- Toolbox MeetingDocument15 pagesToolbox MeetingRich MondNo ratings yet

- Scheduling of Maintenance: Facility Inspection ChecklistDocument2 pagesScheduling of Maintenance: Facility Inspection ChecklistMayuri VarkeyNo ratings yet

- Job Safety Analysis For SupervisorDocument35 pagesJob Safety Analysis For SupervisorSayeed MalikNo ratings yet

- MS B4 - Monthly Report October 2023..Document23 pagesMS B4 - Monthly Report October 2023..safety.nagoor1992No ratings yet

- Ppe ChecklistDocument1 pagePpe ChecklistIvan BaraćNo ratings yet

- Driver Training Assessment ChecklistDocument6 pagesDriver Training Assessment Checklistsantiago morenoNo ratings yet

- Plant and Vicinity Checklists PDFDocument2 pagesPlant and Vicinity Checklists PDFmj santosNo ratings yet

- Chapter 1-Introduction To OshaDocument32 pagesChapter 1-Introduction To OshafettaneNo ratings yet

- Example Risk Assessment For A Bricklaying Company: Setting The SceneDocument9 pagesExample Risk Assessment For A Bricklaying Company: Setting The SceneSorin TecNo ratings yet

- A New GC3Document13 pagesA New GC3Hashim Raza0% (1)

- Description A B C N/A 1 Personal Protective EquipmentDocument3 pagesDescription A B C N/A 1 Personal Protective EquipmentZabidiIbrahimNo ratings yet

- INSP1 MobileCraneDailyInspectionDocument1 pageINSP1 MobileCraneDailyInspectionFuzail Ayaz100% (1)

- Integrated Management System (ISO 9001:2015 - 14001:2015 - ISO 45001:2018)Document2 pagesIntegrated Management System (ISO 9001:2015 - 14001:2015 - ISO 45001:2018)pjosesm100% (1)

- Annexure 9 - Declaration by The Subcontractor For HSE ComplianceDocument1 pageAnnexure 9 - Declaration by The Subcontractor For HSE ComplianceShamim Mahmudur RahmanNo ratings yet

- Permit To Work No.: - 1-General Information - 4 - Additional PrecautionsDocument3 pagesPermit To Work No.: - 1-General Information - 4 - Additional PrecautionsHenry WoartNo ratings yet

- NEBOSH International General Certificate in Occupational Health and SafetyDocument11 pagesNEBOSH International General Certificate in Occupational Health and Safetyananthu.uNo ratings yet

- White Paper Safety 4.0 PDFDocument9 pagesWhite Paper Safety 4.0 PDFAkhtar QuddusNo ratings yet

- Confined Space PlanDocument25 pagesConfined Space PlanPokiko MikotoNo ratings yet

- Fire Extinguisher Training: Firestop EngineersDocument37 pagesFire Extinguisher Training: Firestop Engineersganesha2011No ratings yet

- COSH HousekeepingDocument25 pagesCOSH HousekeepingJeff LugoNo ratings yet

- Training Needs AssessmentDocument5 pagesTraining Needs AssessmentahmadNo ratings yet

- Annotation 2023-02-19 175524Document1 pageAnnotation 2023-02-19 175524Nibu P ShajiNo ratings yet

- Posters A4Document9 pagesPosters A4Nibu P ShajiNo ratings yet

- PM Objectives RevDocument1 pagePM Objectives RevNibu P ShajiNo ratings yet

- Prost HoDocument1 pageProst HoNibu P ShajiNo ratings yet

- (A) PTW System Compliance-Borouge RetubingDocument4 pages(A) PTW System Compliance-Borouge RetubingNibu P ShajiNo ratings yet

- VehicleDocument3 pagesVehicleNibu P ShajiNo ratings yet

- Ad 466 - Emergency Contact Persons - 1Document1 pageAd 466 - Emergency Contact Persons - 1Nibu P ShajiNo ratings yet

- Hot Work in ProgressDocument1 pageHot Work in ProgressNibu P ShajiNo ratings yet

- ScaffoldingDocument1 pageScaffoldingNibu P ShajiNo ratings yet

- Safety Poster - Personal Protective Equipment Is MandatoryDocument1 pageSafety Poster - Personal Protective Equipment Is MandatoryNibu P ShajiNo ratings yet

- High Noise AreaDocument1 pageHigh Noise AreaNibu P ShajiNo ratings yet

- Project Visitor InductionDocument9 pagesProject Visitor InductionNibu P ShajiNo ratings yet

- 02 - 23 - HSEQ - Safety Moment - Moving Vehicles - TEC - Final - ENDocument2 pages02 - 23 - HSEQ - Safety Moment - Moving Vehicles - TEC - Final - ENNibu P ShajiNo ratings yet

- Worker WelfareDocument2 pagesWorker WelfareNibu P ShajiNo ratings yet

- Warning Letter TemplateDocument1 pageWarning Letter TemplateNibu P ShajiNo ratings yet

- Bilfinger Mock DrillDocument2 pagesBilfinger Mock DrillNibu P ShajiNo ratings yet

- FR - HSE - 061 - en Permit To Work Audit ChecklistDocument2 pagesFR - HSE - 061 - en Permit To Work Audit ChecklistNibu P ShajiNo ratings yet

- Blood TransfucionDocument2 pagesBlood TransfucionShreyas WalvekarNo ratings yet

- Suicide Term PaperDocument8 pagesSuicide Term Paperafdtvuzih100% (1)

- Week 5 Nightingale S TheoryDocument72 pagesWeek 5 Nightingale S TheoryAna PimentelNo ratings yet

- Asphalt - MC 800 (Superior) - Superior Refining Company, LLC (Husky Energy)Document11 pagesAsphalt - MC 800 (Superior) - Superior Refining Company, LLC (Husky Energy)Lindsey BondNo ratings yet

- Application Form For Health Intervention and Technology AssessmentDocument3 pagesApplication Form For Health Intervention and Technology AssessmentSonam PhuntshoNo ratings yet

- DSM Diagnostic CodesDocument6 pagesDSM Diagnostic CodesEdward Usca GamarraNo ratings yet

- Childhood Traumatic GriefDocument85 pagesChildhood Traumatic Griefmoi5566No ratings yet

- Pharmacy Practice-I MCQ: A. Nasal CongestionDocument62 pagesPharmacy Practice-I MCQ: A. Nasal CongestionJoyeeta Tahseen KhanNo ratings yet

- PG CQ Phase 1 Collegewise - RevisedDocument54 pagesPG CQ Phase 1 Collegewise - Revisedmanmohansai bacheNo ratings yet

- 2019 Developmentofthe PMGQand Prevalenceof Mobile Gaming Addiction Among Adolescentsin Taiwan Cyberpsychol Behav Soc NetwDocument8 pages2019 Developmentofthe PMGQand Prevalenceof Mobile Gaming Addiction Among Adolescentsin Taiwan Cyberpsychol Behav Soc NetwJr BagaporoNo ratings yet

- Islamic Integrated Cognitive Behavior Therapy: A Shari'ah-Compliant Intervention For Muslims With DepressionDocument10 pagesIslamic Integrated Cognitive Behavior Therapy: A Shari'ah-Compliant Intervention For Muslims With DepressionHANISAH BINTI ABDUL RAHMAN MIC173019No ratings yet

- Medtech Laws and Bioethics MTE 114Document3 pagesMedtech Laws and Bioethics MTE 114Lowin NavarroNo ratings yet

- Presentation 1Document15 pagesPresentation 1Sanjeevini KNo ratings yet

- EA1270 Value Education & EthicsDocument10 pagesEA1270 Value Education & Ethicsraclab sl109No ratings yet

- JSA NEW FORM - Penarikan Kabel FO 37Document6 pagesJSA NEW FORM - Penarikan Kabel FO 37Muchamad SalafudinNo ratings yet

- Sleep Predictors and Sleep Patterns - CarskadonDocument29 pagesSleep Predictors and Sleep Patterns - CarskadonScarlettBlondeNo ratings yet

- Procedures RationaleDocument3 pagesProcedures RationaleJamaica Leslie NovenoNo ratings yet

- Patient Admission Assessment FormDocument1 pagePatient Admission Assessment Formprasanna_326avanthiNo ratings yet

- CXC Social Studies Sba 2023Document27 pagesCXC Social Studies Sba 2023David DillonNo ratings yet

- Suchita Srivastava Chandigarh Case - 35395Document31 pagesSuchita Srivastava Chandigarh Case - 35395Disability Rights AllianceNo ratings yet

- Action Plan in Ok Sa Deped 2023-2024Document5 pagesAction Plan in Ok Sa Deped 2023-2024Evangeline Cansino100% (3)

- Hand Washing LessonDocument6 pagesHand Washing Lessonapi-278856455No ratings yet

- TOPIK 2. Reading Comprehension Tyjpes of NursesDocument6 pagesTOPIK 2. Reading Comprehension Tyjpes of NursesioakasNo ratings yet

- Indian Nutraceutical IndustryDocument64 pagesIndian Nutraceutical Industryhariom100% (2)

- SchizopreniaDocument3 pagesSchizopreniaLillabinNo ratings yet

- Amoebiasis DiseaseDocument10 pagesAmoebiasis Diseaseshruti ghordadeNo ratings yet

- Debretabor Universty: OF Access To ServicesDocument39 pagesDebretabor Universty: OF Access To ServicesGetahun BirhanuNo ratings yet