Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

27 viewsGraphene Oxide As Nano Material in High Strength Self-Compacting Concrete

Graphene Oxide As Nano Material in High Strength Self-Compacting Concrete

Uploaded by

ElZahraa Said1) The document describes the materials and step-by-step process used to fabricate graphene oxide (GO) using a modified Hummers method. Key materials included graphite, sodium nitrate, sulfuric acid, potassium permanganate, hydrogen peroxide, hydrochloric acid, silver nitrate, ethanol, and distilled water.

2) The process involves adding graphite and sodium nitrate to sulfuric acid on ice, then adding potassium permanganate and continuing to stir. The mixture is then heated and water is added. Hydrogen peroxide is added, then the solution is filtered, washed, and tested to check for chloride contamination removal before collecting the final brown GO powder.

3)

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Exp 10: Synthesis of (Co (NH3) 5Cl) Cl2Document8 pagesExp 10: Synthesis of (Co (NH3) 5Cl) Cl2Marla Basa95% (20)

- Lab Report (Final Editied)Document8 pagesLab Report (Final Editied)Alexia Channer100% (4)

- Organic Syntheses Collective Volume 3Document1,060 pagesOrganic Syntheses Collective Volume 3caltexas100% (5)

- Cleopatra MallDocument27 pagesCleopatra MallElZahraa Said100% (1)

- Chemistry Lab Report 1212Document9 pagesChemistry Lab Report 1212api-284826801No ratings yet

- Lab Report Experiment 3 4 and 5Document13 pagesLab Report Experiment 3 4 and 5Nurul Iman Che Awang90% (40)

- Experiments in Organotin ChemistryDocument10 pagesExperiments in Organotin ChemistryAinul Syahirah OmarNo ratings yet

- ASTM - d-1730-03 Standard Practices For Preparation of Aluminum and Aluminum Alloy Surfaces For Painting PDFDocument3 pagesASTM - d-1730-03 Standard Practices For Preparation of Aluminum and Aluminum Alloy Surfaces For Painting PDFAdrian OrtizNo ratings yet

- Seminar ReportDocument14 pagesSeminar ReportPoonam0242No ratings yet

- Synthesis of 1-Amino-2 - (4 - Methoxycarbonyl Ethyl-2 - Methyl) - Phenoxy-4-Hydroxy AnthraquinoneDocument4 pagesSynthesis of 1-Amino-2 - (4 - Methoxycarbonyl Ethyl-2 - Methyl) - Phenoxy-4-Hydroxy AnthraquinoneGhulam MurtazaNo ratings yet

- Jclinpath00001 0034Document4 pagesJclinpath00001 0034sachithudaraNo ratings yet

- Pce SopDocument2 pagesPce SopA MallikNo ratings yet

- Extraction of Silica From Puddy HuskDocument19 pagesExtraction of Silica From Puddy HuskFauzaan KhanNo ratings yet

- Jlpga S 07Document16 pagesJlpga S 07hopkhtnNo ratings yet

- Full Lab Report Exp3Document12 pagesFull Lab Report Exp3keyRien0% (1)

- Ctalyst DesignDocument35 pagesCtalyst DesignmatushriNo ratings yet

- Analytical Method of Total Nitrogen, Phosphorus and Potassium Content in Water Soluble FertilizersDocument12 pagesAnalytical Method of Total Nitrogen, Phosphorus and Potassium Content in Water Soluble FertilizersGenaro PalacioNo ratings yet

- Analytical Method of Total Nitrogen, Phosphorus and Potassium Content in Water Soluble FertilizersDocument12 pagesAnalytical Method of Total Nitrogen, Phosphorus and Potassium Content in Water Soluble FertilizersGenaro PalacioNo ratings yet

- CNTsDocument10 pagesCNTsAisha ranaNo ratings yet

- Jo102169t Si 002Document39 pagesJo102169t Si 002jjoaquincvNo ratings yet

- Ojic 2016042713213847 PDFDocument10 pagesOjic 2016042713213847 PDFJesha LibreaNo ratings yet

- Determination of The Valency of MagnesiumDocument7 pagesDetermination of The Valency of MagnesiumJiaxinOoiNo ratings yet

- VI Baltic Chemistry OlympiadDocument2 pagesVI Baltic Chemistry OlympiadYarga Puritza100% (1)

- Carbohydrates LabDocument20 pagesCarbohydrates LabChristian Dave MativoNo ratings yet

- Experiment 1Document4 pagesExperiment 1Sindiswa Minenhle MngadiNo ratings yet

- 2.1. Preparation of Actived Solid PhasesDocument4 pages2.1. Preparation of Actived Solid PhasesedibuhNo ratings yet

- Organic Matter Determination (Walkley - Black Method)Document5 pagesOrganic Matter Determination (Walkley - Black Method)FIORELLA GLADYS RODRIGUEZ RAMIREZNo ratings yet

- CHM 474 Exp 3 4 5Document15 pagesCHM 474 Exp 3 4 5Syafiqah Ck100% (3)

- Acid Cleaning of Impurities in Natural Circulation High Pressure Drum BoilerDocument7 pagesAcid Cleaning of Impurities in Natural Circulation High Pressure Drum BoilerNeeraj HegdeNo ratings yet

- Treatment of Hydrogen Sulfide Gas Generated in Landfill SitesDocument7 pagesTreatment of Hydrogen Sulfide Gas Generated in Landfill SitesOmar MorónNo ratings yet

- Treatment of Hydrogen Sulfide Gas Generated in Landfill SitesDocument7 pagesTreatment of Hydrogen Sulfide Gas Generated in Landfill SitesOmar MorónNo ratings yet

- Estimation Lactic AcidDocument20 pagesEstimation Lactic AcidpilotplanthtbsNo ratings yet

- Recovery of Germanium by Precipitation From Strongly Alkaline SolutionDocument10 pagesRecovery of Germanium by Precipitation From Strongly Alkaline SolutionGEOLINKS International Conference 2019No ratings yet

- Synthesis of Graphene Oxide-Porphyrin Nanocomposite and Its Application in Removal of Toxic MetalsDocument11 pagesSynthesis of Graphene Oxide-Porphyrin Nanocomposite and Its Application in Removal of Toxic MetalsFamiloni LayoNo ratings yet

- The Modified Fenton Process For Decolorization of Dye WastewaterDocument5 pagesThe Modified Fenton Process For Decolorization of Dye Wastewatermemo_gh89No ratings yet

- Preparation of n-Isopropylidene-n'-2-Nitrobenzenesulfonyl Hydrazine (IPNBSH) and Its Use in Palladium-Catalyzed Synthesis of Monoalkyl Diazenes. Synthesis of 9-AllylanthraceneDocument22 pagesPreparation of n-Isopropylidene-n'-2-Nitrobenzenesulfonyl Hydrazine (IPNBSH) and Its Use in Palladium-Catalyzed Synthesis of Monoalkyl Diazenes. Synthesis of 9-AllylanthraceneYami BaudelaireNo ratings yet

- GFAAS MercuryDocument23 pagesGFAAS MercuryAltaf Ur RehmanNo ratings yet

- Reduction Research PaperDocument3 pagesReduction Research PaperUdai PratapsinghNo ratings yet

- Synthesis, Characteristics and Analysis of Co (III) ComplexesDocument21 pagesSynthesis, Characteristics and Analysis of Co (III) ComplexesNguyễn Công TuyềnNo ratings yet

- MIL-101 CDC SupplDocument51 pagesMIL-101 CDC SupplAnkit MaharshiNo ratings yet

- Leaching of Soluble Constituents From MSW Following Anaerobic BiodegradationDocument9 pagesLeaching of Soluble Constituents From MSW Following Anaerobic BiodegradationMario WhoeverNo ratings yet

- Materials and Methods For Graphene SynthesisDocument3 pagesMaterials and Methods For Graphene SynthesisqamarNo ratings yet

- Estimation of Sulfur in Coal Samples by Rapid Combustion-Iodometric Titration MethodDocument4 pagesEstimation of Sulfur in Coal Samples by Rapid Combustion-Iodometric Titration MethodMetal deptNo ratings yet

- Thesis DataDocument14 pagesThesis DataHaseeb ChaudharyNo ratings yet

- Environmental Research & TechnologyDocument7 pagesEnvironmental Research & TechnologyRaouf BoucharebNo ratings yet

- Quantitativ Analysis Question SeriesDocument4 pagesQuantitativ Analysis Question Seriesshubh.chauhan014No ratings yet

- Laboratory Report CHM 153 (Inorganic Chemistry) : 1. Muhammad Mirza Hizami Bin RajieiDocument4 pagesLaboratory Report CHM 153 (Inorganic Chemistry) : 1. Muhammad Mirza Hizami Bin RajieiMuhd Mirza HizamiNo ratings yet

- Grinard Reagent LabDocument4 pagesGrinard Reagent LabZach McCartyNo ratings yet

- J. Biol. Chem. 1952 Somogyi 19 23Document6 pagesJ. Biol. Chem. 1952 Somogyi 19 23gibrambo5770No ratings yet

- Iso OriginalDocument2 pagesIso OriginalkakkienakkieNo ratings yet

- Molar Volume of Gas LabDocument3 pagesMolar Volume of Gas Labapi-216235465No ratings yet

- The Chemistry of The Aminochromes: Part Vi. The Reaction O F Adrenochrome With Glutathione' "3Document7 pagesThe Chemistry of The Aminochromes: Part Vi. The Reaction O F Adrenochrome With Glutathione' "3Nstm3No ratings yet

- Acetylated Starch Co2Document11 pagesAcetylated Starch Co2Amalia RizkaNo ratings yet

- School of Applied Natural SciencesDocument4 pagesSchool of Applied Natural Sciencesvk100No ratings yet

- Effect of Reflux Time and Cow Urine Concentration On Green Synthesis of Reduced Graphene Oxide (rGO)Document9 pagesEffect of Reflux Time and Cow Urine Concentration On Green Synthesis of Reduced Graphene Oxide (rGO)Medha GijareNo ratings yet

- Air Oxidation of Primary Alcohols Catalyzed by Copper (I) /TEMPO. Preparation of 2-Amino-5-Bromo-BenzaldehydeDocument15 pagesAir Oxidation of Primary Alcohols Catalyzed by Copper (I) /TEMPO. Preparation of 2-Amino-5-Bromo-BenzaldehydeCarlos GonzalezNo ratings yet

- Analisis Pangan (Karbohidrat) Bagian 2Document28 pagesAnalisis Pangan (Karbohidrat) Bagian 2arikuraNo ratings yet

- Experiment 32Document14 pagesExperiment 32Morgan Elizabeth Lepley100% (6)

- As Practical Calculations Worksheets - RedDocument14 pagesAs Practical Calculations Worksheets - RedKeniel YaoNo ratings yet

- FL SopDocument45 pagesFL SopSara JohnsonNo ratings yet

- Lab Report 2Document7 pagesLab Report 2刘哲宁No ratings yet

- Removal of The Ammonia Load of Landfill Leachate by Struvite Precipitation Using Low-Cost ReagentsDocument8 pagesRemoval of The Ammonia Load of Landfill Leachate by Struvite Precipitation Using Low-Cost ReagentsMario WhoeverNo ratings yet

- Supporting InformationDocument7 pagesSupporting InformationNGsalunkheNo ratings yet

- The Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresFrom EverandThe Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresRating: 5 out of 5 stars5/5 (1)

- A 6 1-Toilet-DetailDocument1 pageA 6 1-Toilet-DetailElZahraa SaidNo ratings yet

- Working DrawingsDocument33 pagesWorking DrawingsElZahraa SaidNo ratings yet

- Circulation Dynamics To Improve Commercial Activity in A Mega MallDocument8 pagesCirculation Dynamics To Improve Commercial Activity in A Mega MallElZahraa SaidNo ratings yet

- إدارة٢Document52 pagesإدارة٢ElZahraa SaidNo ratings yet

- حساب تكاليف ومتابعة أعمال المشاريعDocument23 pagesحساب تكاليف ومتابعة أعمال المشاريعElZahraa SaidNo ratings yet

- حصر الكميات للفيلاDocument9 pagesحصر الكميات للفيلاElZahraa SaidNo ratings yet

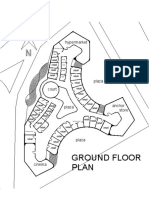

- Ground FloorDocument1 pageGround FloorElZahraa SaidNo ratings yet

- إدارة ١Document23 pagesإدارة ١ElZahraa SaidNo ratings yet

- Design Recover ModelDocument1 pageDesign Recover ModelElZahraa SaidNo ratings yet

- LayoutDocument1 pageLayoutElZahraa SaidNo ratings yet

- HSSCCDocument5 pagesHSSCCElZahraa SaidNo ratings yet

- Batta 2Document5 pagesBatta 2ElZahraa SaidNo ratings yet

- MaterialsDocument4 pagesMaterialsElZahraa SaidNo ratings yet

- IntroductionDocument2 pagesIntroductionElZahraa SaidNo ratings yet

- Concrete Mix Design For High Strength Self-Compacting Concrete Using MetakaolinDocument5 pagesConcrete Mix Design For High Strength Self-Compacting Concrete Using MetakaolinElZahraa SaidNo ratings yet

- Development of High-Strengh Self-Compacting ConcreDocument4 pagesDevelopment of High-Strengh Self-Compacting ConcreElZahraa SaidNo ratings yet

- Fresh and Hardened Properties of High Strength Self-Compacting Concrete Using By-Product Ferronickel Slag Fine Aggregate.Document6 pagesFresh and Hardened Properties of High Strength Self-Compacting Concrete Using By-Product Ferronickel Slag Fine Aggregate.ElZahraa SaidNo ratings yet

- HawasDocument4 pagesHawasElZahraa SaidNo ratings yet

- Understanding Loft Conversions SampleDocument18 pagesUnderstanding Loft Conversions SampleElZahraa SaidNo ratings yet

- Eco Design For A Villa in IsmailiaDocument1 pageEco Design For A Villa in IsmailiaElZahraa SaidNo ratings yet

- EsraaDocument5 pagesEsraaElZahraa SaidNo ratings yet

- Architecture Presentation Board TipsDocument4 pagesArchitecture Presentation Board TipsElZahraa SaidNo ratings yet

- Principles of Planning 2019 2ndDocument49 pagesPrinciples of Planning 2019 2ndElZahraa SaidNo ratings yet

- Irrigation Water QualityDocument47 pagesIrrigation Water QualityfarzanNo ratings yet

- API 510 Brittle FractureDocument50 pagesAPI 510 Brittle Fracturekihal zohirNo ratings yet

- Working With Moving Pulleys 6 PDFDocument8 pagesWorking With Moving Pulleys 6 PDFOyas DubeyNo ratings yet

- PD TopicDocument6 pagesPD TopicAnonymous Flh0GZNo ratings yet

- Chap 05BDocument13 pagesChap 05BAbhishek DasNo ratings yet

- Sizing and Wall ThicknessDocument37 pagesSizing and Wall ThicknessMuhammad NursalamNo ratings yet

- A Cellular Automata Simulation of Atomic Layer Etching Strotmann Et Al 1Document15 pagesA Cellular Automata Simulation of Atomic Layer Etching Strotmann Et Al 1pradeepkarraNo ratings yet

- Preparing For PUPCET Some of The FollowiDocument12 pagesPreparing For PUPCET Some of The Followibry yyy100% (2)

- Topic Take-Off Angle Calculations For Fault-Plane Solutions and Reconstruction of Nodal Planes From The Parameters of Fault-Plane SolutionsDocument6 pagesTopic Take-Off Angle Calculations For Fault-Plane Solutions and Reconstruction of Nodal Planes From The Parameters of Fault-Plane SolutionsFrancisco JavierNo ratings yet

- Colorimetric Methods in Biochemistry: Basma Ahmed Eltonsy 201816890Document4 pagesColorimetric Methods in Biochemistry: Basma Ahmed Eltonsy 201816890Basma EltonsyNo ratings yet

- Tittle: Design Basis: 500MTD TSP. Site Condition: We Have Chosen Feni As Our Plant LocationDocument5 pagesTittle: Design Basis: 500MTD TSP. Site Condition: We Have Chosen Feni As Our Plant Locationসাইদুর রহমানNo ratings yet

- COE Class Test Question-1Document1 pageCOE Class Test Question-1Rahul RajNo ratings yet

- Causes of Air PollutionDocument2 pagesCauses of Air PollutionSharon100% (2)

- Inspection and Testing PlantDocument27 pagesInspection and Testing PlantDaengkulle Firmansyah PuteraNo ratings yet

- Bray-B-1008 ProdProfile 06 07 2016Document13 pagesBray-B-1008 ProdProfile 06 07 2016Osvaldo Junges BomfimNo ratings yet

- Notes 13 DetonationsDocument13 pagesNotes 13 DetonationsBachir El FilNo ratings yet

- Collapse Analysis of Longitudinally Cracked HDPE PipeDocument11 pagesCollapse Analysis of Longitudinally Cracked HDPE PipeMicaela Sarina Alberti EmbonNo ratings yet

- Wastewater Engineering Advanced Wastewater Treatment Systems PDFDocument244 pagesWastewater Engineering Advanced Wastewater Treatment Systems PDFEr Govind Singh ChauhanNo ratings yet

- DPP - 02 Quantum Chemistry: CSIR-NET - IIT-GATE - IIT-JAM - Other Msc. EntranceDocument2 pagesDPP - 02 Quantum Chemistry: CSIR-NET - IIT-GATE - IIT-JAM - Other Msc. Entranceanurag pandeyNo ratings yet

- Asbuton Pracampur Antara Harapan Dan Kenyataan: Asbuton Premix Between Hope and RealityDocument11 pagesAsbuton Pracampur Antara Harapan Dan Kenyataan: Asbuton Premix Between Hope and RealityLabisal mouliNo ratings yet

- Chemical Sensors: Simulation and Modeling Volume 2: Conductometric-Type SensorsDocument69 pagesChemical Sensors: Simulation and Modeling Volume 2: Conductometric-Type SensorsMomentum PressNo ratings yet

- Computer Simulation To Predict Quality Changes of FoodDocument9 pagesComputer Simulation To Predict Quality Changes of FoodAdian RindangNo ratings yet

- Particle Physics: Georgia Karagiorgi Department of Physics, Columbia UniversityDocument81 pagesParticle Physics: Georgia Karagiorgi Department of Physics, Columbia UniversityDenis PetcuNo ratings yet

- Chemical KineticsDocument4 pagesChemical KineticsShubhankar SinhaNo ratings yet

- Sistemul PeriodicDocument1 pageSistemul PeriodicjurjlNo ratings yet

- Introduction To Nanoelectronics FinalDocument18 pagesIntroduction To Nanoelectronics Finalparmis1212No ratings yet

- Construction and Trial Experiment of A Small Size Thermo-Acoustic Refrigeration SystemDocument6 pagesConstruction and Trial Experiment of A Small Size Thermo-Acoustic Refrigeration SystemijeteeditorNo ratings yet

Graphene Oxide As Nano Material in High Strength Self-Compacting Concrete

Graphene Oxide As Nano Material in High Strength Self-Compacting Concrete

Uploaded by

ElZahraa Said0 ratings0% found this document useful (0 votes)

27 views3 pages1) The document describes the materials and step-by-step process used to fabricate graphene oxide (GO) using a modified Hummers method. Key materials included graphite, sodium nitrate, sulfuric acid, potassium permanganate, hydrogen peroxide, hydrochloric acid, silver nitrate, ethanol, and distilled water.

2) The process involves adding graphite and sodium nitrate to sulfuric acid on ice, then adding potassium permanganate and continuing to stir. The mixture is then heated and water is added. Hydrogen peroxide is added, then the solution is filtered, washed, and tested to check for chloride contamination removal before collecting the final brown GO powder.

3)

Original Description:

Original Title

Graphene oxide as Nano material in high strength self-compacting concrete

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) The document describes the materials and step-by-step process used to fabricate graphene oxide (GO) using a modified Hummers method. Key materials included graphite, sodium nitrate, sulfuric acid, potassium permanganate, hydrogen peroxide, hydrochloric acid, silver nitrate, ethanol, and distilled water.

2) The process involves adding graphite and sodium nitrate to sulfuric acid on ice, then adding potassium permanganate and continuing to stir. The mixture is then heated and water is added. Hydrogen peroxide is added, then the solution is filtered, washed, and tested to check for chloride contamination removal before collecting the final brown GO powder.

3)

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

27 views3 pagesGraphene Oxide As Nano Material in High Strength Self-Compacting Concrete

Graphene Oxide As Nano Material in High Strength Self-Compacting Concrete

Uploaded by

ElZahraa Said1) The document describes the materials and step-by-step process used to fabricate graphene oxide (GO) using a modified Hummers method. Key materials included graphite, sodium nitrate, sulfuric acid, potassium permanganate, hydrogen peroxide, hydrochloric acid, silver nitrate, ethanol, and distilled water.

2) The process involves adding graphite and sodium nitrate to sulfuric acid on ice, then adding potassium permanganate and continuing to stir. The mixture is then heated and water is added. Hydrogen peroxide is added, then the solution is filtered, washed, and tested to check for chloride contamination removal before collecting the final brown GO powder.

3)

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 3

1) Materials Used:

The integrant materials used in the research work to develop

HSSCC are:

-Ordinary Portland Cement (OPC)

-Silica-Fume

- GGBS

-Master Gluonium ACE 30 chemical admixture

- Graphite, Sodium

- nitrate (NaNo3)

- Concentrated sulfuric acid (98% H2SO4)

- Potassium

- permanganate (KMnO4)

- Hydrogen peroxide (30% H2O2)

- Hydrochloric acid (5% HCL)

- Silver nitrate

- ethanol and Distilled water

* Fabrication of Graphene Oxide (GO) in laboratory

The following is the step by step procedure for the preparation of GO using modified hummer’s method:

1. Initially, 5 g of graphite, 2 g of sodium nitrate and 30 ml of concentrated Sulphur acid was added to the

conical flask in ice bath with below 20_C and the flask with ice bath was placed on magnetic stirrer for 2

h.

2. After 2 h of continuous stirring, slowly 5 g of potassium permanganate was added to the reaction

mixture while maintaining the same temperature in the ice bath and continued stirring for another ½ hour.

Temperature should be constantly maintained, as increase in temperature results in explosion.

3. Mixture is taken out from ice bath and heated at 350C for ½ hour on magnetic stirrer with hot plate.

4. Next 100 ml of distilled water was added to the mixture and heated the mixture at 900C for 1 h.

5. Later the mixture was cooled at room temperature. After cooling, 300 ml of distilled water was added

and placed the mixture on magnetic stirrer for ½ hour.

6. After ½ hour 30 ml of hydrogen peroxide (30% H2O2) was added and placed the flask on magnetic

stirrer for ½ hour formed Graphene oxide with pH 1.

7. To regulate the PH, this solution was filtered and washed with 200 ml 30% HCL to convert metal ions

to chloride ions. Again, this is repeatedly washed using distilled water to remove chloride

contamination.

8. To check the complete removal of chloride ions, few drops of filtrate

has to be added to of silver nitrate solution and if no white

color appears then it’s clear that all the chlorides are removed.

9. Finally, it was washed with 200 ml of ethanol to get dry brown

color GO powder. Chemical composition of GO was identified

by EDS testing and the values are shown

2) Mix Proportions:

3) Tests:

4) Results and Discussion:

Compressive strength

The results of the compressive strength of HSSCC with GO on

150 mm cube specimen at the end of 7, 28, 56 and 90 days are represented

in Table 4.

Split tensile strength

The details of the split tensile strength of HSSCC with GO based

on 150 mm diameter and 300 mm height cylinder are represented

in Table 5.

Flexural strength

The details of the flexural tensile strength of HSSCC with GO

based on 100 mm _ 100 mm _ 500 mm specimens are shown in

Table 6.

You might also like

- Exp 10: Synthesis of (Co (NH3) 5Cl) Cl2Document8 pagesExp 10: Synthesis of (Co (NH3) 5Cl) Cl2Marla Basa95% (20)

- Lab Report (Final Editied)Document8 pagesLab Report (Final Editied)Alexia Channer100% (4)

- Organic Syntheses Collective Volume 3Document1,060 pagesOrganic Syntheses Collective Volume 3caltexas100% (5)

- Cleopatra MallDocument27 pagesCleopatra MallElZahraa Said100% (1)

- Chemistry Lab Report 1212Document9 pagesChemistry Lab Report 1212api-284826801No ratings yet

- Lab Report Experiment 3 4 and 5Document13 pagesLab Report Experiment 3 4 and 5Nurul Iman Che Awang90% (40)

- Experiments in Organotin ChemistryDocument10 pagesExperiments in Organotin ChemistryAinul Syahirah OmarNo ratings yet

- ASTM - d-1730-03 Standard Practices For Preparation of Aluminum and Aluminum Alloy Surfaces For Painting PDFDocument3 pagesASTM - d-1730-03 Standard Practices For Preparation of Aluminum and Aluminum Alloy Surfaces For Painting PDFAdrian OrtizNo ratings yet

- Seminar ReportDocument14 pagesSeminar ReportPoonam0242No ratings yet

- Synthesis of 1-Amino-2 - (4 - Methoxycarbonyl Ethyl-2 - Methyl) - Phenoxy-4-Hydroxy AnthraquinoneDocument4 pagesSynthesis of 1-Amino-2 - (4 - Methoxycarbonyl Ethyl-2 - Methyl) - Phenoxy-4-Hydroxy AnthraquinoneGhulam MurtazaNo ratings yet

- Jclinpath00001 0034Document4 pagesJclinpath00001 0034sachithudaraNo ratings yet

- Pce SopDocument2 pagesPce SopA MallikNo ratings yet

- Extraction of Silica From Puddy HuskDocument19 pagesExtraction of Silica From Puddy HuskFauzaan KhanNo ratings yet

- Jlpga S 07Document16 pagesJlpga S 07hopkhtnNo ratings yet

- Full Lab Report Exp3Document12 pagesFull Lab Report Exp3keyRien0% (1)

- Ctalyst DesignDocument35 pagesCtalyst DesignmatushriNo ratings yet

- Analytical Method of Total Nitrogen, Phosphorus and Potassium Content in Water Soluble FertilizersDocument12 pagesAnalytical Method of Total Nitrogen, Phosphorus and Potassium Content in Water Soluble FertilizersGenaro PalacioNo ratings yet

- Analytical Method of Total Nitrogen, Phosphorus and Potassium Content in Water Soluble FertilizersDocument12 pagesAnalytical Method of Total Nitrogen, Phosphorus and Potassium Content in Water Soluble FertilizersGenaro PalacioNo ratings yet

- CNTsDocument10 pagesCNTsAisha ranaNo ratings yet

- Jo102169t Si 002Document39 pagesJo102169t Si 002jjoaquincvNo ratings yet

- Ojic 2016042713213847 PDFDocument10 pagesOjic 2016042713213847 PDFJesha LibreaNo ratings yet

- Determination of The Valency of MagnesiumDocument7 pagesDetermination of The Valency of MagnesiumJiaxinOoiNo ratings yet

- VI Baltic Chemistry OlympiadDocument2 pagesVI Baltic Chemistry OlympiadYarga Puritza100% (1)

- Carbohydrates LabDocument20 pagesCarbohydrates LabChristian Dave MativoNo ratings yet

- Experiment 1Document4 pagesExperiment 1Sindiswa Minenhle MngadiNo ratings yet

- 2.1. Preparation of Actived Solid PhasesDocument4 pages2.1. Preparation of Actived Solid PhasesedibuhNo ratings yet

- Organic Matter Determination (Walkley - Black Method)Document5 pagesOrganic Matter Determination (Walkley - Black Method)FIORELLA GLADYS RODRIGUEZ RAMIREZNo ratings yet

- CHM 474 Exp 3 4 5Document15 pagesCHM 474 Exp 3 4 5Syafiqah Ck100% (3)

- Acid Cleaning of Impurities in Natural Circulation High Pressure Drum BoilerDocument7 pagesAcid Cleaning of Impurities in Natural Circulation High Pressure Drum BoilerNeeraj HegdeNo ratings yet

- Treatment of Hydrogen Sulfide Gas Generated in Landfill SitesDocument7 pagesTreatment of Hydrogen Sulfide Gas Generated in Landfill SitesOmar MorónNo ratings yet

- Treatment of Hydrogen Sulfide Gas Generated in Landfill SitesDocument7 pagesTreatment of Hydrogen Sulfide Gas Generated in Landfill SitesOmar MorónNo ratings yet

- Estimation Lactic AcidDocument20 pagesEstimation Lactic AcidpilotplanthtbsNo ratings yet

- Recovery of Germanium by Precipitation From Strongly Alkaline SolutionDocument10 pagesRecovery of Germanium by Precipitation From Strongly Alkaline SolutionGEOLINKS International Conference 2019No ratings yet

- Synthesis of Graphene Oxide-Porphyrin Nanocomposite and Its Application in Removal of Toxic MetalsDocument11 pagesSynthesis of Graphene Oxide-Porphyrin Nanocomposite and Its Application in Removal of Toxic MetalsFamiloni LayoNo ratings yet

- The Modified Fenton Process For Decolorization of Dye WastewaterDocument5 pagesThe Modified Fenton Process For Decolorization of Dye Wastewatermemo_gh89No ratings yet

- Preparation of n-Isopropylidene-n'-2-Nitrobenzenesulfonyl Hydrazine (IPNBSH) and Its Use in Palladium-Catalyzed Synthesis of Monoalkyl Diazenes. Synthesis of 9-AllylanthraceneDocument22 pagesPreparation of n-Isopropylidene-n'-2-Nitrobenzenesulfonyl Hydrazine (IPNBSH) and Its Use in Palladium-Catalyzed Synthesis of Monoalkyl Diazenes. Synthesis of 9-AllylanthraceneYami BaudelaireNo ratings yet

- GFAAS MercuryDocument23 pagesGFAAS MercuryAltaf Ur RehmanNo ratings yet

- Reduction Research PaperDocument3 pagesReduction Research PaperUdai PratapsinghNo ratings yet

- Synthesis, Characteristics and Analysis of Co (III) ComplexesDocument21 pagesSynthesis, Characteristics and Analysis of Co (III) ComplexesNguyễn Công TuyềnNo ratings yet

- MIL-101 CDC SupplDocument51 pagesMIL-101 CDC SupplAnkit MaharshiNo ratings yet

- Leaching of Soluble Constituents From MSW Following Anaerobic BiodegradationDocument9 pagesLeaching of Soluble Constituents From MSW Following Anaerobic BiodegradationMario WhoeverNo ratings yet

- Materials and Methods For Graphene SynthesisDocument3 pagesMaterials and Methods For Graphene SynthesisqamarNo ratings yet

- Estimation of Sulfur in Coal Samples by Rapid Combustion-Iodometric Titration MethodDocument4 pagesEstimation of Sulfur in Coal Samples by Rapid Combustion-Iodometric Titration MethodMetal deptNo ratings yet

- Thesis DataDocument14 pagesThesis DataHaseeb ChaudharyNo ratings yet

- Environmental Research & TechnologyDocument7 pagesEnvironmental Research & TechnologyRaouf BoucharebNo ratings yet

- Quantitativ Analysis Question SeriesDocument4 pagesQuantitativ Analysis Question Seriesshubh.chauhan014No ratings yet

- Laboratory Report CHM 153 (Inorganic Chemistry) : 1. Muhammad Mirza Hizami Bin RajieiDocument4 pagesLaboratory Report CHM 153 (Inorganic Chemistry) : 1. Muhammad Mirza Hizami Bin RajieiMuhd Mirza HizamiNo ratings yet

- Grinard Reagent LabDocument4 pagesGrinard Reagent LabZach McCartyNo ratings yet

- J. Biol. Chem. 1952 Somogyi 19 23Document6 pagesJ. Biol. Chem. 1952 Somogyi 19 23gibrambo5770No ratings yet

- Iso OriginalDocument2 pagesIso OriginalkakkienakkieNo ratings yet

- Molar Volume of Gas LabDocument3 pagesMolar Volume of Gas Labapi-216235465No ratings yet

- The Chemistry of The Aminochromes: Part Vi. The Reaction O F Adrenochrome With Glutathione' "3Document7 pagesThe Chemistry of The Aminochromes: Part Vi. The Reaction O F Adrenochrome With Glutathione' "3Nstm3No ratings yet

- Acetylated Starch Co2Document11 pagesAcetylated Starch Co2Amalia RizkaNo ratings yet

- School of Applied Natural SciencesDocument4 pagesSchool of Applied Natural Sciencesvk100No ratings yet

- Effect of Reflux Time and Cow Urine Concentration On Green Synthesis of Reduced Graphene Oxide (rGO)Document9 pagesEffect of Reflux Time and Cow Urine Concentration On Green Synthesis of Reduced Graphene Oxide (rGO)Medha GijareNo ratings yet

- Air Oxidation of Primary Alcohols Catalyzed by Copper (I) /TEMPO. Preparation of 2-Amino-5-Bromo-BenzaldehydeDocument15 pagesAir Oxidation of Primary Alcohols Catalyzed by Copper (I) /TEMPO. Preparation of 2-Amino-5-Bromo-BenzaldehydeCarlos GonzalezNo ratings yet

- Analisis Pangan (Karbohidrat) Bagian 2Document28 pagesAnalisis Pangan (Karbohidrat) Bagian 2arikuraNo ratings yet

- Experiment 32Document14 pagesExperiment 32Morgan Elizabeth Lepley100% (6)

- As Practical Calculations Worksheets - RedDocument14 pagesAs Practical Calculations Worksheets - RedKeniel YaoNo ratings yet

- FL SopDocument45 pagesFL SopSara JohnsonNo ratings yet

- Lab Report 2Document7 pagesLab Report 2刘哲宁No ratings yet

- Removal of The Ammonia Load of Landfill Leachate by Struvite Precipitation Using Low-Cost ReagentsDocument8 pagesRemoval of The Ammonia Load of Landfill Leachate by Struvite Precipitation Using Low-Cost ReagentsMario WhoeverNo ratings yet

- Supporting InformationDocument7 pagesSupporting InformationNGsalunkheNo ratings yet

- The Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresFrom EverandThe Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresRating: 5 out of 5 stars5/5 (1)

- A 6 1-Toilet-DetailDocument1 pageA 6 1-Toilet-DetailElZahraa SaidNo ratings yet

- Working DrawingsDocument33 pagesWorking DrawingsElZahraa SaidNo ratings yet

- Circulation Dynamics To Improve Commercial Activity in A Mega MallDocument8 pagesCirculation Dynamics To Improve Commercial Activity in A Mega MallElZahraa SaidNo ratings yet

- إدارة٢Document52 pagesإدارة٢ElZahraa SaidNo ratings yet

- حساب تكاليف ومتابعة أعمال المشاريعDocument23 pagesحساب تكاليف ومتابعة أعمال المشاريعElZahraa SaidNo ratings yet

- حصر الكميات للفيلاDocument9 pagesحصر الكميات للفيلاElZahraa SaidNo ratings yet

- Ground FloorDocument1 pageGround FloorElZahraa SaidNo ratings yet

- إدارة ١Document23 pagesإدارة ١ElZahraa SaidNo ratings yet

- Design Recover ModelDocument1 pageDesign Recover ModelElZahraa SaidNo ratings yet

- LayoutDocument1 pageLayoutElZahraa SaidNo ratings yet

- HSSCCDocument5 pagesHSSCCElZahraa SaidNo ratings yet

- Batta 2Document5 pagesBatta 2ElZahraa SaidNo ratings yet

- MaterialsDocument4 pagesMaterialsElZahraa SaidNo ratings yet

- IntroductionDocument2 pagesIntroductionElZahraa SaidNo ratings yet

- Concrete Mix Design For High Strength Self-Compacting Concrete Using MetakaolinDocument5 pagesConcrete Mix Design For High Strength Self-Compacting Concrete Using MetakaolinElZahraa SaidNo ratings yet

- Development of High-Strengh Self-Compacting ConcreDocument4 pagesDevelopment of High-Strengh Self-Compacting ConcreElZahraa SaidNo ratings yet

- Fresh and Hardened Properties of High Strength Self-Compacting Concrete Using By-Product Ferronickel Slag Fine Aggregate.Document6 pagesFresh and Hardened Properties of High Strength Self-Compacting Concrete Using By-Product Ferronickel Slag Fine Aggregate.ElZahraa SaidNo ratings yet

- HawasDocument4 pagesHawasElZahraa SaidNo ratings yet

- Understanding Loft Conversions SampleDocument18 pagesUnderstanding Loft Conversions SampleElZahraa SaidNo ratings yet

- Eco Design For A Villa in IsmailiaDocument1 pageEco Design For A Villa in IsmailiaElZahraa SaidNo ratings yet

- EsraaDocument5 pagesEsraaElZahraa SaidNo ratings yet

- Architecture Presentation Board TipsDocument4 pagesArchitecture Presentation Board TipsElZahraa SaidNo ratings yet

- Principles of Planning 2019 2ndDocument49 pagesPrinciples of Planning 2019 2ndElZahraa SaidNo ratings yet

- Irrigation Water QualityDocument47 pagesIrrigation Water QualityfarzanNo ratings yet

- API 510 Brittle FractureDocument50 pagesAPI 510 Brittle Fracturekihal zohirNo ratings yet

- Working With Moving Pulleys 6 PDFDocument8 pagesWorking With Moving Pulleys 6 PDFOyas DubeyNo ratings yet

- PD TopicDocument6 pagesPD TopicAnonymous Flh0GZNo ratings yet

- Chap 05BDocument13 pagesChap 05BAbhishek DasNo ratings yet

- Sizing and Wall ThicknessDocument37 pagesSizing and Wall ThicknessMuhammad NursalamNo ratings yet

- A Cellular Automata Simulation of Atomic Layer Etching Strotmann Et Al 1Document15 pagesA Cellular Automata Simulation of Atomic Layer Etching Strotmann Et Al 1pradeepkarraNo ratings yet

- Preparing For PUPCET Some of The FollowiDocument12 pagesPreparing For PUPCET Some of The Followibry yyy100% (2)

- Topic Take-Off Angle Calculations For Fault-Plane Solutions and Reconstruction of Nodal Planes From The Parameters of Fault-Plane SolutionsDocument6 pagesTopic Take-Off Angle Calculations For Fault-Plane Solutions and Reconstruction of Nodal Planes From The Parameters of Fault-Plane SolutionsFrancisco JavierNo ratings yet

- Colorimetric Methods in Biochemistry: Basma Ahmed Eltonsy 201816890Document4 pagesColorimetric Methods in Biochemistry: Basma Ahmed Eltonsy 201816890Basma EltonsyNo ratings yet

- Tittle: Design Basis: 500MTD TSP. Site Condition: We Have Chosen Feni As Our Plant LocationDocument5 pagesTittle: Design Basis: 500MTD TSP. Site Condition: We Have Chosen Feni As Our Plant Locationসাইদুর রহমানNo ratings yet

- COE Class Test Question-1Document1 pageCOE Class Test Question-1Rahul RajNo ratings yet

- Causes of Air PollutionDocument2 pagesCauses of Air PollutionSharon100% (2)

- Inspection and Testing PlantDocument27 pagesInspection and Testing PlantDaengkulle Firmansyah PuteraNo ratings yet

- Bray-B-1008 ProdProfile 06 07 2016Document13 pagesBray-B-1008 ProdProfile 06 07 2016Osvaldo Junges BomfimNo ratings yet

- Notes 13 DetonationsDocument13 pagesNotes 13 DetonationsBachir El FilNo ratings yet

- Collapse Analysis of Longitudinally Cracked HDPE PipeDocument11 pagesCollapse Analysis of Longitudinally Cracked HDPE PipeMicaela Sarina Alberti EmbonNo ratings yet

- Wastewater Engineering Advanced Wastewater Treatment Systems PDFDocument244 pagesWastewater Engineering Advanced Wastewater Treatment Systems PDFEr Govind Singh ChauhanNo ratings yet

- DPP - 02 Quantum Chemistry: CSIR-NET - IIT-GATE - IIT-JAM - Other Msc. EntranceDocument2 pagesDPP - 02 Quantum Chemistry: CSIR-NET - IIT-GATE - IIT-JAM - Other Msc. Entranceanurag pandeyNo ratings yet

- Asbuton Pracampur Antara Harapan Dan Kenyataan: Asbuton Premix Between Hope and RealityDocument11 pagesAsbuton Pracampur Antara Harapan Dan Kenyataan: Asbuton Premix Between Hope and RealityLabisal mouliNo ratings yet

- Chemical Sensors: Simulation and Modeling Volume 2: Conductometric-Type SensorsDocument69 pagesChemical Sensors: Simulation and Modeling Volume 2: Conductometric-Type SensorsMomentum PressNo ratings yet

- Computer Simulation To Predict Quality Changes of FoodDocument9 pagesComputer Simulation To Predict Quality Changes of FoodAdian RindangNo ratings yet

- Particle Physics: Georgia Karagiorgi Department of Physics, Columbia UniversityDocument81 pagesParticle Physics: Georgia Karagiorgi Department of Physics, Columbia UniversityDenis PetcuNo ratings yet

- Chemical KineticsDocument4 pagesChemical KineticsShubhankar SinhaNo ratings yet

- Sistemul PeriodicDocument1 pageSistemul PeriodicjurjlNo ratings yet

- Introduction To Nanoelectronics FinalDocument18 pagesIntroduction To Nanoelectronics Finalparmis1212No ratings yet

- Construction and Trial Experiment of A Small Size Thermo-Acoustic Refrigeration SystemDocument6 pagesConstruction and Trial Experiment of A Small Size Thermo-Acoustic Refrigeration SystemijeteeditorNo ratings yet