Professional Documents

Culture Documents

Circuit Description

Circuit Description

Uploaded by

Jorge RaulCopyright:

Available Formats

You might also like

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideFrom EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideRating: 4 out of 5 stars4/5 (9)

- 1078 3Document5 pages1078 3Marco OlivettoNo ratings yet

- enDocument67 pagesenRegistr RegistrNo ratings yet

- JSA - Electrical Testing - Circuit Breaker Field TestDocument4 pagesJSA - Electrical Testing - Circuit Breaker Field TestTawfik Mohamed Abu Zaid0% (1)

- 2008 Jeep Wrangler Unlimited X 2008 Jeep Wrangler Unlimited XDocument12 pages2008 Jeep Wrangler Unlimited X 2008 Jeep Wrangler Unlimited XJorge RaulNo ratings yet

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0406Document5 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0406801400No ratings yet

- 2202-12 14M Implement Sterring Valve ModulDocument9 pages2202-12 14M Implement Sterring Valve ModulAhmad Salimin100% (1)

- 2011 Jeep Liberty Limited 2011 Jeep Liberty Limited: Fig. 73: Transmission Control Output Wiring DiagramDocument7 pages2011 Jeep Liberty Limited 2011 Jeep Liberty Limited: Fig. 73: Transmission Control Output Wiring DiagramcarlosNo ratings yet

- Ford Focus - Alternator - Types and FunctionDocument4 pagesFord Focus - Alternator - Types and FunctionBogdan Sergiu100% (1)

- GM 3.8L Icm Testing PDFDocument4 pagesGM 3.8L Icm Testing PDFJoeNo ratings yet

- PEEC Electronic System Functional TestsDocument66 pagesPEEC Electronic System Functional TestsRichard Chua0% (1)

- J1939 Datalink DiagnosticsDocument29 pagesJ1939 Datalink DiagnosticsBALA100% (1)

- CAT Data Link Circuit-Test - SENR9576 - Sept 2003 - CATERPILLAR PDFDocument15 pagesCAT Data Link Circuit-Test - SENR9576 - Sept 2003 - CATERPILLAR PDFpevare100% (6)

- DTC p1351 Ignition Coil Control Circuit High VoltajeDocument5 pagesDTC p1351 Ignition Coil Control Circuit High VoltajeBenito LopezNo ratings yet

- Cid 2930 (Mid082)Document5 pagesCid 2930 (Mid082)Moch SuyonoNo ratings yet

- Codigo Asfaltadora SsolenoideDocument4 pagesCodigo Asfaltadora SsolenoideJUAN EDUARD QUEZADA CABRERANo ratings yet

- Troubel Shoting Piston PumpDocument7 pagesTroubel Shoting Piston PumpAmir Bambang YudhoyonoNo ratings yet

- 127.0.0.1 Sisweb Sisweb Techdoc Techdoc Print Page - JSPDocument7 pages127.0.0.1 Sisweb Sisweb Techdoc Techdoc Print Page - JSPkhaled fathyNo ratings yet

- DTC p1374Document3 pagesDTC p1374David RosadoNo ratings yet

- MID 039 - CID 0171 - FMI 04: TroubleshootingDocument4 pagesMID 039 - CID 0171 - FMI 04: TroubleshootingNerminTurkenceNo ratings yet

- Bajo Voltaje en SolenoidesDocument7 pagesBajo Voltaje en SolenoidesMAXIMILIANO CASTILLO ANTONIONo ratings yet

- MID 039 - CID 0167 - FMI 12: TroubleshootingDocument5 pagesMID 039 - CID 0167 - FMI 12: TroubleshootingNerminTurkenceNo ratings yet

- Speed Control Test Cat C15Document8 pagesSpeed Control Test Cat C15Mantenimiento La Punta100% (1)

- Air Conditioner Compressor Clutch Solenoid Current Below NormalDocument4 pagesAir Conditioner Compressor Clutch Solenoid Current Below NormalBlowby HighNo ratings yet

- 296-9 Cat CodeDocument5 pages296-9 Cat CodesuelifashNo ratings yet

- Cart A Delco Dig Op 0740Document2 pagesCart A Delco Dig Op 0740josepadilla1987No ratings yet

- Diagnostic AidsDocument4 pagesDiagnostic AidsTony HerediaNo ratings yet

- Mid 039 - Cid 1665 - Fmi 05Document3 pagesMid 039 - Cid 1665 - Fmi 05digirolamoNo ratings yet

- Fuel Shutoff - TestDocument7 pagesFuel Shutoff - TestAdolfo Dario SaavedraNo ratings yet

- Service Manual ExtractDocument6 pagesService Manual ExtractNovica ŽivanovićNo ratings yet

- On-Board Diagnostic (Immobilizer System)Document5 pagesOn-Board Diagnostic (Immobilizer System)pavel35No ratings yet

- Codigo 0070-02 de D6N AkmDocument5 pagesCodigo 0070-02 de D6N AkmMiguel LopezNo ratings yet

- Cmpaveo0342 PDFDocument5 pagesCmpaveo0342 PDFmariodavid1988No ratings yet

- Generator Output Power SensorDocument11 pagesGenerator Output Power SensorHugo CiprianiNo ratings yet

- Scan Tool Does Not Communicate With High Speed GMLAN DeviceDocument6 pagesScan Tool Does Not Communicate With High Speed GMLAN Devicejalvarez_385073No ratings yet

- Mid 06a - Cid 1522 - Fmi 03Document3 pagesMid 06a - Cid 1522 - Fmi 03Power MobileNo ratings yet

- 5 Volt Engine Pressure Sensor Supply Circuit - Test: TroubleshootingDocument7 pages5 Volt Engine Pressure Sensor Supply Circuit - Test: TroubleshootingsyahrilNo ratings yet

- MID 039 - CID 0096 - FMI 03: Shutdown SIS Previous ScreenDocument3 pagesMID 039 - CID 0096 - FMI 03: Shutdown SIS Previous ScreenAmir Bambang YudhoyonoNo ratings yet

- P2138-Accelerator Pedal Position Sensor 1/2 Correlation: 2009 Dodge Pickup R1500 2009 Dodge Pickup R1500Document7 pagesP2138-Accelerator Pedal Position Sensor 1/2 Correlation: 2009 Dodge Pickup R1500 2009 Dodge Pickup R1500pauloNo ratings yet

- Diagrama Electrico de Transmcion 160HDocument4 pagesDiagrama Electrico de Transmcion 160HJuan CarlosNo ratings yet

- 2688 DerechoDocument4 pages2688 DerechoDiego CatariNo ratings yet

- GM 3.1L & 3.4L Icm TestingDocument4 pagesGM 3.1L & 3.4L Icm TestingJoeNo ratings yet

- Generator & RegulatorDocument132 pagesGenerator & Regulatordima65No ratings yet

- Diagnostic Trouble Codes (DTC) : DTC P281 O Solenoid G ElectricalDocument5 pagesDiagnostic Trouble Codes (DTC) : DTC P281 O Solenoid G Electricalluis eduardo corzo enriquezNo ratings yet

- Codigo 588.09 de d6tDocument4 pagesCodigo 588.09 de d6tericNo ratings yet

- Mid 06a - Cid 1523 - Fmi 06Document4 pagesMid 06a - Cid 1523 - Fmi 06Power MobileNo ratings yet

- Tea Sensor de VelocidadeDocument6 pagesTea Sensor de VelocidadeValmaq Prestação Serviço LdaNo ratings yet

- Pajero Full 2008 13Document1,059 pagesPajero Full 2008 13Antonio GasparNo ratings yet

- G - Tests W/Codes - 1.6L & 2.0L Article TextDocument25 pagesG - Tests W/Codes - 1.6L & 2.0L Article TextKoeswara SofyanNo ratings yet

- Testando o Distribuidor - PaseoDocument10 pagesTestando o Distribuidor - PaseoPablo B. SoaresNo ratings yet

- Mid 039 - Cid - FMI 05: TroubleshootingDocument3 pagesMid 039 - Cid - FMI 05: TroubleshootinganiroNo ratings yet

- 2000 Buick Regal Prueba de Sistema y ComponentesDocument158 pages2000 Buick Regal Prueba de Sistema y ComponentesRubenNo ratings yet

- Ignition Control ElectricalDocument19 pagesIgnition Control ElectricalBình Trần100% (1)

- Diagnosis and Testing - Power WindowsDocument22 pagesDiagnosis and Testing - Power WindowsMuhammad ZamanNo ratings yet

- 325DL Tsegaye Mid 039 - Cid 2265 - Fmi 08Document5 pages325DL Tsegaye Mid 039 - Cid 2265 - Fmi 08Daniel TekleNo ratings yet

- Windstar 2000 U1147Document1 pageWindstar 2000 U1147adris banquethNo ratings yet

- Rap System TestsDocument16 pagesRap System TestsBrad FrancNo ratings yet

- Injection Actuation CircuitDocument9 pagesInjection Actuation Circuitsamsularief03No ratings yet

- m322c Mesafent Electrical Power Supply Circuit - TestDocument9 pagesm322c Mesafent Electrical Power Supply Circuit - TestDaniel TekleNo ratings yet

- SM 94Document103 pagesSM 94jhon greigNo ratings yet

- MID 122 - CID 1251 - FMI 03: Product Link 121S/300Document3 pagesMID 122 - CID 1251 - FMI 03: Product Link 121S/300Golbert GolbiNo ratings yet

- 1999-2005 Hyundai H-1 ETMDocument7 pages1999-2005 Hyundai H-1 ETMJorge RaulNo ratings yet

- DTC P0190, P0191, P0192, or P0193 - LNP or LNQ: Diagnostic InstructionsDocument2 pagesDTC P0190, P0191, P0192, or P0193 - LNP or LNQ: Diagnostic InstructionsJorge RaulNo ratings yet

- P1128-Closed Loop Fueling Not Achieved - Bank 1Document10 pagesP1128-Closed Loop Fueling Not Achieved - Bank 1Jorge RaulNo ratings yet

- p0122 1Document4 pagesp0122 1Jorge RaulNo ratings yet

- Roof Function Centre High VersionDocument5 pagesRoof Function Centre High VersionJorge RaulNo ratings yet

- ServiceDocument76 pagesServiceJorge RaulNo ratings yet

- Company LawDocument15 pagesCompany Lawpreetibajaj100% (2)

- Draft Spec. For Set of Panels For LHB Non AC EOG Coaches PDFDocument27 pagesDraft Spec. For Set of Panels For LHB Non AC EOG Coaches PDFVishal Kinikar0% (1)

- HXGP 116 Detailed Course OutlineDocument2 pagesHXGP 116 Detailed Course OutlinePARDON MATARENo ratings yet

- Ethics QuizDocument2 pagesEthics QuizLegogie Moses AnoghenaNo ratings yet

- Lesson Plan 14Document3 pagesLesson Plan 14api-268829047No ratings yet

- Pathogenesis TBDocument39 pagesPathogenesis TBGede Eka Putra NugrahaNo ratings yet

- Acupressure Animal SheltersDocument1 pageAcupressure Animal SheltersIoana SavaNo ratings yet

- How To React To Bad Christmas GiftsDocument3 pagesHow To React To Bad Christmas GiftszakupowamaniaczkaNo ratings yet

- 10 1108 - Ijse 11 2017 0507Document14 pages10 1108 - Ijse 11 2017 0507Hanny PurnomoNo ratings yet

- Pe Lesson Plan 2 16 17Document7 pagesPe Lesson Plan 2 16 17api-350775200No ratings yet

- Past Continuous TenseDocument5 pagesPast Continuous TensePathricia KasumNo ratings yet

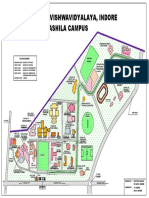

- Devi Ahilya Vishwavidyalaya, Indore Takshashila Campus: Vigyan BhawanDocument1 pageDevi Ahilya Vishwavidyalaya, Indore Takshashila Campus: Vigyan BhawankapasNo ratings yet

- Chapter 2Document3 pagesChapter 2Johane Grei WallNo ratings yet

- Example 3 Relating Downhole Rate With The Rate at Standard ConditionsDocument8 pagesExample 3 Relating Downhole Rate With The Rate at Standard ConditionsMaisam AbbasNo ratings yet

- Investment Analysis and Portfolio Management: Lecture Presentation SoftwareDocument43 pagesInvestment Analysis and Portfolio Management: Lecture Presentation SoftwareNoman KhalidNo ratings yet

- 1 MobilePass VPNDocument8 pages1 MobilePass VPNYashpal SinghNo ratings yet

- 18-Soft Soil Creep Model - PlaxisDocument5 pages18-Soft Soil Creep Model - PlaxisVa Ni SkyNo ratings yet

- Faculty - Accountancy - 2022 - Session 2 - Diploma - Maf251Document7 pagesFaculty - Accountancy - 2022 - Session 2 - Diploma - Maf251NUR FARISHA MOHD AZHARNo ratings yet

- Radiation Heat Transfer ExperimentDocument6 pagesRadiation Heat Transfer ExperimentDaniel IsmailNo ratings yet

- A Brief History of Jazz DrummingDocument8 pagesA Brief History of Jazz DrummingManoloPantalonNo ratings yet

- GSX R600k7e3 PDFDocument104 pagesGSX R600k7e3 PDFAdolfoNo ratings yet

- The Sinister Genius of Qassem Soleimani - WSJ PDFDocument5 pagesThe Sinister Genius of Qassem Soleimani - WSJ PDFMuhammad Anique RawnNo ratings yet

- Notes Receivable and Loan ReceivableDocument21 pagesNotes Receivable and Loan ReceivableLady BelleNo ratings yet

- BEM3060 Managing EntrepreneuriallyDocument13 pagesBEM3060 Managing Entrepreneuriallyngolodedan2No ratings yet

- CV Hamza SadrijaDocument3 pagesCV Hamza SadrijaHamza SadrijaNo ratings yet

- A Seminar Report On: An International Study On A Risk of Cyber TerrorismDocument7 pagesA Seminar Report On: An International Study On A Risk of Cyber TerrorismManish SakalkarNo ratings yet

- The Unstoppable Human Species The Emergence of Homo Sapiens in Prehistory John J Shea 2 All ChapterDocument52 pagesThe Unstoppable Human Species The Emergence of Homo Sapiens in Prehistory John J Shea 2 All Chapterfrieda.jaimes821100% (9)

- Chang 2013Document20 pagesChang 2013Nguyễn HàNo ratings yet

- Bandas PDFDocument3 pagesBandas PDFClaudia DiazNo ratings yet

Circuit Description

Circuit Description

Uploaded by

Jorge RaulOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Circuit Description

Circuit Description

Uploaded by

Jorge RaulCopyright:

Available Formats

1997 GMC Pickup K3500

1997 ENGINE PERFORMANCE Self-Diagnostics - 7.4L C & K Series

DTC P1351 - IGNITION CONTROL (IC) CIRCUIT HIGH VOLTAGE

NOTE: For circuit reference, see the appropriate WIRING DIAGRAMS article. For

connector and terminal identification, see CONNECTOR IDENTIFICATION .

Circuit Description

Enhanced ignition system provides timing input to VCM with a crank sensor. VCM utilizes reference pulse

to determine individual ignition spark timing for each cylinder.

Once VCM calculates ignition timing, timing signal is sent to ignition coil module. Each timing pulse

received by ignition coil module triggers module operation of ignition coil. Secondary ignition voltage is

induced then sent to distributor for distribution to each spark plug. IC signal voltage ranges from about 0.5

volt to 4.5 volts.

DTC will set when the following conditions are present:

l Voltage on IC circuit is greater than 4.9 volts and engine speed less than 250 RPM.

Diagnostic Procedures

1. Perform ON-BOARD DIAGNOSTIC (OBD) SYSTEM CHECK. See the F - BASIC TESTING -

7.4L article. After performing OBD system check, go to next step.

2. Clear DTCs. Disconnect injector connector. Crank engine for 30 seconds. Check if DTC P1351 is set.

If DTC P1351 is set, go to next step. If DTC P1351 is not set, see DIAGNOSTIC AIDS.

3. Turn ignition off. Reconnect injector connector. Disconnect ignition coil module connector. Using

DVOM, probe ignition coil module connector terminal "B" (engine harness side) to ground. With

DVOM on AC scale, crank engine and note voltage reading. If voltage is 1-4 volts, go to step 9). If

voltage is not 1-4 volts, go to next step.

4. Turn ignition off. Disconnect Gray VCM connector. Using DVOM, check resistance between IC

control circuit of VCM and ignition coil module connector terminal "B". If resistance is 10 ohms, go

to step 6). If resistance is not 10 ohms, go to next step.

5. Repair open in IC control circuit between VCM and ignition coil module. Go to step 16).

6. Check for poor connection at VCM. If a problem was found, go to next step. If a problem was not

found, go to step 8).

7. Repair VCM connection. After repairs, go to step 16).

8. Replace VCM. Program replacement VCM using required equipment. After replacing VCM, go to

step 16).

9. Turn ignition off. Using test light, probe ignition coil module connector terminal "C" (engine harness

side) to battery voltage. If test light illuminates, go to step 11). If test light does not illuminate, go to

next step.

10. Repair open in ignition coil module ground circuit. After repairs, go to step 16).

11. Turn ignition on. Using test light, probe ignition coil module connector terminals "D" and "A" (engine

harness side) to ground. If test light illuminates for both terminals, go to step 13). If test light does not

illuminate for both terminals, go to next step.

12. Repair ignition coil module ignition feed circuit. Go to step 16).

13. Check for poor connection at ignition coil module. If a problem was found, go to step 15). If a

problem was not found, go to next step.

miércoles, 4 de mayo de 2022 03:49:43

03:49:37 p. m. Page 1 © 2011 Mitchell Repair Information Company, LLC.

1997 GMC Pickup K3500

1997 ENGINE PERFORMANCE Self-Diagnostics - 7.4L C & K Series

14. Replace ignition coil module. After replacing module, go to step 16).

15. Repair ignition coil module connection. After repairs, go to next step.

16. Using scan tool, select DTC, CLEAR INFO. Start and warm engine to normal operating temperature.

Select DTC, SPECIFIC, then enter DTC P1351. Operate vehicle within the conditions for setting this

DTC. If scan tool indicates that this test ran and passed, go to next step. If scan tool does not indicate

that this test ran and passed, repeat step 2).

17. Using scan tool, select CAPTURE INFO, REVIEW INFO. If any undiagnosed DTC(s) are displayed,

go to applicable DTC test.

Diagnostic Aids

An intermittent may be caused by a poor connection, rubbed-through wire insulation or a broken wire inside

insulation. Inspect VCM harness connectors for backed-out terminals, improper mating, broken locks,

improperly formed or damaged terminals, poor terminal-to-wire connection, and damaged harness.

If connections and harness are okay, using DVOM connected between ignition feed circuit and IC control

circuit of VCM connector, monitor voltage while wiggling related connectors and wiring harness. If a failure

is induced, voltage will change. A change in voltage will assist in isolating location of fault.

miércoles, 4 de mayo de 2022 03:49:37 p. m. Page 2 © 2011 Mitchell Repair Information Company, LLC.

You might also like

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideFrom EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideRating: 4 out of 5 stars4/5 (9)

- 1078 3Document5 pages1078 3Marco OlivettoNo ratings yet

- enDocument67 pagesenRegistr RegistrNo ratings yet

- JSA - Electrical Testing - Circuit Breaker Field TestDocument4 pagesJSA - Electrical Testing - Circuit Breaker Field TestTawfik Mohamed Abu Zaid0% (1)

- 2008 Jeep Wrangler Unlimited X 2008 Jeep Wrangler Unlimited XDocument12 pages2008 Jeep Wrangler Unlimited X 2008 Jeep Wrangler Unlimited XJorge RaulNo ratings yet

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0406Document5 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0406801400No ratings yet

- 2202-12 14M Implement Sterring Valve ModulDocument9 pages2202-12 14M Implement Sterring Valve ModulAhmad Salimin100% (1)

- 2011 Jeep Liberty Limited 2011 Jeep Liberty Limited: Fig. 73: Transmission Control Output Wiring DiagramDocument7 pages2011 Jeep Liberty Limited 2011 Jeep Liberty Limited: Fig. 73: Transmission Control Output Wiring DiagramcarlosNo ratings yet

- Ford Focus - Alternator - Types and FunctionDocument4 pagesFord Focus - Alternator - Types and FunctionBogdan Sergiu100% (1)

- GM 3.8L Icm Testing PDFDocument4 pagesGM 3.8L Icm Testing PDFJoeNo ratings yet

- PEEC Electronic System Functional TestsDocument66 pagesPEEC Electronic System Functional TestsRichard Chua0% (1)

- J1939 Datalink DiagnosticsDocument29 pagesJ1939 Datalink DiagnosticsBALA100% (1)

- CAT Data Link Circuit-Test - SENR9576 - Sept 2003 - CATERPILLAR PDFDocument15 pagesCAT Data Link Circuit-Test - SENR9576 - Sept 2003 - CATERPILLAR PDFpevare100% (6)

- DTC p1351 Ignition Coil Control Circuit High VoltajeDocument5 pagesDTC p1351 Ignition Coil Control Circuit High VoltajeBenito LopezNo ratings yet

- Cid 2930 (Mid082)Document5 pagesCid 2930 (Mid082)Moch SuyonoNo ratings yet

- Codigo Asfaltadora SsolenoideDocument4 pagesCodigo Asfaltadora SsolenoideJUAN EDUARD QUEZADA CABRERANo ratings yet

- Troubel Shoting Piston PumpDocument7 pagesTroubel Shoting Piston PumpAmir Bambang YudhoyonoNo ratings yet

- 127.0.0.1 Sisweb Sisweb Techdoc Techdoc Print Page - JSPDocument7 pages127.0.0.1 Sisweb Sisweb Techdoc Techdoc Print Page - JSPkhaled fathyNo ratings yet

- DTC p1374Document3 pagesDTC p1374David RosadoNo ratings yet

- MID 039 - CID 0171 - FMI 04: TroubleshootingDocument4 pagesMID 039 - CID 0171 - FMI 04: TroubleshootingNerminTurkenceNo ratings yet

- Bajo Voltaje en SolenoidesDocument7 pagesBajo Voltaje en SolenoidesMAXIMILIANO CASTILLO ANTONIONo ratings yet

- MID 039 - CID 0167 - FMI 12: TroubleshootingDocument5 pagesMID 039 - CID 0167 - FMI 12: TroubleshootingNerminTurkenceNo ratings yet

- Speed Control Test Cat C15Document8 pagesSpeed Control Test Cat C15Mantenimiento La Punta100% (1)

- Air Conditioner Compressor Clutch Solenoid Current Below NormalDocument4 pagesAir Conditioner Compressor Clutch Solenoid Current Below NormalBlowby HighNo ratings yet

- 296-9 Cat CodeDocument5 pages296-9 Cat CodesuelifashNo ratings yet

- Cart A Delco Dig Op 0740Document2 pagesCart A Delco Dig Op 0740josepadilla1987No ratings yet

- Diagnostic AidsDocument4 pagesDiagnostic AidsTony HerediaNo ratings yet

- Mid 039 - Cid 1665 - Fmi 05Document3 pagesMid 039 - Cid 1665 - Fmi 05digirolamoNo ratings yet

- Fuel Shutoff - TestDocument7 pagesFuel Shutoff - TestAdolfo Dario SaavedraNo ratings yet

- Service Manual ExtractDocument6 pagesService Manual ExtractNovica ŽivanovićNo ratings yet

- On-Board Diagnostic (Immobilizer System)Document5 pagesOn-Board Diagnostic (Immobilizer System)pavel35No ratings yet

- Codigo 0070-02 de D6N AkmDocument5 pagesCodigo 0070-02 de D6N AkmMiguel LopezNo ratings yet

- Cmpaveo0342 PDFDocument5 pagesCmpaveo0342 PDFmariodavid1988No ratings yet

- Generator Output Power SensorDocument11 pagesGenerator Output Power SensorHugo CiprianiNo ratings yet

- Scan Tool Does Not Communicate With High Speed GMLAN DeviceDocument6 pagesScan Tool Does Not Communicate With High Speed GMLAN Devicejalvarez_385073No ratings yet

- Mid 06a - Cid 1522 - Fmi 03Document3 pagesMid 06a - Cid 1522 - Fmi 03Power MobileNo ratings yet

- 5 Volt Engine Pressure Sensor Supply Circuit - Test: TroubleshootingDocument7 pages5 Volt Engine Pressure Sensor Supply Circuit - Test: TroubleshootingsyahrilNo ratings yet

- MID 039 - CID 0096 - FMI 03: Shutdown SIS Previous ScreenDocument3 pagesMID 039 - CID 0096 - FMI 03: Shutdown SIS Previous ScreenAmir Bambang YudhoyonoNo ratings yet

- P2138-Accelerator Pedal Position Sensor 1/2 Correlation: 2009 Dodge Pickup R1500 2009 Dodge Pickup R1500Document7 pagesP2138-Accelerator Pedal Position Sensor 1/2 Correlation: 2009 Dodge Pickup R1500 2009 Dodge Pickup R1500pauloNo ratings yet

- Diagrama Electrico de Transmcion 160HDocument4 pagesDiagrama Electrico de Transmcion 160HJuan CarlosNo ratings yet

- 2688 DerechoDocument4 pages2688 DerechoDiego CatariNo ratings yet

- GM 3.1L & 3.4L Icm TestingDocument4 pagesGM 3.1L & 3.4L Icm TestingJoeNo ratings yet

- Generator & RegulatorDocument132 pagesGenerator & Regulatordima65No ratings yet

- Diagnostic Trouble Codes (DTC) : DTC P281 O Solenoid G ElectricalDocument5 pagesDiagnostic Trouble Codes (DTC) : DTC P281 O Solenoid G Electricalluis eduardo corzo enriquezNo ratings yet

- Codigo 588.09 de d6tDocument4 pagesCodigo 588.09 de d6tericNo ratings yet

- Mid 06a - Cid 1523 - Fmi 06Document4 pagesMid 06a - Cid 1523 - Fmi 06Power MobileNo ratings yet

- Tea Sensor de VelocidadeDocument6 pagesTea Sensor de VelocidadeValmaq Prestação Serviço LdaNo ratings yet

- Pajero Full 2008 13Document1,059 pagesPajero Full 2008 13Antonio GasparNo ratings yet

- G - Tests W/Codes - 1.6L & 2.0L Article TextDocument25 pagesG - Tests W/Codes - 1.6L & 2.0L Article TextKoeswara SofyanNo ratings yet

- Testando o Distribuidor - PaseoDocument10 pagesTestando o Distribuidor - PaseoPablo B. SoaresNo ratings yet

- Mid 039 - Cid - FMI 05: TroubleshootingDocument3 pagesMid 039 - Cid - FMI 05: TroubleshootinganiroNo ratings yet

- 2000 Buick Regal Prueba de Sistema y ComponentesDocument158 pages2000 Buick Regal Prueba de Sistema y ComponentesRubenNo ratings yet

- Ignition Control ElectricalDocument19 pagesIgnition Control ElectricalBình Trần100% (1)

- Diagnosis and Testing - Power WindowsDocument22 pagesDiagnosis and Testing - Power WindowsMuhammad ZamanNo ratings yet

- 325DL Tsegaye Mid 039 - Cid 2265 - Fmi 08Document5 pages325DL Tsegaye Mid 039 - Cid 2265 - Fmi 08Daniel TekleNo ratings yet

- Windstar 2000 U1147Document1 pageWindstar 2000 U1147adris banquethNo ratings yet

- Rap System TestsDocument16 pagesRap System TestsBrad FrancNo ratings yet

- Injection Actuation CircuitDocument9 pagesInjection Actuation Circuitsamsularief03No ratings yet

- m322c Mesafent Electrical Power Supply Circuit - TestDocument9 pagesm322c Mesafent Electrical Power Supply Circuit - TestDaniel TekleNo ratings yet

- SM 94Document103 pagesSM 94jhon greigNo ratings yet

- MID 122 - CID 1251 - FMI 03: Product Link 121S/300Document3 pagesMID 122 - CID 1251 - FMI 03: Product Link 121S/300Golbert GolbiNo ratings yet

- 1999-2005 Hyundai H-1 ETMDocument7 pages1999-2005 Hyundai H-1 ETMJorge RaulNo ratings yet

- DTC P0190, P0191, P0192, or P0193 - LNP or LNQ: Diagnostic InstructionsDocument2 pagesDTC P0190, P0191, P0192, or P0193 - LNP or LNQ: Diagnostic InstructionsJorge RaulNo ratings yet

- P1128-Closed Loop Fueling Not Achieved - Bank 1Document10 pagesP1128-Closed Loop Fueling Not Achieved - Bank 1Jorge RaulNo ratings yet

- p0122 1Document4 pagesp0122 1Jorge RaulNo ratings yet

- Roof Function Centre High VersionDocument5 pagesRoof Function Centre High VersionJorge RaulNo ratings yet

- ServiceDocument76 pagesServiceJorge RaulNo ratings yet

- Company LawDocument15 pagesCompany Lawpreetibajaj100% (2)

- Draft Spec. For Set of Panels For LHB Non AC EOG Coaches PDFDocument27 pagesDraft Spec. For Set of Panels For LHB Non AC EOG Coaches PDFVishal Kinikar0% (1)

- HXGP 116 Detailed Course OutlineDocument2 pagesHXGP 116 Detailed Course OutlinePARDON MATARENo ratings yet

- Ethics QuizDocument2 pagesEthics QuizLegogie Moses AnoghenaNo ratings yet

- Lesson Plan 14Document3 pagesLesson Plan 14api-268829047No ratings yet

- Pathogenesis TBDocument39 pagesPathogenesis TBGede Eka Putra NugrahaNo ratings yet

- Acupressure Animal SheltersDocument1 pageAcupressure Animal SheltersIoana SavaNo ratings yet

- How To React To Bad Christmas GiftsDocument3 pagesHow To React To Bad Christmas GiftszakupowamaniaczkaNo ratings yet

- 10 1108 - Ijse 11 2017 0507Document14 pages10 1108 - Ijse 11 2017 0507Hanny PurnomoNo ratings yet

- Pe Lesson Plan 2 16 17Document7 pagesPe Lesson Plan 2 16 17api-350775200No ratings yet

- Past Continuous TenseDocument5 pagesPast Continuous TensePathricia KasumNo ratings yet

- Devi Ahilya Vishwavidyalaya, Indore Takshashila Campus: Vigyan BhawanDocument1 pageDevi Ahilya Vishwavidyalaya, Indore Takshashila Campus: Vigyan BhawankapasNo ratings yet

- Chapter 2Document3 pagesChapter 2Johane Grei WallNo ratings yet

- Example 3 Relating Downhole Rate With The Rate at Standard ConditionsDocument8 pagesExample 3 Relating Downhole Rate With The Rate at Standard ConditionsMaisam AbbasNo ratings yet

- Investment Analysis and Portfolio Management: Lecture Presentation SoftwareDocument43 pagesInvestment Analysis and Portfolio Management: Lecture Presentation SoftwareNoman KhalidNo ratings yet

- 1 MobilePass VPNDocument8 pages1 MobilePass VPNYashpal SinghNo ratings yet

- 18-Soft Soil Creep Model - PlaxisDocument5 pages18-Soft Soil Creep Model - PlaxisVa Ni SkyNo ratings yet

- Faculty - Accountancy - 2022 - Session 2 - Diploma - Maf251Document7 pagesFaculty - Accountancy - 2022 - Session 2 - Diploma - Maf251NUR FARISHA MOHD AZHARNo ratings yet

- Radiation Heat Transfer ExperimentDocument6 pagesRadiation Heat Transfer ExperimentDaniel IsmailNo ratings yet

- A Brief History of Jazz DrummingDocument8 pagesA Brief History of Jazz DrummingManoloPantalonNo ratings yet

- GSX R600k7e3 PDFDocument104 pagesGSX R600k7e3 PDFAdolfoNo ratings yet

- The Sinister Genius of Qassem Soleimani - WSJ PDFDocument5 pagesThe Sinister Genius of Qassem Soleimani - WSJ PDFMuhammad Anique RawnNo ratings yet

- Notes Receivable and Loan ReceivableDocument21 pagesNotes Receivable and Loan ReceivableLady BelleNo ratings yet

- BEM3060 Managing EntrepreneuriallyDocument13 pagesBEM3060 Managing Entrepreneuriallyngolodedan2No ratings yet

- CV Hamza SadrijaDocument3 pagesCV Hamza SadrijaHamza SadrijaNo ratings yet

- A Seminar Report On: An International Study On A Risk of Cyber TerrorismDocument7 pagesA Seminar Report On: An International Study On A Risk of Cyber TerrorismManish SakalkarNo ratings yet

- The Unstoppable Human Species The Emergence of Homo Sapiens in Prehistory John J Shea 2 All ChapterDocument52 pagesThe Unstoppable Human Species The Emergence of Homo Sapiens in Prehistory John J Shea 2 All Chapterfrieda.jaimes821100% (9)

- Chang 2013Document20 pagesChang 2013Nguyễn HàNo ratings yet

- Bandas PDFDocument3 pagesBandas PDFClaudia DiazNo ratings yet