Professional Documents

Culture Documents

IMG - 0150 PSME Code 2008 142

IMG - 0150 PSME Code 2008 142

Uploaded by

Arwyn Bermas0 ratings0% found this document useful (0 votes)

3 views1 pageThe document provides inspection guidelines for various parts of boilers and pressure vessels. The inspector should examine internal surfaces for corrosion, scale, deposits, and thin spots. Stays, tubesheets, drums, and joints should be inspected for corrosion, cracks, and other defects. Fusible plugs should be inspected and renewed if not in good condition. The inspector should check for issues that could cause localized overheating and restrict thermal expansion, such as improper burner adjustments or restricted ash/soot.

Original Description:

PSME

Original Title

IMG_0150 PSME Code 2008 142

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides inspection guidelines for various parts of boilers and pressure vessels. The inspector should examine internal surfaces for corrosion, scale, deposits, and thin spots. Stays, tubesheets, drums, and joints should be inspected for corrosion, cracks, and other defects. Fusible plugs should be inspected and renewed if not in good condition. The inspector should check for issues that could cause localized overheating and restrict thermal expansion, such as improper burner adjustments or restricted ash/soot.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

3 views1 pageIMG - 0150 PSME Code 2008 142

IMG - 0150 PSME Code 2008 142

Uploaded by

Arwyn BermasThe document provides inspection guidelines for various parts of boilers and pressure vessels. The inspector should examine internal surfaces for corrosion, scale, deposits, and thin spots. Stays, tubesheets, drums, and joints should be inspected for corrosion, cracks, and other defects. Fusible plugs should be inspected and renewed if not in good condition. The inspector should check for issues that could cause localized overheating and restrict thermal expansion, such as improper burner adjustments or restricted ash/soot.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

CHAPTER 7 _ BOILERS AND PRESSURE VESSELS

to provide a clean metal surface for 6.3.8 Stays

inspection by the plant inspector. After

cleaning, all loose scale and accumulated The plant inspector should note any

deposits should be .removed from the boiler corrosion, or cracking of stays and braces.

and other pressure parts. Brickwork and Particular inspection should be made of any

refractory materials should be dried out welded stays or braces.. All stays, whether

carefully when firing up. diagonal or through, should be examined to

see if they are in even tension. All fastened

The plant inspector should examine all internal ends should be inspected to note if cracks

surfaces.of the exposed metal to observe any exist where the plate is punched or drilled. lf

detrimental action caused by water treatment, stays are not found in proper tension,

scale solvents, oil, or other substances that corrective action is recommended. The plant

may have entered the boiler. The upper half of inspector should test staybolts by tapping one

the drums in the steam space should be end of each bolt with a hainmer, and when

inspected, particularly for signs of grease, oil, practical, a hammer or other heavy tool should

or similar deposits. Any evidence of oil should be held at the opposite end by an assistant to

be taken to prevent the entrance of any make the test more effective.

additional oil into the boiler. Oil or scale

deposits subject to furnace heat in any boiler 6.3.9 Fusible Plugs

may cause tubes or other heating surfaces to

overheat, bulge, or rupture. i Some older boilers of both firetube and

watertube-type have fusible plugs. lf fusible

6.3.7 Corrosion and Grooving plugs are used, determine whether they are

kept in good condition and that they are not

Corrosion along or immediately adjacent to a used for more than 1 year, as provided for in

joint or seam is more serious than a similar ASME Code. When the boiler is opened,

amount of corrosion in the solid plate. scrape clean and brighten the exposed

Grooving or cracking along longitudinal seams surface of the fusible material as well as the

is especially significant as it is likely to occur surface of the boiler near the plugs. lf the

when the material is highly stressed. Severe fusible metal does not appear sound, renew

corrosion is likely to occur at points where the the plug. Never refill a plug with anything but

circulation of water is poor, such places new metal.

should be inspected carefully.

6.3.10 Localization of Heat

Careful inspection of the interior of the boiler

should be made for-.cracks, broken stays, Localization of heat caused by an improperly

pitting, corrosions, erosion, scale, and thin adjusted or defective burner or by poor stoker

place in the drums.; installation or operation, creating a blowtorch

effect upon the furnace and tubes, should be

The interior face of riveted ioints should be corrected and the affected area should be

examined for conditions of riveting, thinness of inspected while the boiler is shut down.

metal, corrosion, cracks, and other defects or

faults. 6.3.11 Freedom of Expansion

Particular attention should also be given to the When boiler or boiler parts are suspended, the

tube ends, tubesheets, and drums. The plant supports and settings should be examined

inspector should note any corrosion or carefully, especially at point when the boiler

cracking of the tubesheets, tube ends, structure comes near the setting walls or floor

furnaces, or drums, signs of leaking tubes, r to make sure that the ash and soot will not

excessive thinning of the tubes from repeated restrict the boiler and produce excessive

rolling, and the condition of any ferrules and strains due to thermal expansion under

nipples within the drums. operating conditions.

The plant inspector should note any evidence 6.3.12 Lap Joints

of corrosion or cracking due to leakage at

manholes and handholes. Boilers with riveted lap joints are apt to crack

where the plates lap in the longitudinal or

142

You might also like

- R912 Installation Instructions - July 2022Document6 pagesR912 Installation Instructions - July 2022Franklin Mata LayaNo ratings yet

- Annexure 3 External Inspection ChecklistDocument5 pagesAnnexure 3 External Inspection Checklistankur100% (1)

- Repairs in Marine BoilersDocument9 pagesRepairs in Marine BoilersSwarg VibhaNo ratings yet

- Common Rail Denso CTM 220 (4.5 & 6.8 Litros)Document677 pagesCommon Rail Denso CTM 220 (4.5 & 6.8 Litros)Jorge Castillo Hdz93% (15)

- Recommended Practice For Prevention, Detection and Correction of Deaerator CrackingDocument2 pagesRecommended Practice For Prevention, Detection and Correction of Deaerator CrackingAnonymous gr5Pr9AV0% (1)

- Boilers InspectionDocument62 pagesBoilers Inspectionrty288% (16)

- OM9210 - 10 Boiler MaintenanceDocument4 pagesOM9210 - 10 Boiler MaintenanceBSF100% (1)

- Exp 4Document4 pagesExp 4Faith de Leon ♥0% (1)

- IMG - 0152 PSME Code 2008 144Document1 pageIMG - 0152 PSME Code 2008 144bnqr584bNo ratings yet

- Drydocking InspectionDocument26 pagesDrydocking Inspectiondan_artimofNo ratings yet

- Boiler MaintenanceDocument4 pagesBoiler Maintenancekeerthi dayarathnaNo ratings yet

- Inspection Procedure of Medium Risk Installed Boilers As Per IBR, 1950Document2 pagesInspection Procedure of Medium Risk Installed Boilers As Per IBR, 1950ratanNo ratings yet

- Tips & Techniques, SK-15, Rev02Document12 pagesTips & Techniques, SK-15, Rev02AntWonxxxNo ratings yet

- API 510 Petrosync Course PDFDocument301 pagesAPI 510 Petrosync Course PDFAkramKassis100% (1)

- Maintenance Boiler Maintenance - Thermal Power Plant A-ZDocument4 pagesMaintenance Boiler Maintenance - Thermal Power Plant A-ZkriziameiahnNo ratings yet

- (Pilot/ Ignitor Assembly at Rear of Grate) : Downloaded From Manuals Search EngineDocument1 page(Pilot/ Ignitor Assembly at Rear of Grate) : Downloaded From Manuals Search EnginegrwgNo ratings yet

- Section15 MAINTENANCE.Document20 pagesSection15 MAINTENANCE.Mithilesh YadavNo ratings yet

- Driskell - Select The Right Control ValveDocument5 pagesDriskell - Select The Right Control ValveDefenceDogNo ratings yet

- Installation, Operation and Maintenance Instructions: Hancock Forged Steel - Gate, Globe and Check ValvesDocument6 pagesInstallation, Operation and Maintenance Instructions: Hancock Forged Steel - Gate, Globe and Check ValvesÁlvaro Martínez FernándezNo ratings yet

- 6KramerFurnaceMaintenance PDFDocument3 pages6KramerFurnaceMaintenance PDFcarrialdi100% (1)

- 130 01 Glass Trac IOM Rev 1Document3 pages130 01 Glass Trac IOM Rev 1vilegual1No ratings yet

- UL-142 R912 Installation InstructionsDocument4 pagesUL-142 R912 Installation InstructionsRodrigoNo ratings yet

- Importance of Maintaining Valve RecordsDocument5 pagesImportance of Maintaining Valve Recordsmuthu kujmarNo ratings yet

- Heat Exchanger Tube Bundle InspectionDocument3 pagesHeat Exchanger Tube Bundle InspectionVenkatesh Natla100% (4)

- Sti R912Document4 pagesSti R912Mauricio AdameNo ratings yet

- FORGED - Gate, Globe & Check Valve Manual - Xomox SanmarDocument20 pagesFORGED - Gate, Globe & Check Valve Manual - Xomox SanmarSaibabu SaiNo ratings yet

- Boiler Inspections GudeDocument4 pagesBoiler Inspections GudeJayanath Nuwan SameeraNo ratings yet

- BestpracticesDocument2 pagesBestpracticesClaudio VieiraNo ratings yet

- Failure Tube BoilerDocument8 pagesFailure Tube Boilerberanosh100% (3)

- VB Om2 0Document5 pagesVB Om2 0THEO CHASIOTISNo ratings yet

- ICST Cooling Tower Inspection GuidelinesDocument6 pagesICST Cooling Tower Inspection GuidelinesIan FletcherNo ratings yet

- 2.1 Boiler Surveys (2013)Document58 pages2.1 Boiler Surveys (2013)Diegos44No ratings yet

- Macroetch Testing of Tool Steel Bars: Standard Practice ForDocument2 pagesMacroetch Testing of Tool Steel Bars: Standard Practice ForAmir AlikhaniNo ratings yet

- Iom Forged GGC ValvesDocument12 pagesIom Forged GGC ValvesMohamadIbnuHassanNo ratings yet

- Part2 Sec3 pg34-41Document8 pagesPart2 Sec3 pg34-41Alexis GaitanNo ratings yet

- Understanding The Hazard: Boiler-Tube ErosionDocument4 pagesUnderstanding The Hazard: Boiler-Tube ErosionIan B. YtomNo ratings yet

- LNG Shutdown ChecksheetDocument4 pagesLNG Shutdown ChecksheethamxammedNo ratings yet

- Om9210 10Document4 pagesOm9210 10Anil KumarNo ratings yet

- Illustration and Analysis of Seal Face Damage PatternsDocument12 pagesIllustration and Analysis of Seal Face Damage PatternsЭдуардс КеистерсNo ratings yet

- Steam Turbine Maintenance: Vibration DampersDocument2 pagesSteam Turbine Maintenance: Vibration Dampersdreamboy87No ratings yet

- External Visual Inspections of Pressure VesselsDocument2 pagesExternal Visual Inspections of Pressure Vesselssamy singaporeNo ratings yet

- Installation, Maintenance and Operating Instructions Cast Iron, Malleable Iron, Brass and Bronze Gate ValvesDocument4 pagesInstallation, Maintenance and Operating Instructions Cast Iron, Malleable Iron, Brass and Bronze Gate ValvesModassir ZaheenNo ratings yet

- Internal & External Inspection GuidelinesDocument5 pagesInternal & External Inspection Guidelinesgeverett2765No ratings yet

- Section 5. Visual Corrosion Inspection Guide For AircraftDocument2 pagesSection 5. Visual Corrosion Inspection Guide For AircraftblackhawkNo ratings yet

- Cryogenic Ball Valves: Installation, Operation and Maintenance InstructionsDocument8 pagesCryogenic Ball Valves: Installation, Operation and Maintenance InstructionsDv Maria PradhikaNo ratings yet

- Isolation Valve - Watts E3243Document4 pagesIsolation Valve - Watts E3243AHMAD ISLAHINo ratings yet

- How To Read Steel Ladle WearDocument7 pagesHow To Read Steel Ladle WearIcaro GavaNo ratings yet

- Installation, Maintenance and Operating Instructions Cast Iron, Malleable Iron and Bronze Globe ValvesDocument4 pagesInstallation, Maintenance and Operating Instructions Cast Iron, Malleable Iron and Bronze Globe ValvesmahmadwasiNo ratings yet

- WTA Bellow Sealed Valve MaintenanceDocument1 pageWTA Bellow Sealed Valve MaintenanceicingrockNo ratings yet

- Check Valve: Product Bulletin 50-13 CDocument2 pagesCheck Valve: Product Bulletin 50-13 CHuong QuangNo ratings yet

- WTA Manual InstructionsDocument2 pagesWTA Manual InstructionsShah Rizal AbidNo ratings yet

- Tail Shaft SurveyDocument9 pagesTail Shaft SurveyrajishrrrNo ratings yet

- Type ValveDocument64 pagesType ValveJepri MarpaungNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentFrom EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNo ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168From EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168No ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Laboratory Manual of Glass-BlowingFrom EverandLaboratory Manual of Glass-BlowingRating: 5 out of 5 stars5/5 (1)

- Site Safety Handbook for the Petroleum IndustryFrom EverandSite Safety Handbook for the Petroleum IndustryRating: 5 out of 5 stars5/5 (1)

- IMG - 0100 MCQ Bank For Computer Fundamentals MRC 25Document1 pageIMG - 0100 MCQ Bank For Computer Fundamentals MRC 25Arwyn BermasNo ratings yet

- IMG - 0320 MCQ Industrial Plant Engg 223Document1 pageIMG - 0320 MCQ Industrial Plant Engg 223Arwyn BermasNo ratings yet

- IMG - 0092 MCQ Bank For Computer Fundamentals MRC 17Document1 pageIMG - 0092 MCQ Bank For Computer Fundamentals MRC 17Arwyn BermasNo ratings yet

- IMG - 0292 MCQ Industrial Plant Engg 169Document1 pageIMG - 0292 MCQ Industrial Plant Engg 169Arwyn BermasNo ratings yet

- IMG - 0094 MCQ Bank For Computer Fundamentals MRC 19Document1 pageIMG - 0094 MCQ Bank For Computer Fundamentals MRC 19Arwyn BermasNo ratings yet

- IMG - 0313 MCQ Industrial Plant Engg 209Document1 pageIMG - 0313 MCQ Industrial Plant Engg 209Arwyn BermasNo ratings yet

- IMG - 0291 MCQ Industrial Plant Engg 167Document1 pageIMG - 0291 MCQ Industrial Plant Engg 167Arwyn BermasNo ratings yet

- IMG - 0091 MCQ Bank For Computer Fundamentals MRC 16Document1 pageIMG - 0091 MCQ Bank For Computer Fundamentals MRC 16Arwyn BermasNo ratings yet

- IMG - 0097 MCQ Bank For Computer Fundamentals MRC 22Document1 pageIMG - 0097 MCQ Bank For Computer Fundamentals MRC 22Arwyn BermasNo ratings yet

- IMG - 0096 MCQ Bank For Computer Fundamentals MRC 21Document1 pageIMG - 0096 MCQ Bank For Computer Fundamentals MRC 21Arwyn BermasNo ratings yet

- IMG - 0099 MCQ Bank For Computer Fundamentals MRC 24Document1 pageIMG - 0099 MCQ Bank For Computer Fundamentals MRC 24Arwyn BermasNo ratings yet

- IMG - 0095 MCQ Bank For Computer Fundamentals MRC 20Document1 pageIMG - 0095 MCQ Bank For Computer Fundamentals MRC 20Arwyn BermasNo ratings yet

- IMG - 0093 MCQ Bank For Computer Fundamentals MRC 18Document1 pageIMG - 0093 MCQ Bank For Computer Fundamentals MRC 18Arwyn BermasNo ratings yet

- IMG - 0073 MCQ EE Board Problem 2012 30Document1 pageIMG - 0073 MCQ EE Board Problem 2012 30Arwyn BermasNo ratings yet

- IMG - 0210 PSME Code 2008 199Document1 pageIMG - 0210 PSME Code 2008 199Arwyn BermasNo ratings yet

- IMG - 0076 MCQ EE Board Problem 2012 33Document1 pageIMG - 0076 MCQ EE Board Problem 2012 33Arwyn BermasNo ratings yet

- IMG - 0074 MCQ EE Board Problem 2012 31Document1 pageIMG - 0074 MCQ EE Board Problem 2012 31Arwyn BermasNo ratings yet

- IMG - 0075 MCQ EE Board Problem 2012 32Document1 pageIMG - 0075 MCQ EE Board Problem 2012 32Arwyn BermasNo ratings yet

- IMG - 0207 PSME Code 2008 196Document1 pageIMG - 0207 PSME Code 2008 196Arwyn BermasNo ratings yet

- IMG - 0295 MCQ Industrial Plant Engg 175Document1 pageIMG - 0295 MCQ Industrial Plant Engg 175Arwyn BermasNo ratings yet

- IMG - 0205 PSME Code 2008 194Document1 pageIMG - 0205 PSME Code 2008 194Arwyn BermasNo ratings yet

- IMG - 0209 PSME Code 2008 198Document1 pageIMG - 0209 PSME Code 2008 198Arwyn BermasNo ratings yet

- IMG - 0208 PSME Code 2008 197Document1 pageIMG - 0208 PSME Code 2008 197Arwyn BermasNo ratings yet

- IMG - 0203 PSME Code 2008 192Document1 pageIMG - 0203 PSME Code 2008 192Arwyn BermasNo ratings yet

- IMG - 0201 PSME Code 2008 190Document1 pageIMG - 0201 PSME Code 2008 190Arwyn BermasNo ratings yet

- IMG - 0077 MCQ EE Board Problem 2012 34Document1 pageIMG - 0077 MCQ EE Board Problem 2012 34Arwyn BermasNo ratings yet

- IMG - 0078 MCQ EE Board Problem 2012 35Document1 pageIMG - 0078 MCQ EE Board Problem 2012 35Arwyn BermasNo ratings yet

- IMG - 0079 MCQ EE Board Problem 2012 36Document1 pageIMG - 0079 MCQ EE Board Problem 2012 36Arwyn BermasNo ratings yet

- IMG - 0071 MCQ EE Board Problem 2012 28Document1 pageIMG - 0071 MCQ EE Board Problem 2012 28Arwyn BermasNo ratings yet

- IMG - 0072 MCQ EE Board Problem 2012 29Document1 pageIMG - 0072 MCQ EE Board Problem 2012 29Arwyn BermasNo ratings yet

- Book 2Document39 pagesBook 2VigneshNo ratings yet

- Spaulding Lighting Lisbon Floodlight Spec Sheet 6-77Document2 pagesSpaulding Lighting Lisbon Floodlight Spec Sheet 6-77Alan MastersNo ratings yet

- Pompa Dari Embung Ke Bak Sirkulasi / Penjernih: ContentsDocument11 pagesPompa Dari Embung Ke Bak Sirkulasi / Penjernih: ContentsewamihawkNo ratings yet

- Fuel Dilution of In-Service Lubricants Using Surface Acoustic Wave SensingDocument6 pagesFuel Dilution of In-Service Lubricants Using Surface Acoustic Wave SensingNabeel H. Al-SaighNo ratings yet

- Wideband Microstrip AntennasDocument181 pagesWideband Microstrip AntennasSimona DanNo ratings yet

- R147isbn9512284170 PDFDocument81 pagesR147isbn9512284170 PDFSureshNo ratings yet

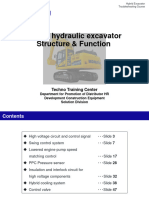

- Hybrid Excavator Structure & FunctionDocument49 pagesHybrid Excavator Structure & Functiontransjakarta0123No ratings yet

- Thesis On Laser CuttingDocument8 pagesThesis On Laser Cuttingtonyacartererie100% (2)

- Fan Shop Testing Procedure BS 848Document3 pagesFan Shop Testing Procedure BS 848panduranganraghurama0% (1)

- Energy Efficiency in Historic BuildingsDocument17 pagesEnergy Efficiency in Historic Buildingstexas_peteNo ratings yet

- NGU Fans Technical SubmittalsDocument104 pagesNGU Fans Technical SubmittalsAhmed NabilNo ratings yet

- Samsung DVM Chiller InstallationManualDocument56 pagesSamsung DVM Chiller InstallationManualjlmoleroNo ratings yet

- ISG11 CM2880 G108 Euro-III 4332905Document1 pageISG11 CM2880 G108 Euro-III 4332905vicente456No ratings yet

- RMU Operation & Installation Manual 2019Document17 pagesRMU Operation & Installation Manual 2019fahad sameerNo ratings yet

- 24-013, 24-014 Catalog Page PDFDocument2 pages24-013, 24-014 Catalog Page PDFAndres Felipe TapiaNo ratings yet

- Apar 2004 2005Document51 pagesApar 2004 2005RamaNo ratings yet

- Figaro: For The Detection of AmmoniaDocument3 pagesFigaro: For The Detection of AmmoniaMbeng TriantoNo ratings yet

- Ola Electric-1Document10 pagesOla Electric-1ANJALA S SNo ratings yet

- Lecture 1-Eng Materials and Iron and Steel MakingDocument44 pagesLecture 1-Eng Materials and Iron and Steel Makingم.ذكى فضل ذكى100% (1)

- Lecture 5 Multi-Evaporator and Cascade SystemsDocument16 pagesLecture 5 Multi-Evaporator and Cascade SystemsMeftah ElfituriNo ratings yet

- Overhaul Packer 2Document2 pagesOverhaul Packer 2maherianto 29No ratings yet

- EEE 483 (Grid Tied PV Systems)Document37 pagesEEE 483 (Grid Tied PV Systems)Sanjoy SanaNo ratings yet

- 2011 MX5 Service ManualDocument3,841 pages2011 MX5 Service ManualSandocars MotorNo ratings yet

- Trane Intellipak 2: Rooftop Comfort SystemDocument8 pagesTrane Intellipak 2: Rooftop Comfort SystemTrever TomesNo ratings yet

- Osha ProjectDocument24 pagesOsha Projectsandhya kondapurNo ratings yet

- 3VM Molded Case Circuit Breakers: General DataDocument1 page3VM Molded Case Circuit Breakers: General DataMarco Antonio Quispe RoqueNo ratings yet

- bài tập sửa lỗi saiDocument2 pagesbài tập sửa lỗi saiVân HươngNo ratings yet

- EWWD-FZ - D-EIMWC00908-16 - Installation and Operation Manuals - EnglishDocument52 pagesEWWD-FZ - D-EIMWC00908-16 - Installation and Operation Manuals - EnglishAnand sNo ratings yet