Professional Documents

Culture Documents

Nokia Global HS&PS Standard Electrical Safety Document EN

Nokia Global HS&PS Standard Electrical Safety Document EN

Uploaded by

Moussa AdamouOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nokia Global HS&PS Standard Electrical Safety Document EN

Nokia Global HS&PS Standard Electrical Safety Document EN

Uploaded by

Moussa AdamouCopyright:

Available Formats

CID202363

Global HS&PS Standard - Electrical Safety

Nokia People Experience Health, Safety and Physical Security

Date 30th September 2016

Author Sameh Eisa

Owner Head of Health, Safety & Physical Security

Organization People Experience Health, Safety & Physical Security

Approver Marty Bishop

Document ID SP-44ISPA3ISPS4-1013285096-137

Doc Location SharePoint/CPO PE HS&PS Intranet

Change History

Version Status Date Handled by Comments

1.0 First Issue 19th December Robert Nolan New Issue

2016

2.0 Approved 18th Jan 2019 Sameh Eisa Minor changes: Creator changed to

Owner and Sameh Eisa. The header

& footer are updated to reflect the

new template.

3.0 Approved 28th June 2022 Sameh Eisa Changes to reflect organizational

changes

11-05-2022 – SP-44ISPA3ISPS4-1013285096-137 - 1 / 19 © Nokia 2022

Table of Contents

1 PRINCIPLES 3

2 KEY DEFINITIONS AND SCOPE 4

3 REQUIREMENTS 7

4 IMPLEMENTATION EXPECTATIONS 18

11-05-2022 – SP-44ISPA3ISPS4-1013285096-137 - 2 / 19 © Nokia 2022

1 Principles

Nokia recognizes that working on or adjacent to electrical systems and equipment is

an essential part of Nokia’s business, if not managed correctly this poses a significant

risk to our employees, contractors and service providers.

This standard describes the minimum health and safety requirements that must be

adopted whilst working on electrical systems and equipment on behalf of Nokia. Nokia

expects that its staff and partners return home safely at the end of each working day

by applying the following principles when working with electricity:

• Under normal circumstances live working is not permitted.

• Live work will only be done when risk controls have been implemented and a

safe system of work established.

• All electrical systems and equipment must be properly designed, installed,

commissioned, maintained and decommissioned.

• All persons working on electrical systems and equipment must be competent to

carry out the intended work.

• All electrical equipment, including tools and associated personal protective

equipment must be suitable for the work being done.

• A First Aider with CPR training will be present at all times when electrical work

with significant risk (Cat 3 and Cat 4) is happening.

This Standard details Nokia’s expectations in relation to working on or near electrical

systems and equipment. The expectations detailed here apply to all Nokia business

units and all contractors and service providers conducting work on its behalf and are in

addition to local legal requirements:

Section 3 contains the minimum requirements that Nokia expects. If these cannot be

achieved a documented exception needs to be agreed upon with both CPO PE HS&PS

and CPO PE S&S setting out the reason why an exception is required and the duration

of the exception.

Section 4 explains who is responsible for ensuring that the requirements are

implemented.

11-05-2022 – SP-44ISPA3ISPS4-1013285096-137 - 3 / 19 © Nokia 2022

2 Key Definitions and Scope

2.1 High voltage* (HV) means all voltage exceeding low voltage (>1000v AC and >1500V DC)

2.2 Low voltage* (LV) means voltage normally exceeding extra-low voltage but not

exceeding 1000V AC or 1500V DC between conductors, or 600V AC or 900V DC between

conductors and earth.

2.3 Extra-low low voltage* (ELV) means voltage not normally exceeding 50V AC or 120V DC,

whether between conductors or to earth.

(Voltage classifications of the International Electrotechnical Commission (IEC) 60038).

2.4 Competent person means someone who has:

2.4.1 Technical knowledge (acquired by academic study or through a combination of

academic study and practical training) of electricity and electrical work;

2.4.2 Knowledge and understanding of the system to be worked on and practical

experience of working on that system;

2.4.3 Understanding of the hazards which may arise during the work and the

precautions which need to be taken;

2.4.4 Knowledge of relevant local safety regulations; and

2.4.5 Ability to recognize at all times whether it is safe to continue.

11-05-2022 – SP-44ISPA3ISPS4-1013285096-137 - 4 / 19 © Nokia 2022

2.5 Conductor means a material or component that can conduct (carry a charge)

electrical energy.

2.6 Dead means not electrically energized.

2.7 Electrical equipment means anything used, intended to be used, or installed for

use to generate, provide, transmit, transform, rectify, convert, conduct,

distribute, control, store, measure or use electrical energy.

2.8 Exclusion zone means a pre-determined area, into which no person can enter

without the permission of the electrical power provider or person in control of

the works.

2.9 Isolated means that the equipment is securely disconnected from all sources of

electrical energy.

2.10 Live means that the equipment in question is connected to a source of electricity

so that parts of it will be at a voltage other than earth potential.

2.11 Live work means work where there is a danger of inadvertent contact with

conductors which are accessible, and which are live or charged.

2.12 PPE means personal protective equipment.

2.13 Safe System of Work means a documented process to identify significant

residual risks and establish effective, practical controls and procedures.

2.14 Electrical system is a combination of electrical equipment which can be or is

connected to a common electrical energy source and includes that source.

2.15 Earth means a conductor of low impedance which provides an electrical

connection between a given point in equipment (an installation or system) and an

earth electrode.

2.16 Fixed wiring installation is the distribution network of electrical cables from the

incoming electrical energy supply to the outlets to which the end equipment is

connected. It includes the wires, fuses circuit breakers, distribution boards and

power outlets of the electrical installation.

11-05-2022 – SP-44ISPA3ISPS4-1013285096-137 - 5 / 19 © Nokia 2022

Scope

This standard applies to all work, including the design, installation, commissioning,

decommissioning and maintenance of electrical systems carried out by or on behalf of Nokia.

Electrical work within the telecoms industry involves working on, or adjacent to the following

types of installation:

• Alternating Current (AC) – usually but not limited to 110Volts, 230 Volts and 415 volts

• Direct Current (DC) – usually 48 Volts DC in telecoms equipment.

In order to simplify the management of electrical Work, the following categories are defined.

Category Description Scope

Work limited to plugging equipment into or out of

racks, turning items of equipment on or off or replacing

Telecommunications

items of equipment.

CAT 1 Equipment & Simple Electrical

These are electrical activities an unskilled person would

Works undertake in their own home.

No live working.

Permitted to carry out minor electrical work on

installations. Work is limited to adding to, repairing or

replacement of existing electrical AC circuits. Low

capacity DC (up to 50Ahr)

CAT 2 Minor Electrical Works

Operatives would require formal electrical training and

be under the direct supervision of someone qualified

to registered electrician level or equivalent standard.

No live working.

High Capacity DC, installation, maintenance and testing

of high capacity DC systems (Over 50Ahr).

CAT 3A High Capacity DC

Qualified registered Electricians or equivalent.

Live working is often unavoidable.

Design, installation and testing of circuits on both AC

and DC systems.

Install test and commission

CAT 4 Certification that the electrical installation is safe and

electrical installations compliant. Qualified registered Electricians or

equivalent.

See Guidance Document for more details on categories.

Nokia operations do not routinely involve working on or managing work on High Voltage

systems and so there are no requirements defined in this standard.

11-05-2022 – SP-44ISPA3ISPS4-1013285096-137 - 6 / 19 © Nokia 2022

3 Requirements

The requirements listed in this Standard apply to all Nokia operations and apply equally to all

contractors, suppliers and partners working on behalf of Nokia. They are non-negotiable.

Electricity presents a variety of risks to exposed workers including, electric shock, heart

defibrillation, burns, arc flash blindness, explosions, fires, smoke and secondary hazards such

as falling as a result of electric shock and death.

People non-negotiable requirements

3.1 General Awareness

3.1.1 Everyone working for Nokia, whose role involves working on or

coming into proximity of electrical systems, circuits and installations

must receive sufficient training related to the electrical risks to

which they are exposed.

3.1.2 The training must cover the risks arising from Nokia or customer

electrical equipment and the associated electrical installation i.e.,

fixed wiring, switches breakers, protective devices, power supplies,

or batteries, in the general vicinity.

3.1.3 The training must cover the defined rules, expected behaviours and

controls detailed in this standard

3.1.4 The training must cover the “right to refuse” to work on something

they believe is dangerous and the escalation process to be followed

for both unsafe practices and reporting unsafe installations

3.2 Competence and Supplier Qualification

All electrical work must be conducted by competent people

3.2.1 Only suppliers that have been H&S qualified to deliver electrical

work are to be used;

3.2.2 Only persons, including subcontractors competent to design,

install, commission, maintain or decommission electrical circuits

and equipment may do so;

3.2.3 Where local electrical registration/certification schemes exist, only

registered/certified electrical contractor’s personnel will be used

for electrical work; Records of certifications or evidence of

11-05-2022 – SP-44ISPA3ISPS4-1013285096-137 - 7 / 19 © Nokia 2022

qualifications must be held and made available on request by

subcontractors;

3.2.4 In countries where no such registration/certification schemes exist,

further evaluation and assessment of the individual/s must be

completed before they are permitted to undertake electrical work

on behalf of Nokia (this must be determined and approved in-

country).

3.2.5 Work on high transmission voltages can only be undertaken by

specialized electricians trained to work in such high voltage

environments.

3.3 Medical Fitness to Work

3.3.1 Electrical workers must be medically and physically fit to work and

be assessed according to local legislation where required.

3.3.2 If no legislative requirements exist, as a minimum, a medical fitness

assessment must check for the absence of colour vision deficiency,

or medical conditions that might impact an individual’s ability to

work with electricity safely.

11-05-2022 – SP-44ISPA3ISPS4-1013285096-137 - 8 / 19 © Nokia 2022

Installation non-negotiable requirements

3.4 Design, Installation & Maintenance of Electrical Systems

3.4.1 All electrical systems and equipment must be designed and installed

by a competent person in accordance with local legal requirements

and must specifically consider the Intended load; electrical source

capacity, cabling requirements, fault, and overload protection,

means of isolation and emergency shut off, earthing and bonding.

3.4.2 When working on third-party premises: The site

occupier/owner/customer must be consulted prior to any

installation or modification of electrical systems i.e., as-built

drawings, circuit diagrams, circuit loading.

3.4.3 Commissioning of Electrical Systems: All new and altered wiring

installations must be inspected, tested, and certified by a

competent person in accordance with local legislation, prior to the

system being put into service.

3.4.4 Maintenance of Electrical Systems. All electrical systems must be

safe to use and work on and must be:

• Inspected and tested in line with manufacturers’ recommendations (e.g., for UPS)

and by a competent person in accordance with local legislation or where this is not

specified, at a maximum interval of 5 years for fixed wiring installations.

• Supported by appropriate records, including up-to-date circuit diagrams/plans.

• Live/functional testing of an electrical system must only be carried out by a

competent person and only after appropriate control measures have been

implemented.

• If the environment in which electrical systems or equipment are located poses a

specific risk, maintenance requirements and schedules must reflect that

additional risk.

3.5 High Voltage Rooms

3.5.1 Access must be restricted to authorized persons using physical

access control

3.5.2 All tools and equipment used must be specifically rated and

insulated;

11-05-2022 – SP-44ISPA3ISPS4-1013285096-137 - 9 / 19 © Nokia 2022

3.5.3 Barriers and signs including hazard warning signs must be in place to

restrict access to the high voltage rooms and the live conductors

within.

3.6 Distribution Boards/Power Supplies

3.6.1 Distribution boards, power supplies and electrical panels must be

fitted with guarding, screening, or shielding to prevent contact with

live terminals or conductors.

3.6.2 Distribution boards and electrical panels within publicly accessible

areas must be locked.

3.6.3 Distribution boards or enclosures containing exposed live busbar

systems or readily accessible uninsulated terminations are

considered live.

3.7 UPS, Batteries and Battery Arrays.

3.7.1 All UPS systems including smaller base station UPSs and the larger

equipment room UPSs, must be designed, and installed in such a

way that live components are insulated and guarded or enclosed to

prevent inadvertent access.

3.7.2 UPS systems can store large amounts of energy at various voltages

and must be maintained by competent trained specialists in

accordance with the manufacturer’s specifications.

3.7.3 The battery manufacturer’s gas venting requirements must be

complied with in all design, installation, and maintenance operations.

Failure to do could result in the accumulation of gas with a risk of

explosion. The presence of the required venting arrangements must

be part of site inspection regimes, with an emergency procedure in

place to react to their absence.

3.7.4 All tools and equipment used must be specifically rated and

insulated.

3.7.5 All work on Nokia and customer UPS systems is to be considered as

CAT 3A, therefore requiring an appropriately trained qualified

electrician, unless the system capacity in ampere-hours is less than

50Ahr.

11-05-2022 – SP-44ISPA3ISPS4-1013285096-137 - 10 / 19 © Nokia 2022

3.8 Management Requirements (Nokia premises)

Nokia People and Places (Real Estate – Workplace Resources) must ensure that:

3.8.1 All electrical systems located within Nokia premises are designed,

installed, commissioned, decommissioned, and maintained in such a

way that makes them safe to be used, worked on or nearby.

3.8.2 Up-to-date circuit diagrams and plans are maintained for all

electrical systems within Nokia premises where Nokia is responsible

for design, installation, or maintenance.

3.8.3 All electrical work carried out within Nokia premises is appropriately

planned and managed.

Nokia Laboratory/R&D/IT groups must ensure that:

3.8.4 All electrical equipment, cabinets/racks, and electrical cords within

their areas are suitably and safely maintained.

3.8.5 All electrical work within their areas, excluding that which takes place

directly on/within test equipment and racking etc., is coordinated,

and controlled by Nokia WR. Only competent persons may undertake

electrical work within labs.

11-05-2022 – SP-44ISPA3ISPS4-1013285096-137 - 11 / 19 © Nokia 2022

Methods and practice non-negotiables

3.9 Working On Live Electrical Systems

3.9.1 Live working is typically prohibited, however, if it is not possible to

isolate the circuits concerned, or de-energizing them creates a

greater hazard, an exception process must be established which

ensures:

• The reasons for the work needing to be conducted live are recorded.

• A safe system of work is defined by a person competent in managing live working

and the controls necessary to reduce the very high risks involved.

• There are at least two qualified persons present i.e., lone working is not permitted.

Note: Swapping out circuit boards or packs that are designed to be swapped out whilst

the rack or unit is powered up is not considered “live” working.

3.10 Isolation of Electrical Systems

3.10.1 Electrical systems must be isolated from all sources of electrical

power prior to working on or adjacent to exposed conductors or

terminals.

This includes supply from backup generators, UPS, control circuits and other dual

supply situations.

3.10.2 Physical isolation methods should be used where possible i.e.,

removal of fuses, circuit isolators, or Lock-out /Tag-out.

3.10.3 If there is the possibility of the system being re-energized by

another person, without the knowledge of the person working on

the system physical isolation is mandatory.

3.10.4 If physical isolation is not possible the switching point must be

supervised for the duration of the work.

3.11 Proving ‘Dead’

3.11.1 The system/equipment/circuit must be tested and “proved dead”

using appropriate insulated test equipment prior to any work

starting.

3.11.2 The test must be repeated after any interruptions such as meal

breaks or needs to leave the location for any amount of time.

11-05-2022 – SP-44ISPA3ISPS4-1013285096-137 - 12 / 19 © Nokia 2022

3.12 First Aid & Emergency Response

3.12.1 An individual or individuals trained and capable of giving first aid and

cardiopulmonary resuscitation (CPR) must be available on-site where

electrical work Category 3A and Category 4 or any live work is

undertaken.

3.12.2 A site-specific emergency plan must be in place and communicated

to workers at sites where electrical work Category 3A and Category 4

are undertaken.

11-05-2022 – SP-44ISPA3ISPS4-1013285096-137 - 13 / 19 © Nokia 2022

3.13 Working Adjacent to Live Electrical Systems

The following work carries risks from adjacent electrical installations.

3.13.1 Buried/Hidden Cables -

The location of all services must be identified using a previously determined and consistent

method prior to any intrusive works. This includes before cutting, piercing, or drilling any wall,

floor, ceiling, or any other structural element where a likelihood of contacting energised

electrical cables or parts exists.

3.13.2 Overhead Lines

When working near overhead power lines:

• Safe horizontal and vertical clearance distances from overhead lines must be

established; if any need to go any closer than 10m horizontal distance you must

seek professional advice from the electricity utility company or competent

professional.

• Clearly marked exclusion zones must be set up and maintained.

• The use of vehicles, plants, machinery, equipment, or materials that could reach

beyond the safe clearance distance is not permitted, except where specific

supplementary controls are implemented to ensure that safe distances are

maintained. See Appendix of Guidance Document for details of safe clearance

distances.

• Where supply lines contact a structure that is to be climbed, the integrity of the

insulation on the cables must be confirmed before climbing can begin. A

combination of visual inspection of the cables at points of contact and the

structure’s earthing arrangements should be undertaken. If this integrity cannot

be confirmed, a competent electrician must inspect the installation and confirm

that it is safe to climb.

3.14 Exclusion Zones

3.14.1 Exclusion zones including the use of barriers and signage must be

used if there is a risk of untrained persons entering the areas where

electrical work is being done.

3.14.2 The access points must be physically controlled or supervised at all

times.

11-05-2022 – SP-44ISPA3ISPS4-1013285096-137 - 14 / 19 © Nokia 2022

3.15 Safety Signs

3.15.1 Safety and warning signs must be used to inform of the danger of

electrical hazards whilst work is ongoing. The signage should be

pictorial and easily recognizable to all persons.

.

11-05-2022 – SP-44ISPA3ISPS4-1013285096-137 - 15 / 19 © Nokia 2022

Tools and Equipment non-negotiables

3.16 Tools & Protective Equipment

Hand Tools: All hand tools used for working on or near live electrical systems must be:

3.16.1 Fully insulated.

3.16.2 Maintained in good condition.

3.16.3 Checked for defects before use and replaced as necessary.

3.16.4 Rated for the voltages they are intended to be used on.

3.17 Portable Power Tools

3.17.1 Electrical power tools must be selected in the following order of

preference unless local legal requirements define more restrictive

requirements:

• Battery powered.

• Those powered by an isolating transformer with an earthed centre tapped voltage of

110V AC.

• If powered directly from a mains supply, be of double insulated construction and

protected at the point of connection by a Residual Current Device (RCD).

• The RCD should be tested using the device test button before use.

3.17.2 All portable electrical power tools and equipment must be

appropriately inspected and maintained which means:

• As a minimum, all portable electrical tools and equipment must be visually inspected

before use and taken out of service if faulty.

• Regular inspection by a competent person should be undertaken; the frequency of

which is dictated by local legal requirements or based on the type of equipment, the

severity of use and usage rate. The frequency of inspection of portable tools should

be at least annually.

• Results of inspections should be recorded.

3.18 Ladders & Platforms

3.18.1 Only non-conductive ladders/platforms can be used in the vicinity of

exposed electrical circuits or whilst undertaking electrical work.

3.18.2 Ladders should be subject to regular documented inspections.

11-05-2022 – SP-44ISPA3ISPS4-1013285096-137 - 16 / 19 © Nokia 2022

3.19 Portable Electrical Appliances

3.19.1 As a minimum, all portable electrical appliances and equipment

(laptop power supplies, kettles, desk lamps, printers, etc.) must be

visually inspected before use and taken out of service if faulty.

3.19.2 In addition, regular inspection by a competent person should be

undertaken; the frequency of which is dictated by local legal

requirements or based on the type of equipment and usage rate.

(Usually referred to as Portable Appliance Testing (PAT).

3.19.3 Results of inspections should be recorded.

3.20 Personal Protective Equipment (PPE)

3.20.1 All PPE must be appropriate for the electrical risk encountered,

inspected at a frequency dictated by local regulations or annually as

a minimum and especially before use, and taken out of service if

defective and replaced.

3.20.2 An approved list of the PPE must be maintained for all foreseeable

works. For electrical works appropriate, hardhats, insulated gloves,

and face guards. Specific selection guidance can be found in the

Guidance to the Electrical Standard.

11-05-2022 – SP-44ISPA3ISPS4-1013285096-137 - 17 / 19 © Nokia 2022

4 Implementation Expectations

4.1 Every business unit leader must ensure, within their area of responsibility, that the

requirements of this standard are implemented.

4.2 CPO PE S&S must ensure that for every location that Nokia operates in, the minimum

requirements defined in section 3 are defined for local implementation, captured in local

documentation, consulted with local stakeholders, and communicated to all relevant

parties. This can be:

4.2.1 Specific to a country;

4.2.2 Defined across a region where there is regional alignment or Nokia requirements

exceed local requirements in all listed areas;

4.2.3 Tailored based on customer requirements or expectations;

4.2.4 Consider local legal requirements and restrictions.

4.3 Nokia People and Places must ensure that:

All electrical systems located within Nokia premises are designed, installed,

commissioned, decommissioned, and maintained in such a way that makes them safe to

use, be worked on or nearby.

4.4 Nokia Laboratory/R&D/IT groups are responsible for ensuring that:

All electrical equipment and cabinets/racks within their areas are suitably and safely

maintained and all electrical work within their areas is coordinated and controlled by

Nokia People and Places.

4.5 Nokia HR must ensure that a process exists for the management of all employed Nokia

employees that:

Enables action to be taken should an individual not meet the requirements defined in the

standard.

4.6 Procurement and Sourcing must ensure that where companies or individuals are sourced

to provide electrical work that:

4.6.1 The requirements in section 3 are communicated and understood and the

supplier can meet these expectations when they are awarded work.

4.6.2 The supplier is made aware of Nokia reporting requirements related to electrical

work.

4.7 Contractors/Third Parties are responsible for ensuring that minimum requirements

defined in section 3 are locally adopted, clearly communicated to their employees,

understood and implemented within their area of work.

11-05-2022 – SP-44ISPA3ISPS4-1013285096-137 - 18 / 19 © Nokia 2022

5. Recommendations

The requirements listed in section 3 apply to all Nokia operations, but the geographical spread

of the business means that the extent of implementation varies. The recommendations

contained in this section aim to guide how to achieve the requirements. Should these be

deviated from, that decision needs to be documented.

Electrical risk is a factor that Nokia field employees, suppliers, contractors, and partners

working for or on behalf of Nokia may be exposed to. Where they are exposed to this risk, the

consequences of an incident can be severe including death.

The requirements of this standard apply to all these groups, when approaching

implementation this needs to be conducted on a risk-based approach.

In order to determine the extent to which the requirements of this standard apply each

business unit should conduct an assessment of the electrical risk posed to their operation.

The requirements in section 3 detail WHAT is expected, as the measures needed to reach this

standard vary around the world, there is a Global HS&PS Guidance Document available that

should be read in conjunction with this standard.

11-05-2022 – SP-44ISPA3ISPS4-1013285096-137 - 19 / 19 © Nokia 2022

You might also like

- Operation Guide - RX Path ImbalanceDocument3 pagesOperation Guide - RX Path ImbalanceBiodun123456775% (4)

- 蒸汽调节阀Document26 pages蒸汽调节阀陈浩祥100% (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- DEWA Regulations 2017Document123 pagesDEWA Regulations 2017siva_nagesh_280% (5)

- ELECTRICAL INSTALLATIONS Task1Document7 pagesELECTRICAL INSTALLATIONS Task1Akmal HazimNo ratings yet

- Sharjah RegulationsDocument129 pagesSharjah RegulationsAbdallah Omar Al Ayoubi86% (121)

- Rocker SwitchDocument24 pagesRocker Switchyamaha640No ratings yet

- 3.3 Selection of Switchyard Equipment For SHPDocument99 pages3.3 Selection of Switchyard Equipment For SHPKrishna Mohan Sharma100% (1)

- Electrical Safety Policy v1.4Document13 pagesElectrical Safety Policy v1.4Mahmoud Al ShamiNo ratings yet

- WWW 20180319 Electricity at WorkDocument13 pagesWWW 20180319 Electricity at WorkMogodan GabrielNo ratings yet

- Medium Voltage Fi Xed Electrical Installations: SANS 10142 - Part 2Document4 pagesMedium Voltage Fi Xed Electrical Installations: SANS 10142 - Part 2Rohit SahNo ratings yet

- CBLMDocument30 pagesCBLMrowell ramosNo ratings yet

- 15869Document4 pages15869danialNo ratings yet

- QP Assistant ElectricianDocument52 pagesQP Assistant Electricianudi969No ratings yet

- CIRED2007 0230 PaperDocument4 pagesCIRED2007 0230 PaperAries dNo ratings yet

- NAC20-33K-DT User ManualDocument21 pagesNAC20-33K-DT User ManualWaldemar Alvares RezendeNo ratings yet

- Global Facilities - Electrical - Electrical Specification Design StandardDocument202 pagesGlobal Facilities - Electrical - Electrical Specification Design StandardaizatmaricanNo ratings yet

- ELC-SU-6206 Electrical Safe Work Practices: Exception To NFPA 70E, 2018Document10 pagesELC-SU-6206 Electrical Safe Work Practices: Exception To NFPA 70E, 2018OSSAI IFEANYI ANTHONYNo ratings yet

- 10SF.11 - MOG-HSEQ-SF-P-081 Rev A1 Electrical SafetyDocument21 pages10SF.11 - MOG-HSEQ-SF-P-081 Rev A1 Electrical SafetySamerNo ratings yet

- 4 - 2015 - Catalog - ABB Cable Accessories 7.2-42 KV - English - IntroductionDocument6 pages4 - 2015 - Catalog - ABB Cable Accessories 7.2-42 KV - English - IntroductionlatifNo ratings yet

- High Voltage Switching Operations: The Next StepDocument2 pagesHigh Voltage Switching Operations: The Next Steplenon chidzivaNo ratings yet

- Electrical SafetyDocument33 pagesElectrical Safetyxp4jjx6wqfNo ratings yet

- NESC 07 12 ChangesDocument31 pagesNESC 07 12 ChangesTim Mit100% (1)

- COES Fundamentals Aug2021Document7 pagesCOES Fundamentals Aug2021arrnobleNo ratings yet

- Portable Earthing Devices (Peds) : GeneralDocument14 pagesPortable Earthing Devices (Peds) : GeneralMazenNo ratings yet

- Assistant ElectricianDocument50 pagesAssistant ElectricianSarkar GattimNo ratings yet

- Technical Guidelines For Small EG ConnectionsDocument28 pagesTechnical Guidelines For Small EG ConnectionsdebasishNo ratings yet

- Manual Planificacion Instalacion DeviceNET ALBR1485PP1N5MN5R1 - Inst PDFDocument91 pagesManual Planificacion Instalacion DeviceNET ALBR1485PP1N5MN5R1 - Inst PDFCarlitos GuerraNo ratings yet

- Bosch Divar Ip 3000 - Installation - GuideDocument32 pagesBosch Divar Ip 3000 - Installation - GuidePuput PutraNo ratings yet

- MS - LVAC Cable Sleve Installation WorksDocument17 pagesMS - LVAC Cable Sleve Installation WorksHafizul TarmiziNo ratings yet

- New Sewa Regulation Book 2017Document226 pagesNew Sewa Regulation Book 2017Ahmed Siddig RihanNo ratings yet

- Electrical SafetyDocument6 pagesElectrical SafetyluisNo ratings yet

- У ДИССЕРТАЦІЮ Реле у залізі з характеристикамиDocument7 pagesУ ДИССЕРТАЦІЮ Реле у залізі з характеристикамиvasiliy vasilievichNo ratings yet

- 4256-0472 KSG-3K-SM3Document38 pages4256-0472 KSG-3K-SM3sdfsgfddgzNo ratings yet

- Eltek Flatpack RectifiersDocument40 pagesEltek Flatpack RectifiersMadd000No ratings yet

- 350002-013 UserGde Flatpack2-Rectifiers-Converters 8v1 PDFDocument40 pages350002-013 UserGde Flatpack2-Rectifiers-Converters 8v1 PDFjunior9742No ratings yet

- Cat A1 SOP 04 Working On or Near Energized Electrical Equipment PDFDocument19 pagesCat A1 SOP 04 Working On or Near Energized Electrical Equipment PDFRached Ben AyedNo ratings yet

- Module 1 of EIM NC II UNIT 1Document31 pagesModule 1 of EIM NC II UNIT 1John Roy GarzonNo ratings yet

- 41 S 2 EdcDocument44 pages41 S 2 EdcMahmoud ChihebNo ratings yet

- Tp21oc 0Document14 pagesTp21oc 0Tushar SarkarNo ratings yet

- Presentation - Non-Domestic Electrical Installation Safety CodeDocument39 pagesPresentation - Non-Domestic Electrical Installation Safety CodeTommy YapNo ratings yet

- Bunbury HVSO Generic Capability Statement Updated Room ImagesDocument2 pagesBunbury HVSO Generic Capability Statement Updated Room Imageslenon chidzivaNo ratings yet

- Intertek IEC EN 60079 25 Intrinsically Safe Electrical SystemsDocument2 pagesIntertek IEC EN 60079 25 Intrinsically Safe Electrical Systemssofiane mokhtariNo ratings yet

- Dewa Installation - Regulstions1997Document62 pagesDewa Installation - Regulstions1997Imran Mughle AzamNo ratings yet

- Delta SOLIVIA Inverter 2.5APG3 Installation GuideDocument148 pagesDelta SOLIVIA Inverter 2.5APG3 Installation Guidekselvan_1No ratings yet

- End of Module ExercisesDocument10 pagesEnd of Module ExercisesEVA EUNICE SUAREZNo ratings yet

- Application of Low Voltage High Resistance GroundiDocument7 pagesApplication of Low Voltage High Resistance Groundiimadedwi697No ratings yet

- 08 Electrical InstallationDocument28 pages08 Electrical InstallationYunus SiregarNo ratings yet

- AMD2 Summary of The Key ChangesDocument47 pagesAMD2 Summary of The Key ChangesshaanNo ratings yet

- Guidelines For The HVDocument12 pagesGuidelines For The HVwbosmanNo ratings yet

- ReportDocument26 pagesReportleungyautatNo ratings yet

- 2NGA001644 - Earthing of Relay To MV SwitchgearDocument6 pages2NGA001644 - Earthing of Relay To MV SwitchgearAlejandro B.No ratings yet

- Local Media3755029224234881121Document7 pagesLocal Media3755029224234881121Czarina VelascoNo ratings yet

- Electricity Procedure UnitacDocument16 pagesElectricity Procedure UnitacaneeshkadapuzhaNo ratings yet

- Surge Protective DevicesDocument8 pagesSurge Protective Devicesthe hawakNo ratings yet

- Harmonic Filter InstallationDocument18 pagesHarmonic Filter Installationagus triprasetyo100% (1)

- 3500 - AC and DC Power SuppliesDocument29 pages3500 - AC and DC Power SuppliestestvsptestNo ratings yet

- Electrical Work ProcedureDocument18 pagesElectrical Work ProcedureWilliam Berrospi Garcia100% (3)

- INWFIPAN001R100 Installation SheetDocument4 pagesINWFIPAN001R100 Installation SheetPaulNo ratings yet

- Analog Dialogue Volume 46, Number 1: Analog Dialogue, #5From EverandAnalog Dialogue Volume 46, Number 1: Analog Dialogue, #5Rating: 5 out of 5 stars5/5 (1)

- Ds H PlusDocument4 pagesDs H PlusMoussa AdamouNo ratings yet

- MN Lpod 100W Ku BUCDocument222 pagesMN Lpod 100W Ku BUCMoussa AdamouNo ratings yet

- Ds LpodDocument3 pagesDs LpodMoussa AdamouNo ratings yet

- Ds H Plus ODUDocument4 pagesDs H Plus ODUMoussa AdamouNo ratings yet

- Networking 2Document5 pagesNetworking 2mugwadiinnocentNo ratings yet

- 1KHL020322 Aen Apn PDF 1 enDocument10 pages1KHL020322 Aen Apn PDF 1 enhaichau199No ratings yet

- ADMET Expert 7600 BrochureDocument7 pagesADMET Expert 7600 BrochureAde DjatnikaNo ratings yet

- Fundamentals of MicroprocessorDocument43 pagesFundamentals of MicroprocessorPrajaktaNo ratings yet

- Active and Passive ComponentsDocument4 pagesActive and Passive ComponentsBisweswar MondalNo ratings yet

- ATR Ata - 23 - CommunicationsDocument126 pagesATR Ata - 23 - CommunicationsJesús Montalvo Fernández100% (1)

- Mohair One DescriptionDocument6 pagesMohair One DescriptionCristi ApostolNo ratings yet

- Unit Ii Multi-Stage Amplifiers: Types of CouplingDocument58 pagesUnit Ii Multi-Stage Amplifiers: Types of Couplingcinthu chizhian22No ratings yet

- Avr Atmega 8 UcDocument14 pagesAvr Atmega 8 UcmalhiavtarsinghNo ratings yet

- Consultancy and R and D Projects:: Department of Electrical Engineering, College of Engineering, PuneDocument3 pagesConsultancy and R and D Projects:: Department of Electrical Engineering, College of Engineering, PuneNp Crush9No ratings yet

- Model MH: Parts List ForDocument8 pagesModel MH: Parts List FormhafizanNo ratings yet

- Pioneer Pdpr04e Plasma Receiver SM (ET)Document182 pagesPioneer Pdpr04e Plasma Receiver SM (ET)djbessacNo ratings yet

- APC Smart-UPS SC BrochureDocument16 pagesAPC Smart-UPS SC BrochurePTR77No ratings yet

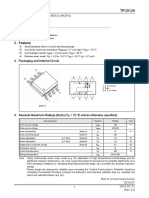

- TPC8129 Datasheet en 20140121 PDFDocument9 pagesTPC8129 Datasheet en 20140121 PDFCHARIS ZEVGARASNo ratings yet

- Cooper Industries Fire Catalogue EnglishDocument92 pagesCooper Industries Fire Catalogue EnglishasifaliabidNo ratings yet

- Frm220 Serial ManualDocument1 pageFrm220 Serial Manualdony rksNo ratings yet

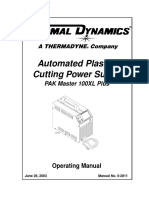

- PakMaster 100XL Plus Operating Manual (0-2811) - Jun2003Document52 pagesPakMaster 100XL Plus Operating Manual (0-2811) - Jun2003Marco Antonio NardyNo ratings yet

- Antenna Design of Millimeter Wave Radar For Smart ToiletDocument3 pagesAntenna Design of Millimeter Wave Radar For Smart Toiletvasuhi srinivasanNo ratings yet

- imageRUNNER+25452535+series+Service+Manual en 9.0 PDFDocument398 pagesimageRUNNER+25452535+series+Service+Manual en 9.0 PDFPierre Chirac100% (1)

- 2008 Rrazavi A Millimeter-Wave Circuit Technique PDFDocument9 pages2008 Rrazavi A Millimeter-Wave Circuit Technique PDFrahmanakberNo ratings yet

- Traffic LightDocument14 pagesTraffic LightIshaanNo ratings yet

- RC 1976 04Document64 pagesRC 1976 04Jan PranNo ratings yet

- TVL Modul 6 Answers Jerimiakenj CabanizasDocument8 pagesTVL Modul 6 Answers Jerimiakenj CabanizasJack FosterNo ratings yet

- 05 Midea 50Hz AC Fan Coil Unit Two-Pipe High Static Pressure Duct Series - 201706Document28 pages05 Midea 50Hz AC Fan Coil Unit Two-Pipe High Static Pressure Duct Series - 201706sidparikh254No ratings yet

- THZ Channel For 6GDocument40 pagesTHZ Channel For 6Gshahnaz1981fatNo ratings yet

- Review of Signals and Systems:: EE4900/EE6720 Digital Communications Suketu NaikDocument25 pagesReview of Signals and Systems:: EE4900/EE6720 Digital Communications Suketu NaikmominaNo ratings yet