Professional Documents

Culture Documents

Is 1828-2 (Iso 7500-2) - 10

Is 1828-2 (Iso 7500-2) - 10

Uploaded by

Svapnesh ParikhCopyright:

Available Formats

You might also like

- PS5 PDFDocument2 pagesPS5 PDFTaib MuffakNo ratings yet

- HSC Physics Module 3: Waves & ThermodynamicsDocument30 pagesHSC Physics Module 3: Waves & ThermodynamicswillNo ratings yet

- WI - Intermediate Check BalanceDocument2 pagesWI - Intermediate Check Balancechinhon83% (6)

- Procedure For Calibration of Machines Welding PDFDocument3 pagesProcedure For Calibration of Machines Welding PDFravi00098100% (1)

- Is 1828-2 (Iso 7500-2) - 8Document1 pageIs 1828-2 (Iso 7500-2) - 8Svapnesh ParikhNo ratings yet

- Is 1828-1 (Iso 7500-1) - 10Document1 pageIs 1828-1 (Iso 7500-1) - 10Svapnesh ParikhNo ratings yet

- Is 1828-1 (Iso 7500-1) - 7Document1 pageIs 1828-1 (Iso 7500-1) - 7Svapnesh ParikhNo ratings yet

- ASTM E384 (2022) - Part10Document1 pageASTM E384 (2022) - Part10david4231993No ratings yet

- ASTM E18 (2019) - Part13Document1 pageASTM E18 (2019) - Part13david4231993No ratings yet

- Is 1828-2 (Iso 7500-2) - 9Document1 pageIs 1828-2 (Iso 7500-2) - 9Svapnesh ParikhNo ratings yet

- ASTM E18 (2019) - Part17Document1 pageASTM E18 (2019) - Part17david4231993No ratings yet

- ASTM E18 (2019) - Part18Document1 pageASTM E18 (2019) - Part18david4231993No ratings yet

- Is 1828-1 (Iso 7500-1) - 8Document1 pageIs 1828-1 (Iso 7500-1) - 8Svapnesh ParikhNo ratings yet

- ASTM E18 (2019) - Part14Document1 pageASTM E18 (2019) - Part14david4231993No ratings yet

- Usbr1012 PDFDocument4 pagesUsbr1012 PDFYCNo ratings yet

- Proceq DY-2 Additional Information Calibration Software Guide - EnglishDocument12 pagesProceq DY-2 Additional Information Calibration Software Guide - EnglishMauricio PiresNo ratings yet

- t22 PDFDocument18 pagest22 PDFRaunak TimilsinaNo ratings yet

- 6umdent: Insofsraa FMN Each WeldingDocument1 page6umdent: Insofsraa FMN Each WeldingTAHIR MAHMOODNo ratings yet

- 7 Initial Measurements and Preconditioning: BS EN 61373:2010Document3 pages7 Initial Measurements and Preconditioning: BS EN 61373:2010soyalNo ratings yet

- On The Estimation EA Guidelines: Publication ReferenceDocument25 pagesOn The Estimation EA Guidelines: Publication ReferenceMarcos LoredoNo ratings yet

- ASTM E18 (2019) - Part35Document1 pageASTM E18 (2019) - Part35david4231993No ratings yet

- 3-FDP-63-M-308-MT Lab-TotalDocument111 pages3-FDP-63-M-308-MT Lab-TotalvenkyNo ratings yet

- Sop UtDocument6 pagesSop UtEddy Dwi CahyonoNo ratings yet

- Is 1828-2 (Iso 7500-2) - 4Document1 pageIs 1828-2 (Iso 7500-2) - 4Svapnesh ParikhNo ratings yet

- AWS Procedure - Rev 2Document40 pagesAWS Procedure - Rev 2Mario Perez100% (1)

- Best Practices For Coriolis Meter Proving: Site & Equipment ConsiderationsDocument2 pagesBest Practices For Coriolis Meter Proving: Site & Equipment Considerationsdiana milena arredondo correaNo ratings yet

- ASTM E384 (2022) - Part11Document1 pageASTM E384 (2022) - Part11david4231993No ratings yet

- ASTM E18 (2019) - Part12Document1 pageASTM E18 (2019) - Part12david4231993No ratings yet

- Description of Gages: 3.3 Area MeasurementDocument1 pageDescription of Gages: 3.3 Area Measurementnate anantathatNo ratings yet

- CTM 205 Jun2007 A11yDocument6 pagesCTM 205 Jun2007 A11yHussein El BeqaiNo ratings yet

- Testing Concrete: BS 1881: Part 115: 1986Document11 pagesTesting Concrete: BS 1881: Part 115: 1986Mohamed AnasNo ratings yet

- AppNote - Understanding Cal CertsDocument7 pagesAppNote - Understanding Cal CertsGala HadNo ratings yet

- Description of Gages: 3.3 Area MeasurementDocument1 pageDescription of Gages: 3.3 Area Measurementnate anantathatNo ratings yet

- Toms Vol2no1 Doi003 PDFDocument8 pagesToms Vol2no1 Doi003 PDFKhaled SaadnehNo ratings yet

- ASTM E18 (2019) - Part34Document1 pageASTM E18 (2019) - Part34david4231993No ratings yet

- E13 Test Requirements For Rotating Machines E13Document5 pagesE13 Test Requirements For Rotating Machines E13Anshul NautiyalNo ratings yet

- Vickers Calibration DetailsDocument1 pageVickers Calibration DetailstomychalilNo ratings yet

- ASTM E18 (2019) - Part15Document1 pageASTM E18 (2019) - Part15david4231993No ratings yet

- Xoqo/4z/: 1. ObjectiveDocument8 pagesXoqo/4z/: 1. ObjectiveBandhan NagariaNo ratings yet

- Is 14858 2000 PDFDocument12 pagesIs 14858 2000 PDFHimanku BoraNo ratings yet

- KASTO 206 (인장 및 압축 시험기) PDFDocument28 pagesKASTO 206 (인장 및 압축 시험기) PDFTJNo ratings yet

- Technical Notes MECH 001: Specific Requirements For Mechanical Testing LaboratoriesDocument11 pagesTechnical Notes MECH 001: Specific Requirements For Mechanical Testing LaboratoriessandeepNo ratings yet

- ASTM E18 (2019) - Part10Document1 pageASTM E18 (2019) - Part10david4231993No ratings yet

- Helicopter GROUND TEST-H Rev ADocument3 pagesHelicopter GROUND TEST-H Rev ATroy Robert ReabeNo ratings yet

- Instrumentation and ControlDocument11 pagesInstrumentation and ControlMohamed Said HassanNo ratings yet

- EURAMET cg-17 V 2.0 Electromechanical ManometersDocument1 pageEURAMET cg-17 V 2.0 Electromechanical ManometersSalah BennourNo ratings yet

- Is 1828-1 (Iso 7500-1) - 4Document1 pageIs 1828-1 (Iso 7500-1) - 4SvapneshNo ratings yet

- 3.3 Area MeasurementDocument1 page3.3 Area Measurementnate anantathatNo ratings yet

- Screenshot 2021-08-09 at 2.59.04 PMDocument23 pagesScreenshot 2021-08-09 at 2.59.04 PMAnurag AgastiNo ratings yet

- A Developed Algorithm For The Evaluation of Calibration Intervals For Equipment Devices in Testing and Calibration LaboratoriesDocument31 pagesA Developed Algorithm For The Evaluation of Calibration Intervals For Equipment Devices in Testing and Calibration LaboratoriesRoberto ColoniaNo ratings yet

- Clause 6. Inspection AWS D1.1/D1.1M:2015: Part FDocument1 pageClause 6. Inspection AWS D1.1/D1.1M:2015: Part FMd. Sahabul IslamNo ratings yet

- F. Lüönd, C. Blaser, K. Vasilatou Federal Institute of Metrology (METAS), SwitzerlandDocument1 pageF. Lüönd, C. Blaser, K. Vasilatou Federal Institute of Metrology (METAS), SwitzerlandcarlosNo ratings yet

- Computing Uncertainty For Charpy Impact Machine Test ResultsDocument42 pagesComputing Uncertainty For Charpy Impact Machine Test ResultsDFLQMSNo ratings yet

- EURAMET CG 16.01 - Hardness PDFDocument23 pagesEURAMET CG 16.01 - Hardness PDFMa'den-i Envâr-ı FütuvvetNo ratings yet

- Force GaugeDocument3 pagesForce Gaugeshakti sindhuNo ratings yet

- Ur E13rev3corr1Document6 pagesUr E13rev3corr1Maan MrabetNo ratings yet

- Compilation of Calibration Data of The Compression Testing MachinesDocument3 pagesCompilation of Calibration Data of The Compression Testing Machinesjepri purwantoNo ratings yet

- EURAMET cg-16 V 2.0 Hardness Measurements PDFDocument22 pagesEURAMET cg-16 V 2.0 Hardness Measurements PDFLalo MejiaNo ratings yet

- Random Vibration TestingDocument3 pagesRandom Vibration TestingsueudemonNo ratings yet

- A1305-Statistical Quality ControlDocument2 pagesA1305-Statistical Quality Controlhari0118No ratings yet

- MCQ MMC MU - Mechanical - Measurement - Control - CBCS PDFDocument3 pagesMCQ MMC MU - Mechanical - Measurement - Control - CBCS PDFNarayan ManeNo ratings yet

- Is 12308-8 - 1997 - 5Document1 pageIs 12308-8 - 1997 - 5Svapnesh ParikhNo ratings yet

- Is 12308-8 - 1997 - 3Document1 pageIs 12308-8 - 1997 - 3Svapnesh ParikhNo ratings yet

- Is 12308-7 - 1991 - 3Document1 pageIs 12308-7 - 1991 - 3Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 12Document1 pageIs 10719 (Iso 1302) - 12Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 1Document1 pageIs 12308-5 - 1991 - 1Svapnesh ParikhNo ratings yet

- Is 12308-7 - 1991 - 5Document1 pageIs 12308-7 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 12308-9 - 1993 - 1Document1 pageIs 12308-9 - 1993 - 1Svapnesh ParikhNo ratings yet

- Is 12308-6 - 1991 - 4Document1 pageIs 12308-6 - 1991 - 4Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 5Document1 pageIs 12308-5 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 11166 - 1993 - 10Document1 pageIs 11166 - 1993 - 10Svapnesh ParikhNo ratings yet

- Is 12308-6 - 1991 - 5Document1 pageIs 12308-6 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 8Document1 pageIs 10719 (Iso 1302) - 8Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 3Document1 pageIs 12308-5 - 1991 - 3Svapnesh ParikhNo ratings yet

- Is 12308-3 - 1987 - 1Document1 pageIs 12308-3 - 1987 - 1Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 14Document1 pageIs 10719 (Iso 1302) - 14Svapnesh ParikhNo ratings yet

- Is 12308-4 - 1988 - 4Document1 pageIs 12308-4 - 1988 - 4Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 5Document1 pageIs 10719 (Iso 1302) - 5Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 4Document1 pageIs 10719 (Iso 1302) - 4Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 11Document1 pageIs 10719 (Iso 1302) - 11Svapnesh ParikhNo ratings yet

- Is 8422-8 - 1977 - 2Document1 pageIs 8422-8 - 1977 - 2Svapnesh ParikhNo ratings yet

- Is 8422-2 - 1977 - 3Document1 pageIs 8422-2 - 1977 - 3Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 1Document1 pageIs 10719 (Iso 1302) - 1Svapnesh ParikhNo ratings yet

- Is 8422-6 - 1977 - 4Document1 pageIs 8422-6 - 1977 - 4Svapnesh ParikhNo ratings yet

- Is 8422-8 - 1977 - 5Document1 pageIs 8422-8 - 1977 - 5Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 1Document1 pageIs 8422-3 - 1977 - 1Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 3Document1 pageIs 8422-3 - 1977 - 3Svapnesh ParikhNo ratings yet

- Is 8422-2 - 1977 - 6Document1 pageIs 8422-2 - 1977 - 6Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 2Document1 pageIs 8422-3 - 1977 - 2Svapnesh ParikhNo ratings yet

- Is 8422-1 - 1977 - 5Document1 pageIs 8422-1 - 1977 - 5Svapnesh ParikhNo ratings yet

- Is 8422-1 - 1977 - 2Document1 pageIs 8422-1 - 1977 - 2Svapnesh ParikhNo ratings yet

- Crystal Field Theory & Jahn-Teller EffectDocument16 pagesCrystal Field Theory & Jahn-Teller Effectvatsala soniNo ratings yet

- IS17417-Part1-2020-ISO 4965-1Document18 pagesIS17417-Part1-2020-ISO 4965-1Supriya ManojNo ratings yet

- BTS - 0000 (Zero O'Clock)Document8 pagesBTS - 0000 (Zero O'Clock)Triesha SyifahatiNo ratings yet

- Question Paper: Biology - 100 Chemistry - 50 Physics - 50Document24 pagesQuestion Paper: Biology - 100 Chemistry - 50 Physics - 50harita shindeNo ratings yet

- Q2 Lesson 3 - Reflection of LightDocument57 pagesQ2 Lesson 3 - Reflection of LightKarl AguilarNo ratings yet

- Ch3rolconbear1 200312773Document56 pagesCh3rolconbear1 200312773Mix TubeNo ratings yet

- Astm 1035Document6 pagesAstm 1035Santosh Ramakrishna KandalaNo ratings yet

- NewDocument3 pagesNewAngelica P. CaingcoyNo ratings yet

- CH - 9 Differential EquationsDocument45 pagesCH - 9 Differential EquationsGopa Das KunduNo ratings yet

- Physics 2Document2 pagesPhysics 2Elyse FallarmeNo ratings yet

- 1995 - Structural Design Sensitivity - Continuum and Discrete Approaches PDFDocument24 pages1995 - Structural Design Sensitivity - Continuum and Discrete Approaches PDFGuatavo91No ratings yet

- Syllabus Coverage Report-July23Document2 pagesSyllabus Coverage Report-July23Mech HoDNo ratings yet

- Maths PP1 Kcse Cluster PredDocument34 pagesMaths PP1 Kcse Cluster PredBonface Kenani100% (1)

- Managed Pressure Drilling Modeling & Simulation (A Case Study)Document8 pagesManaged Pressure Drilling Modeling & Simulation (A Case Study)Mejbahul SarkerNo ratings yet

- Appendix 59.docx Inventory Custodian SlipDocument2 pagesAppendix 59.docx Inventory Custodian SlipJimmy CootNo ratings yet

- 5.4 Packet PDFDocument6 pages5.4 Packet PDFVed PatelNo ratings yet

- SPE-126320 Propped-Fracture Stimulation Performed From A Jackup Rig in The North SeaDocument14 pagesSPE-126320 Propped-Fracture Stimulation Performed From A Jackup Rig in The North SeaBruceNo ratings yet

- Physics Paper Class 11thDocument10 pagesPhysics Paper Class 11thMahiNo ratings yet

- Acces Steel - Design of Portal Frame Eaves Connections PDFDocument23 pagesAcces Steel - Design of Portal Frame Eaves Connections PDFMuresanAnna-KarinaNo ratings yet

- ChemDocument3 pagesChemLouie Mae SantosNo ratings yet

- Bmat 2Document1 pageBmat 2Ariel SantillanNo ratings yet

- Physics: Cambridge International Examinations General Certificate of Education Ordinary LevelDocument12 pagesPhysics: Cambridge International Examinations General Certificate of Education Ordinary LevelequakeroatsNo ratings yet

- Magnetic Effect Galvanomter Into AmmterDocument3 pagesMagnetic Effect Galvanomter Into Ammterpraveen godaraNo ratings yet

- Math Module Ch1Document22 pagesMath Module Ch1Jonaria CopisNo ratings yet

- The Sisters of Mary School - Adlas, Inc. Adlas, Silang Cavite, 4118Document3 pagesThe Sisters of Mary School - Adlas, Inc. Adlas, Silang Cavite, 4118Santy Enril Belardo Jr.No ratings yet

- 2023 CIVN2011A and STAT3029A Lecture 6B - Special Discrete Distributions - ContinuedDocument13 pages2023 CIVN2011A and STAT3029A Lecture 6B - Special Discrete Distributions - ContinuedeurekaripfumeloNo ratings yet

- Journal of Heat TransferDocument9 pagesJournal of Heat TransferIsidora GoicocheaNo ratings yet

Is 1828-2 (Iso 7500-2) - 10

Is 1828-2 (Iso 7500-2) - 10

Uploaded by

Svapnesh ParikhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Is 1828-2 (Iso 7500-2) - 10

Is 1828-2 (Iso 7500-2) - 10

Uploaded by

Svapnesh ParikhCopyright:

Available Formats

IS

ISO

1828 ( Part 2 ) :2002

7500-2:1996 ,

!

:“

d

5.6 Assessment of the force applied bythe 6.2 Deadweightcreeptestingmachines

machine

Normaiiy the grading will be determined by the accu- ~

5.6.1 Relative accuracyerror racies of the masses used to apply the verification

forces and of the mass of the ioad suspension system ‘“

The relative accuracy error, q, expressed as a percent- beiow the test piece. However, for machines with

age of the mean value of the true load ~, is given by guides below the test piece which could introduce ‘‘,,

friction effects, it is necessary to calibrate the ma- b:

the equation :,

chine using a proving device. The calibration authority

shall be satisfied that the axis of loading is through the ;.

longitudinal axis to the test piece.

‘.

7 Verification report

5.6.2 Relative repeatability error !

‘

3

The verification report shall contain at least the foiiow-

The repeatability error, b, is, for each discrete force,

ing information:

the difference between the highest and lowest values

measured with respect to the mean value of true load. !

a)Gneral information:

It is given by the equation

/

j

1) reference to this part of ISO 7500;

Fm.. - ‘rein x ,0. i

b= 2) identification of the testing machine (type,

F

make, serial number);

3) location of the machine;

4) method of verification used (see 5.1) and the

6 Class of the testing machine identity, class and date of the last calibration

certificate of the verification equipment used;

.Table 3 gives the maximum permissible values for the

5) the average temperature of the verification

relative errors of accuracy and repeatability which

equipment at the time of verification;

characterizes a testing machine in accordance with

the appropriate class. 6) date of verification;

7) name of mark of the verifying se~ice which

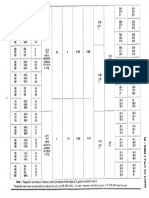

Table 3 — Characteristics of the classes of performed the verification.

machine j

b) Results of verification: ~

Maximm permissiblevalues(%)

\

Classof Relative Relativeerrorof 1) for each force-measuring system used, the

machine discrimination class of each range verified and, if requested,

threshold repeatability accuracy

the discrete values of relative errors of accu-

a b 4 racy, repeatability;

0,5 0,25 0,5 * 0,5

2) the lever ratio R used for each load range,

1 0,5 1,0 *lto where applicable;

2 1 2.0 * 2.0

3) when discrete forces have been verified, the

actual forces, the class(es) obtained and, if

requested, the discrete vaiues of relative er-

rors of repeatability;

6.1 Levercreeptestingmachines

4) any anomaly found during the general in-

The grading shall cease to apply below the minimum spection.

load that complies with these requirements.

8 Intervals between verifications

It is possible for a range to be given several classes

but each class shall satisfy the requirements defined

The machine shall be verified at intervals not exceed-

in 5.5.5.

ing 5 years. However, if the predicted test iife ex-

ceeds the date of the expiry of the verification

It is permissible to classify a machine for one or sev-

certificate, then the machine shall be reverified prior

eral discrete forces, for each discrete force three to commencement of the creep test. Any machine

measurements shall be conducted. The classification

shail also be reverified if it has been dismantled for

obtained is valid only for the discrete forces verified. moving or subject to major repair or adjustment

You might also like

- PS5 PDFDocument2 pagesPS5 PDFTaib MuffakNo ratings yet

- HSC Physics Module 3: Waves & ThermodynamicsDocument30 pagesHSC Physics Module 3: Waves & ThermodynamicswillNo ratings yet

- WI - Intermediate Check BalanceDocument2 pagesWI - Intermediate Check Balancechinhon83% (6)

- Procedure For Calibration of Machines Welding PDFDocument3 pagesProcedure For Calibration of Machines Welding PDFravi00098100% (1)

- Is 1828-2 (Iso 7500-2) - 8Document1 pageIs 1828-2 (Iso 7500-2) - 8Svapnesh ParikhNo ratings yet

- Is 1828-1 (Iso 7500-1) - 10Document1 pageIs 1828-1 (Iso 7500-1) - 10Svapnesh ParikhNo ratings yet

- Is 1828-1 (Iso 7500-1) - 7Document1 pageIs 1828-1 (Iso 7500-1) - 7Svapnesh ParikhNo ratings yet

- ASTM E384 (2022) - Part10Document1 pageASTM E384 (2022) - Part10david4231993No ratings yet

- ASTM E18 (2019) - Part13Document1 pageASTM E18 (2019) - Part13david4231993No ratings yet

- Is 1828-2 (Iso 7500-2) - 9Document1 pageIs 1828-2 (Iso 7500-2) - 9Svapnesh ParikhNo ratings yet

- ASTM E18 (2019) - Part17Document1 pageASTM E18 (2019) - Part17david4231993No ratings yet

- ASTM E18 (2019) - Part18Document1 pageASTM E18 (2019) - Part18david4231993No ratings yet

- Is 1828-1 (Iso 7500-1) - 8Document1 pageIs 1828-1 (Iso 7500-1) - 8Svapnesh ParikhNo ratings yet

- ASTM E18 (2019) - Part14Document1 pageASTM E18 (2019) - Part14david4231993No ratings yet

- Usbr1012 PDFDocument4 pagesUsbr1012 PDFYCNo ratings yet

- Proceq DY-2 Additional Information Calibration Software Guide - EnglishDocument12 pagesProceq DY-2 Additional Information Calibration Software Guide - EnglishMauricio PiresNo ratings yet

- t22 PDFDocument18 pagest22 PDFRaunak TimilsinaNo ratings yet

- 6umdent: Insofsraa FMN Each WeldingDocument1 page6umdent: Insofsraa FMN Each WeldingTAHIR MAHMOODNo ratings yet

- 7 Initial Measurements and Preconditioning: BS EN 61373:2010Document3 pages7 Initial Measurements and Preconditioning: BS EN 61373:2010soyalNo ratings yet

- On The Estimation EA Guidelines: Publication ReferenceDocument25 pagesOn The Estimation EA Guidelines: Publication ReferenceMarcos LoredoNo ratings yet

- ASTM E18 (2019) - Part35Document1 pageASTM E18 (2019) - Part35david4231993No ratings yet

- 3-FDP-63-M-308-MT Lab-TotalDocument111 pages3-FDP-63-M-308-MT Lab-TotalvenkyNo ratings yet

- Sop UtDocument6 pagesSop UtEddy Dwi CahyonoNo ratings yet

- Is 1828-2 (Iso 7500-2) - 4Document1 pageIs 1828-2 (Iso 7500-2) - 4Svapnesh ParikhNo ratings yet

- AWS Procedure - Rev 2Document40 pagesAWS Procedure - Rev 2Mario Perez100% (1)

- Best Practices For Coriolis Meter Proving: Site & Equipment ConsiderationsDocument2 pagesBest Practices For Coriolis Meter Proving: Site & Equipment Considerationsdiana milena arredondo correaNo ratings yet

- ASTM E384 (2022) - Part11Document1 pageASTM E384 (2022) - Part11david4231993No ratings yet

- ASTM E18 (2019) - Part12Document1 pageASTM E18 (2019) - Part12david4231993No ratings yet

- Description of Gages: 3.3 Area MeasurementDocument1 pageDescription of Gages: 3.3 Area Measurementnate anantathatNo ratings yet

- CTM 205 Jun2007 A11yDocument6 pagesCTM 205 Jun2007 A11yHussein El BeqaiNo ratings yet

- Testing Concrete: BS 1881: Part 115: 1986Document11 pagesTesting Concrete: BS 1881: Part 115: 1986Mohamed AnasNo ratings yet

- AppNote - Understanding Cal CertsDocument7 pagesAppNote - Understanding Cal CertsGala HadNo ratings yet

- Description of Gages: 3.3 Area MeasurementDocument1 pageDescription of Gages: 3.3 Area Measurementnate anantathatNo ratings yet

- Toms Vol2no1 Doi003 PDFDocument8 pagesToms Vol2no1 Doi003 PDFKhaled SaadnehNo ratings yet

- ASTM E18 (2019) - Part34Document1 pageASTM E18 (2019) - Part34david4231993No ratings yet

- E13 Test Requirements For Rotating Machines E13Document5 pagesE13 Test Requirements For Rotating Machines E13Anshul NautiyalNo ratings yet

- Vickers Calibration DetailsDocument1 pageVickers Calibration DetailstomychalilNo ratings yet

- ASTM E18 (2019) - Part15Document1 pageASTM E18 (2019) - Part15david4231993No ratings yet

- Xoqo/4z/: 1. ObjectiveDocument8 pagesXoqo/4z/: 1. ObjectiveBandhan NagariaNo ratings yet

- Is 14858 2000 PDFDocument12 pagesIs 14858 2000 PDFHimanku BoraNo ratings yet

- KASTO 206 (인장 및 압축 시험기) PDFDocument28 pagesKASTO 206 (인장 및 압축 시험기) PDFTJNo ratings yet

- Technical Notes MECH 001: Specific Requirements For Mechanical Testing LaboratoriesDocument11 pagesTechnical Notes MECH 001: Specific Requirements For Mechanical Testing LaboratoriessandeepNo ratings yet

- ASTM E18 (2019) - Part10Document1 pageASTM E18 (2019) - Part10david4231993No ratings yet

- Helicopter GROUND TEST-H Rev ADocument3 pagesHelicopter GROUND TEST-H Rev ATroy Robert ReabeNo ratings yet

- Instrumentation and ControlDocument11 pagesInstrumentation and ControlMohamed Said HassanNo ratings yet

- EURAMET cg-17 V 2.0 Electromechanical ManometersDocument1 pageEURAMET cg-17 V 2.0 Electromechanical ManometersSalah BennourNo ratings yet

- Is 1828-1 (Iso 7500-1) - 4Document1 pageIs 1828-1 (Iso 7500-1) - 4SvapneshNo ratings yet

- 3.3 Area MeasurementDocument1 page3.3 Area Measurementnate anantathatNo ratings yet

- Screenshot 2021-08-09 at 2.59.04 PMDocument23 pagesScreenshot 2021-08-09 at 2.59.04 PMAnurag AgastiNo ratings yet

- A Developed Algorithm For The Evaluation of Calibration Intervals For Equipment Devices in Testing and Calibration LaboratoriesDocument31 pagesA Developed Algorithm For The Evaluation of Calibration Intervals For Equipment Devices in Testing and Calibration LaboratoriesRoberto ColoniaNo ratings yet

- Clause 6. Inspection AWS D1.1/D1.1M:2015: Part FDocument1 pageClause 6. Inspection AWS D1.1/D1.1M:2015: Part FMd. Sahabul IslamNo ratings yet

- F. Lüönd, C. Blaser, K. Vasilatou Federal Institute of Metrology (METAS), SwitzerlandDocument1 pageF. Lüönd, C. Blaser, K. Vasilatou Federal Institute of Metrology (METAS), SwitzerlandcarlosNo ratings yet

- Computing Uncertainty For Charpy Impact Machine Test ResultsDocument42 pagesComputing Uncertainty For Charpy Impact Machine Test ResultsDFLQMSNo ratings yet

- EURAMET CG 16.01 - Hardness PDFDocument23 pagesEURAMET CG 16.01 - Hardness PDFMa'den-i Envâr-ı FütuvvetNo ratings yet

- Force GaugeDocument3 pagesForce Gaugeshakti sindhuNo ratings yet

- Ur E13rev3corr1Document6 pagesUr E13rev3corr1Maan MrabetNo ratings yet

- Compilation of Calibration Data of The Compression Testing MachinesDocument3 pagesCompilation of Calibration Data of The Compression Testing Machinesjepri purwantoNo ratings yet

- EURAMET cg-16 V 2.0 Hardness Measurements PDFDocument22 pagesEURAMET cg-16 V 2.0 Hardness Measurements PDFLalo MejiaNo ratings yet

- Random Vibration TestingDocument3 pagesRandom Vibration TestingsueudemonNo ratings yet

- A1305-Statistical Quality ControlDocument2 pagesA1305-Statistical Quality Controlhari0118No ratings yet

- MCQ MMC MU - Mechanical - Measurement - Control - CBCS PDFDocument3 pagesMCQ MMC MU - Mechanical - Measurement - Control - CBCS PDFNarayan ManeNo ratings yet

- Is 12308-8 - 1997 - 5Document1 pageIs 12308-8 - 1997 - 5Svapnesh ParikhNo ratings yet

- Is 12308-8 - 1997 - 3Document1 pageIs 12308-8 - 1997 - 3Svapnesh ParikhNo ratings yet

- Is 12308-7 - 1991 - 3Document1 pageIs 12308-7 - 1991 - 3Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 12Document1 pageIs 10719 (Iso 1302) - 12Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 1Document1 pageIs 12308-5 - 1991 - 1Svapnesh ParikhNo ratings yet

- Is 12308-7 - 1991 - 5Document1 pageIs 12308-7 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 12308-9 - 1993 - 1Document1 pageIs 12308-9 - 1993 - 1Svapnesh ParikhNo ratings yet

- Is 12308-6 - 1991 - 4Document1 pageIs 12308-6 - 1991 - 4Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 5Document1 pageIs 12308-5 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 11166 - 1993 - 10Document1 pageIs 11166 - 1993 - 10Svapnesh ParikhNo ratings yet

- Is 12308-6 - 1991 - 5Document1 pageIs 12308-6 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 8Document1 pageIs 10719 (Iso 1302) - 8Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 3Document1 pageIs 12308-5 - 1991 - 3Svapnesh ParikhNo ratings yet

- Is 12308-3 - 1987 - 1Document1 pageIs 12308-3 - 1987 - 1Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 14Document1 pageIs 10719 (Iso 1302) - 14Svapnesh ParikhNo ratings yet

- Is 12308-4 - 1988 - 4Document1 pageIs 12308-4 - 1988 - 4Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 5Document1 pageIs 10719 (Iso 1302) - 5Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 4Document1 pageIs 10719 (Iso 1302) - 4Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 11Document1 pageIs 10719 (Iso 1302) - 11Svapnesh ParikhNo ratings yet

- Is 8422-8 - 1977 - 2Document1 pageIs 8422-8 - 1977 - 2Svapnesh ParikhNo ratings yet

- Is 8422-2 - 1977 - 3Document1 pageIs 8422-2 - 1977 - 3Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 1Document1 pageIs 10719 (Iso 1302) - 1Svapnesh ParikhNo ratings yet

- Is 8422-6 - 1977 - 4Document1 pageIs 8422-6 - 1977 - 4Svapnesh ParikhNo ratings yet

- Is 8422-8 - 1977 - 5Document1 pageIs 8422-8 - 1977 - 5Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 1Document1 pageIs 8422-3 - 1977 - 1Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 3Document1 pageIs 8422-3 - 1977 - 3Svapnesh ParikhNo ratings yet

- Is 8422-2 - 1977 - 6Document1 pageIs 8422-2 - 1977 - 6Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 2Document1 pageIs 8422-3 - 1977 - 2Svapnesh ParikhNo ratings yet

- Is 8422-1 - 1977 - 5Document1 pageIs 8422-1 - 1977 - 5Svapnesh ParikhNo ratings yet

- Is 8422-1 - 1977 - 2Document1 pageIs 8422-1 - 1977 - 2Svapnesh ParikhNo ratings yet

- Crystal Field Theory & Jahn-Teller EffectDocument16 pagesCrystal Field Theory & Jahn-Teller Effectvatsala soniNo ratings yet

- IS17417-Part1-2020-ISO 4965-1Document18 pagesIS17417-Part1-2020-ISO 4965-1Supriya ManojNo ratings yet

- BTS - 0000 (Zero O'Clock)Document8 pagesBTS - 0000 (Zero O'Clock)Triesha SyifahatiNo ratings yet

- Question Paper: Biology - 100 Chemistry - 50 Physics - 50Document24 pagesQuestion Paper: Biology - 100 Chemistry - 50 Physics - 50harita shindeNo ratings yet

- Q2 Lesson 3 - Reflection of LightDocument57 pagesQ2 Lesson 3 - Reflection of LightKarl AguilarNo ratings yet

- Ch3rolconbear1 200312773Document56 pagesCh3rolconbear1 200312773Mix TubeNo ratings yet

- Astm 1035Document6 pagesAstm 1035Santosh Ramakrishna KandalaNo ratings yet

- NewDocument3 pagesNewAngelica P. CaingcoyNo ratings yet

- CH - 9 Differential EquationsDocument45 pagesCH - 9 Differential EquationsGopa Das KunduNo ratings yet

- Physics 2Document2 pagesPhysics 2Elyse FallarmeNo ratings yet

- 1995 - Structural Design Sensitivity - Continuum and Discrete Approaches PDFDocument24 pages1995 - Structural Design Sensitivity - Continuum and Discrete Approaches PDFGuatavo91No ratings yet

- Syllabus Coverage Report-July23Document2 pagesSyllabus Coverage Report-July23Mech HoDNo ratings yet

- Maths PP1 Kcse Cluster PredDocument34 pagesMaths PP1 Kcse Cluster PredBonface Kenani100% (1)

- Managed Pressure Drilling Modeling & Simulation (A Case Study)Document8 pagesManaged Pressure Drilling Modeling & Simulation (A Case Study)Mejbahul SarkerNo ratings yet

- Appendix 59.docx Inventory Custodian SlipDocument2 pagesAppendix 59.docx Inventory Custodian SlipJimmy CootNo ratings yet

- 5.4 Packet PDFDocument6 pages5.4 Packet PDFVed PatelNo ratings yet

- SPE-126320 Propped-Fracture Stimulation Performed From A Jackup Rig in The North SeaDocument14 pagesSPE-126320 Propped-Fracture Stimulation Performed From A Jackup Rig in The North SeaBruceNo ratings yet

- Physics Paper Class 11thDocument10 pagesPhysics Paper Class 11thMahiNo ratings yet

- Acces Steel - Design of Portal Frame Eaves Connections PDFDocument23 pagesAcces Steel - Design of Portal Frame Eaves Connections PDFMuresanAnna-KarinaNo ratings yet

- ChemDocument3 pagesChemLouie Mae SantosNo ratings yet

- Bmat 2Document1 pageBmat 2Ariel SantillanNo ratings yet

- Physics: Cambridge International Examinations General Certificate of Education Ordinary LevelDocument12 pagesPhysics: Cambridge International Examinations General Certificate of Education Ordinary LevelequakeroatsNo ratings yet

- Magnetic Effect Galvanomter Into AmmterDocument3 pagesMagnetic Effect Galvanomter Into Ammterpraveen godaraNo ratings yet

- Math Module Ch1Document22 pagesMath Module Ch1Jonaria CopisNo ratings yet

- The Sisters of Mary School - Adlas, Inc. Adlas, Silang Cavite, 4118Document3 pagesThe Sisters of Mary School - Adlas, Inc. Adlas, Silang Cavite, 4118Santy Enril Belardo Jr.No ratings yet

- 2023 CIVN2011A and STAT3029A Lecture 6B - Special Discrete Distributions - ContinuedDocument13 pages2023 CIVN2011A and STAT3029A Lecture 6B - Special Discrete Distributions - ContinuedeurekaripfumeloNo ratings yet

- Journal of Heat TransferDocument9 pagesJournal of Heat TransferIsidora GoicocheaNo ratings yet