Professional Documents

Culture Documents

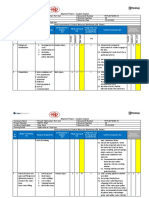

Welding Supervisor

Welding Supervisor

Uploaded by

Santosh LatakeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Supervisor

Welding Supervisor

Uploaded by

Santosh LatakeCopyright:

Available Formats

1.

0 Scope:

This procedure shall be used for the purpose of training and qualification of directly employed personnel

(Welding Supervisors) responsible for supervision activities during qualification of welding procedure and

welder/welding operators for Company Name.

Welding Supervisors shall have satisfactory level of competence in accordance with this procedure. They shall

be qualified by education or experience or training in the following areas:

• knowledge of the requirements of ASME Code Section IX for the qualification of procedures and personnel

• knowledge of the company’s quality control manual

• the scope, complexity, or special nature of the activities to which oversight is to be provided

2.0 Reference and Governing Standards/Specifications

2.1 ASME Section IX - Welding, Brazing, and Fusing Qualifications

2.2 ASME QC Manual

3.0 Responsibilities:

3.1 QA/QC Manager:

QA/QC Manager is responsible for:

• Establishing and approving this procedure

• Training and qualification and designation of welding supervisors as per this procedure

• Maintain education, experience and training records.

• Make this procedure and subsequent revisions available for review by AI

4.0 Education and Experience Requirement:

4.1 Personnel performing supervisory activities shall meet the following initial education and experience

requirements to be considered to qualify as Welding Supervisor.

4.1.1 Shall as a minimum have Engineering Degree or Diploma in Mechanical or Metallurgy field

4.1.2 Degree Engineer shall have a minimum 2 years’ experience in welding activities and a total

of 5 years’ experience; whereas Diploma Engineer have at least 5 years’ experience in

welding activities and a total of 7 Years’ experience. The required experience shall be in

supervision of welding activities with the fabrication industry engaged in pressure vessels or

boilers or piping or structures.

4.1.3 Personnel meeting the above education requirements and additionally having valid AWS-

CWI or CSWIP 3.1 Certification can be credited with one year of experience.

4.1.4 Personnel having valid IWE/EWE/AWS-CWEng certification can be considered as equivalent

to a degree holder.

5.0 Training Requirement:

5.1 QA/QC Manager shall be responsible for identifying and arranging all training

5.2 Training hours shall be documented and shall as a minimum include:

5.2.1 04 (four) hours of training on company’s QC Manual and applicable procedures related to

welding activities

5.2.2 08 (Eight) hours of training related to ASME Section IX requirements for qualification of

welding procedure and personnel. This training requirements can be relaxed or exempted for

persons having adequate experience with pressure vessel and piping fabrication that are

similar in nature to the activities performed by the company provided QA/QC Manager has

verified and satisfied himself with the documentary evidence of experience.

5.3 Additional training based on scope, complexity, or special nature of the welding activities (for

example welding of low or high alloy steels, welding of dissimilar metals, tube to tubesheet welding,

automatic welding, any new welding equipment etc.)

5.4 Training related to QC Manual and related company procedures shall not be relaxed or exempted.

The required training shall be provided by QA/QC Manager or his designee orally to include quality

control processes and welding control processes, related responsibilities, use of various company

forms and reporting system. Additional training may be required (as decided by QA/QC Manager) for

significant revisions in QC Manual.

5.5 Training related to ASME Code Section IX shall include requirements of procedure and personnel

qualifications related to various processes, various welding variables including recording of actual

variables used, various type of tests, preparation of qualification records (WPS, PQR, WPQ) and

maintenance records (qualification list and continuity records).

5.6 Training activity related to ASME Code Section IX can be outsourced from individuals, agencies or

institutes evaluated and selected by QA/QC Manager

6.0 Qualification and Designation:

6.1 Personnel who meets education, experience and training requirements above can be considered as

qualified and competent as per this procedure and can be designated as welding Supervisor by

QA/QC Manager. Letter of designation shall be issued and maintained of file.

6.2 Letter of designation is valid for a period of 3 years and can be renewed based on continued

employment and satisfactory performance. The designation shall be deemed revoked when the

employment is terminated.

7.0 Records:

7.1 The QA/QC Manager shall maintain the following records on file and make them available to Authorized

inspector, Authorized Inspector Supervisor and ASME Designee as when requested for their verification.

7.1.1 All Education, Experience and training records of Welding Supervisors.

7.1.2 Letter of Designation as Welding Supervisor.

You might also like

- Welding Log FormDocument1 pageWelding Log Formdenni kurniawanNo ratings yet

- Nitinol Af Testing StrategiesDocument5 pagesNitinol Af Testing StrategiesTodd DicksonNo ratings yet

- Jonathan's Last Day: Reading Comprehension QuizDocument3 pagesJonathan's Last Day: Reading Comprehension QuizLoja Vtr43% (7)

- The Star and Criss Supervision: Proactive and Reactive Practices of A Supervisor Instructional LeadershipDocument31 pagesThe Star and Criss Supervision: Proactive and Reactive Practices of A Supervisor Instructional LeadershipEvangeline LapitanNo ratings yet

- MS-M2101 (S09) - HSSE-GP-003 ERP Rev 0Document32 pagesMS-M2101 (S09) - HSSE-GP-003 ERP Rev 0Lau Poung HieNo ratings yet

- JHA Arc WeldingDocument2 pagesJHA Arc WeldingechaNo ratings yet

- JSA For The Lifting and SlingingDocument1 pageJSA For The Lifting and SlingingMIAN MATEENNo ratings yet

- ISO 15609-5 Welding Procedure Specification Part 5 Resistance WeldingDocument21 pagesISO 15609-5 Welding Procedure Specification Part 5 Resistance WeldingdneprmtNo ratings yet

- F&AE - 5SemiAutomaticand AutomaticWeldingDocument8 pagesF&AE - 5SemiAutomaticand AutomaticWeldingFaiz IshakNo ratings yet

- Rubber Lining CoverDocument1 pageRubber Lining CoverhannanNo ratings yet

- Material Safety Data Sheet: MSDS No. GW001 Carbon Steel Gas Welding RodsDocument7 pagesMaterial Safety Data Sheet: MSDS No. GW001 Carbon Steel Gas Welding Rodssajeev27No ratings yet

- Job Safety Analysis Sheet: FacilityDocument1 pageJob Safety Analysis Sheet: FacilityHelza RahmanniaNo ratings yet

- Poly Cell Adhesive: Main ApplicationDocument2 pagesPoly Cell Adhesive: Main ApplicationHung Mai VanNo ratings yet

- Projects Assessments For Welding ProcessDocument8 pagesProjects Assessments For Welding ProcessKamarul NizamNo ratings yet

- 01fitting in FabricationDocument11 pages01fitting in Fabricationv.bhamidi100% (1)

- HJ-001 Hydrojetting and Steam Boiler Operation Procedure - June 11, 2023Document16 pagesHJ-001 Hydrojetting and Steam Boiler Operation Procedure - June 11, 2023allawee2011No ratings yet

- Training Feedback Form - : Trainee Name: Training Date: Designation: Batch: Trainer's NameDocument1 pageTraining Feedback Form - : Trainee Name: Training Date: Designation: Batch: Trainer's NamekopaljsNo ratings yet

- Aramco - Interview Preparation TipsDocument3 pagesAramco - Interview Preparation TipsM F ANo ratings yet

- MOG-HSEQ-P-xxx Rev P1 PPE ManagementDocument47 pagesMOG-HSEQ-P-xxx Rev P1 PPE ManagementSamerNo ratings yet

- NDT - Visual Inspection Checklist Page 1 of 4Document4 pagesNDT - Visual Inspection Checklist Page 1 of 4thindmanmohanNo ratings yet

- Name: Nihat First Name (S) : WPQ N°: TUR-19-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWDocument2 pagesName: Nihat First Name (S) : WPQ N°: TUR-19-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWSabit CirdiNo ratings yet

- Good Practices Guide To Dark Rooms OperationsDocument3 pagesGood Practices Guide To Dark Rooms OperationsJayvee Baradas Valdez0% (1)

- Control of Documents & RecordDocument19 pagesControl of Documents & RecordSugunthan SelvarasuNo ratings yet

- SOP For Unloading, Storage, Handling and Use of Compressed Gas CylindersDocument3 pagesSOP For Unloading, Storage, Handling and Use of Compressed Gas CylindersSolomonNo ratings yet

- 04 Dye Penetration TestDocument10 pages04 Dye Penetration TestTulasidas SugguNo ratings yet

- Confined Space ProcedureDocument24 pagesConfined Space Proceduresergio100% (1)

- WPS NMB 001Document6 pagesWPS NMB 001mohamed nasserNo ratings yet

- The Outline of Welder Training ProgramDocument1 pageThe Outline of Welder Training ProgramSatish KeskarNo ratings yet

- NCR AG I 055 With Vendors ReplyDocument12 pagesNCR AG I 055 With Vendors ReplymuhammedemraanNo ratings yet

- Dye Penetrant Inspection - Wikipedia, The Free EncyclopediaDocument5 pagesDye Penetrant Inspection - Wikipedia, The Free Encyclopediaviswamanoj100% (1)

- Ating Removal and OpenholeDocument7 pagesAting Removal and OpenholearunmirandaNo ratings yet

- Plan of Typical Welder Training ProgramDocument1 pagePlan of Typical Welder Training ProgramSatish KeskarNo ratings yet

- EsscDocument56 pagesEsscMakwana Mehul100% (1)

- Inspection Flash Report: RFI NO & Date: 1.0 Type of VisitDocument3 pagesInspection Flash Report: RFI NO & Date: 1.0 Type of VisitFahad AhmadNo ratings yet

- 10 - Destructive and Non-Destructive Tests Os WeldsDocument20 pages10 - Destructive and Non-Destructive Tests Os WeldsRamu Amara0% (1)

- QAF5153 Rev.0 Pre-Mobilization Inspection Checklist - Guidelines - 1Document1 pageQAF5153 Rev.0 Pre-Mobilization Inspection Checklist - Guidelines - 1Mohamed El-SawahNo ratings yet

- 4066-To Perform Hot Work Activities (Welding, Oxy Cutting, Grinding, Cutting, Heat Gun andDocument3 pages4066-To Perform Hot Work Activities (Welding, Oxy Cutting, Grinding, Cutting, Heat Gun andEric TingNo ratings yet

- Bolt TorquingDocument2 pagesBolt TorquingREHAN IQBALNo ratings yet

- Plant Inspector, Elsayed Hamed Updated 11-2023..Document17 pagesPlant Inspector, Elsayed Hamed Updated 11-2023..Mohamed100% (1)

- Aqib Javed CV and DocumentsDocument15 pagesAqib Javed CV and DocumentsSher DilNo ratings yet

- Incident and Investigation Report SampleDocument3 pagesIncident and Investigation Report SamplemehdiNo ratings yet

- Permit To WorkDocument37 pagesPermit To WorkTayyab Hasnain Saadat JanjuaNo ratings yet

- TM 1 T EMPLATESDocument60 pagesTM 1 T EMPLATESDhess Dulay Bamba100% (1)

- Procedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Document2 pagesProcedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Walid BdeirNo ratings yet

- Job Explanation MeetingDocument26 pagesJob Explanation Meetingjp2udhayaNo ratings yet

- Inspection Engineer Grade 1Document43 pagesInspection Engineer Grade 1ahmad taiyabiNo ratings yet

- Initial Screening FOR Tank Cleaning, Repair & Painting Services General Bid SlateDocument5 pagesInitial Screening FOR Tank Cleaning, Repair & Painting Services General Bid SlateJamal Mohamed RahamathullahNo ratings yet

- Method For Installation of NMFOC & OPGW at GOSP 10Document10 pagesMethod For Installation of NMFOC & OPGW at GOSP 10Subhash Chekka SEC 115KV ProjectNo ratings yet

- Released: Company Document No: Document ClassDocument32 pagesReleased: Company Document No: Document ClassShajahan AsanarNo ratings yet

- Ut PWPS 001Document1 pageUt PWPS 001Goutam Kumar Deb100% (1)

- Hope Certificate - IOSH-11654Document1 pageHope Certificate - IOSH-11654Muhammad ImranNo ratings yet

- Elephant Project - Sayakha GujaratDocument8 pagesElephant Project - Sayakha Gujaratalla malikNo ratings yet

- Weld Inspection Report / Sentence Sheet Print Full Name: Specimen NumberDocument6 pagesWeld Inspection Report / Sentence Sheet Print Full Name: Specimen NumberWalid BdeirNo ratings yet

- ML 07 WeldingDocument11 pagesML 07 WeldingDeepakNo ratings yet

- p999999 100zd11 000 zd0001 - 0 Welding StandardDocument25 pagesp999999 100zd11 000 zd0001 - 0 Welding StandardJennyNo ratings yet

- Confined Space Entry Log SheetDocument1 pageConfined Space Entry Log SheetJobin FrancisNo ratings yet

- ESTA-OMEGA 2000 - Electrostatic Powder Coating UnitDocument19 pagesESTA-OMEGA 2000 - Electrostatic Powder Coating UnitRenato AbalosNo ratings yet

- 5 Welding Processes 1Document62 pages5 Welding Processes 1adelNo ratings yet

- CV - Abdul RahimanDocument4 pagesCV - Abdul Rahimanpasser byNo ratings yet

- Team Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitDocument1 pageTeam Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitRakesh KumarNo ratings yet

- WDI-WPS-072 Rev.00 SMAW 2Document4 pagesWDI-WPS-072 Rev.00 SMAW 2MohamedNo ratings yet

- Cswipws 190Document17 pagesCswipws 190Vin BdsNo ratings yet

- INSTECH API 577 Welding Inspection Metallurgy Course DESCRIPTIONDocument2 pagesINSTECH API 577 Welding Inspection Metallurgy Course DESCRIPTIONDavid Jimenez GonzalezNo ratings yet

- Kofco Catalog (2015-08)Document103 pagesKofco Catalog (2015-08)Santosh LatakeNo ratings yet

- Dish Head DetailDocument1 pageDish Head DetailSantosh LatakeNo ratings yet

- Procedure For Certification of Design PersonnelDocument6 pagesProcedure For Certification of Design PersonnelSantosh LatakeNo ratings yet

- Final - Desginer For ASME U Designator VesselDocument10 pagesFinal - Desginer For ASME U Designator VesselSantosh LatakeNo ratings yet

- 20130401Document15 pages20130401SebNo ratings yet

- Bioflavor Biopang (02 06)Document5 pagesBioflavor Biopang (02 06)Fadila Artameivia AunuraNo ratings yet

- Profitability and Marketability of The Top 55 U.S. Commercial BanksDocument19 pagesProfitability and Marketability of The Top 55 U.S. Commercial BanksSasa LuNo ratings yet

- SPM30 PDF Eng PDFDocument0 pagesSPM30 PDF Eng PDFValdemar Miguel SilvaNo ratings yet

- Os Lab Manual AimlDocument107 pagesOs Lab Manual Aimlpooja ppNo ratings yet

- Analisis de Pesticidas Usandom FragmentacionDocument159 pagesAnalisis de Pesticidas Usandom FragmentacionroxanaNo ratings yet

- Linguistics of Ancient India and Its Main DirectionsDocument8 pagesLinguistics of Ancient India and Its Main DirectionsastaNo ratings yet

- Climate Variability and Climate Change 2016Document91 pagesClimate Variability and Climate Change 2016Laila Guarin100% (1)

- Grid Code For FgPeninsular MalaysiaDocument460 pagesGrid Code For FgPeninsular MalaysiaberapiNo ratings yet

- Fingerprint - Based Employee Attendance System - Free Source Code Projects and TutorialsDocument8 pagesFingerprint - Based Employee Attendance System - Free Source Code Projects and Tutorialswilson greenNo ratings yet

- Lesson 4 - Visual Art and Its PurposeDocument6 pagesLesson 4 - Visual Art and Its PurposeMae CherryNo ratings yet

- Development On Plot No. Donyo Sabuk/Komarock BLOCK 1/25878 Client: Lilian Lutta MalobaDocument12 pagesDevelopment On Plot No. Donyo Sabuk/Komarock BLOCK 1/25878 Client: Lilian Lutta MalobaAustin AnindoNo ratings yet

- CAR-T TherapyDocument14 pagesCAR-T TherapyrameshaachariarNo ratings yet

- SF - SafeFlame Data Sheet UVIRDocument2 pagesSF - SafeFlame Data Sheet UVIRVincent GabrielNo ratings yet

- Archaeological Landmarks in TurkeyDocument2 pagesArchaeological Landmarks in TurkeyMoustafa Ben AmorNo ratings yet

- NB Private Equity Partners Ltd.Document68 pagesNB Private Equity Partners Ltd.ArvinLedesmaChiong100% (1)

- 5mm LED Datasheet PDFDocument1 page5mm LED Datasheet PDFAlex ZXNo ratings yet

- Roll No. 31 - SportsDocument8 pagesRoll No. 31 - SportsAdnan NawabNo ratings yet

- Maths - MS-JMA01 - 01 - Rms - 20180822 PDFDocument11 pagesMaths - MS-JMA01 - 01 - Rms - 20180822 PDFAmali De Silva67% (3)

- New Hptu Syllabus CSEDocument138 pagesNew Hptu Syllabus CSEerankursharma1985No ratings yet

- Dobor Rezystorow B628xx StepUp Chip - vbc-VB9208-v1.0Document9 pagesDobor Rezystorow B628xx StepUp Chip - vbc-VB9208-v1.0asdfNo ratings yet

- PM265 ch2Document47 pagesPM265 ch2M. AhmedNo ratings yet

- Manual de Servicio Treadmill 2000Document150 pagesManual de Servicio Treadmill 2000pirihuey1234No ratings yet

- Maths Coursework Mark SchemeDocument4 pagesMaths Coursework Mark Schemef5d7ejd0100% (2)

- One Time Registration For TNPSCDocument2 pagesOne Time Registration For TNPSCtrismaheshNo ratings yet

- Acupressure Animal SheltersDocument1 pageAcupressure Animal SheltersIoana SavaNo ratings yet

- Applying Machine Learning in Capital MarketsDocument5 pagesApplying Machine Learning in Capital MarketsmaritzaNo ratings yet