Professional Documents

Culture Documents

Al-V Phase Diagram

Al-V Phase Diagram

Uploaded by

kasturiCopyright:

Available Formats

You might also like

- The Handbook of Infrared and Raman Characteristic Frequencies of Organic MoleculesFrom EverandThe Handbook of Infrared and Raman Characteristic Frequencies of Organic MoleculesRating: 5 out of 5 stars5/5 (2)

- Engine + Generator - Engineering Manual Rev.1 (RECIBIDO 6-11-12) PDFDocument159 pagesEngine + Generator - Engineering Manual Rev.1 (RECIBIDO 6-11-12) PDFJavier Everest50% (2)

- 2009 O Level Chem Questions With AnswersDocument14 pages2009 O Level Chem Questions With AnswersGertrude Ramsbottom50% (2)

- Boletin de Fallas Atra 2012Document34 pagesBoletin de Fallas Atra 2012marcelo ustarezNo ratings yet

- 2010 Jeep PatriotDocument2 pages2010 Jeep PatriotswiftNo ratings yet

- RB211 Bleed ValvDocument10 pagesRB211 Bleed Valvyasser_nasef5399100% (1)

- BCWP ManualDocument80 pagesBCWP ManualBottle Mani100% (1)

- Circuit Laboratory Experiment IDocument4 pagesCircuit Laboratory Experiment Iblackwoodsam3No ratings yet

- 2001-10 Pages 28-32 PDFDocument5 pages2001-10 Pages 28-32 PDFDavidNo ratings yet

- ELC520S-LAB 2 - Sem-2 - 2020Document6 pagesELC520S-LAB 2 - Sem-2 - 2020Tiofelus H. HamutenyaNo ratings yet

- Chapter 1 Electrons and Holes in Semiconductors: 1.1 Silicon Crystal StructureDocument16 pagesChapter 1 Electrons and Holes in Semiconductors: 1.1 Silicon Crystal StructurepurseyNo ratings yet

- Practical Assessment of The Performance of Aluminium Battery TechnologiesDocument9 pagesPractical Assessment of The Performance of Aluminium Battery TechnologiesJorge Andrés BaquerizoNo ratings yet

- Lo:an1jj: II II Lilt IIDocument1 pageLo:an1jj: II II Lilt IIvainateyagoldarNo ratings yet

- Diagrama Al O WriedtDocument6 pagesDiagrama Al O WriedtAlejandra HernandezNo ratings yet

- Three Phase Transformer Winding ConfigurationsDocument40 pagesThree Phase Transformer Winding ConfigurationsbudanaNo ratings yet

- Ahmed ALgendyDocument14 pagesAhmed ALgendymiramirjafari2No ratings yet

- OD!leictioDocument42 pagesOD!leictioanonymNo ratings yet

- Factor For The Specific Gravity Is Positive or Negative, at Various TemperaturesDocument28 pagesFactor For The Specific Gravity Is Positive or Negative, at Various TemperaturesAnonymous dqbb02DUhNo ratings yet

- G01 Lab 4Document12 pagesG01 Lab 4Irtisam AlaviNo ratings yet

- Notes - Switching CircuitsDocument8 pagesNotes - Switching CircuitsCohesive GamerNo ratings yet

- Jan 2005Document10 pagesJan 2005paolo maldiniNo ratings yet

- Documents SteelDocument7 pagesDocuments SteelSauvala HarriNo ratings yet

- The Sigma Phase PDFDocument28 pagesThe Sigma Phase PDFgostokhelwiNo ratings yet

- Removal Exam 1Document1 pageRemoval Exam 1Miko F. RodriguezNo ratings yet

- Transformer Wiring ConfigurationsDocument40 pagesTransformer Wiring ConfigurationsAndres Felipe Triviño LaraNo ratings yet

- Scott - 1982 - The Vibrational Structure of Davydov Solitons PDFDocument9 pagesScott - 1982 - The Vibrational Structure of Davydov Solitons PDFЮрий ЮрийNo ratings yet

- Response Modification Coefficient - For Structural Systems, RDocument3 pagesResponse Modification Coefficient - For Structural Systems, RMuhammad Al MamunNo ratings yet

- PHY121 Electricity and MagnetismDocument74 pagesPHY121 Electricity and Magnetismstephenalfa7No ratings yet

- Potential Divider Student Worksheet: TheoryDocument4 pagesPotential Divider Student Worksheet: TheoryMaha sidNo ratings yet

- ARTICULODocument6 pagesARTICULOPaola Andrea SuarezNo ratings yet

- Lab Manual EE1251 PDFDocument35 pagesLab Manual EE1251 PDFImran KhanNo ratings yet

- Lab Manual EE1251 PDFDocument35 pagesLab Manual EE1251 PDFHitesh VijayNo ratings yet

- Practical Considerations For The Use of A Howland Current SourceDocument4 pagesPractical Considerations For The Use of A Howland Current SourceRamiShaabannnnNo ratings yet

- Een-112 Practical-3 Harsh-Maurya 20117056 Q3-Batch MeDocument5 pagesEen-112 Practical-3 Harsh-Maurya 20117056 Q3-Batch MekeshavmandowraNo ratings yet

- Symmetrical and Unsymmetrical FaultsDocument51 pagesSymmetrical and Unsymmetrical FaultsMohamed SobhyNo ratings yet

- Symmetrical Components WebinarDocument23 pagesSymmetrical Components WebinarSuppenguin100% (2)

- Key Questions For This Chapter: Slide 1-1Document31 pagesKey Questions For This Chapter: Slide 1-1Windarto Properti SoloNo ratings yet

- Mak313 Lab1Document3 pagesMak313 Lab1Erol “DosS” KılıçNo ratings yet

- Physics PracticalDocument25 pagesPhysics PracticalYukti SharmaNo ratings yet

- Physics PracticalDocument6 pagesPhysics PracticalLakshya BhatiNo ratings yet

- Chap. 06 - Electrochemistry: Modul Al-KimiyaDocument38 pagesChap. 06 - Electrochemistry: Modul Al-KimiyasivandreaNo ratings yet

- An Analysis of A Hybrid-Mode in A Twisted Rectangular WaveguideDocument7 pagesAn Analysis of A Hybrid-Mode in A Twisted Rectangular WaveguidehesoyamyecgaaaNo ratings yet

- Lu-Wang - Hall Algebras and QSPDocument75 pagesLu-Wang - Hall Algebras and QSPlandvermesser110No ratings yet

- Qe 01Document10 pagesQe 01cesarNo ratings yet

- Report: QE-0-1: Linear Signal Conditioning Applications With Op-AmpsDocument10 pagesReport: QE-0-1: Linear Signal Conditioning Applications With Op-AmpscesarNo ratings yet

- Book Structural-Stability-Theory-And-Implementation1Document3 pagesBook Structural-Stability-Theory-And-Implementation1هديل عميرةNo ratings yet

- Electrical Axis and Axis Deviation: Mean Qrs Axis: DefinitionDocument9 pagesElectrical Axis and Axis Deviation: Mean Qrs Axis: Definitionrocker_jadulNo ratings yet

- Report: QE-0-1: Linear Signal Conditioning Applications With Op-AmpsDocument10 pagesReport: QE-0-1: Linear Signal Conditioning Applications With Op-AmpscesarNo ratings yet

- Ec Ii Unit3Document23 pagesEc Ii Unit3Unmesh PeriNo ratings yet

- Lecture 5 Fault Modeling FaultDocument18 pagesLecture 5 Fault Modeling FaultbaijunagoriNo ratings yet

- TP Caribbean Examinations: Advanced Proficiency Physics Unit 02 l5Document18 pagesTP Caribbean Examinations: Advanced Proficiency Physics Unit 02 l5Isa Abdul HakeemNo ratings yet

- Properties of Semiconductor Alloys: Group-IV, III-V and II-VI SemiconductorsFrom EverandProperties of Semiconductor Alloys: Group-IV, III-V and II-VI SemiconductorsNo ratings yet

- Passive and Discrete Circuits: Newnes Electronics Circuits Pocket Book, Volume 2From EverandPassive and Discrete Circuits: Newnes Electronics Circuits Pocket Book, Volume 2No ratings yet

- Electrical and Electronic Principles 3 Checkbook: The Checkbook SeriesFrom EverandElectrical and Electronic Principles 3 Checkbook: The Checkbook SeriesNo ratings yet

- Band Structure And Nuclear Dynamics: Proceedings of the International Conference On Band Structure And Nuclear Dynamics Tulane University, New OrleansFrom EverandBand Structure And Nuclear Dynamics: Proceedings of the International Conference On Band Structure And Nuclear Dynamics Tulane University, New OrleansA.L. GoodmanNo ratings yet

- Ion-Containing Polymers: Physical Properties and StructureFrom EverandIon-Containing Polymers: Physical Properties and StructureA. EisenbergNo ratings yet

- Introduction to the Theory of Shells: Structures and Solid Body MechanicsFrom EverandIntroduction to the Theory of Shells: Structures and Solid Body MechanicsNo ratings yet

- 1 s2.0 S0376738817328053 MainDocument10 pages1 s2.0 S0376738817328053 MainkasturiNo ratings yet

- Metals 10 00027Document13 pagesMetals 10 00027kasturiNo ratings yet

- Pd-Coated v-AlJeon Park Magnone Current Applied Physics (2012)Document8 pagesPd-Coated v-AlJeon Park Magnone Current Applied Physics (2012)kasturiNo ratings yet

- 1 s2.0 S0925838817330177 MainDocument8 pages1 s2.0 S0925838817330177 MainkasturiNo ratings yet

- 1 s2.0 S0925838814025018 MainDocument6 pages1 s2.0 S0925838814025018 MainkasturiNo ratings yet

- 1 s2.0 S0376738812003766 MainDocument8 pages1 s2.0 S0376738812003766 MainkasturiNo ratings yet

- 1 s2.0 S0022311503003179 MainDocument7 pages1 s2.0 S0022311503003179 MainkasturiNo ratings yet

- 1 s2.0 S0966979514001277 MainDocument6 pages1 s2.0 S0966979514001277 MainkasturiNo ratings yet

- 1 s2.0 S0921509316309534 MainDocument7 pages1 s2.0 S0921509316309534 MainkasturiNo ratings yet

- 1 s2.0 S0925838822050757 MainDocument8 pages1 s2.0 S0925838822050757 MainkasturiNo ratings yet

- VFT 400 KVDocument9 pagesVFT 400 KVNandkumar ChinaiNo ratings yet

- Chapter 5: The Project Life Cycle: Just Enough Structured AnalysisDocument28 pagesChapter 5: The Project Life Cycle: Just Enough Structured AnalysisMarcelo RojasNo ratings yet

- 07 2018 Biomedical Instrumentation - Electrical Stimulation PDFDocument48 pages07 2018 Biomedical Instrumentation - Electrical Stimulation PDFviki mikiNo ratings yet

- Duraplate 8200Document4 pagesDuraplate 8200Carlos VillacrizNo ratings yet

- GPU Gems - Chapter 7Document13 pagesGPU Gems - Chapter 7Sebastian SytaNo ratings yet

- DC Inverter VRF Air Conditioning SystemsDocument35 pagesDC Inverter VRF Air Conditioning SystemsTudor SorbanNo ratings yet

- Sample Project Report On Financial Analysis at B D K LTD HubaliDocument102 pagesSample Project Report On Financial Analysis at B D K LTD HubalihareeshngvNo ratings yet

- IAL PresentationDocument55 pagesIAL PresentationPanneer SelvamNo ratings yet

- New Progress in Senior Mathematics Compulsory Part SolutionDocument2 pagesNew Progress in Senior Mathematics Compulsory Part Solutioninvincibilitized abdominizerNo ratings yet

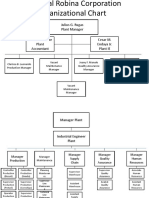

- Julius G. Rugas Plant Manager Cesar M. Endaya Jr. Plant IEDocument4 pagesJulius G. Rugas Plant Manager Cesar M. Endaya Jr. Plant IEJoshua MalibongNo ratings yet

- ALTIVAR 28 Quick Reference GuideDocument1 pageALTIVAR 28 Quick Reference Guidesuperpuma86100% (1)

- TeluxDocument85 pagesTeluxMuhammadAnasNo ratings yet

- Audi Maintenance Schedule Model Year 2008Document1 pageAudi Maintenance Schedule Model Year 2008api-247506078No ratings yet

- Fox3 17Document12 pagesFox3 17orellanasebasNo ratings yet

- NASA Facts Ion PropulsionDocument4 pagesNASA Facts Ion PropulsionRich GarrNo ratings yet

- Infinitesimal 0.3 Technical SheetDocument2 pagesInfinitesimal 0.3 Technical SheetBmwmotorsport GabriNo ratings yet

- Envisioning Sustainable Infrastructure For Smart CitiesDocument10 pagesEnvisioning Sustainable Infrastructure For Smart Citiesdrcss5327No ratings yet

- Physics: Behind The ConceptDocument10 pagesPhysics: Behind The ConceptAditya Shiva AppallaNo ratings yet

- CPM5x00 Appendix - High Ton InstallationDocument8 pagesCPM5x00 Appendix - High Ton InstallationtrailNo ratings yet

- DCinv V6 Rev2 CleanDocument38 pagesDCinv V6 Rev2 Cleanyasirarafat91No ratings yet

- Input - OutputDocument15 pagesInput - Outputsushil4056No ratings yet

- Lab ReportDocument2 pagesLab ReportNayhomi PenaNo ratings yet

- Design of Wind Turbine BladesDocument13 pagesDesign of Wind Turbine BladesmasoodkamaliNo ratings yet

- Steam Peeler - OrbitDocument2 pagesSteam Peeler - OrbitMoaz TajammalNo ratings yet

- Aluminum Crust BreakerDocument8 pagesAluminum Crust BreakersenamotoNo ratings yet

Al-V Phase Diagram

Al-V Phase Diagram

Uploaded by

kasturiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Al-V Phase Diagram

Al-V Phase Diagram

Uploaded by

kasturiCopyright:

Available Formats

AI-V

AI-V (Aluminum-Vanadium)

J.L. Murray

Alcoa Technical C e n t e r

Alloy Technology Division

Alcoa Center, PA 15069

Equilibrium Diagram dilute liquidus. Special points of the assessed diagram

are listed in Table 1. Conflicting reports are described

The Al-V intennetallic phases are structurally well below.

characterized, and the solubilityof V in diluteliquidAl is

known, but the phase diagram as a whole stillcontains The equilibrium sofid AI-V phases are:

many uncertainties. On the V-rich side, high melting • The fcc (AI) and bcc (V) solid solutions---the former

temperatures make the liquidus and solidus tempera- with a very narrow homogeneity range (0 to 0.3 at.%

tures difficult to measure and also make equilibrium V) and the latter with a wide ( - 5 0 to 100 at.% V)

difficult to achieve in the solid state. Interest in the pos- range

sibility that "A1V3" would have good superconducting • The Al-rich compounde complex cubic AI21V2 (also

properties has led to numerous investigations around 75 designated AI llV or AI loV), monoclinic A145V7 (also

at.% V, with conflicting results. designated AI7V), hexagonal A123V4 (also designated

On the Al-rich side, the melting reactions are of the AleV), and AI3V with D022 structure

peritectic type and therefore sluggish: it is possible that • AIsV5, with cubic 7 brass structure, which is thought

metastable reactions have been interpreted as stable to have some range of homogeneity at high tempera-

ones, and/or that decomposition of one or more inter- ture. (This range, not being quantitatively known, is

metallics in the solid state has been missed, and that this not indicated in Fig. 1.)

is the reason for conflicting phase diagrams. The as-

sessed AI-V phase diagram (Fig. 1) is based on work by V-Rich Llquldus

Bailey et al. [59Bail for invariant reactions and on work Melting points were determined by Rostoker and

by Willey [53Will and by Eremenko et al. [81Ere] for the Yamamoto [54Ros] and by Carlson et al. [55Carl for al-

Fig. 1 Assessed AI-V Phase Diagram with Experimental Data

Weight Percent Vanadium

0 l0 20 30 40 50 B0 79 ~0 gO 100

~000 .... I....,.I ....... I ..... J. . . 1 I I I i i i I ., i I

......... , ......... , ......... , . . . . . . . . . . . . | ......... i .........

1910°C

leoo, L .........................:::;...:...'-e..........."v............a"'~;;'"'v"~"O°"

lOOK}, ..~ . . . . . r. . . . . V

.."'~1670 i ",

o ,,, : ',

~) 1400. " O '', ' (V)

asoo, ,," > i ~ "

-~ / ~i 2 \ Io 55Cor I

" 738°c I

.... I ........

600 ~" ""'::"" ":::"".

(")[ I GI< I /// B2: ..... ......

4oo~l....... :'lb" ....' i o " ' ~ ........ 4'0 ........ '~ ........ leos.-..... ,~ ........ , ....... :'i~" ...... ioo

Al Atomic Percent Vanadium v

J.L. Murray, 1989.

Bulletin of Alloy Phase Diagrams Vol. 10 No. 4 1989 351

AI-V

Fig. 2 "AI-Rich AIoV Phase Diagram

Weight P e r c e n t V a n a d i u m

0 2 4 6 8 10 12 14 16 IB 20 22

llO0 . . . . . . - . . . . , . . . . . . - . . ,

x 40Rot, XRD

• 55Car. t h e r m a l a n a l y s i s

1000- L ~

o 55EI1, c h e m i c a l a n a l y s i s

~0 0 0 e 59Bai, t h e r m a l a n a l . h e a t i n g

O

1100-

/ ~O •

• 61Geb, t h e r m a l a n a l y s i s

• 61Geb, t w o - p h a s e

÷ 81Ere, chemical analysis

::3 soo- o 53WiI, chemical analysis

•*'J •

<0 736°C

-m a $

¢) ?00- 688.°C , .

iaa

. . . . _

662.1°C

p- ,¢

> > :>

Lt~ ¢q

~" OJ

,oo V-(Al) e-.-4

< < <¢

400

0

......... i ........

2

' " ] ~"- - ~"- . . . . ! . . . . . . . . .

4 6

*

8

.... + xb. . . . . . ~+"

A1 Atomic P e r c e n t V a n a d i u m

J.L. Murray, 1989.

Table I Special Points of the Assessed AI-V Phase Diagram

C o m p o s i t i o n of t h e

r e s p e c t i v e phases, Temperature, Reaction

Reaction at.% v °(2 type

L ~, (A1}........................................... 0 660.452 Melting point

L + AI21V2- (A1) ........................... 0.09 8.7 0.3 662.1 Peritectic

L + A145V7~ A121V2....................... 0.1 13.5 8.7 670 Peritectic

L + A12nV4.~-AJ45V7....................... 0.13 14.8 13.5 688 Peritectic

L + Al:N - AI23V4.......................... 0.22 25 14.8 736 Peritectic

L + AlsV5+-Al:~V............................ 14 38.5 25 - 1360 Peritectic

L + ( V ) - Al~Vr, ..............................

28 46 38.5 - 1670 Peritectic

L--(V) ............................................. 100 1910 Melting point

loys containing more than 5 at.% V (see Fig. 1). Carlson AI-Rich Liquidus

et al. used optical pyrometry with induction or internal The liquidus up to 3 at.% V has been investigated

resistance heating; melting was observed as roundingof [81Ere, 53Wil, 55Ell, 61Geb]. The first three used

a hole or of the edges of irregularly shaped pieces of alloy chenfical analysis of extracted equilibrated liquid and

placed in a graphite crucible. The melting point of pure the last used thermal analysis on cooling. Because of the

V was reported by Carlson e t a l . as 1845 +_. 10 °C (the as- sluggishness of peritectic reactions, substantial (> 100

sessed value is 1910 °C); therefore, a somewhat larger °C) undercoolings were observed in the thermal

uncertainty should be attributed to the melting analysis. Three of the results [53Wil, 55Ell, and 81Ere]

temperatures of V-rich alloys. Incongruent melting of are in reasonable agreement. The Russian liquidus

AlaV.rI and Al3V was reported at 1670 and 1360 °C, points [81Ere] are the lowest, and those of Elliott

respectively. The latter temperature was also deter- [55Ell] are the highest. The assessed liquidus (Fig. 2 and

mined from cooling curves. By determination of in- 3) gives most weight to lower solubilities.

cipient melting via optical pyrometry, Rostoker and

Yanmmoto found the peritectic melting of Al3V at about Four intermetallic compounds have been identified in

1370 °C, in good agreement with the Carlson value of Al-rich alloys--Al21V2, A145V7, A123V4 and Al3V. Al-

1360 °C. though there is reasonable agreement among tempera-

352 Bulletin of Alloy Phase Diagrams Vol. 10 No. 4 1989

AI-V

Fig. 3 Solubility of V in Liquid AI

Weight Percent Vanadium

I 2 3 4 5 8

|0~0 . . I .... I ...... I ...... i I . . . . I ....

0

IO00,g,~O. 0 0 0 O

L)

o

gO0- + 0 0

850- JO 0

~o

B Z3..s2_c.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7~. ~ 688~C L+AIs3V4 L+AI45Vv\

"[ /6 70 C

o/662 °c (A1)+AletVe

"°°o ....... o.s' ......... l . . . . . . . . L6'

. . . . . . . . -' ....... ~ ......... ~ ....... -a.,,

Al Atomic Percent Vanadium

J.L.Murray, 1989.

tures of invariant reactions (see Table 2 and Fig. 2), the Metallographic and microprobe analyses [76Lit] were

interpretations of the reactions conflict. Major ex- made on dilute alloys heat treated for short times at

perimental contributions have been made [53Wil, temperatures between 500 and 740 °C. They concluded

55Car, 55EII, 59Bai, 76Lit]. that only AI3V and 'Tk16V" (A123V4) are equilibrium

phases, and that A]21V 2 appears only as a nletastable

Willey [53Wil] used a filtrationtechnique to obtain liq-

transition phase.

uid equilibrated at several temperatures for chemical

analysis. A break in the liquidus curve was found at A two-phase assemblage of (AI) + another phase (not

about 703 °C; the solidphases were identifiedas A121V 2 A121V2), was formed in melt-spun 10 at.% V ribbons held

below 703 °C and AI3V above 703 °C. at 600 °C [86Sch]. However, a fine dispersion ofAl21V2

Bailey et aL [59Bai] performed thermal analysis on was found in a 1.8 at.% V alloy solidified by plasma-jet

heating and establishedthat reactionsoccur at 670, 688, spraying after holding at 600 °C [68Mos].

and 736 °C; they noted that cooling data could not be There is thus some agreement that AI3V, A123V4,and

fused, because large supercooling effects masked the AI21V2 phases predominate, and that AI45V7 is the most

small heats of transfomnation. Although this work es- difficult phase to produce from the liquid. However,

tablished the temperatures of invariant reactions, no there are discrepancies in two major areas: (1) whether

microstructural evidence was presented to show which Al21V2 is a stable phase in equilibrium with (AI) to low

phases were in equilibrium in the invariant reactions. temperature; and (2) whether 736 °C is to be interpreted

Bailey et al. [59Bai] assumed a simple cascade of as the incongruent melting temperature of AI23V4. If

peritectic reactions--that AI21V2, A145V7, and AI23V 4 A123V 4 is in equilibrium with the melt to higher

are the phases melting at 670, 688, and 736 °C, respec- temperatures, then it renmins to determine its peritec-

tively. Gebhardt and Joseph [61Geb] also interpreted tic melting temperature and to correctly interpret the

thermal analysis (cooling) data according to this reac- three invariant reactions at 736, 688, and 670 °C.

tion scheme.

Solubility of V in (AI)

Elliott[55EII] found a peritecticreaction at 727 °C and Based on latticeparameter data, the solubilityof V in

identified the phases in equilibrium with the liquid solid (Al)at 620 °C isabout 0.2 at.% [40Rot]. Varich et al.

above and below 727 °C as Al23V4 and AI21V2 respective- [63Var] used the maximum in paramagnetic suscep-

ly. Elliott found A123V4 to be the equilibrium intermetal- tibility to estimate that the maximum solubility of V in

lic phase up to at least 850 °C, in contradiction with (Al) is 0.3 at.%; the two values are consistent with each

other reports [53Wil, 59Bai]. other and with thermodynamic properties.

Bulletinof Alloy Phase Diagrams Vol. 10 No. 4 1989 353

AI-V

The (AI) solid solution melts by a peritectic reaction, other attempts to synthesize AIV3 were unsuccessful be-

reported to lie a t 1.6 _+ 0.2 °C [55E11] or 1.7 °C [59Bai] cause too high annealing temperatures were chosen.

above the melting point o f pure AI (660.452 °C [Melt]). This view is supported by work [82Sud] with 70.5, 75,

The two values were averaged to give 662.1 °C for the and 90 at.% V alloys using X-ray diffraction (XRD),

peritectic temperature. By extrapolation o f the liquidus electron diffraction,and transmission electron micros-

to 662.1 °C, the composition of the liquid in the peritectic copy (TEM). By XRD, only the bcc phase was found.

equilibrium is less t h a n 0.1 at.% V. Specifically, ther- Howevel; superlatticereflectionsof CsCI structure were

modynandc calculation gives 0.085 and 0.3 at.% V for found in 70.5 and 75 at.% V alloys by electron diffrac-

the compositions o f liquid and (AI) at 662.1 °C. tion, and diffuse scattering corresponding to the A15

structure was also observed.

V-Rich Alloys It can be concluded tentativelythat above 600 and 700

Numerous a t t e m p t s have been made to synthesize an °C, the disordered bcc phase is stable in the binary sys-

A15 compound, AIV3, because of its potential as a super- tem. Small particles,undetected by XRD, of a second

conducting nmterial. Reports [63Hol, 71Kod] have been phase m a y form during quenching. The number of equi-

made of A15 structures formed by annealing a t 100 °C librium phases is not known, nor are the phase boun-

in quartz tubes, with lattice p a r a m e t e r s o f 0.4812 and daries. It is not known how or whether to include the

0.4926 nm, respectively. Kornilov and Matveeva hexagonal [73Leg], tetragonal [73Leg], and pseudo-

[68Kor] tried to duplicate these results, but found that cubic [73Hat] structures in a binary phase diagram at

the only A15 compound present was V3Si; they con- low pressures.

cluded that annealing in quartz tubes causes con-

tamination by Si, and t h a t only the bcc phase is stable in

the binary system. O t h e r s [55Cax; 64Ram, 70Shi] have Table 2 Reported Invariant Reactions for AI-Rich Al-

also reported t h a t only the bcc phase was found in V-rich loys

alloys. Similar findings exist for samples annealed at

700 and 1000 °C [75Hat], but some evidence was Reaction

reported for a martensitic t r a n s f o r m a t i o n to a n un- Postulated temperature

known pseudocubic s t r u c t u r e a f t e r annealing at 1500 Reference reaction ~C

°C. Hexagonal /~ A1V3, with a = 0.7070 and c = [53Wil] .............. L + A13V,~ AI21V2 703

0.9565 nm, was reported to form u n d e r pressures [54Ros] ............. L + AI3V ~, ? < 1210

greater than 30 kbar and above 1500 °C and tetragonal [55Car] ............. L + AI3V,~ A123V4 735

aAIV3, with a = 0.6167 and c ffi 0.9481 nm, appeared at L + AI23V4~ AI21V2 685

lower t e m p e r a t u r e s a n d pressures [73Leg]. No A15 [55Ell] ............... L + A123V4 ~. Al21V2 727

phase was found up to 70 kbar above 1000 °C. L + Al3V ~. A123V4 >850

[59Bai] .............. L + Al3V~ A123V4 736

Hartsough and H a m m o n d [71Har] p e r f o r m e d vacuum L + AI23v4 ~ A]46V7 088

evaporation experiments using substrate t e m p e r a t u r e s L + A145v7- Al2 IV2 670

of 350 to 450 °C and found an A15 phase o f lattice |61Geb] ............. L + AI3V ~* AI23V4 735

p a r a m e t e r 0.4829 nm. With increasing AI content, bcc L + A123V4 ~. A145V7 689

+ A15 and bcc phases were formed. The A15 phase L + A145V7--Al21V2 680

decomposed between 600 and 700 °C. This suggests that

Table 3 AI-V Crystal Structure Data

Struktur-

Composition, Pearson Space bericht

Phase at.% V symbol group designation Prototype Reference

(AI)........................... 0 to 0.3 cF4 Fm~m A1 Cu [Pearson2}

AI21V2....................... -8.7 to 9.1 cF176 Fd~m ... AIIoV [57Bro}

A145V7....................... ~13.5 mC104 C2/m ... AI45V7 [59Brol

AI2:~V4....................... ~ 14.8 hP54 P6~mmc ... AI2.~V4 [60Rayl

AhV .......................... ~25 tI8 I4/mmm D022 AI3Ti 143Bra]

AlsVr) ........................... ci52 I43m D82 CusZn8 [77BraJ

(V) ............................ - 4 6 to 100 ci2 Im3m A2 W [Pearson2]

Other possible phases

AIV:~............................. cP8 Pm'3m A15 Cr3Si [70Sur]

t~AIV:~........................... h** ... . . . . . . [73Leg}

.AIV;j ........................... t** ... . . . . . . [73Leg]

354 Bulletinof Alloy Phase Diagrams Vol. 10 No. 4 1989

AI-V

Table 4 AI-V Lattice Parameter Data

Composition, Lattice parameters, nm

Phase at.% V a b e Reference

( A l ) ............................................. 0 0.40496 . . . . . . [Ma~alski]

Al21V~......................................... 9.1 1.4492 [57Bro]

Al4~V7......................................... 13.5 2.54 0.759~a) 1.1() [59Bro]

Al2:W4......................................... 14.8 0.76928 ... 1.7040 [578nfi, 60Ray]

Al:W ............................................ 25 0.3780 ... 0.8321 [43Bra]

AlsV5 .......................................... 39.5 0.92345 . . . . . . [77Bra]

( v ) ............................................... 100 0.30240 . . . . . . [Massalski]

Other possible phases

AlV.~............................................ 75 [70Sur]

flAlV:j(b) ..................................... 75 0.7'070 iii 0.956 [73Leg]

.AlV:jib) ..................................... 75 0.6167 ... 0.9481 [73Leg]

(a)/? = 127°. (b) May not be a stable phase at normally ambient temperature and pressure.

parameter and ndcrostructural data [55Carl; however,

Fig. 4 Heats of Formation of Solid AI-V Phases,

quantitative studies were not nmde. Thus, a simple line

Referenced to Solid fcc AI and bcc V

compound is shown in Fig. 1.

Metastable Phases

0 1 ........ ' ...... ' ........ ' ..... ' ....... ' ......... ' ........ ' ......... ' ........ ' ........

The achievement of extended solubility of V in (AI) by

rapid solidification has been reported [63Var, 68Mos,

86Ino, 87Kim], with the maximum value being 2 at.% V

by splat quenching [87Kim].

A145V7 I h~ o A quasicrystalline icosahedral phase has been identified

~-~oo0~_~ooo AIz3V4 ~ o° o [ ° a

in rapidly solidified alloys containing 10 [86Sch], 13.9

[87Kim], and 14.3 at.% V [86Ino]. Kim and Froes

[87Kim] found the icosahedral phase only as a minor

-30000,

~_q

0

constituent, with AI3V predominating, whereas Inoue e t

~ -Sf~O0 0

a/. [86Ino] reported higher volume fractions of the

icosahedral phase, also together with AI3V. Inoue e t a l .

identified the composition of the icesahedral phase as

approximately AI4V by EDXS.

1 o

Crystal Structures and Lattice Parameters

A1 Atomic Percent Vanadium v

Crystal structures of the AI-V phases are listed in Table

3, and lattice parameters are listed in Table 4. The

structures of AI21V2, AI23V4, and A145V7 have an

J.L. Murray, 1989. icosahedron as a basic structural unit [77Bha]. The

structure of AI21V2 is the same as that of AllsMg~Cr2. In

The possibility of the occurrence of stable ordered the binary AI-V system, the structure occurs with vacan-

phases is indicated in Fig. 1 by the boundaries sketched cies on AI sites, hence the common designation AIloV.

within the bcc (V) field. They are not intended to be in- The structure of A]23V4 is closely related to that of

terpreted quantitatively. Al loMn3, AlsCo2, A19SiMn3, and AI loNiFe 3.

The (V) solvus was derived from lattice parameter data Thermodynamics

[55Car]. Enff measurements [67Joh] suggested a some-

what ( - 5 at.%) greater solubility of Al in (V); the lattice [Hnltgren, B] reviewed heat of formation data for solid

parameter data are preferred, because good consistency AI-V alloys (25 to 60 at.% V) from direct reaction

was not found among partial Gibbs energies, heats of calorimetry [60Kub, 69Nec] and partial molal Gibbs

formation, and phase boundary data. That there is some energies, GAb from isopiestic measurements at 1000 °C

homogeneity range of AIsV5 was shown by lattice for 24 to 88 at.% V alloys [67Joh]. More recent inves-

Bulletin of Alloy Phase Diagrams Vol. 10 No. 4 1989 355

AI-V

Table 5 Gibbs Energies of AI-V Phases T. Sources for the Gibbs energies of the pure elements

are listed with the optimized parameters in Table 5.

Thermodynamic properties of the pure e l e m e n t s Heats of formation of the intermetallic compounds were

AG{Al,fcc)= 0 constructed, based on the assumptions that all the inter-

AG(AI,L)= 10 708 - 11.4697 T {86Din] metallics are stable phases at 0 K, and that the mini-

AG(V,L)= 21 500-9.8488 T {86DinJ m u m heat of formation occurs at the AI3V composition.

AGIV,fcc) = 7500-1.70000 T [88Gui] It can be seen from Fig. 5 that very small adjustments in

the heats of formation can lead to instabilities of some of

Excess properties of solution phases the intermetallic phases.

A(L) = - 6 8 700 + 46.59285 T A feature that occurs in all thermodynamic calculations

B(L) = -19 000 + 7.95275 T

of this system is a congruent or near-congruent point in

A(fcc) = -40 500 the bcc liquidus. This feature is a natural result of the

Gibbs energies o f compounds, referenced to fcc AI large difference between bcc AI and V melting points,

and bcc V coupled with the high solubility of AI in (V) and fiat

^rG(AiSVS) =-22 500 + 5.27736 T solidus on the V-rich side of the diagram. Thus the es-

AfG(Al3V) = -26 600 + 8.50273 T tinmted liquidus (Fig. 1) is drawn somewhat different

A~G(AI21V2) = -10 140 + 3.5 T from the liquidus shown in previous assessments such

as Hansen.

Note: Values in J/g-atom.

Cited References

tigations are enff measurements of GAI for 40 to 95 at.%

V and 660 to 767 °C [71Sam], and measurements of 40Rot: A. Roth, '~n Investigation of the Aluminum-

Vanadium System," Z. MetalIkd., 32, 356-359 (1940). {Equi

AmixH of the liquid at 1534 °C for 0 to 8 at.% V [85Bat]. Diagram; Experimental)

The two determinations of heats of formation agree well 53WII,"L.A. Willey,Alcoa Research Labs, unpublished research

and were used in the calculation of the phase diagram; (1953 ).(Equi Diagram; Experimental)

they are shown in Fig. 4. The more recent values of GAI 54Ros: W. Rostoker and A. Yamamoto, "A Survey ofVanadium

[71Sam] are very high compared with those reported Binary Systems," Trans. ASM, 46, 1136-1167 (1954). (Equi

earlier [67Joh], and the heats of formation of the bcc Diagram; Experimental)

solution derived from these newer results [71Sam] are 55Car: O.N. Carlson, D.J. Kenney, and H.A. Wilhelm, "The

inconsistent with the direct calorimetric measure- Aluminum-Vanadium Alloys System," Trans. ASM, 47, 1-20

ments. Values for GAI at 1000 °C [Hultgren,B] do not (1955). (Equi Diagram; Experimental)

agree with the work [67Joh] upon which they are osten-

55Elh R.P. Elliott, "Discussion--The Aluminum-Vanadimn

siblybased. Alloy System," Trans. ASM, 47, 538-540 (1955). (Equi

Diagram; Review)

Calculation of the Phase Diagram

Gibbs energy functions for the liquid, fcc, A121V2, A13V, 57Ray: A.E. Ray and J.F.Smith, "Composition Variation in the

and AIsV5 phases are listed in Table 5. In view of the dis- Alpha-Phase Compound of the Vanadimn-Aluminum Sys-

tem,"Acta Crysta]logr.,10, 604-605 (1957).(Crys Structure;

agreements about both the phase diagram and ther- Experimental)

modynamic quantities, these Gibbs energies should be

viewed with skepticism. They allow the Al-rich portion 57Smi.* J.F. Smith and A.E. Ray, "The Structure of V4Al2s,"

of the liquidus to be calculated, with a peritectic reac- Acta Crystallogr.,10, 169-172 (19571. (Crys Structure; Ex-

perimental)

tion, L + A121V2 ~ AI3V,,at about 700 °C. A Gibbs energy

function for the bcc phase can also be constructed to 59Bai: D.M. Bailey, O.N. Carlson, told J.F. Smith, "The

reproduce the V-rich liquidus and solvus, but it is not Aluminum-Rich End of the Aluminum-Vm]adium System,"

tabulated, because it differs from experimental results

Trans. ASM, 51, 1097-1102 (19591. {Equi Diagram; Ex-

perimentall

[67Joh, 71Sam].

60Kub: O. Kubaschewski and G. Heymer, "Heats ofFormation

Thermodynamic calculations were done by nonlinear of Transition-Metal Alumh]ides," Trans. Faraday Soc.,56,

least-squares optimization of coefficients of Gibbs ener- 473-478 (1960).(Thermo; Experimentall

gy expansions with respect to selected phase diagram 60Ray: A.E. Ray and J.E Smith, "A Test forElectron Transfer

and thermochemical data. The Gibbs energy of a solu- in V4Al2,~,"ActaCrystallogr.,13, 876-884(1960). (Crys Struc-

tion phase ¢ is expressed as a function of X i n atom frac- ture; Experimental)

tion V and temperature T in K as: 61Geb: E. Gebhardt and G. Joseph, "On the Ternary

AmG(¢) = XAfG(AI,¢) (1 -X) AfG(V,¢) Aluminum-Silicon-Vanadium System," Z. Metallkd., 310-

+ R T [XInX +(1 - X ) In (1 -X)]

317 (1961).(Equi Diagram; Experhnental)

+ X(1 -X) [A(T) + (1 - 2X) B(T)] 63Hoi: H. Holleck,F.Benesovsky, and H. Nowotny, "The Crys-

tal Structure of V.3AIm~d Its Solubilityin IsotypicPhases,"

where X is the mole fraction of A1 and the coefficients to Monatsh. Chem., 94, 477-481 (1963). (Equi Diagram; Ex-

be optimized (A and B) are at most linear formations of perimental)

356 Bulletin of Alloy Phase Diagrams Vol. 10 No. 4 1989

AI-V

63Vat. N.I. Varich, L.M. Burov, K.Ye.Kolesnichenko, and/LP. Low Temp. Phys., 10(3/4), 271-284 (1973). (Equi Diagram;

Maksimenko, "HighlySupersaturated AI-V,Al-Moand A1-W Experimental)

Solid Solutions Obtained at a High Rate of Cooling," F/z. 73Le~ J.M. Leger and H.T Hall, "Pressure and Temperature

Met. Mctalloved., 15(2), 292-295 (1963) in Russian; TR: Phys. Formation of AaB Compounds," J. Less.Common Met., 32,

Met. Metallogr., 15(2), 111-113 (1963). (Equi Diagram, Meta 181-187 (1973). (Equi Diagram, Crys Structure; Experimen-

Phases; Experin~ental ) tab

64Ram: A. Raman and K. Schubert, "On the Widespread Oc- 77Bha: KK. Bhandary and K. Girgis, "Coordination

currence of Zr2Cu and Cr2A1-TypeStructure," Z. Metallkd., Polyhedra and Structure of Alloys: Binary Alloys of

55, 798-804 (1964). (Equi Diagram; Experimental) Vanadium with Group IIIB and IVB Elements," Acta Crys.

67Jolu W.Johnson, K. Komarek, E. Miller, New York Univer- tallogr. A, 33, 903-913 {1977). (Crys Structure; Experimen-

sity Research Division, Contact Nonr- 285(64 ) (1967). (Equi tad

Diagram, Thermo; Experimental) 77Brat J.K. Brandon, W.B.Pearson, and P.W.Riley, "Ganmm-

68Kom I.I. Kornilov and N.M. Matveeva, "Problem of the Brasses with R Cells," Acta Crystallogr. B, 33, 1088-1095

Compound V:tAI,"Dokl. Ahad. Nauk SSSR, 179(4), 870-871 (1977). (Crys Structure; Experimental )

(1968) in Russian; TR: Dokl. Chem. Proc. Acad. Sci. USSR,

81Ere: V.N. Eremenko, Ya.V. Natanzon, and V.P. Titov,

298-299 (1968). (Equi Diagram; Experimental)

"Kinetics of Dissolution of Vanadium in Liquid Aluminum,"

68Mos: M. Moss, "Dispersion Hardening in Al-Vby Plasm-jet Russ. Me(all., {5), 34-37 (1981). (Equi Diagram; Experimen-

Spray Quenching," Acta Me(all., 16, 321-326 (1968). (Meta tad

Phases; Experimental

82Sud: S.V. Sudareva and V.A. Rassokhin, "Electron Micro-

69Nect A~Neckel and H. Nowotny, Fifth International Con- scopic Investigation of the Structure of V-AI Alloys," Fiz.

ference on Light Metals, Leoben, 72-76 (1968). (Thermo; Ex- Met. Metalloved., 56(4), 1138-1146 (1982~ in Russian; TR:

perimental ) Phys. Met. Metallogr., 54(6), 89-97 (1982). (Equi Diagram;

70Shi: A.Ya. Shinyayev and D.B. Butrymowicz, "Interdif- Experimental)

fusion in and the Phase Diagram for Vanadium-Rich Alloys 85Bat: G.I. Batalin, Vs. Sudavtsova, and N.N. Maryanchik,

ofthe V-AI System at Pressures 0 to 47 Kbar," Metall.Trans., "Thermodynamic Properties of Liquid Binary Alloys of the

1, 1905-1907 (1970).(Equi Diagranl; Experimental) Al-Sc, A1-V,and Al-Ti System," Ukr. Khim. Zh., 51(8), 817-

7 1 H a ~ L.D. Hartsough toldR.H. Hammond, "The Synthesis 819 (1985).(Thermo; Experimental)

of Low Temperature Phases by the Co-Condensation of the

86Din: &T. Dinsdale and I.Ansara, "Models and Expressions

Elements: A N e w SuperconductingA15 Compound, V3AI,"

Solid State Commun., 9, 885-889 ( 1971). (Equi Diagram; Ex- used by S G T E for Pure Components," private communica-

perimental ) tion (1986). (Thermo; Theory)

71Kod: B.N. Kodess, V.I. Surikov, V.L. Zagryazhskii, A.K. 86Ino: & Inoue, L. Arnberg, B. Lehtinen, M. Oguchi, and T

Shtol'ts, and P.V.Gle'd, "Temperatures of Transition to the Masumoto, "Compositional Analysis of the Icosahedral

SuperconductingState ofV:}Ge,V.~A1,and Solid Solutions of Phase in Rapidly Quenched A1-Mnand AI-VAlloys,"Metall.

V;~GexAll_x and V3GexGal-x," Izv. Akad. Nauk SSSR, Trans. A, 17, 1657-1664 (1986). (Meta Phases; Experimen-

Neorg. Mater., 7(5), 853-854 {1971) in Russian; TR: Russ. J. tad

Inorg. Mater., 7(5), 746-747 (1971). (Equi Diagram; Ex- 86Sch: R.J. Schaefer, National Bureau of Standards, private

perimental) communication (1986). (Meta Phases; Experimental)

71Sam: V.V.Samokhval, PA. Poleshchuk, and A.A. Vecher, 87Kim: Y.-W.Kim and EH. Froes, "Rapid Solidification of A1-

"Thermodynmnic Properties of Aluminum-Titanium and rich Al-V Alloys," 6th Int. Conf. Rapidly Quenched Met.

Aluminum-Vanadium Alloys," Russ. J. Phys. Chem., 45(8), (RQ6 },Montreal, Quebec, 3-7 Aug. (1987). (Meta Phases; Ex-

1174-1175 (1971). (Thermo; Experimental} perimental)

73Hat: B.A.Hatt, J.K.R. Page, and V.G.Rivlin, "The Structure 88Gui: A.F. Guillermet and W.Huang, "Calphad Estimates of

and Superconducting Behavior of Some V-Al Binary Alloys the Lattice Stabilities for High Meltingbcc Metals: V,Nb and

and ofTernary 'Beta-W' AlloysBased on the V-AISystem,"J. Ta," Z. Metallkd., 79, 88-95 (1988). (Thermo; Theory)

AI-VevaluationbyJ.L. Murra~ AlcoaTechnicalCenter,AlloyTechnologyDivision,AlcoaCenter, PA 15069.Literature searchedthrough 1988.

Dr.Mma'ay isthe ASM/NIST Data Program CategoryEditorforthe binaryalmninum alloys.

Bulletin of Alloy Phase Diagrams Vol. 10 No. 4 1989 357

You might also like

- The Handbook of Infrared and Raman Characteristic Frequencies of Organic MoleculesFrom EverandThe Handbook of Infrared and Raman Characteristic Frequencies of Organic MoleculesRating: 5 out of 5 stars5/5 (2)

- Engine + Generator - Engineering Manual Rev.1 (RECIBIDO 6-11-12) PDFDocument159 pagesEngine + Generator - Engineering Manual Rev.1 (RECIBIDO 6-11-12) PDFJavier Everest50% (2)

- 2009 O Level Chem Questions With AnswersDocument14 pages2009 O Level Chem Questions With AnswersGertrude Ramsbottom50% (2)

- Boletin de Fallas Atra 2012Document34 pagesBoletin de Fallas Atra 2012marcelo ustarezNo ratings yet

- 2010 Jeep PatriotDocument2 pages2010 Jeep PatriotswiftNo ratings yet

- RB211 Bleed ValvDocument10 pagesRB211 Bleed Valvyasser_nasef5399100% (1)

- BCWP ManualDocument80 pagesBCWP ManualBottle Mani100% (1)

- Circuit Laboratory Experiment IDocument4 pagesCircuit Laboratory Experiment Iblackwoodsam3No ratings yet

- 2001-10 Pages 28-32 PDFDocument5 pages2001-10 Pages 28-32 PDFDavidNo ratings yet

- ELC520S-LAB 2 - Sem-2 - 2020Document6 pagesELC520S-LAB 2 - Sem-2 - 2020Tiofelus H. HamutenyaNo ratings yet

- Chapter 1 Electrons and Holes in Semiconductors: 1.1 Silicon Crystal StructureDocument16 pagesChapter 1 Electrons and Holes in Semiconductors: 1.1 Silicon Crystal StructurepurseyNo ratings yet

- Practical Assessment of The Performance of Aluminium Battery TechnologiesDocument9 pagesPractical Assessment of The Performance of Aluminium Battery TechnologiesJorge Andrés BaquerizoNo ratings yet

- Lo:an1jj: II II Lilt IIDocument1 pageLo:an1jj: II II Lilt IIvainateyagoldarNo ratings yet

- Diagrama Al O WriedtDocument6 pagesDiagrama Al O WriedtAlejandra HernandezNo ratings yet

- Three Phase Transformer Winding ConfigurationsDocument40 pagesThree Phase Transformer Winding ConfigurationsbudanaNo ratings yet

- Ahmed ALgendyDocument14 pagesAhmed ALgendymiramirjafari2No ratings yet

- OD!leictioDocument42 pagesOD!leictioanonymNo ratings yet

- Factor For The Specific Gravity Is Positive or Negative, at Various TemperaturesDocument28 pagesFactor For The Specific Gravity Is Positive or Negative, at Various TemperaturesAnonymous dqbb02DUhNo ratings yet

- G01 Lab 4Document12 pagesG01 Lab 4Irtisam AlaviNo ratings yet

- Notes - Switching CircuitsDocument8 pagesNotes - Switching CircuitsCohesive GamerNo ratings yet

- Jan 2005Document10 pagesJan 2005paolo maldiniNo ratings yet

- Documents SteelDocument7 pagesDocuments SteelSauvala HarriNo ratings yet

- The Sigma Phase PDFDocument28 pagesThe Sigma Phase PDFgostokhelwiNo ratings yet

- Removal Exam 1Document1 pageRemoval Exam 1Miko F. RodriguezNo ratings yet

- Transformer Wiring ConfigurationsDocument40 pagesTransformer Wiring ConfigurationsAndres Felipe Triviño LaraNo ratings yet

- Scott - 1982 - The Vibrational Structure of Davydov Solitons PDFDocument9 pagesScott - 1982 - The Vibrational Structure of Davydov Solitons PDFЮрий ЮрийNo ratings yet

- Response Modification Coefficient - For Structural Systems, RDocument3 pagesResponse Modification Coefficient - For Structural Systems, RMuhammad Al MamunNo ratings yet

- PHY121 Electricity and MagnetismDocument74 pagesPHY121 Electricity and Magnetismstephenalfa7No ratings yet

- Potential Divider Student Worksheet: TheoryDocument4 pagesPotential Divider Student Worksheet: TheoryMaha sidNo ratings yet

- ARTICULODocument6 pagesARTICULOPaola Andrea SuarezNo ratings yet

- Lab Manual EE1251 PDFDocument35 pagesLab Manual EE1251 PDFImran KhanNo ratings yet

- Lab Manual EE1251 PDFDocument35 pagesLab Manual EE1251 PDFHitesh VijayNo ratings yet

- Practical Considerations For The Use of A Howland Current SourceDocument4 pagesPractical Considerations For The Use of A Howland Current SourceRamiShaabannnnNo ratings yet

- Een-112 Practical-3 Harsh-Maurya 20117056 Q3-Batch MeDocument5 pagesEen-112 Practical-3 Harsh-Maurya 20117056 Q3-Batch MekeshavmandowraNo ratings yet

- Symmetrical and Unsymmetrical FaultsDocument51 pagesSymmetrical and Unsymmetrical FaultsMohamed SobhyNo ratings yet

- Symmetrical Components WebinarDocument23 pagesSymmetrical Components WebinarSuppenguin100% (2)

- Key Questions For This Chapter: Slide 1-1Document31 pagesKey Questions For This Chapter: Slide 1-1Windarto Properti SoloNo ratings yet

- Mak313 Lab1Document3 pagesMak313 Lab1Erol “DosS” KılıçNo ratings yet

- Physics PracticalDocument25 pagesPhysics PracticalYukti SharmaNo ratings yet

- Physics PracticalDocument6 pagesPhysics PracticalLakshya BhatiNo ratings yet

- Chap. 06 - Electrochemistry: Modul Al-KimiyaDocument38 pagesChap. 06 - Electrochemistry: Modul Al-KimiyasivandreaNo ratings yet

- An Analysis of A Hybrid-Mode in A Twisted Rectangular WaveguideDocument7 pagesAn Analysis of A Hybrid-Mode in A Twisted Rectangular WaveguidehesoyamyecgaaaNo ratings yet

- Lu-Wang - Hall Algebras and QSPDocument75 pagesLu-Wang - Hall Algebras and QSPlandvermesser110No ratings yet

- Qe 01Document10 pagesQe 01cesarNo ratings yet

- Report: QE-0-1: Linear Signal Conditioning Applications With Op-AmpsDocument10 pagesReport: QE-0-1: Linear Signal Conditioning Applications With Op-AmpscesarNo ratings yet

- Book Structural-Stability-Theory-And-Implementation1Document3 pagesBook Structural-Stability-Theory-And-Implementation1هديل عميرةNo ratings yet

- Electrical Axis and Axis Deviation: Mean Qrs Axis: DefinitionDocument9 pagesElectrical Axis and Axis Deviation: Mean Qrs Axis: Definitionrocker_jadulNo ratings yet

- Report: QE-0-1: Linear Signal Conditioning Applications With Op-AmpsDocument10 pagesReport: QE-0-1: Linear Signal Conditioning Applications With Op-AmpscesarNo ratings yet

- Ec Ii Unit3Document23 pagesEc Ii Unit3Unmesh PeriNo ratings yet

- Lecture 5 Fault Modeling FaultDocument18 pagesLecture 5 Fault Modeling FaultbaijunagoriNo ratings yet

- TP Caribbean Examinations: Advanced Proficiency Physics Unit 02 l5Document18 pagesTP Caribbean Examinations: Advanced Proficiency Physics Unit 02 l5Isa Abdul HakeemNo ratings yet

- Properties of Semiconductor Alloys: Group-IV, III-V and II-VI SemiconductorsFrom EverandProperties of Semiconductor Alloys: Group-IV, III-V and II-VI SemiconductorsNo ratings yet

- Passive and Discrete Circuits: Newnes Electronics Circuits Pocket Book, Volume 2From EverandPassive and Discrete Circuits: Newnes Electronics Circuits Pocket Book, Volume 2No ratings yet

- Electrical and Electronic Principles 3 Checkbook: The Checkbook SeriesFrom EverandElectrical and Electronic Principles 3 Checkbook: The Checkbook SeriesNo ratings yet

- Band Structure And Nuclear Dynamics: Proceedings of the International Conference On Band Structure And Nuclear Dynamics Tulane University, New OrleansFrom EverandBand Structure And Nuclear Dynamics: Proceedings of the International Conference On Band Structure And Nuclear Dynamics Tulane University, New OrleansA.L. GoodmanNo ratings yet

- Ion-Containing Polymers: Physical Properties and StructureFrom EverandIon-Containing Polymers: Physical Properties and StructureA. EisenbergNo ratings yet

- Introduction to the Theory of Shells: Structures and Solid Body MechanicsFrom EverandIntroduction to the Theory of Shells: Structures and Solid Body MechanicsNo ratings yet

- 1 s2.0 S0376738817328053 MainDocument10 pages1 s2.0 S0376738817328053 MainkasturiNo ratings yet

- Metals 10 00027Document13 pagesMetals 10 00027kasturiNo ratings yet

- Pd-Coated v-AlJeon Park Magnone Current Applied Physics (2012)Document8 pagesPd-Coated v-AlJeon Park Magnone Current Applied Physics (2012)kasturiNo ratings yet

- 1 s2.0 S0925838817330177 MainDocument8 pages1 s2.0 S0925838817330177 MainkasturiNo ratings yet

- 1 s2.0 S0925838814025018 MainDocument6 pages1 s2.0 S0925838814025018 MainkasturiNo ratings yet

- 1 s2.0 S0376738812003766 MainDocument8 pages1 s2.0 S0376738812003766 MainkasturiNo ratings yet

- 1 s2.0 S0022311503003179 MainDocument7 pages1 s2.0 S0022311503003179 MainkasturiNo ratings yet

- 1 s2.0 S0966979514001277 MainDocument6 pages1 s2.0 S0966979514001277 MainkasturiNo ratings yet

- 1 s2.0 S0921509316309534 MainDocument7 pages1 s2.0 S0921509316309534 MainkasturiNo ratings yet

- 1 s2.0 S0925838822050757 MainDocument8 pages1 s2.0 S0925838822050757 MainkasturiNo ratings yet

- VFT 400 KVDocument9 pagesVFT 400 KVNandkumar ChinaiNo ratings yet

- Chapter 5: The Project Life Cycle: Just Enough Structured AnalysisDocument28 pagesChapter 5: The Project Life Cycle: Just Enough Structured AnalysisMarcelo RojasNo ratings yet

- 07 2018 Biomedical Instrumentation - Electrical Stimulation PDFDocument48 pages07 2018 Biomedical Instrumentation - Electrical Stimulation PDFviki mikiNo ratings yet

- Duraplate 8200Document4 pagesDuraplate 8200Carlos VillacrizNo ratings yet

- GPU Gems - Chapter 7Document13 pagesGPU Gems - Chapter 7Sebastian SytaNo ratings yet

- DC Inverter VRF Air Conditioning SystemsDocument35 pagesDC Inverter VRF Air Conditioning SystemsTudor SorbanNo ratings yet

- Sample Project Report On Financial Analysis at B D K LTD HubaliDocument102 pagesSample Project Report On Financial Analysis at B D K LTD HubalihareeshngvNo ratings yet

- IAL PresentationDocument55 pagesIAL PresentationPanneer SelvamNo ratings yet

- New Progress in Senior Mathematics Compulsory Part SolutionDocument2 pagesNew Progress in Senior Mathematics Compulsory Part Solutioninvincibilitized abdominizerNo ratings yet

- Julius G. Rugas Plant Manager Cesar M. Endaya Jr. Plant IEDocument4 pagesJulius G. Rugas Plant Manager Cesar M. Endaya Jr. Plant IEJoshua MalibongNo ratings yet

- ALTIVAR 28 Quick Reference GuideDocument1 pageALTIVAR 28 Quick Reference Guidesuperpuma86100% (1)

- TeluxDocument85 pagesTeluxMuhammadAnasNo ratings yet

- Audi Maintenance Schedule Model Year 2008Document1 pageAudi Maintenance Schedule Model Year 2008api-247506078No ratings yet

- Fox3 17Document12 pagesFox3 17orellanasebasNo ratings yet

- NASA Facts Ion PropulsionDocument4 pagesNASA Facts Ion PropulsionRich GarrNo ratings yet

- Infinitesimal 0.3 Technical SheetDocument2 pagesInfinitesimal 0.3 Technical SheetBmwmotorsport GabriNo ratings yet

- Envisioning Sustainable Infrastructure For Smart CitiesDocument10 pagesEnvisioning Sustainable Infrastructure For Smart Citiesdrcss5327No ratings yet

- Physics: Behind The ConceptDocument10 pagesPhysics: Behind The ConceptAditya Shiva AppallaNo ratings yet

- CPM5x00 Appendix - High Ton InstallationDocument8 pagesCPM5x00 Appendix - High Ton InstallationtrailNo ratings yet

- DCinv V6 Rev2 CleanDocument38 pagesDCinv V6 Rev2 Cleanyasirarafat91No ratings yet

- Input - OutputDocument15 pagesInput - Outputsushil4056No ratings yet

- Lab ReportDocument2 pagesLab ReportNayhomi PenaNo ratings yet

- Design of Wind Turbine BladesDocument13 pagesDesign of Wind Turbine BladesmasoodkamaliNo ratings yet

- Steam Peeler - OrbitDocument2 pagesSteam Peeler - OrbitMoaz TajammalNo ratings yet

- Aluminum Crust BreakerDocument8 pagesAluminum Crust BreakersenamotoNo ratings yet