Professional Documents

Culture Documents

74-Article Text-252-2-10-20200808

74-Article Text-252-2-10-20200808

Uploaded by

janCopyright:

Available Formats

You might also like

- Appeal To Authority: A Failure of TrustDocument19 pagesAppeal To Authority: A Failure of Trustclapujugas100% (3)

- An Android INCU Analyzer Design To Calibrate Infant Incubator Using Bluetooth Communication For Real-Time and Wireless MonitoringDocument8 pagesAn Android INCU Analyzer Design To Calibrate Infant Incubator Using Bluetooth Communication For Real-Time and Wireless MonitoringArga HantaraNo ratings yet

- An Android INCU Analyzer Design To Calibrate Infant Incubator Using Bluetooth Communication For Real-Time and Wireless MonitoringDocument8 pagesAn Android INCU Analyzer Design To Calibrate Infant Incubator Using Bluetooth Communication For Real-Time and Wireless MonitoringAyu NissaNo ratings yet

- Arduino Based Infant Monitoring SystemDocument7 pagesArduino Based Infant Monitoring SystemZegebrial DrarNo ratings yet

- Incubator Analyzer Using Bluetooth AndroidDocument7 pagesIncubator Analyzer Using Bluetooth AndroidIlyes KHOUILDINo ratings yet

- Controlling of Temperature and Humidity For An InfDocument9 pagesControlling of Temperature and Humidity For An InfAuria RiaNo ratings yet

- Real Time Respiration Rate Measurement Using Temperature SensorDocument3 pagesReal Time Respiration Rate Measurement Using Temperature SensorEditor IJRITCCNo ratings yet

- Impact Factor: 8.423: Volume 12, Issue 4, April 2023Document9 pagesImpact Factor: 8.423: Volume 12, Issue 4, April 2023ted gcgdNo ratings yet

- REVISI AGIL SalinanDocument8 pagesREVISI AGIL SalinanTEKMED FARIZ AGIEL PRAMUDYANo ratings yet

- Air Pollution Monitoring With IOT Decice Report File NTCCDocument18 pagesAir Pollution Monitoring With IOT Decice Report File NTCCÅřījīt ÑāñdïNo ratings yet

- Design and Development of Patient Monitoring SysteDocument7 pagesDesign and Development of Patient Monitoring SysteMuhammad MustakimNo ratings yet

- IOT Based Health Monitoring System Using Arduino UNODocument8 pagesIOT Based Health Monitoring System Using Arduino UNOIJRASETPublications100% (1)

- IOT Based Health Monitoring System UsingDocument8 pagesIOT Based Health Monitoring System UsingDoctor IggyNo ratings yet

- Indoor Temperature and Humidity Monitoring System: January 2020Document10 pagesIndoor Temperature and Humidity Monitoring System: January 2020boy sadNo ratings yet

- مشروع التخرجDocument35 pagesمشروع التخرجAbeeesy AmrakeyNo ratings yet

- Intelligent Customers Checking DeviceDocument6 pagesIntelligent Customers Checking DeviceIJRASETPublicationsNo ratings yet

- Detection of Respiratory Infections Using RGB-Infrared Sensors On Portable DeviceDocument8 pagesDetection of Respiratory Infections Using RGB-Infrared Sensors On Portable DeviceJulia GuintoNo ratings yet

- System For Remote Monitoring and Control of Baby Incubator and Warmer PDFDocument7 pagesSystem For Remote Monitoring and Control of Baby Incubator and Warmer PDFMaimunah Novita SariNo ratings yet

- Review Paper On E-Smart Watch For Early Detection of Covid-19-IJRASETDocument6 pagesReview Paper On E-Smart Watch For Early Detection of Covid-19-IJRASETIJRASETPublicationsNo ratings yet

- 244-Article Text-940-1-10-20220731Document10 pages244-Article Text-940-1-10-20220731norlanjameslaureano14No ratings yet

- Novel Approach of A Smart Medical Mirror System For Medical ApplicationsDocument6 pagesNovel Approach of A Smart Medical Mirror System For Medical Applicationschieftains380No ratings yet

- Iotpaper JournalofcriticalreviewsDocument6 pagesIotpaper Journalofcriticalreviewsadwinraj29No ratings yet

- Pic Microcontroller Based Efficient Baby IncubatorDocument6 pagesPic Microcontroller Based Efficient Baby IncubatorShaikh AfzalNo ratings yet

- Prinyakupt 2019Document6 pagesPrinyakupt 2019Hafshah DeviNo ratings yet

- Smartphone-Based Analysis of Biochemical Tests For Health Monitoring Support at HomeDocument6 pagesSmartphone-Based Analysis of Biochemical Tests For Health Monitoring Support at Homeخير الحفظNo ratings yet

- Real Time Monitoring and Control of Neonatal Incubator Using LabviewDocument6 pagesReal Time Monitoring and Control of Neonatal Incubator Using LabviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Research Paper On Arduino and Its ApplicationDocument6 pagesResearch Paper On Arduino and Its ApplicationKunalNo ratings yet

- Development of In-Patient Healthcare Monitoring SystemDocument4 pagesDevelopment of In-Patient Healthcare Monitoring SystemChristine MadridNo ratings yet

- ds18b20 Sensor ResearchDocument9 pagesds18b20 Sensor ResearchMuhammad Danish HakimNo ratings yet

- 12 Controlling PDFDocument8 pages12 Controlling PDFハンター ジェイソンNo ratings yet

- Iotpaper JournalofcriticalreviewsDocument6 pagesIotpaper JournalofcriticalreviewsVishnu MuraleedharanNo ratings yet

- Research Plan Project Summary For 1a 1Document3 pagesResearch Plan Project Summary For 1a 1api-404815004No ratings yet

- Smart RestroomDocument18 pagesSmart RestroomatikpNo ratings yet

- Development of A Low-Cost Portable Pediatric Infection Screening System Using Simultaneous Measurement of Multiple Vital SignsDocument4 pagesDevelopment of A Low-Cost Portable Pediatric Infection Screening System Using Simultaneous Measurement of Multiple Vital SignsShiferaw TesfayeNo ratings yet

- Wearable Sensing and Intelligent Data Analysis for Respiratory ManagementFrom EverandWearable Sensing and Intelligent Data Analysis for Respiratory ManagementRui Pedro PaivaNo ratings yet

- Air Quality Monitoring Using Arduino and Cloud Based System in IoTDocument7 pagesAir Quality Monitoring Using Arduino and Cloud Based System in IoTIJRASETPublicationsNo ratings yet

- 78-Article Text-255-3-10-20200808Document8 pages78-Article Text-255-3-10-20200808letphuongNo ratings yet

- Ijamscr 19 359 - 915 920Document6 pagesIjamscr 19 359 - 915 920Azwar MudaNo ratings yet

- A. Background of The StudyDocument4 pagesA. Background of The Studyyin0110yangNo ratings yet

- Phototherapymachin MonitorDocument7 pagesPhototherapymachin MonitorDibya DeyNo ratings yet

- Fin Irjmets1658055887Document4 pagesFin Irjmets1658055887Dileep VishwakarmaNo ratings yet

- Group AssignmentDocument16 pagesGroup AssignmentSujan ShresthaNo ratings yet

- Air PrognosticatorDocument43 pagesAir Prognosticatorsce21cs079No ratings yet

- Research Article: Design and Development of A Low-Cost, Portable Monitoring Device For Indoor Environment QualityDocument15 pagesResearch Article: Design and Development of A Low-Cost, Portable Monitoring Device For Indoor Environment QualitykentNo ratings yet

- Sensors: Assessment and Certification of Neonatal Incubator Sensors Through An Inferential Neural NetworkDocument20 pagesSensors: Assessment and Certification of Neonatal Incubator Sensors Through An Inferential Neural NetworkRyanRRNo ratings yet

- Remote Monitoring of A Premature InfantsDocument7 pagesRemote Monitoring of A Premature InfantsYOSEF AbdoNo ratings yet

- Calibration of Infusion Pumps AnalyserDocument7 pagesCalibration of Infusion Pumps AnalyserAwaludin LaiaNo ratings yet

- DigitalDocument8 pagesDigitalHARSHAVARDHAN DORANo ratings yet

- Name Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentDocument11 pagesName Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentchristinemjenNo ratings yet

- Telemedicine ReportDocument26 pagesTelemedicine ReportFaiyaz FarahNo ratings yet

- Iot Based Smart Saline Bottle For Healthcare IJERTV10IS060457Document5 pagesIot Based Smart Saline Bottle For Healthcare IJERTV10IS060457Brunda SNo ratings yet

- Sensors: Sensors in The Autoclave-Modelling and Implementation of The Iot Steam Sterilization Procedure CounterDocument17 pagesSensors: Sensors in The Autoclave-Modelling and Implementation of The Iot Steam Sterilization Procedure CounterUsman Ali Usman AliNo ratings yet

- IOT Based IV Bag Monitoring, Controlling and Alerting SystemDocument5 pagesIOT Based IV Bag Monitoring, Controlling and Alerting Systemkolihs090302No ratings yet

- A Review - Android Based Health Care Monitoring SystemDocument9 pagesA Review - Android Based Health Care Monitoring Systemdeshmukhds2492No ratings yet

- A Real-Time Infant Health Monitoring System For Hard of Hearing Parents by Using Android-Based Mobil DevicesDocument7 pagesA Real-Time Infant Health Monitoring System For Hard of Hearing Parents by Using Android-Based Mobil DevicesKaaviya NanadakumarNo ratings yet

- Research Article Development of An Iot-Based Indoor Air Quality Monitoring PlatformDocument15 pagesResearch Article Development of An Iot-Based Indoor Air Quality Monitoring PlatformMohamed AashiqNo ratings yet

- Team 19 Report-2Document15 pagesTeam 19 Report-2RITIK KUMAR SINGHNo ratings yet

- IOT Based Health Monitoring SystemDocument7 pagesIOT Based Health Monitoring SystemIJRASETPublications100% (1)

- Project Form RuhanDocument7 pagesProject Form RuhanRuhan Madni NaqashNo ratings yet

- Harnessing Arduino-Based Labs For Monitoring and Optimizing Biological ProcessesDocument6 pagesHarnessing Arduino-Based Labs For Monitoring and Optimizing Biological ProcessesResearch ParkNo ratings yet

- Tohnichi - Katalog 2007 ENDocument52 pagesTohnichi - Katalog 2007 END.T.No ratings yet

- MHH_Torque_convertorDocument1 pageMHH_Torque_convertorjanNo ratings yet

- MotorizedOpManualDocument102 pagesMotorizedOpManualjanNo ratings yet

- Investigation On Oxygen Permeability and Surface Properties of A GarfilmsDocument10 pagesInvestigation On Oxygen Permeability and Surface Properties of A GarfilmsjanNo ratings yet

- Conducting Flow Measurement Laboratory Test Work: M. B. KimeDocument7 pagesConducting Flow Measurement Laboratory Test Work: M. B. KimejanNo ratings yet

- Paper 1Document21 pagesPaper 1janNo ratings yet

- Delgado Vs CaDocument2 pagesDelgado Vs CaNissi JonnaNo ratings yet

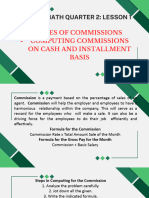

- Businessmath Lesson1 Quarter2Document18 pagesBusinessmath Lesson1 Quarter2Lynn DomingoNo ratings yet

- Presentation 1Document15 pagesPresentation 1sruthi_k7776No ratings yet

- Boombot ProDocument13 pagesBoombot Proriadh.bachwellNo ratings yet

- Students Material Case StudyDocument2 pagesStudents Material Case StudyFatima syedaNo ratings yet

- Half Yearly Examination (2016 - 17) Class - XII: Delhi Public School, Jodhpur Subject - Business StudiesDocument4 pagesHalf Yearly Examination (2016 - 17) Class - XII: Delhi Public School, Jodhpur Subject - Business Studiesmarudev nathawatNo ratings yet

- One Pager v2Document2 pagesOne Pager v2JuanCarlosMarrufoNo ratings yet

- Sources For MADELEY: Printed TextsDocument2 pagesSources For MADELEY: Printed TextsWen WahyudiNo ratings yet

- 10 STG WelcomeToYourEngagement LM 02 UC Financial Statements PY-IsADocument12 pages10 STG WelcomeToYourEngagement LM 02 UC Financial Statements PY-IsAHumbertNo ratings yet

- Sari ProjectDocument96 pagesSari ProjectRamesh AnkathiNo ratings yet

- MAS Running Calculator v2.1Document7 pagesMAS Running Calculator v2.1Ariadna Alegre MirallesNo ratings yet

- Module 02.2 Moving Average Weighted Moving Average and Exponential SmoothingDocument6 pagesModule 02.2 Moving Average Weighted Moving Average and Exponential SmoothingJunmirMalicVillanuevaNo ratings yet

- Copper Testing For Adsl/2/2+Document8 pagesCopper Testing For Adsl/2/2+markNo ratings yet

- Muhammad Amin Muhammad Amin Muhammad Amin Ghulam Ali Ghulam Ali Ghulam Ali 71303-0342329-1 71303-0342329-1 71303-0342329-1Document1 pageMuhammad Amin Muhammad Amin Muhammad Amin Ghulam Ali Ghulam Ali Ghulam Ali 71303-0342329-1 71303-0342329-1 71303-0342329-1امین ثانیNo ratings yet

- DX340LCADocument20 pagesDX340LCArayendraNo ratings yet

- Gopalkrishna Charitable Trust: Name Designation Pan AadhaarDocument4 pagesGopalkrishna Charitable Trust: Name Designation Pan AadhaarSalman KhanNo ratings yet

- Thymatron 4Document8 pagesThymatron 4srinivasanaNo ratings yet

- Engineers Report PtoDocument5 pagesEngineers Report PtoLito LeonardoNo ratings yet

- Chapter No.1 - Introduction To Personal SellingDocument52 pagesChapter No.1 - Introduction To Personal SellingAyush100% (1)

- DDD 3360Document23 pagesDDD 3360Rixall Jun SanchezNo ratings yet

- ATADU2002 DatasheetDocument3 pagesATADU2002 DatasheethindNo ratings yet

- Modeling and Simulation PMSG Based On Wind Energy Conversion System in MATLAB/SIMULINKDocument5 pagesModeling and Simulation PMSG Based On Wind Energy Conversion System in MATLAB/SIMULINKRITWIK MALNo ratings yet

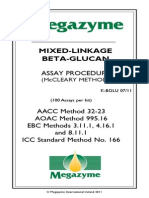

- K-Bglu 1107 DataDocument16 pagesK-Bglu 1107 Datapi_yoanaNo ratings yet

- Toy Market Research StudyDocument7 pagesToy Market Research StudyAtul KumarNo ratings yet

- Jotun Thinner No.25 Base PDFDocument14 pagesJotun Thinner No.25 Base PDFSatishNo ratings yet

- PL BT enDocument304 pagesPL BT enOssian89No ratings yet

- Unit 1-At6402 Automotive ChassisDocument39 pagesUnit 1-At6402 Automotive ChassisSathis KumarNo ratings yet

- Principles of Macroeconomics 11Th Edition Case Test Bank Full Chapter PDFDocument36 pagesPrinciples of Macroeconomics 11Th Edition Case Test Bank Full Chapter PDFjacob.toupin212100% (17)

- Plant Design TemplateDocument13 pagesPlant Design TemplateRishabhGupta 2k20umba32No ratings yet

74-Article Text-252-2-10-20200808

74-Article Text-252-2-10-20200808

Uploaded by

janOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

74-Article Text-252-2-10-20200808

74-Article Text-252-2-10-20200808

Uploaded by

janCopyright:

Available Formats

Journal of Electronics, Electromedical, and Medical Informatics (JEEEMI)

Vol. 2, No. 2, July 2020, pp. 74-79

DOI: 10. 35882/jeeemi.v2i2.6 ISSN:2656-8632

Development of Incubator Analyzer Using Personal

Computer Equiped With Measurement Certificate

Laily Nurrohmah, Dwi Herry Andayani, Andjar Pudji

Department of Medical Electronics Engineering Technology Poltekkes Kemenkes, Surabaya

Jl. Pucang Jajar Timur No. 10, Surabaya, 60245, Indonesia

Article Info Abstract

History Articles: Baby incubators are used for premature babies when babies are born prematurely. In order to ensure

Received May 19, 2020 the accuracy of medical devices, periodic tests and controls are needed, which aim to reduce the risk of

Revised July 14, 2020 measurement. The baby incubator can be tested with a calibration device that is used to calibrate

temperature, noise, humidity, and airflow so that the conditions remain stable and within normal limits.

Accepted July 21, 2020

The purpose of this study is to develop a calibrator device based on a computer to measure noise and

airflow parameters. The standard incubator analyzer is not equipped with a computer interfacing.

Keywords: Furthermore, it needs data processing via Excel. Therefore, in this study, an incubator analyzer device

is proposed, which has four parameters to measure, namely, temperature, noise, humidity, and airflow.

Incubator Analyzer

The main part of this design is the Atmega328 Microcontroller, in which the function is used as a data

Noise processor, equipped with Bluetooth communication and data storage. Furthermore, the output will be

Airflow displayed in a computer unit. In this study, the noise was measured using analog sound Sensor V2; and

Bluetooth have the most significant error at 37oC setting temperature that is equal to 0.17%. At the same time,

Arduino the airflow parameter measured using an airflow sensor, type D6F-V3A01. Based on the measurement,

the error was 0.5% at a temperature setting of 36oC and 37oC. The use of displays on personal

computers and data processing using Excel allows users to monitor calibration and data processing. The

feasibility of this device is proven. Therefore, this design can be used for baby incubator calibration.

The corresponding author: This work is an open-access article and licensed under

a Creative Commons Attribution-ShareAlike 4.0

andayanidwiherry@yahoo.co.id International License (CC BY-SA 4.0).

Department of Medical Electronics Engineering Technology

Poltekkes Kemenkes, Surabaya, Indonesia

I. INTRODUCTION out, aimed at reducing the risk or preventing inaccurate or

The baby incubator is a type of life support health inaccurate measurements [4]. If the noise and airflow

equipment that serves to support the lives of patients who have parameters of the baby incubator are made inadequate or

failed in certain organs such as the heart and lungs, to monitor inaccurate measurements, it can threaten the baby's safety.

many vital functions of the baby's body such as heart rate, blood Emre Ozdemđ, et al [4] once analyzed the "Reliability

pressure, oxygen saturation and to support baby's breathing if Assessments of Infant Incubators and the Analyzer" states that

needed. Some newborns who have a gestational age or too light if a baby incubator exceeds the normal limits agreed upon, it

birth weight will place the baby at a high risk of death [1]. In will harm the baby, for example, if the airflow exceeds the

developing countries, 20 million premature babies or low birth normal limit will Asphyxia occurs in infants, and if the noise

weight babies die due to unreliable baby incubators, of which 4 exceeds the normal limit there will be dizziness, increased

million premature babies die in the first month [2]. Important blood pressure, and decreased fluid in the baby's brain [3] In

parameters for baby incubators include temperature, relative 2018, G.Gnancy Subha and M.Fazilath made an incubator

humidity, noise, and airflow velocity. All four parameters must analyzer using sensors to detect the presence of toxic gas in

be within the measured standard. To see errors in the baby baby incubators. The study stated that the parameters of

incubator device can be measured or confirmed with a baby temperature, humidity, noise, and airflow in the baby incubator

incubator calibration device. The baby incubator calibration must be at the limit that refers to ANSI / AAMI. If it exceeds

device, the incubator analyzer, can help determine whether a the rule limit (for example airflow <0.4m / s), it will have an

baby incubator is eligible or not [3]. To ensure the accuracy of impact on the health and safety of infants [5]. In 2019 the device

medical devices, periodic tests and controls need to be carried was developed by Niki Putri by displaying measurement results

Journal of Electronics, Electromedical Engineering and Medical Informatics (JEEEMI)

71

Journal of Electronics, Electromedical, and Medical Informatics (JEEEMI)

Vol. 2, No. 2, July 2020, pp. 74-79

DOI: 10. 35882/jeeemi.v2i2.6 ISSN:2656-8632

through Delphi and SD Card storage. According to the author, relative humidity of 80%-90%. [25] Referring to SNI IEC

the module is less effective because if the data is stored in the 60601-2-19: 2014, each relative humidity value shown must

SD Card if the calibration officer will display the measurement have an accuracy of +10% against the actual measured value.

results must first take the SD Card and put it on a personal [8]

computer. c. Airflow velocity (m / s)

Seeing this weakness, the researchers made a device Measurement of airflow is a measurement needed in

incubator analyzer based on the computer by adding data various fields such as medical instrumentation, process control,

processing in Microsoft Excel so that the operator or calibration environmental monitoring, and so on [22] Airflow or air

officer did not process the measurement results manually and circulation rate is very calculated in the baby incubator because

display on a personal computer that is on Delphi. it can affect the health of the baby. In normal use, the airspeed

The composition of this article consists of five section, should not be more than 0.35 m/s. The limit of 0.35 m/s is taken

Section I presented the introduction of this study, section II from measurements on units which in this case are deemed to

described the materials and methods, section III explained the have met the requirements [8] To detect airflow in a baby

Result of the experiment, section IV discussed the result, and incubator using a sensor from OMRON with type D6F-V30A1

section V is the conclusion. which is designed to measure air velocity and has a flow range

of 0 to 3 m/s, by having Micro Electromechanical Systems

II. MATERIALS AND METHODS (MEMS) technology the sensor can detect flow rates and flow

A. Theory directions [20] [21] In 2012 there was a study using the D6F-

Incubator Analyzer is a device designed to verify the work V03A1 sensor which measures the airflow of the Air

system and environmental conditions in the Baby Incubator Conditioner. It was explained that sensors near the AC showed

device. This calibration device can detect several parameters an increase in airflow velocity greater than sensors that were far

such as airflow, noise, temperature, and relative humidity [3] from the AC [23]

The standards required for a Baby Incubator device to be d. Noise

operated and used on patients can be seen at AAMI (Advancing Noise is an unwanted sound from a business or activity at

Safety in Health Technology) consisting of more than 100 a certain level and time that can cause human health problems

technical committees and working groups that produce and environmental comfort that are spatially and temporally

recommended practice standards and reports on technical spread [8] [9] [15] or all unwanted sounds that originate from

information for medical devices. Recommended standards and the devices - production process equipment and/or work

practices represent national consensus and many have been devices at a certain level can cause hearing loss [10]. Spatial

approved by the American National Standards Institute (ANSI) and temporal distribution are related [16]. Spatial is the spread

as American National Standards. AAMI also manages several related to space, while temporal is the spread associated with

international technical committees from the International the cycle of time. [17] To detect noise in a baby incubator using

Organization for Standardization (ISO) and the International Analog Sound Sensor V2. The output of this sensor is analog,

Electrotechnical Commission (IEC), and the US Technical so it must be treated with a signal conditioning circuit. Signal

Advisory Group (TAG). conditioners that can be used to handle small signals are signal

Every parameter on the baby incubator must enter within conditioners with a gain method so that the output can be

the range specified in one of the standards above. One of the processed with electrical circuits or digital systems [18] [19].

standards that will be explained below is SNI IEC 60601-2-19: 1. Baby Incubator

2014, the purpose of this special standard is to establish special Baby Incubator is a device used to warm newborns and is

basic safety requirements and essential performance for infant often used on babies born prematurely. This baby incubator also

incubators that can minimize harm to patients and operators and serves to maintain the warmth, the humidity of the baby's body

determine tests that are compatible with requirements can be and can prevent respiratory infections in infants and to isolate

verified. The range of conditions needed so that an infant newborns, especially babies born prematurely [6].

incubator can be used are as follows: 2. Calibration

a. Temperature According to ISO / IEC Guide 17025: 2005 and

Temperature regulation is the most important factor Vocabulary of International Metrology (VIM), calibration is an

affecting the premature baby [24] Average incubator activity to determine the conventional correctness of the value

temperatures can be taken at regular intervals obtained during of measuring instruments and measuring materials by

stable temperature conditions. During an hour the temperature comparing them against traceable standards to national and

of the incubator should not change more than 1 ° C. Compliance international standards for units international and/or certified

is checked by measuring at a controlled temperature of 32 ° C standards and reference materials [7].

and 36 ° C in at least 1 hour [8]

b. Humidity 3. Delphi

Babies treated in incubators with a relative humidity of Delphi is an application to provide database connectivity

30%-60% have a higher mortality rate than babies treated at a for programmers [11]. Delphi's strengths are ease of preparation

Journal of Electronics, Electromedical Engineering and Medical Informatics (JEEEMI)

72

Journal of Electronics, Electromedical, and Medical Informatics (JEEEMI)

Vol. 2, No. 2, July 2020, pp. 74-79

DOI: 10. 35882/jeeemi.v2i2.6 ISSN:2656-8632

of the User Interface, Object Pascal Language, and Native Code microcontroller Arduino Uno, HC-05 for Bluetooth module,

[12]. LCD, and Personal Computer as a display.

4. Microsoft Excel

Microsoft Excel is a data processing software from D. Experiment

Microsoft in the form of spreadsheets. In Excel, there is a In this study, the researchers measured the noise and airflow

workbook [13]. Inside the workbook there is a worksheet that in the baby incubator with the temperature setting 340C, 360C,

is used to process data [14]. In processing the measurement and 370C. This measurement takes 60 minutes every

results there are several sheets such as worksheets, data temperature setting. After that Bluetooth HC-05 in module

analysis, interpolation, uncertainty analysis, supervisors, sends data to the personal computer and shows at Delphi. Then

customers, and safety tests. all data be processed in Excel to determine the baby incubator

5. Uncertainty eligibility on the certificate. Measurement of this module using

There are several types of uncertainty, i.e.: the Fluke Biomedical Brand II Incubator Analyzer for

a. Uncertainty Type A (UA) is a source of uncertainty derived comparison. This research was conducted in Direktorat

from a determination by statistical methods. The formula for Poltekkes Surabaya.

uncertainty is as follows:

𝑆𝐷

UA = (1) INPUT PROSES OUTPUT

√𝑛

Note: SD: Standard Deviation

n: A lot of data

Baterai LCD

b. Type B (UB) uncertainty is a source of uncertainty derived

from scientific information such as device calibration

certificates or scientific journals. The formula for uncertainty SW On/Off Bluetooth

is as follows:

𝑈𝑛𝑐𝑒𝑟𝑡𝑎𝑖𝑛𝑡𝑦 𝑜𝑓 𝑖𝑛𝑓𝑜𝑟𝑚𝑎𝑡𝑖𝑜𝑛

UB = (2) Start

PC (Personal

𝑘

Computer)

Note: k: Coverage Factor is worth 2

c. Combined uncertainty (UC) is a combination of uncertainty Reset Excel

in both type A and type B. Arduino Uno

Atmega 328

𝑈𝐶 = √𝑈𝐴2 + 𝑈𝐵 2 (3) Sensor Noise SD Card

Sensor

d. The uncertainty of the stretch is the magnitude that defines Airflow

the interval around the expected measurement results

including most of the distribution of values that can be given

on the measuring scale. Whereas the coverage factor

contained in the calculation of type B uncertainty is the Sensor

Temperature

numerical factor used as a multiplier of the combined

standard uncertainty to obtain the uncertainty of the stretch Sensor

(U95). Humidity

U95 = | k | x UC (4)

Note: Fig. 1. Block diagram of Incubator Analyzer

UC: Combined uncertainty Type A and Type B

E. The Block Diagram

B. Experimental Setup When the on / off button is pressed, all circuits get voltage

This research uses baby incubator objects and Fluke including all sensors, so that the sensor is ready and ready to

Biomedical Brand II Incubator Analyzer. Data collection is done use. Then when the start button is pressed, the noise sensor and

sequentially starting from the temperature 340C, 360C, and 370C airflow sensor will start operating detecting noise and airflow

and carried out every 10 minutes as much as 6 times. velocity around the closed hood of the baby incubator. The

C. Materials and Device sensor readings will be processed into Arduino Uno AT Mega

This study uses a sensor Analog Sound Sensor V2 for noise 328 and then displayed on the LCD and displayed on a PC

parameter and Airflow sensor from OMRON type D6F-V30A1 (Personal Computer) sent via Bluetooth. Data from the

for the airflow parameter. Components used as a sensor measurement/reading of the two sensors will be processed by

excel automatically which will be generated a calibration

Journal of Electronics, Electromedical Engineering and Medical Informatics (JEEEMI)

73

Journal of Electronics, Electromedical, and Medical Informatics (JEEEMI)

Vol. 2, No. 2, July 2020, pp. 74-79

DOI: 10. 35882/jeeemi.v2i2.6 ISSN:2656-8632

certificate. After the process is complete, the reset button can noise sensor and the Arduino on port A0 where the noise

be pressed to start the measurement (reading) of other baby measurement inside the baby incubator uses the Analog

incubator devices (Fig. 1). Sound Sensor V2 sensor (Fig. 3).

F. The Flowchart

Arduino program runs like a flowchart shown in Fig. 2.

When the start button is pressed, the noise sensor and airflow

sensor will operate to read the noise and airflow inside the baby

incubator. After that, the measurement results will be sent via

Bluetooth (transmitter) which will be received by the receiver,

namely PC (Personal Computer). Then the data will be

processed automatically using Excel. The reset button is used if

the user (calibration officer) wants to calibrate again.

Start

Fig. 3. Non-Inverting Amplifier

Initialize 2) Airflow Circuit

Sensor

Reading Airflow sensors from OMRON with type D6F-V30A1 is

connected to the Arduino Microcontroller circuit by

connecting the sensor pin 2 outputs to analog Arduino pin

Result (Fig. 4).

Sensor Reading

Noise and Airflow

3.3 VDC

Airf low Sensor

Display to SD CARD Arduino 1

Bluetooth

LCD 1 2

3

A1

Send the Serial Data

from Sensor Fig. 4. Airflow Circuit

Reading

III. RESULT

Below are the results of the research conducted by

researchers.

Incoming Data?

EXCEL

Computer

End

Fig. 2. Flowchart Program Arduino

Fig. 5. Incubator Analyzer Module

G. Circuit 1) Incubator Analyzer Design

1) Non-Inverting Amplifier Image design devices can be seen in Fig. 5 and Fig. 6.

The below network is a non-inverting network that acts There are 4 parameters in the incubator analyzer module

as an amplifier for low-voltage noise sensor output voltage. namely temperature, humidity, noise, and airflow. The focus of

The non-inverting network is the connection between the this research is noise and airflow. The results of measurements

Journal of Electronics, Electromedical Engineering and Medical Informatics (JEEEMI)

74

Journal of Electronics, Electromedical, and Medical Informatics (JEEEMI)

Vol. 2, No. 2, July 2020, pp. 74-79

DOI: 10. 35882/jeeemi.v2i2.6 ISSN:2656-8632

from the module are displayed via LCD. there is a save button 3) Incubator Analyzer Using Program Arduino

to save data on the SD card and a reset button to repeat the baby The Arduino program is divided into 2 namely the noise and

incubator measurements from the start. airflow reading program and the data delivery program to

Delphi.

Pseudo Code: Sensor Reading Program

INIT:

d

int bising;float x; float db; float airflow; float ms; float

a data7; float data9;

int datakirim1, datakirim2, datakirim3, datakirim4,

c b datakirim5, datakirim6, datakirim7, datakirim8

datakirim9;

LOOP:

Fig. 6. Incubator Analyzer Circuit int bising = analogRead(A0);

Note: x=bising*3.3/1023;

a. Airflow Sensor Circuit IF (x>=0.02&&x<0.03) THEN

b. Arduino Uno db = ((200 * x) + 36);

c. Temperature Sensor Circuit ENDIF

d. Noise Sensor Circuit float data7a = db;

data7a= db;

2) Personal Computer Display by Delphi lcd.setCursor(0, 1);

PRINT db

Button description on the Delphi display (Fig.PI7 and Fig. 8) :

a. The Setting is to fill com manually in the settings button float airflow = analogRead(A1);

according to the Bluetooth serial port. x = airflow*3.3/1023;

b. The Start is to show in Delphi all parameter values in ms = (0.100*x) + 0.1;

Delphi. data9 = ms;

c. The Stop is to stop all the programs in the Delphi display. float data9a=ms;

d. The Reset is to resets all data in the Delphi display. lcd.setCursor(0, 4);

e. Excel is to open Microsoft Excel. PRINT airflow

f. Save is to open workbooks in Microsoft Excel with the

PRINT

name "bismillah" on Local Disk D.

ENDLOOP

The program above is a program for reading noise sensors and

airflow sensors.

Pseudo Code:. Sending data to Delphi.

LOOP:

PRINTSERIAL “a”

adc1=datakirim7/100;

adc2=datakirim7%100;

PRINTSERIAL adc1

Fig. 7. Delphi Display

PRINTSERIAL adc2

adc1=datakirim9/100;

adc2=datakirim9%100;

PRINTSERIAL adc1

PRINTSERIAL adc2

PRINTSERIAL “b”

ENDLOOP

Fig. 8. The button of Delphi Display

Journal of Electronics, Electromedical Engineering and Medical Informatics (JEEEMI)

75

Journal of Electronics, Electromedical, and Medical Informatics (JEEEMI)

Vol. 2, No. 2, July 2020, pp. 74-79

DOI: 10. 35882/jeeemi.v2i2.6 ISSN:2656-8632

The above program is to display the value of each sensor on the

serial monitor that functions for sending data to Delphi. At each Data from these columns will be copied and entered into an

sensor initialization given an alphabetical code, this code is then excel file that already has a certificate format. As follows (Fig.

used to initialize the Delphi application and the Delphi 10)

application must use the same alphabetical code so that the

value of each sensor can be displayed on the Delphi display.

4) Incubator Analyzer Using Delphi Programming

Pseudo Code:. Saving data in Excel

DO:

Ex:=CreateOleObject('Excel.Application');

Ex.Workbooks.Open ('D:\bismillah.xls');

Ex.Visible:=true;

END;

Fig. 10. An example of measurement certificate in Bahasa

After all files are copied, the data will be calculated or

The program above is a program for storing measurement processed in the certificate to determine the eligibility of the

data from a module into Microsoft Excel which already contains calibrated baby incubator.

a certificate format that is saved with the file name "file1.txt" on

Local Disk D. 6) The Error Measurement

The chart above explains the noise error between the

measurement results of the module and the standard device

(Fig. 11 and Fig. 12). When the temperature 34°C and 36°C

error is 0.13%, the temperature 37°C error is 0.17%.

37.5

37

36.5

Temperature (0C)

36

35.5

35

34.5

34

33.5

0 0.05 0.1 0.15 0.2

Error (%)

Fig. 11. Noise error between design and incu II (calibrator)

37.5

Fig. 9. Delphi Display 37

5) Data from Delphi to Excel 36.5

Temperature (°C)

Baby incubator measurements that have been made and 36

performed at Delphi will then be processed or counted into 35.5

certificates to determine the appropriateness of the calibrated 35

device. In Delphi display there are columns to display the

34.5

measurement results of the incubator analyzer module. When

34

the measurement has been completed, the user presses the Save

33.5

button on the Delphi display to open a certificate format in

0 0.1 0.2 0.3 0.4 0.5 0.6

Excel that has been created and is on Local Disk D with the file

Error (%)

name "bismillah". After opening the user presses the Excel

button to copy data from Delphi into the certificate (Fig. 9). Fig. 12. Airflow error between module and incu II

Journal of Electronics, Electromedical Engineering and Medical Informatics (JEEEMI)

76

Journal of Electronics, Electromedical, and Medical Informatics (JEEEMI)

Vol. 2, No. 2, July 2020, pp. 74-79

DOI: 10. 35882/jeeemi.v2i2.6 ISSN:2656-8632

The chart above explains the airflow error between the The results of the certificate on the baby incubator

measurement results of the module and the standard device. calibration that uses INCU II (standard equipment) states that

When the temperature 34°C error is 0.4%, the temperature 36°C the baby incubator is suitable for use (Fig. 15 and Fig. 16).

and 37°C error is 0.5%.

b. Temperature Setting 36 0C

7) The Result of the Certificate

Below is the result of the comparison of certificates from

INCU II devices and the incubator analyzer module (Fig. 13

and Fig. 14):

a. Temperature Setting 34 0C

Fig. 15. An example of measurement certificate in Bahasa

The results of the certificate on the baby incubator

calibration that uses the module states that the baby incubator is

not suitable for use because there are parameters that exceed the

Fig. 13. An example of measurement certificate in Bahasa maximum allowable error.

The results of the certificate on the baby incubator

calibration that uses the module states that the baby incubator is

not suitable for use because there are parameters that exceed the

maximum allowable error.

Fig. 16. An example of measurement certificate in Bahasa

The results of the certificate on the baby incubator

calibration that uses INCU II (standard equipment) states that

the baby incubator is suitable for use.

Fig. 14. An example of measurement certificate in Bahasa

Journal of Electronics, Electromedical Engineering and Medical Informatics (JEEEMI)

77

Journal of Electronics, Electromedical, and Medical Informatics (JEEEMI)

Vol. 2, No. 2, July 2020, pp. 74-79

DOI: 10. 35882/jeeemi.v2i2.6 ISSN:2656-8632

c. Temperature Setting 37 0C

Result of Module

The results of the certificate on the baby incubator calibration

that uses the module states that the baby incubator is not

suitable for use because there are parameters that exceed the not feasible 370C

maximum allowable error (Fig. 17 and Fig. 18).

not feasible 360 C

not feasible 340 C

Fig. 19. Comparison of certificate results between design and incu II

(calibrator)

Result of INCU II

feasible 370C

feasible 360C

Fig. 17. An example of measurement certificate in Bahasa feasible 340C

Fig. 20. Comparison of certificate results between design and incu II

(calibrator)

The diagram states that if the calibration results from the

module at all setting temperatures are 340C, 360C, and 370C

states that the baby incubator is not suitable for use, while the

calibration results from INCU II at all temperature settings

indicate the baby incubator is suitable for use (Fig. 19 and Fig.

20).

IV. DISCUSSION

This study states that the measurement process using the

module incubator analyzer can be seen or observed through a

personal computer and the measurement results will be

processed into Microsoft Excel to determine the eligibility of the

baby incubator device. This can make it easier for users to more

effectively and quickly find out the results of the calibration.

Whereas in previous studies, the module incubator analyzer has

Fig. 18. An example of measurement certificate in Bahasa not used processing through Microsoft Excel.

Then based on measurements made by comparing the results

The results of the certificate on the baby incubator calibration between the module and INCU II with a time of 60 minutes for

that uses INCU II (standard equipment) states that the baby each temperature setting and making 6 measurements, then the

incubator is suitable for use. error value of each parameter will be obtained. The biggest error

in noise parameters lies in the temperature regulation of 37 0C

and the biggest error in the regulation of airflow parameters is

360C and 370C.

Journal of Electronics, Electromedical Engineering and Medical Informatics (JEEEMI)

78

Journal of Electronics, Electromedical, and Medical Informatics (JEEEMI)

Vol. 2, No. 2, July 2020, pp. 74-79

DOI: 10. 35882/jeeemi.v2i2.6 ISSN:2656-8632

[17] B. Setioko, “Transformasi Ruang Perkotaan di Permukiman Nelayan

(Studi Kasus: Tambakmulyo, Semarang),” J. Tataloka, vol. 15, no. 3, p.

V. CONCLUSION 192, 2013.

The airflow sensor module has the highest error at 360C and [18] M. T. Iwan Setiawan, S.T., “Sensor dan Tranduser,” Semarang, pp. 1–

370C that is equal to 0.5%, and the highest error of noise sensor 49, 2011.

module is 0.17% at 37°C setting temperature, this can be [19] A. H. Novianto, “Pengkondisi Sinyal Dan Akuisisi Data Sensor

influenced by operator reading errors and noise conditions Tekanan :,” 2016.

around the baby incubator. Using data transmission with [20] M. Flow-sensor, “D6F-V03A1 The unique dust separating structure ,”

Bluetooth HC-05 displayed on a Personal Computer (PC) via pp. 3–6.

Delphi as well as processing certificates through Excel. The [21] H. Lim, F. Xue, S. Liu, S. Pan, J. Miao, and L. K. Norford,

measurement results displayed on Delphi will be stored in the “Demonstration Abstract: A MEMS-based Air Flow Sensor Network,”

certificate processing sheet which will facilitate the user to do vol. 0, pp. 321–322, 2014.

data processing. There are differences in the results of [22] Y. H. Wang, C. Y. Lee, and C. M. Chiang, “A MEMS-based air flow

sensor with a free-standing microcantilever structure,” Sensors, vol. 7, no.

certificates in the Incubator Analyzer and INCU II modules. 10, pp. 2389–2401, 2007.

[23] S. Ueki, H. Imamoto, K. Ando, T. Fujimori, and S. Sugiyama,

“Development of Multi-functional Sensor Module for Energy Saving Air

REFERENCE Conditioner System,” 2012.

[1] H. Mittal, L. Mathew, and A. Gupta, “Design and Development of an

Infant Incubator for Controlling Multiple Parameters,” Int. J. Emerg. [24] M. Koli, P. Ladge, B. Prasad, R. Boria, and N. J. Balur, “Intelligent Baby

Trends Electr. Electron., vol. 11, no. 5, pp. 2320–9569, 2015. Incubator,” Proc. 2nd Int. Conf. Electron. Commun. Aerosp. Technol.

ICECA 2018, no. Iceca, pp. 1036–1042, 2018.

[2] M. Shaib, M. Rashid, L. Hamawy, M. Arnout, I. El Majzoub, and A. J.

Zaylaa, “Advanced portable preterm baby incubator,” Int. Conf. Adv. [25] L. Glass and L. Glass, “Preterm Infant Incubator Humidity Levels : A

Biomed. Eng. ICABME, vol. 2017-Octob, pp. 1–4, 2017. Systematic Review Walden University This is to certify that the doctoral

study by,” 2019.

[3] E. Ozdemİrcİ, M. Özarslan Yatak, F. Duran, and M. R. Canal, “Reliab ility

assessments of infant incubator and the analyzer,” Gazi Univ. J. Sci., vol.

27, no. 4, pp. 1169–1175, 2014.

[4] G. T. Sen and M. Yuksekkaya, “Desing and Test of an Incubator

Analyzer,” in ISMSIT 2018 - 2nd International Symposium on

Multidisciplinary Studies and Innovative Technologies, Proceedings,

2018.

[5] M. F. G.Gnancy Subha, “Incubator-Analayzer-With-Automatic-Shutter-

Opener,” Int. J. Adv. Inf. Eng. Technol., vol. 5, pp. 15–18, 2018.

[6] A. S. Utomo, A. B. Satrya, and Y. Tapparan, “Monitoring Baby Incubator

Sentral Dengan Komunikasi Wireless,” Simetris J. Tek. Mesin, Elektro

dan Ilmu Komput., vol. 9, no. 1, pp. 225–230, 2018.

[7] O. M. Vasilevskyi, “Calibration method to assess the accuracy of

measurement devices using the theory of uncertainty,” Int. J. Metrol.

Qual. Eng., vol. 5, no. 4, p. 403, 2014.

[8] ANSI/AAMI/IEC, “Medical electrical equipment — Part 2-4 : Particular

requirements for basic safety and essential performance of cardiac

defibrillators Objectives and uses of AAMI standards and recommended

practices,” Med. Instrum., 2011.

[9] Keputusan, M. N. L. Hidup, And N. : Kep-48/Menlh/11/1996,

“Keputusan Menteri Negara Lingkungan Hidup,” pp. 1–7, 1996.

[10] Menteri Tenaga Kerja Kep .51/Men/1999, “Keputusan Menteri Tenaga

Kerja Republik Indonesia No.51 Tentang Nilai Ambang Batas Faktor

Fisika di Tempat Kerja,” Kep .51/Men/1999, pp. 1–9, 1999.

[11] C. Vogel, S. Zwolinsky, C. Griffiths, M. Hobbs, E. Henderson, and E.

Wilkins, “A Delphi study to build consensus on the definition and use of

big data in obesity research,” Int. J. Obes., vol. 43, no. 12, pp. 2573–2586,

2019.

[12] E. J. Billo, Excel Formulas and Functions. 2011.

[13] Kusnassriyanto, Belajar Pemrograman Delphi, 1st ed. Bandung: Modula

Bandung, 2011.

[14] A. Stevens, C programming, vol. 27, no. 12. 2002.

[15] L. Hallett, M. Tatum, G. Thomas, S. Sousan, K. Koehler, and T. Peters,

“An inexpensive sensor for noise,” J. Occup. Environ. Hyg., vol. 15, no.

5, pp. 448–454, 2018.

[16] J. Holland, T. Gordon, and E. Lahelma, “Temporal, spatial and embodied

relations in the teacher’s day at school,” Ethnogr. Educ., vol. 2, no. 2, pp.

221–237, 2007.

Journal of Electronics, Electromedical Engineering and Medical Informatics (JEEEMI)

79

You might also like

- Appeal To Authority: A Failure of TrustDocument19 pagesAppeal To Authority: A Failure of Trustclapujugas100% (3)

- An Android INCU Analyzer Design To Calibrate Infant Incubator Using Bluetooth Communication For Real-Time and Wireless MonitoringDocument8 pagesAn Android INCU Analyzer Design To Calibrate Infant Incubator Using Bluetooth Communication For Real-Time and Wireless MonitoringArga HantaraNo ratings yet

- An Android INCU Analyzer Design To Calibrate Infant Incubator Using Bluetooth Communication For Real-Time and Wireless MonitoringDocument8 pagesAn Android INCU Analyzer Design To Calibrate Infant Incubator Using Bluetooth Communication For Real-Time and Wireless MonitoringAyu NissaNo ratings yet

- Arduino Based Infant Monitoring SystemDocument7 pagesArduino Based Infant Monitoring SystemZegebrial DrarNo ratings yet

- Incubator Analyzer Using Bluetooth AndroidDocument7 pagesIncubator Analyzer Using Bluetooth AndroidIlyes KHOUILDINo ratings yet

- Controlling of Temperature and Humidity For An InfDocument9 pagesControlling of Temperature and Humidity For An InfAuria RiaNo ratings yet

- Real Time Respiration Rate Measurement Using Temperature SensorDocument3 pagesReal Time Respiration Rate Measurement Using Temperature SensorEditor IJRITCCNo ratings yet

- Impact Factor: 8.423: Volume 12, Issue 4, April 2023Document9 pagesImpact Factor: 8.423: Volume 12, Issue 4, April 2023ted gcgdNo ratings yet

- REVISI AGIL SalinanDocument8 pagesREVISI AGIL SalinanTEKMED FARIZ AGIEL PRAMUDYANo ratings yet

- Air Pollution Monitoring With IOT Decice Report File NTCCDocument18 pagesAir Pollution Monitoring With IOT Decice Report File NTCCÅřījīt ÑāñdïNo ratings yet

- Design and Development of Patient Monitoring SysteDocument7 pagesDesign and Development of Patient Monitoring SysteMuhammad MustakimNo ratings yet

- IOT Based Health Monitoring System Using Arduino UNODocument8 pagesIOT Based Health Monitoring System Using Arduino UNOIJRASETPublications100% (1)

- IOT Based Health Monitoring System UsingDocument8 pagesIOT Based Health Monitoring System UsingDoctor IggyNo ratings yet

- Indoor Temperature and Humidity Monitoring System: January 2020Document10 pagesIndoor Temperature and Humidity Monitoring System: January 2020boy sadNo ratings yet

- مشروع التخرجDocument35 pagesمشروع التخرجAbeeesy AmrakeyNo ratings yet

- Intelligent Customers Checking DeviceDocument6 pagesIntelligent Customers Checking DeviceIJRASETPublicationsNo ratings yet

- Detection of Respiratory Infections Using RGB-Infrared Sensors On Portable DeviceDocument8 pagesDetection of Respiratory Infections Using RGB-Infrared Sensors On Portable DeviceJulia GuintoNo ratings yet

- System For Remote Monitoring and Control of Baby Incubator and Warmer PDFDocument7 pagesSystem For Remote Monitoring and Control of Baby Incubator and Warmer PDFMaimunah Novita SariNo ratings yet

- Review Paper On E-Smart Watch For Early Detection of Covid-19-IJRASETDocument6 pagesReview Paper On E-Smart Watch For Early Detection of Covid-19-IJRASETIJRASETPublicationsNo ratings yet

- 244-Article Text-940-1-10-20220731Document10 pages244-Article Text-940-1-10-20220731norlanjameslaureano14No ratings yet

- Novel Approach of A Smart Medical Mirror System For Medical ApplicationsDocument6 pagesNovel Approach of A Smart Medical Mirror System For Medical Applicationschieftains380No ratings yet

- Iotpaper JournalofcriticalreviewsDocument6 pagesIotpaper Journalofcriticalreviewsadwinraj29No ratings yet

- Pic Microcontroller Based Efficient Baby IncubatorDocument6 pagesPic Microcontroller Based Efficient Baby IncubatorShaikh AfzalNo ratings yet

- Prinyakupt 2019Document6 pagesPrinyakupt 2019Hafshah DeviNo ratings yet

- Smartphone-Based Analysis of Biochemical Tests For Health Monitoring Support at HomeDocument6 pagesSmartphone-Based Analysis of Biochemical Tests For Health Monitoring Support at Homeخير الحفظNo ratings yet

- Real Time Monitoring and Control of Neonatal Incubator Using LabviewDocument6 pagesReal Time Monitoring and Control of Neonatal Incubator Using LabviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Research Paper On Arduino and Its ApplicationDocument6 pagesResearch Paper On Arduino and Its ApplicationKunalNo ratings yet

- Development of In-Patient Healthcare Monitoring SystemDocument4 pagesDevelopment of In-Patient Healthcare Monitoring SystemChristine MadridNo ratings yet

- ds18b20 Sensor ResearchDocument9 pagesds18b20 Sensor ResearchMuhammad Danish HakimNo ratings yet

- 12 Controlling PDFDocument8 pages12 Controlling PDFハンター ジェイソンNo ratings yet

- Iotpaper JournalofcriticalreviewsDocument6 pagesIotpaper JournalofcriticalreviewsVishnu MuraleedharanNo ratings yet

- Research Plan Project Summary For 1a 1Document3 pagesResearch Plan Project Summary For 1a 1api-404815004No ratings yet

- Smart RestroomDocument18 pagesSmart RestroomatikpNo ratings yet

- Development of A Low-Cost Portable Pediatric Infection Screening System Using Simultaneous Measurement of Multiple Vital SignsDocument4 pagesDevelopment of A Low-Cost Portable Pediatric Infection Screening System Using Simultaneous Measurement of Multiple Vital SignsShiferaw TesfayeNo ratings yet

- Wearable Sensing and Intelligent Data Analysis for Respiratory ManagementFrom EverandWearable Sensing and Intelligent Data Analysis for Respiratory ManagementRui Pedro PaivaNo ratings yet

- Air Quality Monitoring Using Arduino and Cloud Based System in IoTDocument7 pagesAir Quality Monitoring Using Arduino and Cloud Based System in IoTIJRASETPublicationsNo ratings yet

- 78-Article Text-255-3-10-20200808Document8 pages78-Article Text-255-3-10-20200808letphuongNo ratings yet

- Ijamscr 19 359 - 915 920Document6 pagesIjamscr 19 359 - 915 920Azwar MudaNo ratings yet

- A. Background of The StudyDocument4 pagesA. Background of The Studyyin0110yangNo ratings yet

- Phototherapymachin MonitorDocument7 pagesPhototherapymachin MonitorDibya DeyNo ratings yet

- Fin Irjmets1658055887Document4 pagesFin Irjmets1658055887Dileep VishwakarmaNo ratings yet

- Group AssignmentDocument16 pagesGroup AssignmentSujan ShresthaNo ratings yet

- Air PrognosticatorDocument43 pagesAir Prognosticatorsce21cs079No ratings yet

- Research Article: Design and Development of A Low-Cost, Portable Monitoring Device For Indoor Environment QualityDocument15 pagesResearch Article: Design and Development of A Low-Cost, Portable Monitoring Device For Indoor Environment QualitykentNo ratings yet

- Sensors: Assessment and Certification of Neonatal Incubator Sensors Through An Inferential Neural NetworkDocument20 pagesSensors: Assessment and Certification of Neonatal Incubator Sensors Through An Inferential Neural NetworkRyanRRNo ratings yet

- Remote Monitoring of A Premature InfantsDocument7 pagesRemote Monitoring of A Premature InfantsYOSEF AbdoNo ratings yet

- Calibration of Infusion Pumps AnalyserDocument7 pagesCalibration of Infusion Pumps AnalyserAwaludin LaiaNo ratings yet

- DigitalDocument8 pagesDigitalHARSHAVARDHAN DORANo ratings yet

- Name Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentDocument11 pagesName Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentchristinemjenNo ratings yet

- Telemedicine ReportDocument26 pagesTelemedicine ReportFaiyaz FarahNo ratings yet

- Iot Based Smart Saline Bottle For Healthcare IJERTV10IS060457Document5 pagesIot Based Smart Saline Bottle For Healthcare IJERTV10IS060457Brunda SNo ratings yet

- Sensors: Sensors in The Autoclave-Modelling and Implementation of The Iot Steam Sterilization Procedure CounterDocument17 pagesSensors: Sensors in The Autoclave-Modelling and Implementation of The Iot Steam Sterilization Procedure CounterUsman Ali Usman AliNo ratings yet

- IOT Based IV Bag Monitoring, Controlling and Alerting SystemDocument5 pagesIOT Based IV Bag Monitoring, Controlling and Alerting Systemkolihs090302No ratings yet

- A Review - Android Based Health Care Monitoring SystemDocument9 pagesA Review - Android Based Health Care Monitoring Systemdeshmukhds2492No ratings yet

- A Real-Time Infant Health Monitoring System For Hard of Hearing Parents by Using Android-Based Mobil DevicesDocument7 pagesA Real-Time Infant Health Monitoring System For Hard of Hearing Parents by Using Android-Based Mobil DevicesKaaviya NanadakumarNo ratings yet

- Research Article Development of An Iot-Based Indoor Air Quality Monitoring PlatformDocument15 pagesResearch Article Development of An Iot-Based Indoor Air Quality Monitoring PlatformMohamed AashiqNo ratings yet

- Team 19 Report-2Document15 pagesTeam 19 Report-2RITIK KUMAR SINGHNo ratings yet

- IOT Based Health Monitoring SystemDocument7 pagesIOT Based Health Monitoring SystemIJRASETPublications100% (1)

- Project Form RuhanDocument7 pagesProject Form RuhanRuhan Madni NaqashNo ratings yet

- Harnessing Arduino-Based Labs For Monitoring and Optimizing Biological ProcessesDocument6 pagesHarnessing Arduino-Based Labs For Monitoring and Optimizing Biological ProcessesResearch ParkNo ratings yet

- Tohnichi - Katalog 2007 ENDocument52 pagesTohnichi - Katalog 2007 END.T.No ratings yet

- MHH_Torque_convertorDocument1 pageMHH_Torque_convertorjanNo ratings yet

- MotorizedOpManualDocument102 pagesMotorizedOpManualjanNo ratings yet

- Investigation On Oxygen Permeability and Surface Properties of A GarfilmsDocument10 pagesInvestigation On Oxygen Permeability and Surface Properties of A GarfilmsjanNo ratings yet

- Conducting Flow Measurement Laboratory Test Work: M. B. KimeDocument7 pagesConducting Flow Measurement Laboratory Test Work: M. B. KimejanNo ratings yet

- Paper 1Document21 pagesPaper 1janNo ratings yet

- Delgado Vs CaDocument2 pagesDelgado Vs CaNissi JonnaNo ratings yet

- Businessmath Lesson1 Quarter2Document18 pagesBusinessmath Lesson1 Quarter2Lynn DomingoNo ratings yet

- Presentation 1Document15 pagesPresentation 1sruthi_k7776No ratings yet

- Boombot ProDocument13 pagesBoombot Proriadh.bachwellNo ratings yet

- Students Material Case StudyDocument2 pagesStudents Material Case StudyFatima syedaNo ratings yet

- Half Yearly Examination (2016 - 17) Class - XII: Delhi Public School, Jodhpur Subject - Business StudiesDocument4 pagesHalf Yearly Examination (2016 - 17) Class - XII: Delhi Public School, Jodhpur Subject - Business Studiesmarudev nathawatNo ratings yet

- One Pager v2Document2 pagesOne Pager v2JuanCarlosMarrufoNo ratings yet

- Sources For MADELEY: Printed TextsDocument2 pagesSources For MADELEY: Printed TextsWen WahyudiNo ratings yet

- 10 STG WelcomeToYourEngagement LM 02 UC Financial Statements PY-IsADocument12 pages10 STG WelcomeToYourEngagement LM 02 UC Financial Statements PY-IsAHumbertNo ratings yet

- Sari ProjectDocument96 pagesSari ProjectRamesh AnkathiNo ratings yet

- MAS Running Calculator v2.1Document7 pagesMAS Running Calculator v2.1Ariadna Alegre MirallesNo ratings yet

- Module 02.2 Moving Average Weighted Moving Average and Exponential SmoothingDocument6 pagesModule 02.2 Moving Average Weighted Moving Average and Exponential SmoothingJunmirMalicVillanuevaNo ratings yet

- Copper Testing For Adsl/2/2+Document8 pagesCopper Testing For Adsl/2/2+markNo ratings yet

- Muhammad Amin Muhammad Amin Muhammad Amin Ghulam Ali Ghulam Ali Ghulam Ali 71303-0342329-1 71303-0342329-1 71303-0342329-1Document1 pageMuhammad Amin Muhammad Amin Muhammad Amin Ghulam Ali Ghulam Ali Ghulam Ali 71303-0342329-1 71303-0342329-1 71303-0342329-1امین ثانیNo ratings yet

- DX340LCADocument20 pagesDX340LCArayendraNo ratings yet

- Gopalkrishna Charitable Trust: Name Designation Pan AadhaarDocument4 pagesGopalkrishna Charitable Trust: Name Designation Pan AadhaarSalman KhanNo ratings yet

- Thymatron 4Document8 pagesThymatron 4srinivasanaNo ratings yet

- Engineers Report PtoDocument5 pagesEngineers Report PtoLito LeonardoNo ratings yet

- Chapter No.1 - Introduction To Personal SellingDocument52 pagesChapter No.1 - Introduction To Personal SellingAyush100% (1)

- DDD 3360Document23 pagesDDD 3360Rixall Jun SanchezNo ratings yet

- ATADU2002 DatasheetDocument3 pagesATADU2002 DatasheethindNo ratings yet

- Modeling and Simulation PMSG Based On Wind Energy Conversion System in MATLAB/SIMULINKDocument5 pagesModeling and Simulation PMSG Based On Wind Energy Conversion System in MATLAB/SIMULINKRITWIK MALNo ratings yet

- K-Bglu 1107 DataDocument16 pagesK-Bglu 1107 Datapi_yoanaNo ratings yet

- Toy Market Research StudyDocument7 pagesToy Market Research StudyAtul KumarNo ratings yet

- Jotun Thinner No.25 Base PDFDocument14 pagesJotun Thinner No.25 Base PDFSatishNo ratings yet

- PL BT enDocument304 pagesPL BT enOssian89No ratings yet

- Unit 1-At6402 Automotive ChassisDocument39 pagesUnit 1-At6402 Automotive ChassisSathis KumarNo ratings yet

- Principles of Macroeconomics 11Th Edition Case Test Bank Full Chapter PDFDocument36 pagesPrinciples of Macroeconomics 11Th Edition Case Test Bank Full Chapter PDFjacob.toupin212100% (17)

- Plant Design TemplateDocument13 pagesPlant Design TemplateRishabhGupta 2k20umba32No ratings yet