Professional Documents

Culture Documents

Speeds and Feeds 1053 1054

Speeds and Feeds 1053 1054

Uploaded by

P CH0 ratings0% found this document useful (0 votes)

23 views1 pageThis document provides recommended speeds and feeds (SFM and feed per tooth) for end mills made of solid carbide with TIALN coating when machining various materials including aluminum, steels, stainless steels, titanium, inconel, copper, and brass. Guidelines are also provided for slotting, profiling, coolant use, tool concentricity, chip formation, and avoiding thermal shock to achieve best cutting results. Parameters may need adjustment for specific conditions.

Original Description:

Original Title

speeds-and-feeds-1053-1054

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides recommended speeds and feeds (SFM and feed per tooth) for end mills made of solid carbide with TIALN coating when machining various materials including aluminum, steels, stainless steels, titanium, inconel, copper, and brass. Guidelines are also provided for slotting, profiling, coolant use, tool concentricity, chip formation, and avoiding thermal shock to achieve best cutting results. Parameters may need adjustment for specific conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

23 views1 pageSpeeds and Feeds 1053 1054

Speeds and Feeds 1053 1054

Uploaded by

P CHThis document provides recommended speeds and feeds (SFM and feed per tooth) for end mills made of solid carbide with TIALN coating when machining various materials including aluminum, steels, stainless steels, titanium, inconel, copper, and brass. Guidelines are also provided for slotting, profiling, coolant use, tool concentricity, chip formation, and avoiding thermal shock to achieve best cutting results. Parameters may need adjustment for specific conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

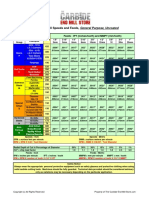

Speeds and Feeds for 1053 and 1054 style end mills.

Solid carbide 4 flute variable helix and

indexing with TIALN coating. End Mills are made in the USA.

Hardness Feed Per Tooth

Material Bhn SFM 1/8”dia ¼” 3/8” ½” ¾” 1”

Aluminum 2011,2024,6061,7075 -- 800 .001 .0018 .003 .004 .006 .0065

Free Machining 12L14, 1215,11L17 80-150 550 .0006 .0015 .0022 .004 .005 .0055

Low Carbon Steel 1008, 1018, 1020 125-175 500 .0006 .0014 .002 .003 .004 .0045

Medium Carbon Steel 4140, 8620 200-280 400 .0005 .0012 .0018 .0025 .0035 .004

Tool Steel, H.S.S A2,D2,M2,M42 300-400 240 .0004 .001 .0016 .0022 .0032 .0035

Cast Iron 120-175 500 .0005 .0014 .002 .0035 .005 .0052

Stainless Steel 300 Series 160-200 375 .0005 .0014 .002 .0035 .005 .0052

Stainless Steel 400 Series 180-260 200 .0004 .0013 .0018 .0032 .0045 .0046

Stainless Steel 15-5, 17-4 160-200 230 .0005 .0015 .002 .0035 .005 .0052

Titanium 6AL-4V 320-380 300 .0005 .001 .0016 .0022 .0035 .004

Inconel 625, 718 280-320 60 .0002 .0006 .0014 .0018 .0028 .0032

Copper, Bronze 120-160 400 .0006 .0015 .0022 .004 .005 .0055

Brass (360 half hard) -- 550 .0009 .0017 .0025 .0035 .0055 .006

Feed Per Tooth is based on.....

slotting depth of .5 x Cutting Diameter, for deeper slotting reduce feed and speed

profiling with Axial depth up to 2x Cutting Diameter and Radial Depth of .25x Cutting Diameter,

when profiling less than .25 cutting diameter increase feed and speed

Blue material box indicates coolant is required for proper operation

non colored materials can be run dry with air blast or with coolant, assuming all safety and

ventilation guidelines are followed

6 guidelines for best cutting results

keep overall gage length short keep tool concentricity low climb milling is generally best

workpiece rigidity is important avoid double cutting chips avoid thermal shock

Note: Cutting speeds, feeds, and lubrication data are given as starting values only. Parameters should

be varied to suite your particular conditions. MariTool is constantly improving products, tolerances, and

reliability. As such, these speeds and feeds are subject to change without prior notice. Cutting tools

may shatter and or produce dangerous fumes when being used. Appropriate protection is advised.

You might also like

- Astm C633 PDFDocument8 pagesAstm C633 PDFKH100% (1)

- WPC Wall Panel of BAIJAXDocument16 pagesWPC Wall Panel of BAIJAXanand gowdaNo ratings yet

- Tamiya Colour ChartDocument7 pagesTamiya Colour Chartmike_hobbs_6100% (3)

- MachiningDocument12 pagesMachiningwardendavid5591100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Copper ProcessingDocument26 pagesCopper ProcessingDiego GaliciaNo ratings yet

- Cutting SpeedDocument5 pagesCutting Speedokooy erusNo ratings yet

- NTK General TechnicalDocument32 pagesNTK General TechnicalsathishelakkiyaNo ratings yet

- Carbide End Mill Feeds and Speeds General Purpose TiNDocument1 pageCarbide End Mill Feeds and Speeds General Purpose TiNjoshNo ratings yet

- Carbide End Mill Speeds and Feeds, General Purpose, UncoatedDocument1 pageCarbide End Mill Speeds and Feeds, General Purpose, UncoatedMihir SevakNo ratings yet

- Speeds & Feeds DrillsDocument9 pagesSpeeds & Feeds DrillsHolleyMooreNo ratings yet

- 05 MachiningDocument12 pages05 MachiningVisvas RajyaguruNo ratings yet

- Dura Bar Machining GuideDocument4 pagesDura Bar Machining GuidericassterNo ratings yet

- AISI 1035 Steel, Cold Drawn, High Temperature, Stress Relieved, 16-22 MM (0.625-0.875 In) RoundDocument2 pagesAISI 1035 Steel, Cold Drawn, High Temperature, Stress Relieved, 16-22 MM (0.625-0.875 In) RoundJakJhonNo ratings yet

- AFNOR 42 CD 4 SteelDocument2 pagesAFNOR 42 CD 4 SteelMagoroku D. YudhoNo ratings yet

- Aisi 4140Document3 pagesAisi 4140BayuPrasetyaPutraNo ratings yet

- HSS Carbide Reamers Speeds Feeds p497 498Document2 pagesHSS Carbide Reamers Speeds Feeds p497 498Ravi DahiwalaNo ratings yet

- Speeds and Feeds For Metal CuttingDocument4 pagesSpeeds and Feeds For Metal CuttingAnonymous dh6DITNo ratings yet

- Speed and Feed-Variable Helix and RoughersDocument1 pageSpeed and Feed-Variable Helix and RoughersabyzenNo ratings yet

- Standard ThreadmillsDocument1 pageStandard ThreadmillsshawntsungNo ratings yet

- 010 - AR200 Product Data Sheet 2012 04 01Document2 pages010 - AR200 Product Data Sheet 2012 04 01Baihaki StNo ratings yet

- Tool BitsDocument10 pagesTool BitsRamiro Duran ZambranoNo ratings yet

- Userguide For SSDocument26 pagesUserguide For SSehsan4uNo ratings yet

- Suggested Speed & Feed Rates: Maximum Performance End Mills From Dura-MillDocument2 pagesSuggested Speed & Feed Rates: Maximum Performance End Mills From Dura-MillVíctor BravoNo ratings yet

- Cutting Edge BrochureDocument2 pagesCutting Edge BrochureKen SmithNo ratings yet

- Materials FerrousDocument3 pagesMaterials Ferrousjohnson_regoNo ratings yet

- Standards R M Salem - UserguideDocument49 pagesStandards R M Salem - Userguidearunas1081No ratings yet

- Al - 1050ADocument2 pagesAl - 1050Adejo1986100% (1)

- Cutting Speed and Feedrate SouthbayDocument5 pagesCutting Speed and Feedrate SouthbayShahed FacebookNo ratings yet

- AISI 4140 - 42Cr4Mo2Document2 pagesAISI 4140 - 42Cr4Mo2rajbir_singh75% (4)

- C45 - Specification1Document7 pagesC45 - Specification1gowtham_venkat_4No ratings yet

- Gasno Zavarivanje UputstvoDocument15 pagesGasno Zavarivanje UputstvoRadivojevic SasaNo ratings yet

- RFQ of C45 SteelDocument3 pagesRFQ of C45 Steelnhirpara1No ratings yet

- Material SpecificationDocument50 pagesMaterial SpecificationSangyt Karna0% (2)

- Tubular Products From Special MetalsDocument26 pagesTubular Products From Special Metalskaveh-bahiraeeNo ratings yet

- RFQ of C45 SteelDocument3 pagesRFQ of C45 Steelnhirpara1No ratings yet

- Alumec PDFDocument7 pagesAlumec PDFetamil87No ratings yet

- Steel UserguideDocument50 pagesSteel UserguideBhanu Pratap ChoudhuryNo ratings yet

- All Types of MaterialsDocument8 pagesAll Types of MaterialsAniket KabadeNo ratings yet

- 2 ATI Steellram U INCIMA DimenzijeDocument4 pages2 ATI Steellram U INCIMA DimenzijeBosko LukavicNo ratings yet

- Recommended Cutting Speeds For Dapra SBN CuttersDocument1 pageRecommended Cutting Speeds For Dapra SBN CuttersEduardo Aleman ReynaNo ratings yet

- 6005 Aluminum Sheet SuppliersDocument15 pages6005 Aluminum Sheet Supplierssanghvi overseas incNo ratings yet

- Application - Cast Iron RepairDocument16 pagesApplication - Cast Iron RepairAnonymous L0ChmPGNo ratings yet

- SAF Welding Cutting GuideDocument165 pagesSAF Welding Cutting GuideSelvem0% (1)

- Ati 302™/ati 304™/ati 304l™/ati 305™Document11 pagesAti 302™/ati 304™/ati 304l™/ati 305™Vivek JainNo ratings yet

- AISI 1040: Typical AnalysisDocument2 pagesAISI 1040: Typical Analysisho_chauhanNo ratings yet

- Technical DataDocument17 pagesTechnical Datat_syamprasadNo ratings yet

- Aisi Type 403 (Chemical Composition)Document7 pagesAisi Type 403 (Chemical Composition)MiguelPacheecoAgamezNo ratings yet

- Cast Iron Welding AlloysDocument4 pagesCast Iron Welding AlloysKhin Aung ShweNo ratings yet

- Cutting ToolsDocument143 pagesCutting ToolsTone RatanalertNo ratings yet

- Stainless Steel Structure Design HandbookDocument20 pagesStainless Steel Structure Design Handbookgnino2No ratings yet

- ENB 04 0553 Rev B Bearing Materials Technical InformationDocument4 pagesENB 04 0553 Rev B Bearing Materials Technical Informationmanasha majhiNo ratings yet

- MaterialData - Aço 1045Document2 pagesMaterialData - Aço 1045Victhor AraujoNo ratings yet

- General Information Theory - LindabDocument27 pagesGeneral Information Theory - LindabaudithanNo ratings yet

- Section 2.0 Alloy SteelsDocument10 pagesSection 2.0 Alloy SteelsAloísio NascimentoNo ratings yet

- Radit Supriyanto - Tabel Cutting SpeedDocument4 pagesRadit Supriyanto - Tabel Cutting SpeedNasserNo ratings yet

- Stainless Steel 630Document1 pageStainless Steel 630manjubd1No ratings yet

- Carbon Steel: Application Material GroupDocument27 pagesCarbon Steel: Application Material Groupharishkumar.ravichandranNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- Disston Lumberman Handbook - Containing A Treatise Of The Construction Of Saws And How To Keep Them In OrderFrom EverandDisston Lumberman Handbook - Containing A Treatise Of The Construction Of Saws And How To Keep Them In OrderNo ratings yet

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- Typical PFD of Residue Catalytic CrackingDocument2 pagesTypical PFD of Residue Catalytic CrackingKmt_AeNo ratings yet

- A Review On Gasifier Modification For Tar Reduction in Biomass GasificationDocument16 pagesA Review On Gasifier Modification For Tar Reduction in Biomass GasificationisttNo ratings yet

- Catalog Profile StandardDocument16 pagesCatalog Profile StandardBogdan AndreiNo ratings yet

- C75C - Ck75 Steel DataDocument2 pagesC75C - Ck75 Steel DatavinibeNo ratings yet

- CeramicDocument14 pagesCeramicIrham SyahmiNo ratings yet

- Foundry BindersDocument48 pagesFoundry BindersJorge RodriguezNo ratings yet

- Unit 6 - Week 4: Abrasive Mass Finishing Operations & Surface Integrity in Abrasive ProcessDocument3 pagesUnit 6 - Week 4: Abrasive Mass Finishing Operations & Surface Integrity in Abrasive ProcessAbhishek VishwakarmaNo ratings yet

- Paint System: Cargotec Finland Oy TampereDocument1 pagePaint System: Cargotec Finland Oy TampereEdward Erney Salas ValenzuelaNo ratings yet

- Dhanalakshmi College of Engineering Department of Mechanical Engineering Me 6302 Manufacturing Technology - 1 (Question Bank)Document10 pagesDhanalakshmi College of Engineering Department of Mechanical Engineering Me 6302 Manufacturing Technology - 1 (Question Bank)arulNo ratings yet

- 5.co - DMB 3152 Joining TechnologyDocument6 pages5.co - DMB 3152 Joining TechnologyFadhly AzmyNo ratings yet

- SUS420FDocument2 pagesSUS420FarnettoNo ratings yet

- Casting AssignmentDocument2 pagesCasting AssignmentAyush BaliNo ratings yet

- Materi Kuliah 4 PDFDocument19 pagesMateri Kuliah 4 PDFarif menceroNo ratings yet

- Tentative Calendar of Events INDOCOR 2017Document2 pagesTentative Calendar of Events INDOCOR 2017Firlan MaulanaNo ratings yet

- Introduction To Metal Casting ProcessDocument8 pagesIntroduction To Metal Casting ProcessRiya PanwarNo ratings yet

- Aws A2.4 2Document83 pagesAws A2.4 2Ярослав ДорошенкоNo ratings yet

- 20160323010442-C50E (Ck50)Document2 pages20160323010442-C50E (Ck50)novkovic1984No ratings yet

- Research MethodsDocument7 pagesResearch MethodsRutendo BudaiNo ratings yet

- Detail A Scale 8: 1: Consolidated Sterilizer SystemsDocument1 pageDetail A Scale 8: 1: Consolidated Sterilizer Systemsapi-435501670No ratings yet

- Forging Machine ToolsDocument14 pagesForging Machine ToolsJAFFERNo ratings yet

- FSPZ - 65 Sheet Extrusion LineghDocument1 pageFSPZ - 65 Sheet Extrusion LineghAnonymous 6EW2MsFbkNo ratings yet

- Surface Preparation & Painting Procedure r1Document4 pagesSurface Preparation & Painting Procedure r1Wijayanto BekasiNo ratings yet

- Welding ExamDocument6 pagesWelding ExamAnthony AbenaNo ratings yet

- Lakshya DraftingDocument13 pagesLakshya DraftingAbhinav KumarNo ratings yet

- Brazing Technology of Ti Alloy/stainless Steel Dissimilar Metal Joint at System Integrated Modular Advanced ReactorDocument131 pagesBrazing Technology of Ti Alloy/stainless Steel Dissimilar Metal Joint at System Integrated Modular Advanced Reactormojtaba nNo ratings yet

- 20NiCrMoS2 2Document1 page20NiCrMoS2 2Bogdan CraciunNo ratings yet