Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

23 viewsTroubleshooting

Troubleshooting

Uploaded by

Baltija MechanikasCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Complete Manual FESDocument200 pagesComplete Manual FESBaltija Mechanikas100% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hidral Maintenance HandbookDocument32 pagesHidral Maintenance HandbookBaltija MechanikasNo ratings yet

- Chemistry LabDocument34 pagesChemistry LabBaltija MechanikasNo ratings yet

- TC 2 001961 en 01Document73 pagesTC 2 001961 en 01Baltija MechanikasNo ratings yet

- BA100.User ManualDocument40 pagesBA100.User ManualBaltija MechanikasNo ratings yet

- Cabin Installation Manual L310-L320 - EN81.20Document52 pagesCabin Installation Manual L310-L320 - EN81.20Baltija MechanikasNo ratings yet

- TeSys Deca Overload Relays - LRD21Document3 pagesTeSys Deca Overload Relays - LRD21Baltija MechanikasNo ratings yet

- Field Test Genius 20Document4 pagesField Test Genius 20Baltija MechanikasNo ratings yet

- Lift Rescue OperationsDocument3 pagesLift Rescue OperationsBaltija MechanikasNo ratings yet

- DR-DW3N (En) 20221110Document2 pagesDR-DW3N (En) 20221110Baltija MechanikasNo ratings yet

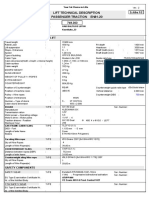

- Lift Technical DescriptionDocument2 pagesLift Technical DescriptionBaltija MechanikasNo ratings yet

- InstrukcijaDocument12 pagesInstrukcijaBaltija MechanikasNo ratings yet

- 7000 SeriesDocument85 pages7000 SeriesBaltija MechanikasNo ratings yet

- Owner''s DocumentationDocument35 pagesOwner''s DocumentationBaltija MechanikasNo ratings yet

- v65 Electronic 4dDocument70 pagesv65 Electronic 4dBaltija MechanikasNo ratings yet

- Omega Curved Inclined Platform Lift Owner's ManualDocument24 pagesOmega Curved Inclined Platform Lift Owner's ManualBaltija MechanikasNo ratings yet

- FormaDocument2 pagesFormaBaltija MechanikasNo ratings yet

Troubleshooting

Troubleshooting

Uploaded by

Baltija Mechanikas0 ratings0% found this document useful (0 votes)

23 views4 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

23 views4 pagesTroubleshooting

Troubleshooting

Uploaded by

Baltija MechanikasCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 4

Donotacr |e fault display: Eliminate]

1 [tne problems according to the]

“When without fault display. Check IXW [sult display

oo

Nosmal + Green LED of IXWis ome J [Abnoummal © Green LED of ROW i]

1 lnor one

Check TAQ relay or contactor

z

[Exchange the two power of duce

I

foccmalr eucocto7 a] [Atnorimal + contactor] x

— pase to nonmal

lo lof JQ is aot pulled]

[Whar PLCOCHO8 4s not ea] 1

fmeans thar dcive chain |

ee [Check the thermal overtond 7 =

roken oF loosen or contact if Ite: wether she bones eet Litis not pated in

JOCR is pulled in or not

Juot om the normal position

jist PLC.OCELOS is not cal

jascane that reversal |

I ie aot come t9 the aormal position of

moter is overload: Check whether the

(iseuit of moter is short aad whether

Jeontser is not on the normal

ponnon [check whether theamal] (motor can act mu freely: Whethes

y erlond celay. safety} lorake is loosen or not

[Check ey switch] contact and emergency

Jcontact ae on nosmal

£ 1 osston or no Eliminate the problem

[Nortaal + «| ‘Abnormal L come fo normal

PLCoCHLOI is Elinunate the problem

jon. which is up| [Repair te snd come to normal

ection lnosmat

PLCOCHEO3 |

jon, which is

ldown ditecion.

1

‘Check monitoring

switch of brake

Abnosmal

[Normal + +

'PLC.10CE205 is on.

'Tuere is a voltage between] <4

|matce the brake switch work normally

10 and 11 of 10.

[Etiminate the mechanical problems and

[oneck wheder all

contacts or relays

have mechanical

problems

+ When the running direction is not comrect

Ebininate the problems ‘Adjust the eable im dhe control boxt +

and come to normal [Exchange U21 and 21* +

t [Exchange 22 and V22" nly used for Yo

fie runing] systems +

laizection "Exchange U3 and V3* only used for VVVF)

system

fe

[The protection of speed monitor:

lOperate the esxalator in checking

[PLC.OCH.00 is not on means shat

contact is damage or junction is|

fis passenger conveyor stop]

Passen y - jerong: setting value of time of speed

Jauromatically because of problems in 5s

juonitor is not correct: Modifying the

f— lprocedure of PLC to decrease the

Nout hvalne of DM230 and to increase the

- value of DM231

No.

Fault Deseriotion

Solution

Motor doesn’t run

+ Outer Powers stil ON* +

Check the safety circuit

* safety relay/contactor and the input of PLCIMIC

Processor Board should be check* # LCD fault

display exists, it could help to judge the faults +

Check the ‘UXW “ight

Check “OCR” contact ete.

Motor runs wrong direction

4 Check “UP or D" wiring

2 €heek the motor wiring

* exchange random two phase wiring terminal, for

example to V21 or to wate

and V2 or U22 and W22 should

bbe exchanged the same timer +

3 €heck the aitection signal

noticeable

Motor speed protection

1.Check the voltage of the sensor

* new motor speed sensor can be atest * *

2.Check the relevant wiring

3.Cheek the motor voltage

Handrail speed protection

1.Check the voltage of the sensor

+ new handrail speed sensor can he atest + +

2.Check the relevant wiring

‘Step missing protection

1.Check the voltage of the sensor

* new step missing sensor can be atest * ©

2.Check the relevant wiring

Contact adhered protection

Check "Us Br Y= = + JEZ* JX" etc, flenlsle or not

Brake open protection

Cheek brake OK or not

Sensors which check

passenger no useful

1.Check the voltage of the sensor

* pay attention to the influence from inverter

and the earth line connection well or not* +

Check the relevant wiring

Buzzer fauit|

1.Cheek the voltage of buzzer

* new buzzer can be a test* *

2.Cheek the relevant wiring

+ new buzzer can be a tests *

Direction display fault

1.Check the voltage of the direction display

* new direction display can be atest? *

Check the relevant wiring

+ new direction display can be atest? +

‘Auto running time is too long

or too short

‘Modify the parameter in PLC program

2.Operate the escalator to run in auto-learning time

mode

Reversal-proaf function

(escalator runs in down

direction wellt up direction

badly * and the same time

safety brake works)

Check the NRS ewiteh

2.Check the switch relevant wiring

Safety brake works

1.Check the motor speed protection system

(Cheek the drive chain switen

3.Cheek the NRS swith + enly when work in up

direction *

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Complete Manual FESDocument200 pagesComplete Manual FESBaltija Mechanikas100% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hidral Maintenance HandbookDocument32 pagesHidral Maintenance HandbookBaltija MechanikasNo ratings yet

- Chemistry LabDocument34 pagesChemistry LabBaltija MechanikasNo ratings yet

- TC 2 001961 en 01Document73 pagesTC 2 001961 en 01Baltija MechanikasNo ratings yet

- BA100.User ManualDocument40 pagesBA100.User ManualBaltija MechanikasNo ratings yet

- Cabin Installation Manual L310-L320 - EN81.20Document52 pagesCabin Installation Manual L310-L320 - EN81.20Baltija MechanikasNo ratings yet

- TeSys Deca Overload Relays - LRD21Document3 pagesTeSys Deca Overload Relays - LRD21Baltija MechanikasNo ratings yet

- Field Test Genius 20Document4 pagesField Test Genius 20Baltija MechanikasNo ratings yet

- Lift Rescue OperationsDocument3 pagesLift Rescue OperationsBaltija MechanikasNo ratings yet

- DR-DW3N (En) 20221110Document2 pagesDR-DW3N (En) 20221110Baltija MechanikasNo ratings yet

- Lift Technical DescriptionDocument2 pagesLift Technical DescriptionBaltija MechanikasNo ratings yet

- InstrukcijaDocument12 pagesInstrukcijaBaltija MechanikasNo ratings yet

- 7000 SeriesDocument85 pages7000 SeriesBaltija MechanikasNo ratings yet

- Owner''s DocumentationDocument35 pagesOwner''s DocumentationBaltija MechanikasNo ratings yet

- v65 Electronic 4dDocument70 pagesv65 Electronic 4dBaltija MechanikasNo ratings yet

- Omega Curved Inclined Platform Lift Owner's ManualDocument24 pagesOmega Curved Inclined Platform Lift Owner's ManualBaltija MechanikasNo ratings yet

- FormaDocument2 pagesFormaBaltija MechanikasNo ratings yet