Professional Documents

Culture Documents

Rework Procedure

Rework Procedure

Uploaded by

Tushar WaghCopyright:

Available Formats

You might also like

- P2P Test Scenario ListDocument5 pagesP2P Test Scenario Listnani2003No ratings yet

- Rework & Repair ProcedureDocument1 pageRework & Repair ProcedureManu Sharma100% (5)

- QMS 065 Manufacturing Rework Procedure SampleDocument5 pagesQMS 065 Manufacturing Rework Procedure Sampleevil genius100% (1)

- Deploying aspenONE V10 With SCCM Best PracticesDocument56 pagesDeploying aspenONE V10 With SCCM Best Practicesryan sandi100% (1)

- Annexure A - Draft Formal Report - Agst Knysna Mun - Procurement From Knysna T..Document50 pagesAnnexure A - Draft Formal Report - Agst Knysna Mun - Procurement From Knysna T..Sune Payne- Daily MaverickNo ratings yet

- QAD Procedure - Inspection & Testing (Inprocess & Final Inspection)Document1 pageQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)suman100% (2)

- PEIPL-SOP-01 For Incoming Material Insp.Document1 pagePEIPL-SOP-01 For Incoming Material Insp.Balkishan DyavanapellyNo ratings yet

- QSP Qad 08Document2 pagesQSP Qad 08prabha_1No ratings yet

- PPAP IV Edition TrainingDocument38 pagesPPAP IV Edition Trainingshariq warsi100% (1)

- Sample Procedure FlowDocument3 pagesSample Procedure Flowvyly1723No ratings yet

- In Process Inspection Stage Flow Chart: Spacechem EnterprisesDocument6 pagesIn Process Inspection Stage Flow Chart: Spacechem EnterprisesSourav SharmaNo ratings yet

- Sop-47 F5 Product Stability ProtocollDocument1 pageSop-47 F5 Product Stability Protocollketone acidNo ratings yet

- Work Centers and Storekeeping: (FG) WarehouseDocument4 pagesWork Centers and Storekeeping: (FG) WarehouseFatima Erica I. DatumangudaNo ratings yet

- Interaction of ProcessesDocument1 pageInteraction of ProcessesBharath100% (1)

- System Improvment FormDocument2 pagesSystem Improvment FormAdnan AkramNo ratings yet

- Magna Electronics (MEI) - 4 Phases of APQP For Supplier Development EngineeringDocument20 pagesMagna Electronics (MEI) - 4 Phases of APQP For Supplier Development EngineeringBob Zepfel100% (4)

- A Simplified Commissioning L - 2012 - Chemical and Process Plant Commissioning HDocument1 pageA Simplified Commissioning L - 2012 - Chemical and Process Plant Commissioning HGabriel BarretoNo ratings yet

- Development Time LineDocument1 pageDevelopment Time LineMohitrajranikashyapNo ratings yet

- 888 S4HANA1709 Process Overview EN USDocument4 pages888 S4HANA1709 Process Overview EN USRicardo SepulvedaNo ratings yet

- Management System Manual: Title Doc. No. ProcessDocument2 pagesManagement System Manual: Title Doc. No. ProcessZina CabreraNo ratings yet

- Turtle Diagram StoreDocument1 pageTurtle Diagram StoreRiyu Rathod0% (1)

- Quality Control Three StagesDocument1 pageQuality Control Three Stagesfouad elferdiNo ratings yet

- JitDocument2 pagesJitmobylayNo ratings yet

- QP-ENG-PRC-008 - QP Procedure For Site Acceptance Test - Rev 00Document13 pagesQP-ENG-PRC-008 - QP Procedure For Site Acceptance Test - Rev 00salem elhajNo ratings yet

- 207-04a - Control of Customer Supplied MaterialsDocument7 pages207-04a - Control of Customer Supplied MaterialsYusufNo ratings yet

- Process Validation Protocol of Granules For Oral AdministrationDocument6 pagesProcess Validation Protocol of Granules For Oral AdministrationRezaul haque himelNo ratings yet

- Guidelines For Manufacturers and TradersDocument46 pagesGuidelines For Manufacturers and TraderstesteNo ratings yet

- SAP QM Introduction DeckDocument22 pagesSAP QM Introduction DeckVikash RanjanNo ratings yet

- QSPIFCDocument3 pagesQSPIFCsathyabalaraman100% (1)

- Apqp Workbook PDF FreeDocument20 pagesApqp Workbook PDF FreeHazemNo ratings yet

- PPAP - 4th Edition - Course MaterialDocument18 pagesPPAP - 4th Edition - Course MaterialMy Dad My WorldNo ratings yet

- Ppap Iv EditionDocument19 pagesPpap Iv EditionpandajayNo ratings yet

- Quality Disruption Process AuditDocument11 pagesQuality Disruption Process AuditVorapoj Lertsuwunseri100% (1)

- 212-04a - INSPECTION AND TEST STATUSDocument5 pages212-04a - INSPECTION AND TEST STATUSYusufNo ratings yet

- Rework Processing (Stock-Manufactured Material) - 2GGDocument4 pagesRework Processing (Stock-Manufactured Material) - 2GGsowjanyaNo ratings yet

- QAD Procedure - Control of Non-Conforming Products P2Document2 pagesQAD Procedure - Control of Non-Conforming Products P2sumanNo ratings yet

- Final CommisionDocument11 pagesFinal CommisionSam MNo ratings yet

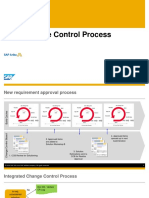

- ARI.022 - PMAR.307 - Agile Change Control ProcessDocument3 pagesARI.022 - PMAR.307 - Agile Change Control ProcessCleberton Antunes100% (1)

- MRM - Jan-2015Document8 pagesMRM - Jan-2015RajVardhanNo ratings yet

- Authorizations: HMIQP-1012 - Product TraceabilityDocument2 pagesAuthorizations: HMIQP-1012 - Product TraceabilityAKNo ratings yet

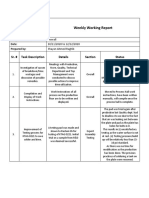

- Weekly Working Report: Sr. # Task Description Details Section StatusDocument2 pagesWeekly Working Report: Sr. # Task Description Details Section StatusSaAhRaNo ratings yet

- As Is - Inspection and GRN - Paper CoreDocument1 pageAs Is - Inspection and GRN - Paper CoreYousuf KhanNo ratings yet

- 211-04a - CONTROL OF INSPECTION, MEASURINGDocument7 pages211-04a - CONTROL OF INSPECTION, MEASURINGYusufNo ratings yet

- 39) Procedure For Inspection & Testing - 104931Document5 pages39) Procedure For Inspection & Testing - 104931Sagar DaundNo ratings yet

- 215-04a - HANDLING, STORAGE, PACKAGING, PRESERVATION AND DELIVERYDocument8 pages215-04a - HANDLING, STORAGE, PACKAGING, PRESERVATION AND DELIVERYyusuf.yuzuakNo ratings yet

- Understanding Internal ControlsDocument31 pagesUnderstanding Internal ControlsVenus Lyka LomocsoNo ratings yet

- 210-05 - Inspection and TestingDocument13 pages210-05 - Inspection and TestingYusufNo ratings yet

- Factory Acceptance Test Procedure For DCS - Page 1Document2 pagesFactory Acceptance Test Procedure For DCS - Page 1kapsarcNo ratings yet

- DTP - Supplier Management SOP QA.008Document13 pagesDTP - Supplier Management SOP QA.008Faizah LokmanNo ratings yet

- Lims Sap Integration PDF FreeDocument24 pagesLims Sap Integration PDF FreePavan ReddyNo ratings yet

- 206-05 - ProcurementDocument10 pages206-05 - ProcurementYusufNo ratings yet

- Procedure For EcnDocument8 pagesProcedure For EcnChintamani GiramkarNo ratings yet

- OBJECTIVE 2018-2019: Employee Name: Muhammad UmairDocument2 pagesOBJECTIVE 2018-2019: Employee Name: Muhammad Umairrafiq noorNo ratings yet

- VQCA Guideline For Suppliers Brief SummaryDocument34 pagesVQCA Guideline For Suppliers Brief SummaryYeimy CorredorNo ratings yet

- Chapter8Document6 pagesChapter8surajNo ratings yet

- Customer Complaint HandlingDocument7 pagesCustomer Complaint HandlingpapplionNo ratings yet

- Buffco Eng AS9100 Quality Manual 2-28-06Document26 pagesBuffco Eng AS9100 Quality Manual 2-28-06savlafNo ratings yet

- SIPOC TemplateDocument3 pagesSIPOC TemplatesadaNo ratings yet

- Technology Transfer Plan & Exhibit TJDocument19 pagesTechnology Transfer Plan & Exhibit TJTejashreeNo ratings yet

- H84 Scen Overview EN DEDocument34 pagesH84 Scen Overview EN DEssahu1979No ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- Каталог ССК и инструментаDocument162 pagesКаталог ССК и инструментаШилоNo ratings yet

- Change Management & Leadership: Diploma in Business Management - Level 6Document20 pagesChange Management & Leadership: Diploma in Business Management - Level 6Aayush AnejaNo ratings yet

- Brookes Pharma DONEDocument14 pagesBrookes Pharma DONEmisbah khanNo ratings yet

- Minimum Viable Product (For Disribution)Document25 pagesMinimum Viable Product (For Disribution)Yash Aggarwal BD20073No ratings yet

- Uns W Student GuideDocument27 pagesUns W Student Guidemmm123No ratings yet

- Ceo at 22 Book v1.0Document177 pagesCeo at 22 Book v1.0eruditebookkeepingNo ratings yet

- Boat 235V2 Fast Charging Bluetooth Headset: Grand Total 1199.00Document1 pageBoat 235V2 Fast Charging Bluetooth Headset: Grand Total 1199.00AjayNo ratings yet

- Eng - Osama BadrDocument3 pagesEng - Osama BadrAmr GodaNo ratings yet

- Mec 8910a Lecture 6Document59 pagesMec 8910a Lecture 6Miguel HenaoNo ratings yet

- DEED OF ABSOLUTE SALE - SampleDocument2 pagesDEED OF ABSOLUTE SALE - SampleRoland Rosales100% (1)

- NAIR Webinar - TPI SystemDocument2 pagesNAIR Webinar - TPI Systemtommaverick154No ratings yet

- Branding of Industrial ProductsDocument5 pagesBranding of Industrial ProductsvishwajeetarivastavNo ratings yet

- Internship Under CA Final ReportDocument22 pagesInternship Under CA Final ReportChahatNo ratings yet

- IMPORTANT INFORMATION - : Baggage AllowanceDocument2 pagesIMPORTANT INFORMATION - : Baggage AllowanceHla Cho HtutNo ratings yet

- State The Reasons Behind The Failure of Xerox and NokiaDocument4 pagesState The Reasons Behind The Failure of Xerox and NokiaSyed NomanNo ratings yet

- God's Grace Forex BookDocument11 pagesGod's Grace Forex BookMatimu Nene ChabalalaNo ratings yet

- Nike LawsuitDocument24 pagesNike LawsuitJ RohrlichNo ratings yet

- Seattle Greenwell: ExperienceDocument1 pageSeattle Greenwell: Experienceseattle greenwellNo ratings yet

- SS - (535 - 550) - 72MTF SunovaDocument2 pagesSS - (535 - 550) - 72MTF SunovaPaulo Henrique SantosNo ratings yet

- Business Practices ofDocument5 pagesBusiness Practices ofAbid FerdowsNo ratings yet

- Umali Quiz For Ra 9266Document2 pagesUmali Quiz For Ra 9266Rogelio MaligayaNo ratings yet

- Resume-Pramod-Bhupathi TeamconnectDocument3 pagesResume-Pramod-Bhupathi TeamconnectHaseeb KhanNo ratings yet

- PHC Tech BrochureDocument9 pagesPHC Tech BrochuretanmaysutariaNo ratings yet

- TAXATIONDocument23 pagesTAXATIONJessica AragonNo ratings yet

- Cheries Business PlanDocument5 pagesCheries Business PlanCheries Jane MoringNo ratings yet

- 2020 PDFDocument7 pages2020 PDFNaveen R J JamesNo ratings yet

- ABB Robot Control S4C or S4P in Conjunction With WAGO Profibus Components 750-303 and 750-301Document12 pagesABB Robot Control S4C or S4P in Conjunction With WAGO Profibus Components 750-303 and 750-301Diogo CoelhoNo ratings yet

Rework Procedure

Rework Procedure

Uploaded by

Tushar WaghOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rework Procedure

Rework Procedure

Uploaded by

Tushar WaghCopyright:

Available Formats

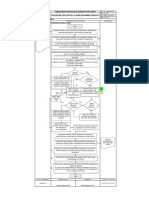

QMS-065 Manufacturing Rework Procedure

Flowchart – Rework Process Flow

Process deviation or quality

concern raised

DR raised

Rework required?

QA to assess

QA approve for rework to go Critical product defect? Only QAM approve for

ahead rework to go ahead

Production planner is to

schedule a rework

In-Process Manufactured Manufactured Finished

Goods (IPMG) Goods (MFG)

Planner to create rework

QA to raise a rework

RBPN

protocol, TEM-125

QA to raise a rework

Protocol approved and protocol, TEM-115

signed off

Protocol approved and

signed off

Rework done

Production to request goods

Completed Rework Protocol to transfer from warehouse.

included in the batch Use ‘Goods Return for

documents Rework Form’

Warehouse picks and send

goods/material as requested

Rework done. Retention

sample kept.

Completed Rework Protocol

included in the batch

documents

You might also like

- P2P Test Scenario ListDocument5 pagesP2P Test Scenario Listnani2003No ratings yet

- Rework & Repair ProcedureDocument1 pageRework & Repair ProcedureManu Sharma100% (5)

- QMS 065 Manufacturing Rework Procedure SampleDocument5 pagesQMS 065 Manufacturing Rework Procedure Sampleevil genius100% (1)

- Deploying aspenONE V10 With SCCM Best PracticesDocument56 pagesDeploying aspenONE V10 With SCCM Best Practicesryan sandi100% (1)

- Annexure A - Draft Formal Report - Agst Knysna Mun - Procurement From Knysna T..Document50 pagesAnnexure A - Draft Formal Report - Agst Knysna Mun - Procurement From Knysna T..Sune Payne- Daily MaverickNo ratings yet

- QAD Procedure - Inspection & Testing (Inprocess & Final Inspection)Document1 pageQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)suman100% (2)

- PEIPL-SOP-01 For Incoming Material Insp.Document1 pagePEIPL-SOP-01 For Incoming Material Insp.Balkishan DyavanapellyNo ratings yet

- QSP Qad 08Document2 pagesQSP Qad 08prabha_1No ratings yet

- PPAP IV Edition TrainingDocument38 pagesPPAP IV Edition Trainingshariq warsi100% (1)

- Sample Procedure FlowDocument3 pagesSample Procedure Flowvyly1723No ratings yet

- In Process Inspection Stage Flow Chart: Spacechem EnterprisesDocument6 pagesIn Process Inspection Stage Flow Chart: Spacechem EnterprisesSourav SharmaNo ratings yet

- Sop-47 F5 Product Stability ProtocollDocument1 pageSop-47 F5 Product Stability Protocollketone acidNo ratings yet

- Work Centers and Storekeeping: (FG) WarehouseDocument4 pagesWork Centers and Storekeeping: (FG) WarehouseFatima Erica I. DatumangudaNo ratings yet

- Interaction of ProcessesDocument1 pageInteraction of ProcessesBharath100% (1)

- System Improvment FormDocument2 pagesSystem Improvment FormAdnan AkramNo ratings yet

- Magna Electronics (MEI) - 4 Phases of APQP For Supplier Development EngineeringDocument20 pagesMagna Electronics (MEI) - 4 Phases of APQP For Supplier Development EngineeringBob Zepfel100% (4)

- A Simplified Commissioning L - 2012 - Chemical and Process Plant Commissioning HDocument1 pageA Simplified Commissioning L - 2012 - Chemical and Process Plant Commissioning HGabriel BarretoNo ratings yet

- Development Time LineDocument1 pageDevelopment Time LineMohitrajranikashyapNo ratings yet

- 888 S4HANA1709 Process Overview EN USDocument4 pages888 S4HANA1709 Process Overview EN USRicardo SepulvedaNo ratings yet

- Management System Manual: Title Doc. No. ProcessDocument2 pagesManagement System Manual: Title Doc. No. ProcessZina CabreraNo ratings yet

- Turtle Diagram StoreDocument1 pageTurtle Diagram StoreRiyu Rathod0% (1)

- Quality Control Three StagesDocument1 pageQuality Control Three Stagesfouad elferdiNo ratings yet

- JitDocument2 pagesJitmobylayNo ratings yet

- QP-ENG-PRC-008 - QP Procedure For Site Acceptance Test - Rev 00Document13 pagesQP-ENG-PRC-008 - QP Procedure For Site Acceptance Test - Rev 00salem elhajNo ratings yet

- 207-04a - Control of Customer Supplied MaterialsDocument7 pages207-04a - Control of Customer Supplied MaterialsYusufNo ratings yet

- Process Validation Protocol of Granules For Oral AdministrationDocument6 pagesProcess Validation Protocol of Granules For Oral AdministrationRezaul haque himelNo ratings yet

- Guidelines For Manufacturers and TradersDocument46 pagesGuidelines For Manufacturers and TraderstesteNo ratings yet

- SAP QM Introduction DeckDocument22 pagesSAP QM Introduction DeckVikash RanjanNo ratings yet

- QSPIFCDocument3 pagesQSPIFCsathyabalaraman100% (1)

- Apqp Workbook PDF FreeDocument20 pagesApqp Workbook PDF FreeHazemNo ratings yet

- PPAP - 4th Edition - Course MaterialDocument18 pagesPPAP - 4th Edition - Course MaterialMy Dad My WorldNo ratings yet

- Ppap Iv EditionDocument19 pagesPpap Iv EditionpandajayNo ratings yet

- Quality Disruption Process AuditDocument11 pagesQuality Disruption Process AuditVorapoj Lertsuwunseri100% (1)

- 212-04a - INSPECTION AND TEST STATUSDocument5 pages212-04a - INSPECTION AND TEST STATUSYusufNo ratings yet

- Rework Processing (Stock-Manufactured Material) - 2GGDocument4 pagesRework Processing (Stock-Manufactured Material) - 2GGsowjanyaNo ratings yet

- QAD Procedure - Control of Non-Conforming Products P2Document2 pagesQAD Procedure - Control of Non-Conforming Products P2sumanNo ratings yet

- Final CommisionDocument11 pagesFinal CommisionSam MNo ratings yet

- ARI.022 - PMAR.307 - Agile Change Control ProcessDocument3 pagesARI.022 - PMAR.307 - Agile Change Control ProcessCleberton Antunes100% (1)

- MRM - Jan-2015Document8 pagesMRM - Jan-2015RajVardhanNo ratings yet

- Authorizations: HMIQP-1012 - Product TraceabilityDocument2 pagesAuthorizations: HMIQP-1012 - Product TraceabilityAKNo ratings yet

- Weekly Working Report: Sr. # Task Description Details Section StatusDocument2 pagesWeekly Working Report: Sr. # Task Description Details Section StatusSaAhRaNo ratings yet

- As Is - Inspection and GRN - Paper CoreDocument1 pageAs Is - Inspection and GRN - Paper CoreYousuf KhanNo ratings yet

- 211-04a - CONTROL OF INSPECTION, MEASURINGDocument7 pages211-04a - CONTROL OF INSPECTION, MEASURINGYusufNo ratings yet

- 39) Procedure For Inspection & Testing - 104931Document5 pages39) Procedure For Inspection & Testing - 104931Sagar DaundNo ratings yet

- 215-04a - HANDLING, STORAGE, PACKAGING, PRESERVATION AND DELIVERYDocument8 pages215-04a - HANDLING, STORAGE, PACKAGING, PRESERVATION AND DELIVERYyusuf.yuzuakNo ratings yet

- Understanding Internal ControlsDocument31 pagesUnderstanding Internal ControlsVenus Lyka LomocsoNo ratings yet

- 210-05 - Inspection and TestingDocument13 pages210-05 - Inspection and TestingYusufNo ratings yet

- Factory Acceptance Test Procedure For DCS - Page 1Document2 pagesFactory Acceptance Test Procedure For DCS - Page 1kapsarcNo ratings yet

- DTP - Supplier Management SOP QA.008Document13 pagesDTP - Supplier Management SOP QA.008Faizah LokmanNo ratings yet

- Lims Sap Integration PDF FreeDocument24 pagesLims Sap Integration PDF FreePavan ReddyNo ratings yet

- 206-05 - ProcurementDocument10 pages206-05 - ProcurementYusufNo ratings yet

- Procedure For EcnDocument8 pagesProcedure For EcnChintamani GiramkarNo ratings yet

- OBJECTIVE 2018-2019: Employee Name: Muhammad UmairDocument2 pagesOBJECTIVE 2018-2019: Employee Name: Muhammad Umairrafiq noorNo ratings yet

- VQCA Guideline For Suppliers Brief SummaryDocument34 pagesVQCA Guideline For Suppliers Brief SummaryYeimy CorredorNo ratings yet

- Chapter8Document6 pagesChapter8surajNo ratings yet

- Customer Complaint HandlingDocument7 pagesCustomer Complaint HandlingpapplionNo ratings yet

- Buffco Eng AS9100 Quality Manual 2-28-06Document26 pagesBuffco Eng AS9100 Quality Manual 2-28-06savlafNo ratings yet

- SIPOC TemplateDocument3 pagesSIPOC TemplatesadaNo ratings yet

- Technology Transfer Plan & Exhibit TJDocument19 pagesTechnology Transfer Plan & Exhibit TJTejashreeNo ratings yet

- H84 Scen Overview EN DEDocument34 pagesH84 Scen Overview EN DEssahu1979No ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- Каталог ССК и инструментаDocument162 pagesКаталог ССК и инструментаШилоNo ratings yet

- Change Management & Leadership: Diploma in Business Management - Level 6Document20 pagesChange Management & Leadership: Diploma in Business Management - Level 6Aayush AnejaNo ratings yet

- Brookes Pharma DONEDocument14 pagesBrookes Pharma DONEmisbah khanNo ratings yet

- Minimum Viable Product (For Disribution)Document25 pagesMinimum Viable Product (For Disribution)Yash Aggarwal BD20073No ratings yet

- Uns W Student GuideDocument27 pagesUns W Student Guidemmm123No ratings yet

- Ceo at 22 Book v1.0Document177 pagesCeo at 22 Book v1.0eruditebookkeepingNo ratings yet

- Boat 235V2 Fast Charging Bluetooth Headset: Grand Total 1199.00Document1 pageBoat 235V2 Fast Charging Bluetooth Headset: Grand Total 1199.00AjayNo ratings yet

- Eng - Osama BadrDocument3 pagesEng - Osama BadrAmr GodaNo ratings yet

- Mec 8910a Lecture 6Document59 pagesMec 8910a Lecture 6Miguel HenaoNo ratings yet

- DEED OF ABSOLUTE SALE - SampleDocument2 pagesDEED OF ABSOLUTE SALE - SampleRoland Rosales100% (1)

- NAIR Webinar - TPI SystemDocument2 pagesNAIR Webinar - TPI Systemtommaverick154No ratings yet

- Branding of Industrial ProductsDocument5 pagesBranding of Industrial ProductsvishwajeetarivastavNo ratings yet

- Internship Under CA Final ReportDocument22 pagesInternship Under CA Final ReportChahatNo ratings yet

- IMPORTANT INFORMATION - : Baggage AllowanceDocument2 pagesIMPORTANT INFORMATION - : Baggage AllowanceHla Cho HtutNo ratings yet

- State The Reasons Behind The Failure of Xerox and NokiaDocument4 pagesState The Reasons Behind The Failure of Xerox and NokiaSyed NomanNo ratings yet

- God's Grace Forex BookDocument11 pagesGod's Grace Forex BookMatimu Nene ChabalalaNo ratings yet

- Nike LawsuitDocument24 pagesNike LawsuitJ RohrlichNo ratings yet

- Seattle Greenwell: ExperienceDocument1 pageSeattle Greenwell: Experienceseattle greenwellNo ratings yet

- SS - (535 - 550) - 72MTF SunovaDocument2 pagesSS - (535 - 550) - 72MTF SunovaPaulo Henrique SantosNo ratings yet

- Business Practices ofDocument5 pagesBusiness Practices ofAbid FerdowsNo ratings yet

- Umali Quiz For Ra 9266Document2 pagesUmali Quiz For Ra 9266Rogelio MaligayaNo ratings yet

- Resume-Pramod-Bhupathi TeamconnectDocument3 pagesResume-Pramod-Bhupathi TeamconnectHaseeb KhanNo ratings yet

- PHC Tech BrochureDocument9 pagesPHC Tech BrochuretanmaysutariaNo ratings yet

- TAXATIONDocument23 pagesTAXATIONJessica AragonNo ratings yet

- Cheries Business PlanDocument5 pagesCheries Business PlanCheries Jane MoringNo ratings yet

- 2020 PDFDocument7 pages2020 PDFNaveen R J JamesNo ratings yet

- ABB Robot Control S4C or S4P in Conjunction With WAGO Profibus Components 750-303 and 750-301Document12 pagesABB Robot Control S4C or S4P in Conjunction With WAGO Profibus Components 750-303 and 750-301Diogo CoelhoNo ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)