Professional Documents

Culture Documents

Ark Procedure-A

Ark Procedure-A

Uploaded by

Ansaf AskyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ark Procedure-A

Ark Procedure-A

Uploaded by

Ansaf AskyCopyright:

Available Formats

A R K P R E FA B C o .

, LT D

1. PROCEDURE

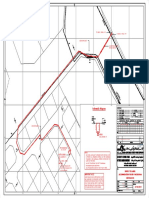

1.1 Flow chart of container assembly and installation

1.2 Mobilization

• RLIC Work permits (e-CPW) shall be obtained prior to any work being executed.

Work shall commence in accordance with the specific measures itemized in the

permit.

• Prefabricated building parts and trans-pack containers to be assembled will be

dispatched to the site.

• The construction area of the building to be assembled and the area for the

material storage should be kept clean, tied, and barricaded.

• The necessary hand tools and equipment shall be kept ready at the site before

the installation works will start.

上海浦东绣川路 581 号 A 座 701 室

RM. 701, BLOCK A,NO. 581 XIUCHUAN RD.,PUDONG,SHANGHAI,PRC

T:+86(0) 21 60838082 F:+86(0) 21 60838081

www.arkprefab.com

A R K P R E FA B C o . , LT D

1.3 Unloading of Material

• Certified lifting equipment shall be used for the operations and all related

equipment shall be inspected and approved by authorized personnel before the

work is started.

• Assembly boxes and container trans-packs of the related building will be

unloaded at the site using a crane and forklift in accordance with the unloading

instructions.

• Non-authorized personnel should not stay around the crane during lifting

operations while trans packs and other materials are unloaded.

• Steel members and panel packages should be laid over metal or wooden wedges

to prevent probable contact with water.

• Proximity to the assembly area will be taken into consideration to provide less

effort and time during site transportation and assembly.

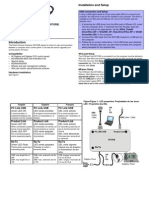

Figure-1

Panel Type:G1/M1/P1 etc

Roof / Floor type:ARKUxxxxxx

• All dispatched materials and components shall be checked in terms of quantity and quality

and then shall be classified according to the checklists and loading lists.

• In case any missing and/or damaged material is detected, non‐conformity report should be

prepared, and the manufacturer should be notified with the relevant photos and documents.

上海浦东绣川路 581 号 A 座 701 室

RM. 701, BLOCK A,NO. 581 XIUCHUAN RD.,PUDONG,SHANGHAI,PRC

T:+86(0) 21 60838082 F:+86(0) 21 60838081

www.arkprefab.com

A R K P R E FA B C o . , LT D

1.4 Building Assembly and Installation

9.4.1 Unbolting Packing Parts

• Before the column assembly, container pack components shall be dismantled.

• Bolts & nuts used for the packs should be kept carefully to be used during the column assembly.

9.4.2 Corner Column & Roof Chassis Assembly

• Before the corner column assembly, roof chassis shall be lifted from 4 lifting points as shown in the

Figure 2. Proper connection between the lifting hook and lifting plate needs tobe obtained and checked

before the lifting operation.

Figure 2

上海浦东绣川路 581 号 A 座 701 室

RM. 701, BLOCK A,NO. 581 XIUCHUAN RD.,PUDONG,SHANGHAI,PRC

T:+86(0) 21 60838082 F:+86(0) 21 60838081

www.arkprefab.com

A R K P R E FA B C o . , LT D

• Corner columns shall be placed to each four corner of the container and after proper

placement, all columns will be fixed to the base and roof chassis by bolts & nuts as shown

in the Figure 3.

Figure 3

上海浦东绣川路 581 号 A 座 701 室

RM. 701, BLOCK A,NO. 581 XIUCHUAN RD.,PUDONG,SHANGHAI,PRC

T:+86(0) 21 60838082 F:+86(0) 21 60838081

www.arkprefab.com

A R K P R E FA B C o . , LT D

9.4.3 External and Internal Wall Panel Assembly

• Before the assembly of panels, insulation material (rockwool) of the related columns

shouldbe placed as shown in the Figure 4.

Figure 4

• External panels shall be assembled as per the wall panel layout of each different module.

Assembly should be started from one edge and each panel end should be pass into each

other as shown Figure 5.

Figure 5

• Window & doors will be installed onto the panel as window / door panel, will also be

installed as per the wall panel layout of each different module.

上海浦东绣川路 581 号 A 座 701 室

RM. 701, BLOCK A,NO. 581 XIUCHUAN RD.,PUDONG,SHANGHAI,PRC

T:+86(0) 21 60838082 F:+86(0) 21 60838081

www.arkprefab.com

A R K P R E FA B C o . , LT D

• After the placement of all, the panels should sit onto the floor chassis by channel

and be fixed to the roof by thehelp of wall panel top claps, fixed to the columns by

screws as shown Figure 6

Figure 6

• Before the assembly of internal walls, 30x30 ‘L’ Profile should be fixed to the ceiling

cladding and structure (where possible) and to the base chassis as shown Figure 7A

andFigure 7B.

Figure 7A

上海浦东绣川路 581 号 A 座 701 室

RM. 701, BLOCK A,NO. 581 XIUCHUAN RD.,PUDONG,SHANGHAI,PRC

T:+86(0) 21 60838082 F:+86(0) 21 60838081

www.arkprefab.com

A R K P R E FA B C o . , LT D

Figure 7B

• After L Profiles assembly, internal panels are assembled as per the wall panel layout

of each module. Assembly should be started from one edge and each panelend

should be pass into each other as shown Figure 8.

Figure 8

上海浦东绣川路 581 号 A 座 701 室

RM. 701, BLOCK A,NO. 581 XIUCHUAN RD.,PUDONG,SHANGHAI,PRC

T:+86(0) 21 60838082 F:+86(0) 21 60838081

www.arkprefab.com

A R K P R E FA B C o . , LT D

1.5 Containerized Module Assembly

• Starting module assembly from one side of the building can be a good practice

to control the possible elongations. Modules should be unloaded in order of

assembly orinstalled directly from the truck.

• Each module is lifted on its spot. Guiding parts should be used to get the modular

elementto the right spot and to stay within installation tolerances. Marking assembly

points for the modules before the assembly can also be used as a method.

• Once it is ensured that the place and position of the module is within tolerance,

adjacentmodule can be placed.

• Modules and panel of modules should be made according to layout in assembly drawing.

• After the module placement is finished, the modules should be fixed to each other

using the linking plates and bolts as shown Figure 9.

Figure 9

• Also modules should be anchored to the ground.

• External & internal vertical and horizontal joints between the adjacent modules

must be sealed with rubber seals as shown Figure 10.

Figure 12

上海浦东绣川路 581 号 A 座 701 室

RM. 701, BLOCK A,NO. 581 XIUCHUAN RD.,PUDONG,SHANGHAI,PRC

T:+86(0) 21 60838082 F:+86(0) 21 60838081

www.arkprefab.com

A R K P R E FA B C o . , LT D

1.6 Trim Assembly

• Closure assembly should be according to closure layout, so closure layout

should beexamined carefully before assembly.

Figure 13

Figure 14

• Insulation material (rockwool) should be used to under closure.

• Before the installation of closures to the joints of adjacent modules, rockwool

insulationshould be used as an infill material.

上海浦东绣川路 581 号 A 座 701 室

RM. 701, BLOCK A,NO. 581 XIUCHUAN RD.,PUDONG,SHANGHAI,PRC

T:+86(0) 21 60838082 F:+86(0) 21 60838081

www.arkprefab.com

A R K P R E FA B C o . , LT D

1.7 Roof Installation

• First the steel frames are assembled in a clear area away from the building, as per

theassembly drawings.

• Roof supports are then fixed onto the containerized units.

• The assembled frames are then lifted to the building with a crane and fixed onto the

roofsupports.

• All workers in the building rood must always maintain 100% tie off.

• Once the steel framing has been installed on the roof. One crew will commence

alignmentand installation of corrugated sheeting. A second crew will follow behind

the first crew andinstall the flashing.

• Manlift will be used for the flashing installation.

ISO 272 Strength classes for steel bolts per ISO 898-1

diameter pitch wrench

ISO

Ø mm mm mm Cs Fo Cs Fo Cs Fo Cs Fo Cs Fo Cs Fo Cs Fo

1,6** 0,35 3,2 0,075 234 0,105 327 0,12 374 0,16 499 0,18 561 0,235 732 0,275 857

2** 0,4 4 0,159 388 0,222 544 0,254 621 0,339 829 0,381 932 0,498 1 217 0,582 1 424

1 1

2,5** 0,45 5 0,33 648 0,463 907 0,529 0,705 1 382 0,793 1,04 2 030 1,21 2 375

036 555

1 1 2

3 0,5 5,5 0,57 972 0,8 362 0,91 556 1,21 2 075 1,38 335 1,79 3 048 2,09 3 567

1 2 2 4

4 0,7 7 1,3 1,83 2,09 2,78 3 594 3,16 4,09 5 279 4,79 6 178

685 359 696 044

2 3 4 6 10

5 0,8 8 2,59 759 3,62 862 4,14 414 5,5 5 886 6,27 626 8,1 8 645 9,5 116

3 5 6 9 12 14

6 1 10 4,49 6,2 7,1 9,5 8 302 10,84 14 16,4

891 448 226 334 194 269

7 10 11 15 17 22 26

8 1,25 13 10,9 145 15,2 003 17,4 432 23 242 26,34 146 34 388 40 198

上海浦东绣川路 581 号 A 座 701 室

RM. 701, BLOCK A,NO. 581 XIUCHUAN RD.,PUDONG,SHANGHAI,PRC

T:+86(0) 21 60838082 F:+86(0) 21 60838081

www.arkprefab.com

A R K P R E FA B C o . , LT D

11 15 18 24 27 35 41

10 1,5 16 21 30 34 46 52 67 79

379 930 206 275 313 655 724

16 23 26 35 39 51 60

12 1,75 18 37 594 52 231 59 550 79 401 90 835 116 995 136 845

22 31 36 48 54 71 83

14 2 21 59 789 83 905 95 463 127 618 143 570 187 408 219 563

31 43 50 66 75 98 115

16 2 24 93 385 130 939 148 216 198 955 224 422 291 340 341 079

38 53 60 83 119 139

18 2,5 27 128 123 179 373 205 998 283 746 402 454 471 787

49 68 78 107 153 179

20 2,5 30 182 039 254 655 291 463 402 941 570 657 667 811

61 85 98 134 192 224

22 2,5 34 250 326 350 857 400 123 552 806 783 157 917 865

70 98 112 155 221 258

24 3 36 313 616 438 863 500 986 691 489 981 266 1 148 928

93 130 148 204 291 341

27 3 41 463 042 649 259 741 868 1 022 577 1 452 534 1 700 157

113 158 180 248 354 414

30 3,5 46 628 045 880 263 1 005 872 1 387 811 1 969 209 2 305 500

141 197 225 310 441 517

33 3,5 50 854 009 1 195 412 1 366 614 1 884 343 2 676 828 3 132 033

165 231 264 363 518 606

36 4 55 1 096 409 1 534 573 1 754 655 2 418 974 3 435 282 4 020 501

198 278 318 437 623 729

39 4 60 1 424 910 1 994 474 2 279 257 3 139 669 4 463 253 5 223 339

227 318 364 500 713 834

42** 4,5 65 1 760 588 2 464 624 2 816 141 3 872 694 5 515 110 6 453 491

266 373 426 586 835 977

45** 4,5 70 2 203 613 3 085 258 3 525 580 4 847 548 6 903 386 8 079 579

299 419 479 658 938 1 098

48** 5 75 2 659 530 3 722 342 4 254 248 5 849 966 8 330 528 9 748 277

359 503 575 791 10 1 127 12 1 318

52** 5 80 3 425 684 4 795 558 5 480 495 7 335 306 731 011 558 843

上海浦东绣川路 581 号 A 座 701 室

RM. 701, BLOCK A,NO. 581 XIUCHUAN RD.,PUDONG,SHANGHAI,PRC

T:+86(0) 21 60838082 F:+86(0) 21 60838081

www.arkprefab.com

A R K P R E FA B C o . , LT D

415 581 664 913 13 1 300 15 1 522

56** 5,5 85 4 270 172 5 978 240 6 832 275 9 394 378 379 871 656 296

485 679 776 11 1 067 16 1 520 19 1 779

60** 5,5 90 5 306 416 7 428 583 8 490 666 673 916 625 971 455 860

548 768 10 878 14 1 207 19 1 720 23 2 012

64** 6 95 6 382 969 8 935 556 212 350 041 731 998 102 402 885

*Class 8-8a up to Ø 16 mm, 8-8b for Ø 18 mm and above. ** Values per Fr. Std. E 25-030.

Tensile load (Fo)

The force in newtons (N) which maintains pressure contact between assembled components.

Tightening torque (Cs) [ values are in N·m ]

The product of a force and the leverage length at which it is applied: Torque (N·m) = Force (in newtons) x Length (in metres).

Note: per european conventional usage; the comma ( , ) is used as the decimal point ( . ) in these charts

上海浦东绣川路 581 号 A 座 701 室

RM. 701, BLOCK A,NO. 581 XIUCHUAN RD.,PUDONG,SHANGHAI,PRC

T:+86(0) 21 60838082 F:+86(0) 21 60838081

www.arkprefab.com

You might also like

- Method Statement For Precast Boundary Wall WorksDocument5 pagesMethod Statement For Precast Boundary Wall WorksRsjBugtong100% (1)

- Anchor Bolt MSDocument7 pagesAnchor Bolt MSGaneshNo ratings yet

- Method Statement For PILINGDocument7 pagesMethod Statement For PILINGcworld86% (7)

- Method Statement For Mock-Up InstallationDocument17 pagesMethod Statement For Mock-Up InstallationshareyhouNo ratings yet

- Method Statement Fo Method Statement For Precast Boundary Wall Worksr Precast Boundary Wall WorksDocument5 pagesMethod Statement Fo Method Statement For Precast Boundary Wall Worksr Precast Boundary Wall Workscprelator100% (3)

- Tank Erection ProcedureDocument15 pagesTank Erection Procedurejohney294% (16)

- Method Statement AbutmentDocument9 pagesMethod Statement AbutmentRamesh Joshi100% (2)

- How to Build a Global Model Earthship Operation II: Concrete WorkFrom EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- ls10 30,40 PDFDocument105 pagesls10 30,40 PDFJohnny Martinez100% (1)

- Tank Erection ProcedureDocument13 pagesTank Erection ProcedureAshokkumar ThangarajNo ratings yet

- K SpanDocument36 pagesK SpanMerve MerveNo ratings yet

- Method of StatementDocument23 pagesMethod of StatementChad SoribelloNo ratings yet

- 02 Construction Guide For TankDocument16 pages02 Construction Guide For TankARABONo ratings yet

- Precast Substructure SpecificationDocument7 pagesPrecast Substructure SpecificationTimothy CruseNo ratings yet

- Work Procedure For STB Steel ErectionDocument108 pagesWork Procedure For STB Steel ErectionLeo PascualNo ratings yet

- Method Statement For For Cable Tray and Conduit Installation With Risk AssesmentDocument9 pagesMethod Statement For For Cable Tray and Conduit Installation With Risk Assesmentobasiigwe8499100% (1)

- Method Statement For Fabrication of Steel WorksDocument10 pagesMethod Statement For Fabrication of Steel WorksB S ArunNo ratings yet

- Steel Erection MethodologyDocument26 pagesSteel Erection MethodologyLiniel de JesusNo ratings yet

- MP Tec Assembly Manual SnowflakeDocument12 pagesMP Tec Assembly Manual SnowflakeKarbonKaleNo ratings yet

- Scope of WorkDocument1 pageScope of WorkSam MacerinNo ratings yet

- Methodology of PSC Girder StressingDocument8 pagesMethodology of PSC Girder StressingRavikant TyagiNo ratings yet

- Erection ProceduresDocument7 pagesErection ProceduresIbrahim AlsayedNo ratings yet

- Method Statement - DEMOLITION BUILDING - FENCINGDocument7 pagesMethod Statement - DEMOLITION BUILDING - FENCINGprisma integratedNo ratings yet

- Method of statement Structural Steel work for Securty TowerDocument8 pagesMethod of statement Structural Steel work for Securty TowerAkram Al SayabNo ratings yet

- Erection MOSDocument11 pagesErection MOSmothafur.abuasbaNo ratings yet

- 1.MS - FoundationDocument11 pages1.MS - FoundationMalik BilalNo ratings yet

- Sequatchie Concrete Service: Precast Prestressed Hollow Core Concrete Floor and Roof Systems Design ManualDocument31 pagesSequatchie Concrete Service: Precast Prestressed Hollow Core Concrete Floor and Roof Systems Design ManualNirmal KishorNo ratings yet

- Drainnage Piping SystemDocument9 pagesDrainnage Piping SystemqaqcmepteamNo ratings yet

- 1 - MS-PVC Conduitingaccessories Installation WorksDocument6 pages1 - MS-PVC Conduitingaccessories Installation WorksAraf KalamNo ratings yet

- Method Statement: ApprovalDocument21 pagesMethod Statement: ApprovalzhanghuiNo ratings yet

- General Method Statement NewDocument4 pagesGeneral Method Statement NewSaju Varughese InventureNo ratings yet

- MJ Idarro 2Document47 pagesMJ Idarro 2AbudaFrancisNo ratings yet

- 02-FOT-MS-Block Works - Rev.0Document5 pages02-FOT-MS-Block Works - Rev.0rachidassaad91No ratings yet

- NIDAA METHOD STATEMENT - Concrete work - DraftDocument7 pagesNIDAA METHOD STATEMENT - Concrete work - DraftAkram Al SayabNo ratings yet

- Method of Statements - Precast WallDocument17 pagesMethod of Statements - Precast WallEd Salanga100% (3)

- Fabrication ProcedureDocument7 pagesFabrication ProcedureokkymparNo ratings yet

- Procedure For Steel Structure: Fabrication & ErectionDocument2 pagesProcedure For Steel Structure: Fabrication & ErectionnksNo ratings yet

- Section 09250Document9 pagesSection 09250Im ChinithNo ratings yet

- Cap InstallationDocument32 pagesCap InstallationLucio CastrillonNo ratings yet

- Erection Manual With ProtocolsDocument18 pagesErection Manual With ProtocolsPankaj KumarNo ratings yet

- INSTALLATION - Anchor BoltsDocument8 pagesINSTALLATION - Anchor BoltsScribdTranslationsNo ratings yet

- Mos For Pilling Foundation - SucDocument9 pagesMos For Pilling Foundation - SucEngr Muhammad Azam ThaheemNo ratings yet

- Manhole Installation Guide PDFDocument68 pagesManhole Installation Guide PDFLovepreet Singh100% (1)

- Bored Cast-In Situ PilesDocument7 pagesBored Cast-In Situ PilesPathankot MandiNo ratings yet

- 2 R-ME-MS-002 Method Statement of Penstock InstallationDocument23 pages2 R-ME-MS-002 Method Statement of Penstock Installationrotimi olalekan fatai100% (1)

- Central Business District of The New Administrative Capital: Prestressed Concrete Construction 348313 - Page of 10Document11 pagesCentral Business District of The New Administrative Capital: Prestressed Concrete Construction 348313 - Page of 10lf chNo ratings yet

- SECTION 08100 Metal Doors and Frames Part 1 - General 1.1Document4 pagesSECTION 08100 Metal Doors and Frames Part 1 - General 1.1Im ChinithNo ratings yet

- 132kv ProgressDocument5 pages132kv Progressbee398No ratings yet

- Personal Protective Equipment (Ppe) (Ohs Code Part 18, Personal Protective Equipment)Document6 pagesPersonal Protective Equipment (Ppe) (Ohs Code Part 18, Personal Protective Equipment)AnbralerNo ratings yet

- Faculty of Civil EngineeringDocument12 pagesFaculty of Civil EngineeringAnang SdjNo ratings yet

- Method Statement of Pipe RackDocument8 pagesMethod Statement of Pipe RackLEIXIAO ZHANGNo ratings yet

- Performance Specification For Post Tensioned Works.Document15 pagesPerformance Specification For Post Tensioned Works.Tharanga PradeepNo ratings yet

- H-6745 00 Mef 00 081 DCDocument33 pagesH-6745 00 Mef 00 081 DCfuad aliNo ratings yet

- MS For FormworksDocument6 pagesMS For FormworksShan THALANo ratings yet

- Guide Lines For Erection of Verticallift GatesDocument46 pagesGuide Lines For Erection of Verticallift GatesMahipal Reddy100% (1)

- Methodology: Contractors Engineers ConsultantsDocument1 pageMethodology: Contractors Engineers Consultantsᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔No ratings yet

- Erection and Painting of Steel StructureDocument11 pagesErection and Painting of Steel StructureomarcadNo ratings yet

- Installation of Girders and BeamsDocument11 pagesInstallation of Girders and BeamsVladimir Ramos CariNo ratings yet

- Switchboard & PanelboardDocument8 pagesSwitchboard & PanelboardWalidNo ratings yet

- PKG02 Aihssb S612 SD El Fa 0009Document1 pagePKG02 Aihssb S612 SD El Fa 0009Ansaf AskyNo ratings yet

- PKG02 Asssg S711 SD El Fa 0012Document1 pagePKG02 Asssg S711 SD El Fa 0012Ansaf AskyNo ratings yet

- 건축표준품셈 (001-020) ko enDocument20 pages건축표준품셈 (001-020) ko enAnsaf AskyNo ratings yet

- Market Research For The Last BatchDocument5 pagesMarket Research For The Last BatchAnsaf AskyNo ratings yet

- Lifting Station 3Document1 pageLifting Station 3Ansaf AskyNo ratings yet

- PKG02 Asssg S711 SD El Fa 0013Document1 pagePKG02 Asssg S711 SD El Fa 0013Ansaf AskyNo ratings yet

- Model 1Document1 pageModel 1Ansaf AskyNo ratings yet

- HAMAD KITCHEN - OneDriveDocument1 pageHAMAD KITCHEN - OneDriveAnsaf AskyNo ratings yet

- Cables and Pipelines, 11Document19 pagesCables and Pipelines, 11Ansaf AskyNo ratings yet

- Camp-Basket Ball Court Lighting PlanDocument1 pageCamp-Basket Ball Court Lighting PlanAnsaf AskyNo ratings yet

- WAH Rescue Plan - W10 Tress & Roof Works - 25.03.2023Document3 pagesWAH Rescue Plan - W10 Tress & Roof Works - 25.03.2023Ansaf AskyNo ratings yet

- Camp-Foot Ball Ground Lighting PlanDocument1 pageCamp-Foot Ball Ground Lighting PlanAnsaf AskyNo ratings yet

- Quotaion SummaryDocument1 pageQuotaion SummaryAnsaf AskyNo ratings yet

- Schematic Diagram: Supply To Labor Accommodation For BP # M/2020/466 Abal GarareesDocument1 pageSchematic Diagram: Supply To Labor Accommodation For BP # M/2020/466 Abal GarareesAnsaf AskyNo ratings yet

- Camp-Vally Ball Court Lighting PlanDocument1 pageCamp-Vally Ball Court Lighting PlanAnsaf AskyNo ratings yet

- Cricket Match 2023Document8 pagesCricket Match 2023Ansaf AskyNo ratings yet

- Labour RatesDocument2 pagesLabour RatesAnsaf AskyNo ratings yet

- 22-NFXP-RLIC-QGC-RLC-TML-00793 - Potable Water Hydrotest Package For EPC Camp 2Document1 page22-NFXP-RLIC-QGC-RLC-TML-00793 - Potable Water Hydrotest Package For EPC Camp 2Ansaf AskyNo ratings yet

- IQSSL (L3) Course Work 2022 - Contract ManagementDocument6 pagesIQSSL (L3) Course Work 2022 - Contract ManagementAnsaf AskyNo ratings yet

- FF & Drainage WorksheetDocument3 pagesFF & Drainage WorksheetAnsaf AskyNo ratings yet

- WAH Rescue Plan - W10 Tress & Roof Works - 25.03.2023Document3 pagesWAH Rescue Plan - W10 Tress & Roof Works - 25.03.2023Ansaf AskyNo ratings yet

- Tools - Consumables-Nov-22-Altron - Al-KhorDocument2 pagesTools - Consumables-Nov-22-Altron - Al-KhorAnsaf AskyNo ratings yet

- Steel Cable TrayDocument41 pagesSteel Cable TrayAnsaf AskyNo ratings yet

- Job Costing SampleDocument37 pagesJob Costing SampleAnsaf AskyNo ratings yet

- Minutes of Meeting - ALTRONDocument3 pagesMinutes of Meeting - ALTRONAnsaf AskyNo ratings yet

- Electrical RatesDocument14 pagesElectrical RatesAnsaf AskyNo ratings yet

- Clearance List For ActivitiesDocument1 pageClearance List For ActivitiesAnsaf AskyNo ratings yet

- BOQ and Rates Oil GasDocument93 pagesBOQ and Rates Oil GasAnsaf AskyNo ratings yet

- Form of Schedule - RayDocument6 pagesForm of Schedule - RayAnsaf AskyNo ratings yet

- FormatDocument27 pagesFormatAnsaf AskyNo ratings yet

- Manual de Servicio Aiwa+Nsx Sz80+Nsx Sz83+Nsx Aj80+Nsx Sz80eDocument47 pagesManual de Servicio Aiwa+Nsx Sz80+Nsx Sz83+Nsx Aj80+Nsx Sz80eCarlos Jesus SerranoNo ratings yet

- TRP 3145Document3 pagesTRP 3145Petcu MariusNo ratings yet

- Fan - KDKDocument2 pagesFan - KDKmitra perkasa multigunaNo ratings yet

- FDocument10 pagesFSans lucas HoyamaNo ratings yet

- Bridge Erection MethodDocument9 pagesBridge Erection MethodChi-chi Rahayu HarikeNo ratings yet

- Unit 13 - Week 12: Assignment 12Document3 pagesUnit 13 - Week 12: Assignment 12Raushan KashyapNo ratings yet

- ETSI ES 201 235-3: Specification of Dual Tone Multi-Frequency (DTMF) Transmitters and Receivers Part 3: ReceiversDocument12 pagesETSI ES 201 235-3: Specification of Dual Tone Multi-Frequency (DTMF) Transmitters and Receivers Part 3: Receivershadiranji4No ratings yet

- AIGA 012 - 04 - Cleaning of Equipment For Oxygen ServiceDocument60 pagesAIGA 012 - 04 - Cleaning of Equipment For Oxygen Serviceryanmakua100% (1)

- Chapter 2 ReviewDocument4 pagesChapter 2 ReviewSunnynightwingNo ratings yet

- Renr7167 02 01 All PDFDocument44 pagesRenr7167 02 01 All PDFИгорь СамоукинNo ratings yet

- McNichols 2023-3107148Document4 pagesMcNichols 2023-3107148Yaser Dario ContrerasNo ratings yet

- Basic Machine Tools: Nikunj PatelDocument23 pagesBasic Machine Tools: Nikunj PatelIshan Patel100% (1)

- SKH Metals LTD.: Process Control StanderdDocument2 pagesSKH Metals LTD.: Process Control StanderdshinuNo ratings yet

- 3410 Lecture Notes v1.0Document226 pages3410 Lecture Notes v1.0MICHAEL K. E. DonkorNo ratings yet

- BD646, BD648, BD650, BD652Document7 pagesBD646, BD648, BD650, BD652Alfredo Valencia RodriguezNo ratings yet

- 307usb Ti08Document2 pages307usb Ti08Salvador ZafraNo ratings yet

- Sdkandruntimeguide - Aix.70 7.0Document602 pagesSdkandruntimeguide - Aix.70 7.0Carlos SantiagosNo ratings yet

- Object Oriented Analysis and Design - SyllabusDocument1 pageObject Oriented Analysis and Design - SyllabusDeepa LakshmiNo ratings yet

- Ansi MV Ovcb Sdv7 Enclosure Im enDocument56 pagesAnsi MV Ovcb Sdv7 Enclosure Im enrhap_0925060No ratings yet

- Technical Data Accessories DEMAG DC-COM Chain Hoist PDFDocument40 pagesTechnical Data Accessories DEMAG DC-COM Chain Hoist PDFMarco SilvaNo ratings yet

- MNC Cos DataDocument3,627 pagesMNC Cos DataAditya Sharma100% (1)

- Convert Part Number SealDocument84 pagesConvert Part Number SealEko FebriyantoNo ratings yet

- Flyer English 2023Document20 pagesFlyer English 2023wshtoolsinternationalNo ratings yet

- Logic Pro X 10.4: Exam Preparation GuideDocument19 pagesLogic Pro X 10.4: Exam Preparation Guidemik logicNo ratings yet

- DEME Anual Report 2015Document72 pagesDEME Anual Report 2015Frank MartinezNo ratings yet

- Continuous Level Measurement Guided Wave Radar TransmittersDocument43 pagesContinuous Level Measurement Guided Wave Radar TransmittersAlen KušecNo ratings yet

- Bus Bar Voltage Drop Calculation: Bus Bar No SR - No Location Sub Panel No Power Line Length (MT) Line Current (Amp)Document6 pagesBus Bar Voltage Drop Calculation: Bus Bar No SR - No Location Sub Panel No Power Line Length (MT) Line Current (Amp)MANIKANDA100% (1)

- About Initial Solidification of Steel in Continuous CastingDocument9 pagesAbout Initial Solidification of Steel in Continuous CastingSoumya VaranasiNo ratings yet