Professional Documents

Culture Documents

Eng 163284747

Eng 163284747

Uploaded by

RamonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eng 163284747

Eng 163284747

Uploaded by

RamonCopyright:

Available Formats

Body builder instructions

Volvo Truck Corporation

Supersedes VBI Release 07 from Date 4.2022

Changes are marked with a bar (|) in the margin. Electricity

Main electrical preparation variants

FM (4), FH (4)

Contents

“Variant TAILPREP”, page 2

“Variant TAILPRE2”, page 2

“General (TAILPREP and TAILPRE2)”, page 3

“Function description for variant TAILPRE2”, page 4

“Connections for tail lift at end of frame (tractors, behind cab)”, page 5

“Schematic, electrical installation”, page 10

“Electrical tipper body preparation kit”, page 11

“Variant BEPR-T2”, page 11

“Work Remote tipper functionality”, page 13

“SPEED-DU – Electrical preparation kit for rear loaded vehicles”, page 21

“Function”, page 21

“Driver information”, page 21

“Connector in cab for RCV bodywork”, page 22

“Parameters for SPEED-DU”, page 25

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 1 (30)

All Rights Reserved

Main electrical preparation variants

Variant TAILPREP

The TAILPREP variant is a special preparation variant • Battery plus connector in frame rail (rigid trucks only).

developed for trucks to be equipped with tail lift. The TAILPREP variant uses and requires the variant

TAILPREP kit includes: BBCHAS1 or BBCHAS3. This means that the remain-

ing, unused, wires from the tail lift chassis connector

• A tail lift enables switch in the instrument panel. are available in the BBEC2 connector in body builder

In a truck equipped with “Work Remote”, Volvo’s Wire- electrical centre in the cab.

less remote control (variant REMC-MF) and BBM

(variants ECBB-MED/ECBB-HIG/ECBB-H12), the

tail lift can also be enabled from the Work Remote.

• An icon in the instrument display showing that the

tail lift is not closed.

T9070288

• Control wires to a 7-pole connector at end of frame

(behind the cab for tractors).

Variant TAILPRE2

Only available in combination with “Work Remote”, Volvo’s Wireless remote control (variant REMC-MF) and

BBM (variants ECBB-MED/ECBB-HIG/ECBB-HI2).

The TAILPRE2 version is a special preparation variant developed for trucks to be equipped with tail lift. TAILPRE2

includes:

• Tail lifting control support from Work Remote Control

• A tail lift enables switch on the instrument panel.

• An icon for “tail lift not closed” in the instrument display.

• Control wires to two 7 pole connectors at end of frame (for tractors behind the cab).

• Battery plus connector in frame rail (Rigid Only).

• A BBM unit with a special pinout to support tail lifting control.

Flexible switches for bodywork functions AUX3, AUX4 (in variant AESW2-PK) can be used together with the variant

TAILPRE2.

If the slide in/slide out function (retractable tail lifts) is not used, AUX5 and AUX6 (in variant AESW2-PK) can be used.

This is because the outputs from BBM for those switches are used for tail lifting control.

The TAILPRE2 variant uses and requires the variant BBCHAS3. This means that the remaining, unused, wires from the

tail lift chassis connector are available in the BBEC2 connector in body builder electrical centre in the cab. See the wiring

diagram for more information.

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 2 (30)

General (TAILPREP and TAILPRE2)

Refer to the “wiring diagram” document, page ND and

ND_VT5, for the complete wiring diagram.

The tail lift enable switch is located on the instrument pan-

el, in the area between the steering wheel and the driver T9070288

door.

The tail lift can be activated independently of the ignition key. A function LED in the switch indicates that either the switch

is activated or the tail lift is not in the closed position and the ignition is on.

When the tail lift is not in the closed position, regardless of whether the tail lift function is enabled or not, an icon will ap-

pear on the instrument display.

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 3 (30)

Function description for variant TAILPRE2

If the tail lift unit mounted to the truck supports remote

control, this variant can be used to enable and control the

tail lift from the Work Remote.

When the tail lift is enabled, either from the enable switch

on the instrument panel or from the Work Remote, by de-

fault the driver must use the external tail lifting control de-

vice to open or to fully close the tail lift. This is to avoid

unintentional movements of the tail lift. When a feedback

signal is transmitted from the tail lift to the truck (normally

when the tail lift is in a horizontal position +/- 10 degrees)

the Work Remote can be used to lift, lower or tilt the tail lift.

The body builder must ensure tilt movements of the tail lift T9080703

are stopped before the feedback signal to the truck is re-

moved. If this is not done, the user will be forced again to Work Remote Control.

use the external control device to move the tail lift back in-

to a position where a feedback signal is transmitted and

remote control is allowed.

This feature can be disabled by setting a parameter so

that the complete stroke of the tail lift can be controlled

from the Work Remote. Consider local requirements be-

fore changing this setting.

To control the tail lift from the Work Remote, the tail lift

menu must first be selected (the tail lift function will be au-

tomatically enabled when the tail lift menu is entered and

the selected conditions are fulfilled).

By default, an input from the tail lift to the truck that remote

control is permitted, must be present. If the input isn't

there, the following message will be shown.

This can be because it is not permitted to open the tail lift

from a completely closed position with the Work Remote

control. If the normal outdoor control device is to open the

tail lift to a position where the tail lift is providing a signal T9080742

to the truck informing that remote control is allowed.

Note: Some tail lifts have a built-in system-inhibiting opening and complete closing from a remote control. If so, the Work

Remote function will be disabled.

When there is a feedback signal to the truck that informing that the remote control is allowed (or the safety feature is dis-

abled) the view shown here will be displayed.

In this view, the tail lift can be controlled according to the following:

Action Description

Arrow up Lift the platform.

Arrow down Lower the platform

Arrow left Tilt up/close the platform.

Arrow right Tilt down/open the platform.

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 4 (30)

When the truck is equipped with Volvo Load Indicator, the

axle loads will be shown in the tail lift view.

T9080741

Depending on the vehicle type and axle configuration,

truck or trailer views can be selected.

If the tail lift is of the sliding type (and it supports remote

control), the Work Remote can be used. See AUX5 and

AUX6 in the AUX switch menu.

T9080743

Connections for tail lift at end of frame (tractors, behind cab)

Cables used to connect the tail lift to the chassis connectors BB1 and BB3.

These cables, which are found in the cab, are mounted (together with the B+ cable) by the body builder.

BB1/Connector 1, variants TAILPREP and TAILPRE2

Extension wire from connector BB1.

Pinout (connector according to DIN 72585)

Pin Note

1 + 24 V when switch in cab is activated.

Maximum load 4 A (fused 5 A from fuse 4 in A02P fuse box)

2 Free*. Wire size 1,5 mm2. Available in BBEC2:2

3 Free*. Wire size 1,5 mm2. Available in BBEC2:3

4 Free*. Wire size 1,5 mm2. Available in BBEC2:4

5 Free*. Wire size 1,5 mm2. Available in BBEC2:5

6 Tail lift not closed. Will turn on the “not closed tail lift” icon in the instrument display, when this wire is con-

nected to ground. DI L

7 Free. Wire size 1,5 mm2. Available in BBEC2:7

(*) In variant ECBB-HI2 (combination with BBIOM), these wires are used for connections to the BBIOM. Please refer to

wiring diagram ND5_VT for further detailed information.

Trucks with alarm

When variant TAILPREP or TAILPRE2 is selected in a truck with alarm, variant anti-theft alarm, a wire is pre-routed to

connector BB2, pin 1 in the chassis frame. With variant ALARM-B, this input is disabled. With variant ALARM-E, this in-

put is enabled. Parameter settings will determine if the alarm will be triggered when pin 1 (connector BB2) is connected

to ground, or if the alarm will be triggered when the connection to ground is interrupted.

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 5 (30)

BB3/Connector 2, variant TAILPRE2

Extension wire from connector BB3.

This is an extra control wire for tail lifting control from Wireless Remote Control.

Pin Description

1 Enable remote control. DI H from tail lift.

+24 V signal from tail lift when control from Work Remote is permitted (for example when tail lift is in hori-

zontal position +/- 10 degrees).

This function can be disabled setting a parameter making remote control be possible irrespective of the

input to this pin.

It is the tail lift manufacture’s responsibility to ensure that the tilt movement of the tail lift is stopped before

this input is removed; this makes it possible to tilt the tail lift back.

2 Tail lift up. DO H. Maximum power 1 A.

3 Tail lift slide out (AUX5). Maximum power 1 A.

4 Overload. Digital input high when the tail lift is overloaded.

5 Tail lift down. DO H. Maximum power 1 A.

6 Tail lift tilt. DO H. Maximum power 1 A.

7 Tail lift slide in (AUX6). DO H. Maximum power 1 A.

The tail lift must be equipped with the following connector to be able to connect to the extension cable from BB1/BB3.

Pin insulator

Description Dimension Part number

Insulator housing — 25371156

Lock ring — 3963413

Bullet terminal 0.5–1 mm2 984945

Wire seal 0.5–1 mm2 20734499 T3009603

Blanking plug, transparent — 970771

Mating connector for control wire

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 6 (30)

Power studs

For rigid trucks, the power stud (X25) is located within the

frame rail, behind the gearbox cross member. The stud is

supplied via a 35 mm2 wire from a 200 A body builder fuse

(FM1) in the battery box.

For tractors, power can be taken directly from the 200 A

fuse for body applications, located in the battery box.

T9093996

Ground connection

For rigid trucks, a ground stud is located on the right-hand side of the frame rail.

For tractors, a ground stud can be mounted on the right-hand side of the frame rail.

Volvo ground screw is according to the following table.

This screw requires a Ø15,7 mm hole.

Volvo ground screw, required parts

Part Part number

Screw 995041

Nut M14 992328

Nut M10 983716

Washer 994873

WARNING

If the power supply to a tail lift on a trailer is taken from

the truck, the body builder must ensure that the minus

connection from the tail lift to the truck is working cor-

rectly. If not, ground wires for trailer lighting can be

overloaded and severely damaged.

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 7 (30)

Parameters for tail lift

Parameter Description Min Default Max

code value

P1CXB Tail lift or Crane function, enable. 0 0/1 2

Default = Enabled in variants TAILPREP and TAILPRE2

0 = Functions disabled

1 = Tail lift enabled

2 = Crane enabled

P1JU2 Enable remote control of tail lift. 0 0/1 1

Default = Enabled in variant TAILPRE2

0 = Disabled

1 = Enabled

P1ILP Enable of tail lift or crane function in Work Remote. 0 0/1 2

Default = Tail lift enabled in variant TAILPRE2

0 = Functions disabled

1 = Tail lift enabled

2 = Crane enabled

P1CW9 Logic of tail lift enable switch (bistable or monostable switch 0 1 1

type)

0 = monostable switch

1 = Bistable switch

P1EAA Flexible switch ID 008 0 0/1 1

tail lift switch in cab diagnostics enabled

0 = Disabled

1 = Enabled

P1ITO Parking brake applied as condition to enable tail lift. 0 0 2

0 = No condition

1 = Applied as entry condition

2 = Entry & Exit condition

P1JGE Parking brake applied as condition to control tail lift motion from 0 0 1

Work Remote

0 = Disabled

1 = Enabled

P1C22 Automatic deactivation of tail lift in minutes after activation 0 240 2550

Unit: Minutes

P1JGF Decides if a digital input high is required from control. 0 1 1

0 = No input required

1 = Input required

P1BVQ Engine start inhibit function enable False

(VMCU) True/False.

P1B80 Inhibit start request when tail lift enabled No

(VMCU) Yes/No.

P1B9X Work Remote, Wireless remote control present. False/True

Default = TRUE in variant TAILPRE2

True/False

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 8 (30)

Parameters for alarm

The following parameters apply only to trucks with an alarm and are related to the cargo alarm input, pin 1 in connector

BB2 in chassis frame rail.

Parameter code Description Setting

P1ES4 Enable the cargo alarm input. False (input disabled) default setting by

ALARM-B

True (input enabled) default setting by

ALARM-E

P1ETB Cargo alarm input behaviour False (default) = Normally opened. The alarm

is triggered when the circuit is connected to

ground potential.

True = Normally closed. The alarm is triggered

when the circuit is disconnected from ground

potential.

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 9 (30)

Pinout for tail lift functions

In variant TAILPRE2, some pins in connector BBEC1 and in BBM have changed functions, compared to default setting.

BBEC1 connector in body builder electrical centre

Pin Default function Function in TAILPRE2 variant Type

3 Flexible switch, ID8 Tail lift enable switch, ID8 DI H

5 Instrument Warning Icon, “Body not in driv- Instrument Warning Icon, “tail lift not closed” DI L

ing position”

10 Alarm Trailer/Cargo Alarm Trailer/Cargo DI L

BBM

Pin Default function Function in TAILPRE2 variant Type

B1:9 Display icon, Equipment status 2 Instrument Warning Icon, “tail lift overload” DI H

B1:25 PTO3/Splitbox PTO, request Remote control enables DI H

B3:1 PTO3/Splitbox PTO, solenoid valve Tail lift, up DO H

B3:5 Auxiliary switch 5, ID58 Tail lift slide, out DO H

B3:6 Auxiliary switch 6, ID59 Tail lift slide, in DO H

B3:7 Engine speed > 1000 rpm Tail lift, down DO H

B3:10 PTO4 valve Tail lift, tilt DO H

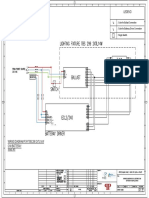

Schematic, electrical installation

Variants TAILPREP and TAILPRE2

T9108205

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 10 (30)

Electrical tipper body preparation kit

Variant BEPR-T2

Tipper body control from Work Remote

The BEPR-T2 variant is a special preparation kit developed for trucks, which will be equipped with a tipper body. It sup-

ports a rigid tipper truck with or without drawbar tipper trailer and tractors with tipper (semi) trailer.

The BEPR-T2 variant includes:

• Work Remote with special tipper menus for tipper on truck and trailer.

• BBM unit with special pinout configuration for support of tipper on truck and trailer.

• An icon showing “Body not in driving position” in the instrument display.

• Wires prerouted to chassis for tipper control.

The BEPR-T2 variant requires and uses the variant BBCHAS3 wire. An extra wiring harness to solenoid valves and

switches on the chassis is available. This chassis wiring harness has a single, two position connector for each of the fol-

lowing functions listed (for use with a rigid tipper body or tractor/semi trailer tipper):

• Tipper body up

• Tipper body down (automatic lowering possible)

• Tailgate open

• Tailgate close

• Tarpaulin in

• Tarpaulin out

• Position switch for “Body not in driving position” warning

• Vibrator (relay)

• External chassis mounted Stop switch.

• Extra hydraulic dump valve

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 11 (30)

The chassis BB2 connector contains pins for extra tipper body on drawbar trailer:

• Tipper body up

• Tipper body down (automatic lowering possible)

• Tailgate open

• Tailgate close

• Tarpaulin in

• Tarpaulin out

Note: It is important that the body builder uses solenoid valves incorporating a reverse current diode. This is especially

important when both the truck and the trailer have a tipper body.

Trucks with variant BEPR-T2 tipper control will be supported from the Work Remote only. The variant does not include

any other control devices in the cab.

Flexible switches for bodywork functions AUX3, AUX4, AUX5 and AUX6 (variant AESW2–PK) cannot be used together

with the variant BEPR-T2.

The BEPR-T2 variant requires the variant BBCHAS3. This is because these wires are used to control the tipper body

functions.

See the wiring diagram for further information.

BEPR-T2 is not available together with the variant ECBB-HI2 (BBIOM).

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 12 (30)

Work Remote tipper functionality

The tipper body, and the PTO, can be controlled from the

Work Remote.

To control the tipper body from the remote, the tipper

menu must be selected.

In the tipper menu, the truck will have priority by default.

The left and right arrow buttons are used to navigate be-

tween the truck and trailer options.

To select the option, Press OK.

The selected option will be highlighted.

T9080744

Work Remote control.

In the view shown here, the tipper on a drawbar trailer has

been selected.

If a drawbar trailer will never be used, this option can be

disabled by setting a parameter.

T9080745

Tipper functions

When tipper truck icon is selected, view shown here will

be displayed.

In this view, the truck tipper body can be controlled from

the Work Remote according to the following:

Action Result

Arrow up Lift tipper body.

Arrow down Lower the tipper body. Au-

tomatic lowering can be

enabled. T9080746

Arrow left Close powered tailgate/

flap.

Arrow right Release tailgate or open

powered tailgate/flap.

Button 1 Open tarpaulin

Button 2 Close tarpaulin

Button 3 Shaker/vibrator

If the shaker/vibrator or remote controlled tarpaulin is not used, the buttons 1 -3 can be given other functions. The icons

in the Work Remote for these functions can be replaced using parameter settings.

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 13 (30)

Lifting the tipper body

Assuming that the hydraulic pump is running, pressing the UP arrow will lift the tipper body.

When the up button and the OK buttons are pressed at the same time, the engine speed will increase to the engine

speed selected in Engine Speed Mode 0 (see “engine speed control” the VBI chapter Vehicle Electronics).

When one of the buttons is released, the engine will automatically return to low idle.

Lowering the tipper body

Pressing the DOWN arrow will lower the tipper body.

Tipper body lowering can also be performed with the engine shut off. This requires that the key is at least in the Acces-

sory position.

Automatic lowering

Automatic lowering of the tipper body can be selected by parameters.

When selected, after the arrow down button has been pressed for a preset time (set by the user), the body will continue

to lower for a preset time (set by the user). This time will be set so that it is ensured that the tipper body has reached the

bottom position before the lowering action is ended. Automatic lowering can be stopped by pressing the OK button or the

up or down arrow buttons. The “stop button” will also stop the lowering action.

Tailgate

Control of the tailgate/tail flap can be configured by the body builder by setting parameters.

The body builder will set the necessary parameters for the specific tailgate or tail flap used. To avoid unintended opening

of the tailgate, conditions can be set that requires that a PTO is active before the tailgate/tail flap can be controlled.

Four tailgate/tail flap alternatives are available:

0 = No remote controlled tailgate. — Used for mechanically controlled tailgates/tail flaps that cannot be remotely con-

trolled. Tailgate/tail flap control is disabled from the Work Remote.

1 = Hydraulic — Two solenoid valves; one to open and one to close the tailgate or tail flap. Digital outputs to the solenoid

valves are active as long as the corresponding button on the Work Remote is pressed.

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 14 (30)

2 = Pneumatic Open/Close — One solenoid valve. Opens the tailgate/tail flap when active, closes the tailgate/tail when

inactive. Digital outputs to the solenoid valve (tailgate open valve) will activate when the “tailgate open” button, on the

Work Remote, is pressed, and deactivate when the “tailgate close” button on the Work Remote is pressed.

The tailgate/tail flap will also close when the truck enters vehicle mode “Parked”.

3 = Pneumatic Unlock (tailgate release). — One solenoid valve is used to release the tailgate. The tailgate will be re-

leased after the “tailgate open” button, on the Work Remote, has been pressed for two seconds (default setting). The

hooks will be released as long as the button is kept pressed. This kind of tailgate will close/lock by its own weight when

the tipper body is lowered.

Shaker/Vibrator

The shaker/vibrator button will activate the vibrator while the button is pressed, but will automatically shut off the vibrator

after 10 seconds (this time is a parameter setting).

When a shaker/vibrator is not present, this button can be used for some other functions.

Tarpaulin

A tarpaulin can be remotely controlled from the Work Remote. Digital outputs to solenoid valves or motor relays are ac-

tive as long as the corresponding button in Work Remote is pressed.

By default, the maximum vehicle speed is set to 10 km/h to avoid opening the tarpaulin while driving. When remote con-

trolled Tarpaulin is not present, this button can be used for some other functions.

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 15 (30)

Stop button

The stop button on the Work Remote will stop all ongoing commands by shutting off all digital outputs. At the same time,

“stop” digital output (low) will be interrupted. This means that if a “dump” valve is used (to interrupt the hydraulic flew),

this valve will be shut off.

After the stop button has been pressed, the OK button must be pressed to confirm that the dump valve will open and that

the digital outputs for tipper control will be possible to re-enable.

External stop button

The system is prepared for an extra stop button.

The digital input for an extra external stop button will have the same functionality as the stop button on the Work Remote.

If no external stop button is used, this digital input must be connected to ground.

Drawbar trailer with tipper

When a tipper (drawbar) trailer is selected, the view

shown here will be displayed.

The functionality for the trailer tipper will be similar to the

functionality for tipper on truck described earlier.

When the trailer is disconnected, the tipper trailer menu

will not be selectable.

For semi-trailer tippers, the truck menu and outputs will

be used.

T9080747

Connectors in the frame rail for tipper

Connector BB1

Control wire connector specifications (connector according to DIN 72585).

Pin Description

1 Tipper body not in driving position. DI L. Will turn on the warning in cab when grounded.

2 Power supply for dump solenoid valve. Fused 5 A. In fuse box A02P (+24 V)

3 External Stop request. DI L.

Note: External stop will stop all tipper functionality when it is disconnected from ground. If

no external stop button is used, this digital input must be connected to ground.

4 Vibrator, truck. DO H Maximum continuous load 1 A.

5 Ground for solenoid valves and vibrator relay for truck only. Follow wiring diagram.

6 Dump solenoid valve. DI L. Maximum continuous load 1 A.

7 Free. Wire size 1,5 mm2. Available in BBEC2:7

Extension wires from the BB1 connector to switches and solenoid valves in chassis are supplied by Volvo.

Connector BB2

Control wire connector specifications (connector according to DIN 72585).

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 16 (30)

Pin Description

1 Tailgate trailer, close. DO H Maximum continuous load 1 A.

2 Tailgate trailer, open/release. DO H Maximum continuous load 1 A.

3 Tipper body trailer, down. DO H Maximum continuous load 1 A.

4 Tipper body trailer, up. DO H Maximum continuous load 1 A.

5 Tarpaulin trailer, out/close. DO H Maximum continuous load 1 A.

6 Tarpaulin trailer, in/open. DO H Maximum continuous load 1 A.

7 Ground for solenoid valves and vibrator relay for trailer only. Follow wiring diagram.

Extension wires from the BB2 connector are not supplied by Volvo. Wire same wiring harness as from BB3 can be used

for trailer tipper solenoid valves.

Connector BB3

Control wire connector specifications (connector according to DIN 72585).

Pin Description

1 Tailgate truck, close. DO H Maximum continuous load 1 A.

2 Tailgate truck, open/release. DO H Maximum continuous load 1 A.

3 Tipper body truck, down. DO H Maximum continuous load 1 A.

4 Tipper body truck, up. DO H Maximum continuous load 1 A.

5 Tarpaulin truck, out/close. DO H Maximum continuous load 1 A.

6 Tarpaulin truck, in/open. DO H Maximum continuous load 1 A.

7 Ground for solenoid valves and vibrator relay for truck only. Follow wiring diagram.

Extension wires from the BB3 connector to switches and solenoid valves in chassis are supplied by Volvo.

For mating the control wire connector, use Volvo parts according to part numbers in the following table.

Pin insulator

Description Dimension Part number

Insulator housing — 25371156

Lock ring — 3963413

Bullet terminal 0.5–1 mm2 984945

Wire seal 0.5–1 mm2 20734499 T3009603

Blanking plug, transparent — 970771

Mating connector for control wire

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 17 (30)

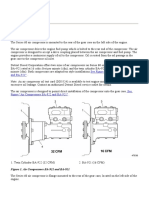

The illustration to the right shows the location of the Body

Builder connectors on the chassis frame rail.

T9093996

Schematic, electrical installation

T9081986

Note: As switching between the truck tipper body and the

trailer tipper body is carried out on the grounded side of the

solenoid valve, it is important that solenoid valves equip-

ped with reverse current diodes are used.

Solenoid valves will also be equipped with “freewheel di-

odes” or similar in aid to suppress voltage peaks.

Note: Solenoid valves, relays, external stop switch and po- T9081108

sition switch are mounted by the body builder and are not

part of the delivery from Volvo.

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 18 (30)

Parameters for Tipper

Parameter Description Min Default Max

code value

P1JPJ Tipper function, enable. 0 0/1 1

Default = Enabled in variant BEPR-T2

0 = Disabled

1 = Enabled

P1JPI Secondary tipper body enable. 0 0 1

Enable when there is a truck tipper body and a drawbar trailer

tipper

0 = Disabled

1 = Enabled

P1KKO Chassis stop button enable 0 0 1

0 = Disabled

1 = Enabled

P1JOA Time the lowering button on the Work Remote must be pressed 0 3,0 25,5

before Auto lowering of the tipper body is activated.

0 = Auto lowering disabled

Unit: Seconds

P1JPO Time the Auto lowering of the tipper body is active. This param- 0 60 255

eter will be set so that it is ensured that the tipper body has

reached the low position before it is deactivated.

0 = Auto lowering disabled

Unit: Seconds

P1JPQ Requirement that the PTO will be active before the tailgate/tail 0 1 1

flap can be controlled

0 = Disabled

1 = Enabled

P1JPK Primary tipper tailgate type 0 0 3

Method of controlling tailgate

0 = Manual

1 = Hydraulic

2 = Pneumatic Open/Close

3 = Pneumatic Unlock (tail flap release)

P1JPL Secondary tipper (drawbar trailer) tailgates type 0 0 3

Method of controlling tailgate

0 = Manual

1 = Hydraulic

2 = Pneumatic Open/Close

3 = Pneumatic Unlock.

P1JOB Tailgate release button time threshold (Intended for tail flap re- 0 2,0 25,5

lease). This is time that the button must be pressed before tail

flap is released.

0 = Disabled (Immediate activation)

Unit: Seconds

P1JPM Shaker/vibrator, enable 0 0 1

0 = Disabled

1 = Enabled

P1JPR Shaker/vibrator, maximum time for activation cycle 0 10,0 25,5

0 = No limit

Unit: Seconds

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 19 (30)

P1JPN Tarpaulin enables 0 0 1

0 = Disabled

1 = Enabled

P1JPP Sets the time gap during which tipper commands are ignored 0,1 0,5 25,5

when switching between tipper truck and tipper trailer

Unit: Seconds

Parameters for Work Remote shortcut buttons in Tipper menu

In the tipper menu, the shortcut buttons (by default set to Tarpaulin open, Tarpaulin close and Shaker) can be used for

other, customer-defined functions.

Functions selected with following parameters will be valid in the tipper menus only.

Parameter Description Min Default Max

code value

P1KL6 Function and Icon for Button 1 in Tipper menu. 0 1 255

P1KL7 Function and Icon for Button 2 in Tipper menu. 0 2 255

P1KL8 Function and Icon for Button 3 in Tipper menu. 0 3 255

Selectable functions

0 = None 8 = Cab Working Light 17 = AUX4

1 = Tipper Tarpaulin Open 9 = Side Reverse Light 18 = AUX5

2 = Tipper Tarpaulin Close 10 = PTO1 19 = AUX6

3 = Tipper Shaker 11 = PTO2 20 = Start/ stop engine

4 = Tail Lift 12 = PTO3 21 = Engine speed idle

5 = Crane 14 = AUX1 22 = Engine speed resume

6 = Beacon Light 15 = AUX2 23–255 = Not used.

7 = fifth wheel Light 16 = AUX3

Example

If a tipper truck does not have the Shaker function, then

this button can instead be used for engine start/stop. This

is done by changing the parameter P1KL8 from value 3

(tipper shaker) to value 20 (engine start/stop). When any

of the AUX-switches are selected (alternatives 14–19),

then the same Icon will be shown for those switches in the

tipper menu that is selected for the corresponding switch

in the PTO/AUX menu.

T9087936

A — Set using parameter P1KL6

B — Set using parameter P1KL7

B — Set using parameter P1KL8

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 20 (30)

SPEED-DU – Electrical preparation kit for rear loaded vehicles

SPEED-DU is a special variant for rear loaded refuse collection vehicles (RCV) intended to follow the demands in

EN1501-1 for “footstep” at the rear of the truck.

Trucks ordered with the variant SPEED-DU are equipped with a BBM electronic control unit with unique parameter

settings.

A connector with in RCVs commonly used signals is available in the body builder electrical centre in the cab.

Autoneutral on parking brake is prepared for but will not be used together with the function Autorelease of the parking

brake. Please refer to chapter Vehicle electronics, paragraph Autoneutral for additional information.

A conversion kit to install SPEED-DU functionality in trucks built from factory without the variant SPEED-DU is available

under Volvo part number 85142230. This kit does not include the further down described “XNS-connector”. Instead con-

nections must be done according to sketch further down.

Function

Vehicle speed is, by default, limited to 30 km/h (RSL2) when there is an active input from the chassis on the “footstep”

input.

When the RSL2 is active (footstep input active), a reverse inhibit function is enabled. This function will apply the brakes

and force the engine to low idle if the gear lever is put into reverse gear position while the “footstep” input is active. The

reverse gear will not either be engaged.

Releasing the applied brakes and resetting the inhibited reverse gear, can only be carried out by removing the “footstep”

input signal and selecting neutral gear.

It is the responsibility of the body builder to ensure the necessary override and related penalty functions.

An immobilisation emergency override can be archived by applying voltage to BBM pin B2:12.

For complete electrical schematics, refer “NL” in the applicable Wiring.

From 2020 week 9:

Backwards rolling (at > 1 km/h) can be detected in BB-CAN message BBM_BBNet_18P, signal: TruckMovingBackward.

In this signal, it is only backwards moving that is detected. No brake appliance will be performed. Backwards rolling can

also be configured to any digital output. Described further down.

Driver information

When any Vehicle Speed Limit is active, a symbol “RSL”

will be shown in the instrument display.

T9070310

Instrument icons with audible signals are also available in

the instrument display for:

Footstep occupied

An icon will be shown in the status bar (no audible signal)

as long as an active input is present at connector XNS,

pin 2.

Body builder display icon number 4 will be used.

T9081727

Communication

An icon will be shown together with an audible signal as

long as an active input is present at connector XNS, pin

19. T9088047

Body builder display icon number 2 will be used.

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 21 (30)

Emergency stop of the bodywork

An icon will be shown together with an audible signal as

long as an active input is present at connector XNS, pin

18. T9088048

Body builder display icon number 3 will be used.

Connector in cab for RCV bodywork

A connector in the body builder electrical centre is pre-

pared for easy connection of RCV bodywork.

This connector contains commonly used signals for RCVs.

The connector is marked XNS and is located as shown

here.

T3180761

XNS connector in body builder electrical centre

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 22 (30)

Connector XNS for SPEED-DU vehicles

For the complete electrical schematics, see the wiring diagram, page NL.

XNS Function Description

2 "Footstep". Input (DI H) "Footstep".

BBM B2:4 Input activates road speed limit, RSL2 (max. 30 km/

h.) And reverse inhibit function acc. to EN1501-1.

5 Engine speed output (DO H) High when engine speed is 1000 rpm.

BBM B3:7 Hysteresis +/- 20 rpm. Max 1,0 A

6 Neutral detection (DO L) Low when gearbox is in neutral or auto-neutral.

BBM B2:1

8 Parking brake info. (DO H) High when p-brake applied. Max 1,0 A.

From connector BBEC1:4

9 Engine speed request, 900 rpm (DI H) Input +24 V. Will request engine speed 900 rpm.

BBM B1:3 (ESM1 is used)

10 PTO1, activation request (DI H) Input +24 V. Will request PTO1.

BBM B1:1

13 BB- CAN network Body builder CAN network, High

BBM B1:29

14 BB- CAN network Body builder CAN network, Low

BBM B1:30

15 Engine speed request, 1000 rpm (DI H) Input +24 V. Will request engine speed 1000 rpm.

BBM B1:7 (ESM2h is used)

16 Supply +24 V Supply to inputs. Max. load 300 mA.

BBM B3:16

18 Emergency stop in bodywork (DI H) Input +24 V. Will show icon in instrument cluster that

BBM B1:10 the bodywork has been emergency stopped and acti-

vate bell sound (Bodywork Display Icon no. 3 is used)

19 Communication signal to driver (DI H) Input +24 V. Will show bell icon in instrument cluster

BBM B1:9 and activate bell sound (Bodywork Display Icon no. 2

is used)

20 Autoneutral enable (DI H) Input +24 V. Enable Autoneutral, for activation when

BBM B2:14 conditions are fulfilled.

Volvo part number for mating connector housing to the connector XNS:

Receptacle housing, 995632 (included and mounted in connector)

Terminals, pos. 1–18, wire size 0,5–1,0 mm2- 990060

Terminals, pos. 1–18, wire size 1,0–1,5 mm2 - 991610

Terminals, pos. 19–25, wire size 0,2–0,5 mm2 - 20375160

T3180676

Terminals, pos. 19–25, wire size 0,5–1,0 mm2 - 20375161

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 23 (30)

Speed limitation in reverse gear

In case a speed limitation is wanted when reversing, the following parameter configuration can be applied.

The third speed limitation (RSL3 described in chapter Vehicle electronics) is used to limit the speed.

Following parameters must be configured for the RSL3.

Parameter code Description Value to use Unit

P1BJH[0] RSL3, enable Yes Yes/No

P1BJH[1] RSL3, limitation speed 9 Km/h

P1BJH[2] RSL3, activation inhibited above the limita- Yes/No

No

tion speed.

To have the speed limitation RSL3 active in reverse gear only, also the following configuration must be done.

Parameter code Value

P1B4Q[60] Operator 0

P1B4Q[60] Operand1 12

P1B4Q[60] Operand2 0

P1B4Q[60] Setting 0

P1O60[60] 0

P1O61[60] 0

P1B4K[17] 61

P1WF8[0] 45

P1BVG[22] 60

The digital input B2:5 (for RSL3) to BBM should be used when it is wanted to limit the vehicle speed to 9 km/h. Also in

the forward direction.

Backwards-rolling detection

Backwards rolling at >1 km/h.can be configured to the BBM digital output B3:10 (DOH) by the following described config-

uration. Backwards-rolling information is also available on BB-CAN.

Parameter code Value

P1B4Q[13] Operator 4

P1B4Q[13] Operand1 11

P1B4Q[13] Operand2 0

P1B4Q[13] Setting 4

P1O60[13] 1

P1O61[13] 0

P1B4K[16] 14

P1BVH[5] 44

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 24 (30)

Parameters for SPEED-DU

The vehicle immobilization function inhibits the truck from being reversed when the footstep is occupied. This function is

enabled by a conversion kit, which is included in the variant SPEED-DU.

The icons, their text and sound can be changed with Tech Tool.

When SPEED-DU is installed with the conversion kit 85142230, these configurations have to be done manually with

Tech Tool.

Parameter Description Min Default Max

code value

P1BJG [0] RSL2, enable Yes

Yes/No.

P1BJG [1] RSL2, speed limit value 5 30 250

Unit: km/h

P1BJG [2] RSL2, activation inhibited above limitation speed Yes

Yes/No.

P1B45 Reverse gear inhibit enable when RSL2 is active. True

True/False

P1B47 Enable reverse inhibit by blocking of reverse gear (valid for au- 0 2 2

tomatic gearboxes only)

0 = Digital input only

1 = BB-CAN command only

2 = Digital input or BB-CAN request.

P1J5Y Vehicle Immobilisation override function. [60] must be config- 0 0 1

ured to a Digital input, in this case B2:12, corresponding to the

value 18

0 = Function disabled

1 = Enabled

P1BJO RSL BB network request enabled 0 1 1

0 = Network request disabled

1 = Network request enabled

P1B4V Autoneutral enables 0 3 3

0 = Autoneutral disabled

1 = Digital input enabled only

2 = BB-CAN request enabled only

3 = Digital input and BB-CAN request enabled.

P1B43 Decides if gear lever must be put in neutral position before Au- False

toneutral is left.

True/False

P1B44 Neutral detection output. 0 2 3

(There will be an active low output on B2:1 when gear is in neu-

tral acc. to description).

0 = No output 1 = Autoneutral only

2 = Autoneutral or neutral gear

3 = Neutral gear only

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 25 (30)

Parameters to configure Bodywork Display Icon no.2.

The corresponding Icon symbolises Communication from footstep.

P1J6U[0] Bodywork Display Icon no.2 True

Functions enable

False/True.

P1J6U [1] Bodywork Display Icon no.2 0 0 1

Enable reactivation of Pop-up icon when parking brake is being

released

0 = Disabled

1 = Enabled

P1J6U[2] Bodywork Display Icon no.2 False

Enable Pop-up icon functionality also when severity “informa-

tion” is selected

False/True.

P1J6U [3] Bodywork Display Icon no.2. 0 255 255

Pop up icon on vehicle speed threshold

Unit: km/h

255 = Conditions disabled

P1J6U [4] Text string to be presented together with pop-up Icon. Text: “Communication from

Max. 32 characters footstep”

P1J6U [5] Icon to be presented as pop-up Icon at event. See following ta- 1 24 100

ble for available icons

24 = Signal from footstep.

P1J6U [6] Icon to be presented in the status bar. 1 24 100

See table in VBI chapter Vehicle electronics

24 = Signal from footstep.

P1J6U[7] Bodywork Display Icon no.2. Severity level 0 0 3

0 = Information level (white info.)

P1J6U [8] Bodywork Display Icon no.2. 0 0 3

Level of warning when Pop-up is activated due to releasing of

parking brake

0 = Information level (white info.)

1 = Yellow warning level

2 = Red warning level

3 = Notice

P1J6U [9] Bodywork Display Icon no.2. 0 0 3

Level of warning when Pop-up is activated due to vehicle speed

threshold

0 = Information level (white info.)

1 = Yellow warning level

2 = Red warning level

3 = Notice

P1J6U [10] Minimum time for status bar icon to be displayed 0 10 30

Unit: Seconds

P1J6U [11] Sound type for status bar Icon (as long as input is active) 0 1 2

0 = None

1 = Single stroke pulsed signal

2 = Rapid intermittent signal.

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 26 (30)

Parameters to configure Bodywork Display Icon no.3.

The corresponding Icon symbolises emergency stop.

P1J6V[0] Bodywork Display Icon no.3 True

Functions enable

False/True.

P1J6V [1] Bodywork Display Icon no.3 0 0 1

Enable reactivation of Pop-up icon when parking brake is being

released

0 = Disabled

1 = Enabled

0 = SPEED-DU

P1J6V[2] Bodywork Display Icon no.3 True

Enable Pop-up icon functionality also when severity “informa-

tion” is selected

False/True.

P1J6V[3] Bodywork Display Icon no.3 0 255 255

. Pop up icon on vehicle speed threshold

0–255 km/h

255 = Conditions disabled.

P1J6V [4] Text string to be presented together with pop-up Icon.

Text: “Emergency stop”

Max. 32 characters

P1J6V [5] Icon to be presented as pop-up Icon at event 1 25 100

25 = Emergency stop active.

P1J6V [6] Icon to be presented in the status bar 1 25 100

25 = Emergency stop active.

P1J6V [7] Bodywork Display Icon no.3. 0 0 3

Severity level

0 = Information level (white info.)

P1J6V [8] Bodywork Display Icon no.3. 0 0 3

Level of warning when Pop-up is activated due to releasing of

parking brake

0 = Information level (white info.)

1 = Yellow warning level

2 = Red warning level

3 = Notice

P1J6V[9] Bodywork Display Icon no.3. 0 0 3

Level of warning when Pop-up is activated due to vehicle speed

threshold

0 = Information level (white info.)

P1J6V [10] Minimum time for status bar icon to be displayed 0 10 30

Unit: Seconds

P1J6V [11] Sound type for status bar Icon (as long as input is active) 0 2 2

0 = None

1 = Single stroke pulsed signal

2 = Rapid intermittent signal.

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 27 (30)

Parameters to configure Bodywork Display Icon no.4.

The corresponding Icon symbolises Footstep occupied.

P1J6W[0] Bodywork Display Icon no.4 True

Functions enable

False/True.

P1J6W[1] Bodywork Display Icon no.4 0 0 1

Enable reactivation of Pop-up icon when parking brake is being

released

0 = Disabled

1 = Enabled

P1J6W [2] Bodywork Display Icon no.4 False

Enable Pop-up icon functionality also when severity “informa-

tion” is selected

True/False.

P1J6W[3] Bodywork Display Icon no.4 0 255 255

. Pop up icon on vehicle speed threshold

0–255 km/h

255 = Conditions disabled.

P1J6W [4] Text string to be presented together with pop-up Icon.

Text: “Footstep occupied”

Max. 32 characters

P1J6W [5] Icon to be presented as pop-up Icon at event 1 63 100

63 = Footstep occupied.

P1J6W [6] Icon to be presented in the status bar 1 63 100

63 = Footstep occupied.

P1J6W [7] Bodywork Display Icon no.4. Severity level 0 0 3

0 = Information level (white info.)

1 = Yellow warning level

2 = Red warning level

3 = Notice

P1J5Y Vehicle Immobilisation override function enable 0 1 1

0 = Function disabled

1 = Enabled

P1F8G Condition used for vehicle state information to bodywork 0 1 2

0 = Engine running

1 = Parking brake applied

2 = Gearbox in neutral

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 28 (30)

Related I/O description

T9088093

BBM pin Function Parameter setting for parking brake release

function

B2:4 Vehicle speed limit 2 (DI H) P1BVG [19] (Body instrument icon 4): Source 9

P1BVG [21] (RSL2 request): Source 9

P1BVG[38] (Reverse gear inhibit): Source 9

P1BVG [47] (Vehicle immobilisation): Source 9

P1BVG [56] (Vehicle immobilisation redundant):

Source 9

B2:12 Vehicle immobilisation emergency override (DI H) P1BVG [60]: Source 18 (Vehicle immobilisation

emergency override)

Parameter P1BVG is required to be manually configured when the aftermarket conversion kit is installed.

Main electrical preparation variants FM (4), FH (4)

ENG163284747 Date 4.2022 Release 08 Page 29 (30)

English 4.2022, 163284747

Last page

Volvo Truck Corporation

www.volvotrucks.com

You might also like

- Curtis 1234 AC ControllerDocument4 pagesCurtis 1234 AC Controllerluis tocoraNo ratings yet

- 1 - 855-S-En-1-C1 Electrical Architecture TEA2+ and Power ManagementDocument98 pages1 - 855-S-En-1-C1 Electrical Architecture TEA2+ and Power ManagementKurniawan RestuNo ratings yet

- Mercedes Mp5 OpbouwDocument66 pagesMercedes Mp5 OpbouwFerry Pauw100% (4)

- VW t5 2009 Wiring Diagrams EngDocument2,359 pagesVW t5 2009 Wiring Diagrams Engmullrarry2010100% (1)

- Scania 4 Series Electrycal System ManualDocument32 pagesScania 4 Series Electrycal System ManualJasenko IsakovićNo ratings yet

- Service Manual JCB 8027Z, 8032Z Mini Excavator (Preview)Document6 pagesService Manual JCB 8027Z, 8032Z Mini Excavator (Preview)Amip Folk0% (1)

- WIRING DIAGRAM FOR TBS 299 2x14 W PDFDocument1 pageWIRING DIAGRAM FOR TBS 299 2x14 W PDFOrita Indonesia100% (1)

- An - Trimble - TuvrDocument2 pagesAn - Trimble - TuvrDaniel Martins0% (1)

- JVC KW-AV61 Owners ManualDocument93 pagesJVC KW-AV61 Owners Manualalejandro sanchez100% (1)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- ImpactDocument4 pagesImpactMyat KhantNo ratings yet

- Vehicle Electronic Control Unit (V-ECU), Description: Service InformationDocument2 pagesVehicle Electronic Control Unit (V-ECU), Description: Service InformationJheckson BalbinotNo ratings yet

- Parametros Bus MidDocument171 pagesParametros Bus Midsalvatore702No ratings yet

- IC, Diagnostic Trouble CodesDocument2 pagesIC, Diagnostic Trouble CodesHari Hara SuthanNo ratings yet

- PTO Configuration TESTDocument34 pagesPTO Configuration TESTEdwin Motta PiambaNo ratings yet

- 2016-12-19-100036-9 Plag T ABS VCS IIDocument1 page2016-12-19-100036-9 Plag T ABS VCS IIAndrey LyutikNo ratings yet

- WSM 0000546 01Document20 pagesWSM 0000546 01Omar ScaniaNo ratings yet

- BB Packages PDFDocument39 pagesBB Packages PDFAbdo FreedomNo ratings yet

- JalTest Soft (JalTest V2-V3) Manual - 2Document43 pagesJalTest Soft (JalTest V2-V3) Manual - 2iMac DiggerNo ratings yet

- 20UP20DNDocument4 pages20UP20DNMizael Medeiros dos SantosNo ratings yet

- NCV4275 5.0 V Low Drop Voltage Regulator: Marking DiagramsDocument13 pagesNCV4275 5.0 V Low Drop Voltage Regulator: Marking DiagramsRafael MonzonNo ratings yet

- MID 140 Instrument Cluster Signal Description (Spesifications 381)Document20 pagesMID 140 Instrument Cluster Signal Description (Spesifications 381)Lazuardhitya oktanandaNo ratings yet

- View GraphicDocument2 pagesView GraphicFelix VelasquezNo ratings yet

- 303 14 PDFDocument38 pages303 14 PDFTuan TranNo ratings yet

- Technical Book DXi13Document25 pagesTechnical Book DXi13Yudha SetiawanNo ratings yet

- 02 Engine With Mounting and EquipmentDocument59 pages02 Engine With Mounting and EquipmentUbeimar Rivera100% (1)

- 93C86Document12 pages93C86francisco_siles_lunaNo ratings yet

- Opis Kostek Lokalizacji I FunkcjiDocument96 pagesOpis Kostek Lokalizacji I FunkcjiTruck Bus ElectronicaNo ratings yet

- Fault Code Information For Bus Models B7R, B9R, B11R, B5RHDocument168 pagesFault Code Information For Bus Models B7R, B9R, B11R, B5RHChinna YadavNo ratings yet

- JPRO Diagnostic Cables Technical Service Bulletin TSB 0001 6 13 - Cable - Electrical ConnectorDocument5 pagesJPRO Diagnostic Cables Technical Service Bulletin TSB 0001 6 13 - Cable - Electrical Connectorram_thriveniNo ratings yet

- Rear Axle, Specifications General InformationDocument5 pagesRear Axle, Specifications General InformationVijju VjuNo ratings yet

- Standard Equipment: Moving You FurtherDocument8 pagesStandard Equipment: Moving You FurtherSabahNo ratings yet

- Scania Pseries Workshop Manual - Removing Front SpringDocument1 pageScania Pseries Workshop Manual - Removing Front SpringocnogueiraNo ratings yet

- GPS Vehicle Tracker: User ManualDocument15 pagesGPS Vehicle Tracker: User ManualPaolo SchittoneNo ratings yet

- Fault Codes: STO U AndriivDocument4 pagesFault Codes: STO U AndriivAtochkavNo ratings yet

- Installation, Examples Un VBG - 15-Pol SavienojumsDocument23 pagesInstallation, Examples Un VBG - 15-Pol SavienojumsЕвгений АксёновNo ratings yet

- Volvo Emissions Oraz Adblue SystemDocument33 pagesVolvo Emissions Oraz Adblue Systemasuskusz100% (1)

- Ebs STD, Ebs Med, Ebs HigDocument15 pagesEbs STD, Ebs Med, Ebs HigSherzad ChemNo ratings yet

- Wiring Diagram FH (4) : Volvo Trucks. Driving ProgressDocument378 pagesWiring Diagram FH (4) : Volvo Trucks. Driving ProgressRoberto Donizete MunizNo ratings yet

- Lear MKR MKS Plus System1Document41 pagesLear MKR MKS Plus System1Sebas CorvalánNo ratings yet

- FH 22 DTCDocument15 pagesFH 22 DTCMOAMMEDNo ratings yet

- Alexander Dennis Enviro400 Pneumatics ManualDocument24 pagesAlexander Dennis Enviro400 Pneumatics ManualJörgen MannbergNo ratings yet

- FIREDEX2204 Zone ManualDocument10 pagesFIREDEX2204 Zone ManualbelhocinesNo ratings yet

- Abs PDFDocument17 pagesAbs PDFReffi NaldiNo ratings yet

- MID 130 PID 33 Clutch Cylinder, PositionDocument1 pageMID 130 PID 33 Clutch Cylinder, PositionAbolfazlNo ratings yet

- Course Catalogue Volvo TrucksDocument14 pagesCourse Catalogue Volvo TrucksCésar PérezNo ratings yet

- ECU DiagnosticsDocument12 pagesECU Diagnosticsesquisof100% (1)

- TI-20-100-01, D7E Valve Clearance Ind, 28th Nov 2008Document4 pagesTI-20-100-01, D7E Valve Clearance Ind, 28th Nov 2008sanikkpNo ratings yet

- Service Bulletin Trucks: NOX Sensor and Control Module (Vertical DPF), ReplacementDocument5 pagesService Bulletin Trucks: NOX Sensor and Control Module (Vertical DPF), ReplacementRolando MancillaNo ratings yet

- Wiking Heating SystemDocument12 pagesWiking Heating SystemDarkoNo ratings yet

- Volvo Toate SistemeleDocument8 pagesVolvo Toate SistemeleNicu Terciu100% (1)

- MSA5T0726A161959 Keyless Entry System PDFDocument3 pagesMSA5T0726A161959 Keyless Entry System PDFMishu MishuNo ratings yet

- Special Tools 3Document20 pagesSpecial Tools 3p_jankoNo ratings yet

- SAE J1772-Compliant Electric Vehicle Service Equipment Reference Design For Level 1 and 2 EV ChargerDocument38 pagesSAE J1772-Compliant Electric Vehicle Service Equipment Reference Design For Level 1 and 2 EV ChargerErik SolisNo ratings yet

- Installing Cable Harness (Preliminary) B9LDocument7 pagesInstalling Cable Harness (Preliminary) B9Lfugega100% (1)

- Service Bulletin Trucks: Immobilizer FeatureDocument7 pagesService Bulletin Trucks: Immobilizer FeatureRegistr RegistrNo ratings yet

- DPA5 BTConfigDocument18 pagesDPA5 BTConfigManuel KusminskyNo ratings yet

- Section: L0 - Electric Al System Ref: 0 - 0.014.3360.4: Multifunction Control UnitDocument1 pageSection: L0 - Electric Al System Ref: 0 - 0.014.3360.4: Multifunction Control UnitEvaldas ŠtrapėlaNo ratings yet

- Diagnostic Manual-A-ECUDocument27 pagesDiagnostic Manual-A-ECURıdvan KurtulduNo ratings yet

- Emotron Syncoption Instruction 01-5828-01r1.enDocument28 pagesEmotron Syncoption Instruction 01-5828-01r1.enhadiNo ratings yet

- Drop BoxDocument3 pagesDrop BoxRamonNo ratings yet

- PM Debug InfoDocument46 pagesPM Debug InfoRamonNo ratings yet

- Settings ProviderDocument10 pagesSettings ProviderRamonNo ratings yet

- A11yprovider LogDocument213 pagesA11yprovider LogRamonNo ratings yet

- Fuelfocus™ Programmer User Manual Revision A00 April 2020: All Rights ReservedDocument40 pagesFuelfocus™ Programmer User Manual Revision A00 April 2020: All Rights ReservedRamonNo ratings yet

- Power Off Reset Reason BackupDocument5 pagesPower Off Reset Reason BackupRamonNo ratings yet

- Preload InstallerDocument1 pagePreload InstallerRamonNo ratings yet

- Erased Log by SosDocument1 pageErased Log by SosRamonNo ratings yet

- FD ListDocument25 pagesFD ListRamonNo ratings yet

- UntitledDocument6 pagesUntitledRamonNo ratings yet

- UntitledDocument6 pagesUntitledRamonNo ratings yet

- Cylinder Cutout Test For MBEDocument4 pagesCylinder Cutout Test For MBERamonNo ratings yet

- InjectorDocument3 pagesInjectorRamonNo ratings yet

- TRSM0170Document62 pagesTRSM0170RamonNo ratings yet

- Eng 153212700Document18 pagesEng 153212700RamonNo ratings yet

- Installation & Operation Manual: Onboard Load ScaleDocument40 pagesInstallation & Operation Manual: Onboard Load ScaleRamonNo ratings yet

- Technical Procedure: Trailer Suspension SystemsDocument8 pagesTechnical Procedure: Trailer Suspension SystemsRamonNo ratings yet

- On-Highway Power: Series 60 - Truck 14 L 515 BHP at 1800 R/min - 1650 LB FTDocument2 pagesOn-Highway Power: Series 60 - Truck 14 L 515 BHP at 1800 R/min - 1650 LB FTRamonNo ratings yet

- On-Highway PowerDocument2 pagesOn-Highway PowerRamonNo ratings yet

- Section 11 - Special EquipmentDocument11 pagesSection 11 - Special EquipmentRamonNo ratings yet

- On-Highway Power: Series 60 EXPORT - Truck 14 L 525 BHP at 1800 R/min - 1850 LB FTDocument2 pagesOn-Highway Power: Series 60 EXPORT - Truck 14 L 525 BHP at 1800 R/min - 1850 LB FTRamonNo ratings yet

- Fuel Gauge & Pump Sender Collar Wrench: KT No. Ø MMDocument1 pageFuel Gauge & Pump Sender Collar Wrench: KT No. Ø MMRamonNo ratings yet

- Section 2 - Fuel SystemDocument80 pagesSection 2 - Fuel SystemRamonNo ratings yet

- Section 5 - Fuel, Lubricating Oil, and CoolantDocument11 pagesSection 5 - Fuel, Lubricating Oil, and CoolantRamon100% (1)

- 70 - Flash Code 70Document4 pages70 - Flash Code 70RamonNo ratings yet

- 60 - Flash Code 60Document4 pages60 - Flash Code 60RamonNo ratings yet

- Section 12 - Operation and VerificationDocument13 pagesSection 12 - Operation and VerificationRamonNo ratings yet

- IndexDocument6 pagesIndexRamonNo ratings yet

- Section 1 - EngineDocument342 pagesSection 1 - EngineRamonNo ratings yet

- 81 - Flash Code 81Document4 pages81 - Flash Code 81RamonNo ratings yet

- Nokia 6670 7610 PDFDocument8 pagesNokia 6670 7610 PDFSrinivasan NarayanaswamiNo ratings yet

- Modicon M238 Micro PLC (Update To M241) - TM238LDD24DTDocument4 pagesModicon M238 Micro PLC (Update To M241) - TM238LDD24DTwalid magdiNo ratings yet

- Introduction To SemiconductorsDocument30 pagesIntroduction To SemiconductorsILIVEFOR MONSTA7No ratings yet

- Hopestar Hot Selling Monitors From CindyDocument2 pagesHopestar Hot Selling Monitors From Cindyyultra057No ratings yet

- Peacefair CatalogoDocument61 pagesPeacefair CatalogoEspaker KaminskiNo ratings yet

- CHERY Tiggo5 T21 Service Manual EN1Document2,266 pagesCHERY Tiggo5 T21 Service Manual EN1Ruberney CarrilloNo ratings yet

- ECE18R277-Assignment-I: Cse-Ii Year Iii Sem September 1, 2021Document2 pagesECE18R277-Assignment-I: Cse-Ii Year Iii Sem September 1, 2021d_ganeshaperumal0% (1)

- Part 00Document2 pagesPart 00Dr-Ahmed AbdulridhaNo ratings yet

- Chapter #6: Bipolar Junction: TransistorsDocument61 pagesChapter #6: Bipolar Junction: TransistorsXolelwa GaselaNo ratings yet

- Service Manual Philips 150s6 170s6190s6Document31 pagesService Manual Philips 150s6 170s6190s6ashmitashrivasNo ratings yet

- (The International Series in Engineering and Computer Science 874) Kathleen Philips, Arthur H. M. van Roermund (auth.) - ΣΔ A - D CONVERSION FOR SIGNAL CONDITIONING-Springer Netherlands (2006)Document229 pages(The International Series in Engineering and Computer Science 874) Kathleen Philips, Arthur H. M. van Roermund (auth.) - ΣΔ A - D CONVERSION FOR SIGNAL CONDITIONING-Springer Netherlands (2006)ndanghaoNo ratings yet

- LM358 Datasheet 16pDocument16 pagesLM358 Datasheet 16ppoetaenatorNo ratings yet

- Pvsyst Trial Pvsyst Trial Pvsyst Trial Pvsyst Trial: Grid-Connected System: Simulation ParametersDocument4 pagesPvsyst Trial Pvsyst Trial Pvsyst Trial Pvsyst Trial: Grid-Connected System: Simulation ParametersMike BrashNo ratings yet

- 13A02803 HVDC TransmissionDocument1 page13A02803 HVDC TransmissionDattam ChranNo ratings yet

- Helios 5.1Document2 pagesHelios 5.1RJ BevyNo ratings yet

- Us 5782874Document26 pagesUs 5782874Captain FranklinNo ratings yet

- C2K Contents Manual BDocument71 pagesC2K Contents Manual BtimonNo ratings yet

- Analysis of Load Output Characteristics of 3600kV Impulse Voltage GeneratorDocument5 pagesAnalysis of Load Output Characteristics of 3600kV Impulse Voltage GeneratorAlessandro SouzaNo ratings yet

- R 103Document1 pageR 103AndyXlerateNo ratings yet

- Whats New in ElectronicsDocument8 pagesWhats New in Electronicsozcan44No ratings yet

- Install Process Instrumentation and Control Cabling and TubingDocument9 pagesInstall Process Instrumentation and Control Cabling and TubingAbela DrrsNo ratings yet

- Efficient Photocatalytic Oxidation of VOCs Using ZnO@Au NanoparticlesDocument25 pagesEfficient Photocatalytic Oxidation of VOCs Using ZnO@Au NanoparticlesTERRY ZHANGNo ratings yet

- A318 - A319 - A320 - A321 - NTM - 01-Aug-2022 - 51-10-16-250-801-A01 - Inspection For Sub-Surface Cracks in Al-Alloy Structure - Procedure ADocument10 pagesA318 - A319 - A320 - A321 - NTM - 01-Aug-2022 - 51-10-16-250-801-A01 - Inspection For Sub-Surface Cracks in Al-Alloy Structure - Procedure ADuy Phan KiếnNo ratings yet

- Autonics E30s ManualDocument1 pageAutonics E30s ManualAndrez BermudezNo ratings yet

- D3.2 - Local Control and Simulation Tools For Large Transmission SystemsDocument90 pagesD3.2 - Local Control and Simulation Tools For Large Transmission Systemszawad mridulNo ratings yet

- LG TV PDP42V5Document59 pagesLG TV PDP42V5Eduardo Cordova100% (1)

- Using ADC On Firebird-V Robot: E-Yantra Team Embedded Real-Time Systems Lab Indian Institute of Technology BombayDocument116 pagesUsing ADC On Firebird-V Robot: E-Yantra Team Embedded Real-Time Systems Lab Indian Institute of Technology BombayRANJITHANo ratings yet

- Bungalow House PlansDocument7 pagesBungalow House PlansluffyNo ratings yet

- Uncirculated Baths: (AMBIENT +5°C TO +100°C)Document4 pagesUncirculated Baths: (AMBIENT +5°C TO +100°C)Johan MolinaNo ratings yet

- 3500-40M Proximitor Monitor Datasheet - 141535 PDFDocument10 pages3500-40M Proximitor Monitor Datasheet - 141535 PDFguichoxljNo ratings yet