Professional Documents

Culture Documents

Centrifuge 8

Centrifuge 8

Uploaded by

admin ptkmi0 ratings0% found this document useful (0 votes)

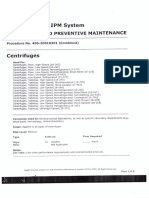

9 views1 pageThis document provides procedures for inspecting and maintaining centrifuges in a laboratory. It outlines three key accuracy checks: temperature accuracy should be within +3°C, timer accuracy should not vary by more than 10%, and speed settings should not vary by more than 1% of the displayed speed. It also lists preventative maintenance steps like cleaning, lubricating, and replacing worn parts per the manufacturer's instructions. A caution tag should be attached if any control settings have been changed during inspection.

Original Description:

Original Title

CENTRIFUGE_8

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides procedures for inspecting and maintaining centrifuges in a laboratory. It outlines three key accuracy checks: temperature accuracy should be within +3°C, timer accuracy should not vary by more than 10%, and speed settings should not vary by more than 1% of the displayed speed. It also lists preventative maintenance steps like cleaning, lubricating, and replacing worn parts per the manufacturer's instructions. A caution tag should be attached if any control settings have been changed during inspection.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

9 views1 pageCentrifuge 8

Centrifuge 8

Uploaded by

admin ptkmiThis document provides procedures for inspecting and maintaining centrifuges in a laboratory. It outlines three key accuracy checks: temperature accuracy should be within +3°C, timer accuracy should not vary by more than 10%, and speed settings should not vary by more than 1% of the displayed speed. It also lists preventative maintenance steps like cleaning, lubricating, and replacing worn parts per the manufacturer's instructions. A caution tag should be attached if any control settings have been changed during inspection.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Procedure No.

456-20010301 Centrituges (Combine

Make sure controls are set in their normal pre-use

positions.

Temperature AccuracY. Check the

temperature control on refrigerated centrifuges

Attach a caution tag in a prominent position to

using an electronic thermometer. Place the

electronic thermometer probe in the centrifuge

alert the user that control settings may have been

changed.

bowl near the automatic temperature control

sensor. (Refer to the manufacturer's specifications

to determine where the temperature control

sensor is located.) Close the centrifuge, sealing

the gasket around the thermometer cable.

Cornpare the temperature control with the

electronic thermometer at each setting or at the

settings being used. The readings should not

differ by more than +3'C. (Major, Acceptance)

Timer Accuracy. Check-the timer against a

stopwatch. A centrifuge should not vary by more

than *10olo. Depending on various state

regulations, this value may need to be recorded

onthe inspection tag. (Major, Acceptance)

Accuracy of Speed Setting. Determine

the range of speeds at which the centrifuge is

used and a typical load (e.9., number of filled

containers). Set the centrifuge to two or three

speeds, and measure the different speeds using a

tachometer. If a centrifuge has an opaque cover,

refer to the manufacturer's service manual to

check the speed accuracy. (Note: A vibrating

reed-type tachometer may be used with most

centrifdges with opaque covers.) The measured

speed should not vary by more than *1oolc of the

disolayed speed. (Note: If brushes have been

changed, check speed settinqs after brushes are

prcperly replaced.) (Major, Acceptance)

Preventive Ma intena nce

Clean. Clean exterior (interior if appropriate).

(Major)

Lubricate. Lubricate per manufacturer's

instructions. (Major)

Replace. Replace brushes, brake, gaskets,

seals, and vacuum PUmP, if needed. (For the

proper procedure for replacing brushes, refer to

the nranufacturer's manual and to the CAP

Laboratory Instrument Evaluation Verification &

Ma intena nce Ma nua l.) ( Major)

Before Returning to Use

All Rights Reserved.

Health Devices Inspection and Preventive Maintenance System O2O01 ECRI Paoe8of8

-

You might also like

- USP General Chapter 1251Document5 pagesUSP General Chapter 1251shdphNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- USP-NF 1251 Weighing On An Analytical BalanceDocument6 pagesUSP-NF 1251 Weighing On An Analytical BalanceMinh LêNo ratings yet

- Operating - Instructions NOxBOXi PDFDocument24 pagesOperating - Instructions NOxBOXi PDFMehaboob RahmanNo ratings yet

- BLP 530 Gas Porosimeter127 20 - InstructionsDocument11 pagesBLP 530 Gas Porosimeter127 20 - InstructionsDonig FermanianNo ratings yet

- Powapak Air Ultra Operating ManualDocument45 pagesPowapak Air Ultra Operating ManualBenrub Flores75% (4)

- Operating Instructions Regloplas 350L PDFDocument60 pagesOperating Instructions Regloplas 350L PDFAlhernan HernandezNo ratings yet

- P1128-Closed Loop Fueling Not Achieved - Bank 1 - WH, XH, Ka, KK - 2007-2010Document9 pagesP1128-Closed Loop Fueling Not Achieved - Bank 1 - WH, XH, Ka, KK - 2007-2010Karl Heinz KerzenschuhNo ratings yet

- SOP CAL Refrigerator FreezerDocument3 pagesSOP CAL Refrigerator FreezerJamall Clt33% (3)

- Health Devices IPM System: Inspection and Preventive MaintenanceDocument8 pagesHealth Devices IPM System: Inspection and Preventive MaintenancePradigda Kresna Putra100% (1)

- Page 9 of 22Document1 pagePage 9 of 22mNo ratings yet

- Easidew Manual (BHEL)Document57 pagesEasidew Manual (BHEL)NILESH100% (1)

- DTF-201 O2 AnalyzerDocument34 pagesDTF-201 O2 AnalyzerAnilNo ratings yet

- Anasthesa Unit VentilatorDocument6 pagesAnasthesa Unit VentilatorWidhiatmoko SangjendralNo ratings yet

- JEIO TECH Manual Baño Con Agitacion - BS - Unlocked PDFDocument23 pagesJEIO TECH Manual Baño Con Agitacion - BS - Unlocked PDFCarlos OrizabalNo ratings yet

- AHU Instruction - BookletDocument12 pagesAHU Instruction - BookletShahNo ratings yet

- Continuous Emission Monitoring System PDFDocument47 pagesContinuous Emission Monitoring System PDFnicoandayNo ratings yet

- User Manual: (Modular Kit)Document16 pagesUser Manual: (Modular Kit)ADRIANA DE JESUS ARGUELLES FLORESNo ratings yet

- Heat Detector Maintenance Testing ProcedureDocument2 pagesHeat Detector Maintenance Testing ProcedureAlvin MiraNo ratings yet

- Ma8750 Manual Eu enDocument28 pagesMa8750 Manual Eu enAcruzbNo ratings yet

- Uritek tc101Document22 pagesUritek tc101Nghi NguyenNo ratings yet

- M MegaTronSSDocument32 pagesM MegaTronSSPrakash SeendraNo ratings yet

- Health Devices IPM System, Inspection and Preventive Maintenance (Centrifuge)Document8 pagesHealth Devices IPM System, Inspection and Preventive Maintenance (Centrifuge)admin ptkmiNo ratings yet

- TSP-1 RevC 04-15Document8 pagesTSP-1 RevC 04-15boulacharNo ratings yet

- TC01 Temp Control ManaulDocument8 pagesTC01 Temp Control ManaulwinhlaingooNo ratings yet

- S9 MaintenanceDocument8 pagesS9 MaintenanceJosue LariosNo ratings yet

- Thermal Vacuum System ManualDocument19 pagesThermal Vacuum System ManualCCESARPLNo ratings yet

- Quo Test User ManualDocument36 pagesQuo Test User ManualBình SêNê-GalNo ratings yet

- Oxigen Analyzer DTF-201 Operation ManualDocument32 pagesOxigen Analyzer DTF-201 Operation ManualAcruzbNo ratings yet

- Official: Á1251Ñ Weighing On An Analytical BalanceDocument6 pagesOfficial: Á1251Ñ Weighing On An Analytical BalanceDilawar BakhtNo ratings yet

- Beta Star 2038 AutoclaveDocument47 pagesBeta Star 2038 AutoclaveJaved KarimNo ratings yet

- CCV-PA500 Ventilator: User'S ManualDocument24 pagesCCV-PA500 Ventilator: User'S ManualDewangga DiraNo ratings yet

- Valvegyr®: Siemens Building TechnologiesDocument16 pagesValvegyr®: Siemens Building TechnologiesAbdul LatheefNo ratings yet

- Usp42-Nf37 226Document6 pagesUsp42-Nf37 226rjagtap1230No ratings yet

- BccontDocument78 pagesBccontIonut GrozaNo ratings yet

- Installation Manual ULC EngDocument5 pagesInstallation Manual ULC Engziad nabilNo ratings yet

- 450 20081015 01 Major Proc CapnometerDocument8 pages450 20081015 01 Major Proc CapnometersantiNo ratings yet

- Basic Temperature Control SystemDocument26 pagesBasic Temperature Control SystemRajeev ValunjkarNo ratings yet

- 〈1251〉 WEIGHING ON AN ANALYTICAL BALANCEDocument6 pages〈1251〉 WEIGHING ON AN ANALYTICAL BALANCEanisoktaviaNo ratings yet

- Ak CH8Document3 pagesAk CH8aman212506No ratings yet

- MWC Testing and CommissioningDocument8 pagesMWC Testing and CommissioningladaojmNo ratings yet

- T 1566Document5 pagesT 1566Erwin Mauricio Alarcon PradenasNo ratings yet

- Hawco Controller TheoryDocument8 pagesHawco Controller TheoryEduardo Ocampo HernandezNo ratings yet

- Opera Ion Instruc IonDocument21 pagesOpera Ion Instruc Ionalan.subs5025No ratings yet

- Actual Model 81D Operating Manual 2015Document23 pagesActual Model 81D Operating Manual 2015Guillermo melendezNo ratings yet

- 13 - Instrumentation & ControlDocument11 pages13 - Instrumentation & ControlNoman Aslam50% (2)

- The Structure of Control System of GLP Animal LaboratoryDocument6 pagesThe Structure of Control System of GLP Animal Laboratoryviet_ha04No ratings yet

- p409s (Orange Electronic) v2Document20 pagesp409s (Orange Electronic) v2RayseanKangNo ratings yet

- User's Manual: Oil Content Meter Model GQS-206Document19 pagesUser's Manual: Oil Content Meter Model GQS-206Bhayu alfianNo ratings yet

- Water Balancing Procedures With Comments From Mechanical QCDocument22 pagesWater Balancing Procedures With Comments From Mechanical QCRaziKhan50% (2)

- Users Manual GQS-206 En1Document19 pagesUsers Manual GQS-206 En1abuzer1981100% (1)

- COF-1000 v11Document14 pagesCOF-1000 v11Sarah LinvilleNo ratings yet

- New Holland T9.390, T9.450, T9.505, T9.560, T9.615, T9.670Document7 pagesNew Holland T9.390, T9.450, T9.505, T9.560, T9.615, T9.670Luiz PolettiNo ratings yet

- 1251 Weighing On An Analytical BalanceDocument6 pages1251 Weighing On An Analytical Balancenonick18No ratings yet

- Fanem Baby IncubatorDocument9 pagesFanem Baby IncubatorMuhammad TanveerNo ratings yet

- 420 20081015 01 Major Proc ApneamonitorDocument8 pages420 20081015 01 Major Proc ApneamonitorsantiNo ratings yet

- PiFLOW OS PreppedDocument4 pagesPiFLOW OS PreppedPauline HölblingNo ratings yet

- 0049 UNIT OPERATION PROCEDDUREDocument72 pages0049 UNIT OPERATION PROCEDDUREGnanasekar VaishniNo ratings yet

- 123 Manual CO2 Inergen R1Document13 pages123 Manual CO2 Inergen R1MomoMaroufNo ratings yet

- Intelligent Photoelectric Smoke SensorsDocument2 pagesIntelligent Photoelectric Smoke Sensorsmubs73No ratings yet

- Centrifuge 7Document1 pageCentrifuge 7admin ptkmiNo ratings yet

- Centrifuge 5Document1 pageCentrifuge 5admin ptkmiNo ratings yet

- Centrifuge 6Document1 pageCentrifuge 6admin ptkmiNo ratings yet

- Centrifuge 4Document1 pageCentrifuge 4admin ptkmiNo ratings yet

- Centrifuge 3Document1 pageCentrifuge 3admin ptkmiNo ratings yet

- Centrifuge 2Document1 pageCentrifuge 2admin ptkmiNo ratings yet

- Health Devices IPM System, Inspection and Preventive Maintenance (Centrifuge)Document8 pagesHealth Devices IPM System, Inspection and Preventive Maintenance (Centrifuge)admin ptkmiNo ratings yet

- Science DLL Grade-3 Q1 Regular-FINALDocument13 pagesScience DLL Grade-3 Q1 Regular-FINALLhavz Meneses GarciaNo ratings yet

- SHS Voucher Program The GuidelinesDocument41 pagesSHS Voucher Program The Guidelinesjeremie cruzNo ratings yet

- Chap 11P Dual Nature of Radiation and Matter Arvind 2023Document50 pagesChap 11P Dual Nature of Radiation and Matter Arvind 2023spiritualmind61No ratings yet

- Advanced Algebra Midterm v1Document2 pagesAdvanced Algebra Midterm v1Eunice FaustinoNo ratings yet

- The Anatomy of The Airfoil: General Aviation Aircraft Design Ó 2014 Elsevier Inc. All Rights ReservedDocument63 pagesThe Anatomy of The Airfoil: General Aviation Aircraft Design Ó 2014 Elsevier Inc. All Rights ReservedmiguelNo ratings yet

- AP Chemistry Syllabus 2020-2021Document13 pagesAP Chemistry Syllabus 2020-2021Chemist Mohamed MohyNo ratings yet

- Lab 3 - Bending Moment DiagramsDocument9 pagesLab 3 - Bending Moment DiagramsTaha KhanNo ratings yet

- Wave Interference: One Word Answers and Numerical Answers Without Work Shown Will Only Be Given Credit!!Document2 pagesWave Interference: One Word Answers and Numerical Answers Without Work Shown Will Only Be Given Credit!!Malak WaleedNo ratings yet

- JEE Main 2021 Feb 24 Second Shift Question PaperDocument18 pagesJEE Main 2021 Feb 24 Second Shift Question PaperDishant ShahNo ratings yet

- Spread Footing Design: ASDIP Foundation 4.4.2Document4 pagesSpread Footing Design: ASDIP Foundation 4.4.2jhon j gomezNo ratings yet

- Craig Vaughan CHPTR 03Document16 pagesCraig Vaughan CHPTR 03amitNo ratings yet

- Weld Metal RT Film InterpretationDocument10 pagesWeld Metal RT Film Interpretationsekarsanthanam95% (22)

- Module 5 Nature of Light and The Principles of Ray OpticsDocument33 pagesModule 5 Nature of Light and The Principles of Ray OpticsXandra Samson100% (1)

- Strut&tieDocument135 pagesStrut&tieRutik PatelNo ratings yet

- Book 5909Document147 pagesBook 5909darch6321darchyahoo.comNo ratings yet

- Actuality and PotentialityDocument8 pagesActuality and PotentialityChristine Zoe SotasoNo ratings yet

- Epcos PDF n87Document7 pagesEpcos PDF n87Ashish KrishnaNo ratings yet

- Expansion Loop Design SheetDocument6 pagesExpansion Loop Design SheetSaqib LaeeqNo ratings yet

- Trajectory Tracking Control of A Differential Wheeled Mobile Robot: A Polar Coordinates Control and LQR ComparisonDocument4 pagesTrajectory Tracking Control of A Differential Wheeled Mobile Robot: A Polar Coordinates Control and LQR ComparisonAntonio MoisesNo ratings yet

- Physics 695: Advanced Topics in Mathematical Physics: Fall, 2007Document7 pagesPhysics 695: Advanced Topics in Mathematical Physics: Fall, 2007Jack Ignacio NahmíasNo ratings yet

- DFGHJ PDFDocument3 pagesDFGHJ PDFGaneshNo ratings yet

- Chapter 8 Quality ToolsDocument63 pagesChapter 8 Quality ToolsArvin RajNo ratings yet

- Internal Loadings Develpoed in Structural MembersDocument17 pagesInternal Loadings Develpoed in Structural MembersEboO QQNo ratings yet

- Agard Ag 207Document186 pagesAgard Ag 207Arockia FenilNo ratings yet

- May 2017Document8 pagesMay 2017anowNo ratings yet

- WTP SRQe BHG EV8 Myu KV K8Document91 pagesWTP SRQe BHG EV8 Myu KV K8KrishnaNo ratings yet

- Trammel ToyDocument1 pageTrammel ToyJennifer WangNo ratings yet

- Lock T Evo - en - 02-20 PDFDocument10 pagesLock T Evo - en - 02-20 PDFmilivoj ilibasicNo ratings yet

- MIT18 440S11 Lecture27Document18 pagesMIT18 440S11 Lecture27Jaco GreeffNo ratings yet

- Patterns and Numbers in Nature and The WorldDocument8 pagesPatterns and Numbers in Nature and The Worldayn pizzaNo ratings yet