Professional Documents

Culture Documents

Cap Bitucoat

Cap Bitucoat

Uploaded by

Medrar TareqCopyright:

Available Formats

You might also like

- BS en 295-3 1991 PDFDocument30 pagesBS en 295-3 1991 PDFKc FungNo ratings yet

- Powerproof: One Component Polyurethane Dispersion Waterproofing MembraneDocument2 pagesPowerproof: One Component Polyurethane Dispersion Waterproofing MembraneFritz Natividad67% (3)

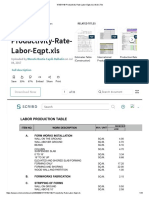

- Productivity Rate Labor EqptDocument16 pagesProductivity Rate Labor EqptZelalem Mengistu0% (1)

- Brown - Introduction To Thermal Analysis. Techniques and Applications PDFDocument267 pagesBrown - Introduction To Thermal Analysis. Techniques and Applications PDFSávio MendesNo ratings yet

- Capcoat E: N F B EDocument2 pagesCapcoat E: N F B EEng-Medrar AlkateryNo ratings yet

- Sikatop - 107 Sealid 221102 105735Document4 pagesSikatop - 107 Sealid 221102 105735Andre SitumeangNo ratings yet

- Sikatop 107 Seal - Pds en PDFDocument3 pagesSikatop 107 Seal - Pds en PDFMarthinus Tonny PangemananNo ratings yet

- Sikatop 107 Seal Pds enDocument3 pagesSikatop 107 Seal Pds enadriansyahNo ratings yet

- MasterSeal® 610Document2 pagesMasterSeal® 610awad.aslamhouriNo ratings yet

- Sikagrout® - 295Document3 pagesSikagrout® - 295Ayman ZakariaNo ratings yet

- BC Bitumen CoatingDocument3 pagesBC Bitumen CoatingSyerifaizal Hj. MustaphaNo ratings yet

- Sikatop®-144 Id: Product Data SheetDocument3 pagesSikatop®-144 Id: Product Data SheetBenny RamadanNo ratings yet

- Bitumen DatasheetsDocument3 pagesBitumen Datasheetstaztika putriNo ratings yet

- Dolphin Bitumimous TDS - CompressedDocument2 pagesDolphin Bitumimous TDS - CompressedMohanned KhalidNo ratings yet

- Cicoputty - PDSDocument2 pagesCicoputty - PDSalberto.20126No ratings yet

- AWAZEL WB SubmittalDocument26 pagesAWAZEL WB SubmittalAbdel Mongy AhmedNo ratings yet

- Dry RBV (UAE) : Rubberized Bitumen Emulsion Modified With SBRDocument2 pagesDry RBV (UAE) : Rubberized Bitumen Emulsion Modified With SBRADEE666No ratings yet

- Polycrete FC: Polymer Modified Cementitious Fairing CoatDocument2 pagesPolycrete FC: Polymer Modified Cementitious Fairing Coatmohamed ragabNo ratings yet

- Sikatop 107 Seal Pds enDocument3 pagesSikatop 107 Seal Pds ensahal_akNo ratings yet

- Masterseal 380Document2 pagesMasterseal 380Francois-No ratings yet

- Master EmacoDocument3 pagesMaster EmacoSmookers HeavenNo ratings yet

- Curacoat PDocument2 pagesCuracoat PSivaramkumarNo ratings yet

- MasterSeal 610Document2 pagesMasterSeal 610Gavriel NgNo ratings yet

- TDS Bostik BoscoSeal PUDocument2 pagesTDS Bostik BoscoSeal PUJp riveraNo ratings yet

- Sika Igasol Emulsionba-6510Document3 pagesSika Igasol Emulsionba-6510PETYTH AIMENo ratings yet

- Tikidan Tds - Revestidan IndoorDocument2 pagesTikidan Tds - Revestidan IndoorsandeepNo ratings yet

- Basf Mastertop P 650 TdsDocument2 pagesBasf Mastertop P 650 Tdstorvee otaruNo ratings yet

- Polyurethane - Weberdry - RBE-LDocument2 pagesPolyurethane - Weberdry - RBE-LAbdel Razak Al AsmarNo ratings yet

- Sikaseal - 105Document3 pagesSikaseal - 105Nader ToutounjiNo ratings yet

- Uspro Tds Rev0.1Document2 pagesUspro Tds Rev0.1debojyotihati100% (1)

- Manual Everbuild Blackjack PrimerDocument3 pagesManual Everbuild Blackjack PrimermickNo ratings yet

- Sika® Concrete Crack Fix: Product Data SheetDocument3 pagesSika® Concrete Crack Fix: Product Data SheetHamidreza AraghianNo ratings yet

- Bitukold Data Sheet - ColasDocument1 pageBitukold Data Sheet - ColasRubul AliNo ratings yet

- Sika Roofcoat Pds enDocument3 pagesSika Roofcoat Pds enlailiNo ratings yet

- Cicobond®HS PDSDocument2 pagesCicobond®HS PDSalberto.20126No ratings yet

- Sikatop 130 FlexkeDocument3 pagesSikatop 130 FlexkeNagarajan KumaranNo ratings yet

- Sikatop 599 SealDocument3 pagesSikatop 599 SealVanessa GuerreroNo ratings yet

- Sikagrout®-295 In: Product Data SheetDocument3 pagesSikagrout®-295 In: Product Data SheetBala KathirveluNo ratings yet

- Contite Seal MortarDocument2 pagesContite Seal MortarShanaei MiskinNo ratings yet

- Davco k10 PlusDocument3 pagesDavco k10 PlusTARGET TRADE LINKSNo ratings yet

- Masterseal 588: Description Packaging and ColorsDocument2 pagesMasterseal 588: Description Packaging and ColorsmariaNo ratings yet

- Tds-Unichem AlumcoatDocument3 pagesTds-Unichem AlumcoatAnvesh BondugulaNo ratings yet

- Cicoprime 10 Technical DatasheetDocument2 pagesCicoprime 10 Technical Datasheetalberto.20126No ratings yet

- Sikagard Colour Enhancer-En - (02-2019) - 1Document2 pagesSikagard Colour Enhancer-En - (02-2019) - 1Andrei GheoNo ratings yet

- TDS Weberdry RoofDocument2 pagesTDS Weberdry RoofMahendra Singh BudhathokiNo ratings yet

- SikaTop Seal-107 PDFDocument4 pagesSikaTop Seal-107 PDFDan BermasNo ratings yet

- Sikarep: Multi-Purpose Patching and Repair Mortar Technical Data SheetDocument4 pagesSikarep: Multi-Purpose Patching and Repair Mortar Technical Data SheetjodemodeNo ratings yet

- Sikatop®-107 Seal KH: Product Data SheetDocument4 pagesSikatop®-107 Seal KH: Product Data SheetReab SimanthNo ratings yet

- Alpha Dry Adhesive Tds 843706Document2 pagesAlpha Dry Adhesive Tds 843706aruncg2No ratings yet

- Sikafloor - 957 SSDDocument3 pagesSikafloor - 957 SSDRodo Samuel SitorusNo ratings yet

- Dlc-Grout C100: General Purpose, High Strength, Non-Shrink Cementitious GroutDocument4 pagesDlc-Grout C100: General Purpose, High Strength, Non-Shrink Cementitious Grout4919404No ratings yet

- sHOTPATCH 10 v3 PDFDocument2 pagessHOTPATCH 10 v3 PDFAnkita Baban GavadeNo ratings yet

- Shalitex Primer: DescriptionDocument2 pagesShalitex Primer: DescriptionRight Solutions Waterproofing ServicesNo ratings yet

- Primer TC PDFDocument3 pagesPrimer TC PDFFrancois-No ratings yet

- DK11 SlurryDocument2 pagesDK11 SlurryRon Jovi GarciaNo ratings yet

- Plyroute MSDDocument2 pagesPlyroute MSDMuhammad hussainNo ratings yet

- Manual Everbuild Evercryl One Coat 15341Document3 pagesManual Everbuild Evercryl One Coat 15341scribd2162No ratings yet

- Dura Grout: A.B.E. Construction ChemicalsDocument3 pagesDura Grout: A.B.E. Construction ChemicalsVirah Sammy ChandraNo ratings yet

- Cleverproof - 400 BT 2KDocument2 pagesCleverproof - 400 BT 2KAarif TanwarNo ratings yet

- WPM 300 TDSDocument2 pagesWPM 300 TDSPetrus PaulusNo ratings yet

- Aquashield BXDocument2 pagesAquashield BXmk779900mkNo ratings yet

- SikaMonoTop 615SD en MY (11 2018) 1 1Document3 pagesSikaMonoTop 615SD en MY (11 2018) 1 1chanqiming51No ratings yet

- Epoxy Steel Primer: KG KGDocument1 pageEpoxy Steel Primer: KG KGMedrar TareqNo ratings yet

- Polywed Supercoat 500: Technical Properties ApplicationDocument2 pagesPolywed Supercoat 500: Technical Properties ApplicationMedrar TareqNo ratings yet

- Oxide Primer: Instruction For Use Product InformationDocument1 pageOxide Primer: Instruction For Use Product InformationMedrar TareqNo ratings yet

- Cap Hydroseal2Document2 pagesCap Hydroseal2Medrar TareqNo ratings yet

- Capgrout GPDocument2 pagesCapgrout GPMedrar TareqNo ratings yet

- Cap Dryshake HardenerDocument2 pagesCap Dryshake HardenerMedrar TareqNo ratings yet

- Ac 500Document2 pagesAc 500Medrar TareqNo ratings yet

- Jalil 2020 IOP Conf. Ser. Mater. Sci. Eng. 737 012078Document11 pagesJalil 2020 IOP Conf. Ser. Mater. Sci. Eng. 737 012078Kliment RadoevNo ratings yet

- Aci 318 Code Provisions For Deflection Control of Two-Way Concrete SlabsDocument81 pagesAci 318 Code Provisions For Deflection Control of Two-Way Concrete SlabslabunasNo ratings yet

- Deck Design GuideDocument63 pagesDeck Design GuideLê Ngọc-HàNo ratings yet

- Department of Civil Engineering B.Tech-3 Semester SyllabusDocument10 pagesDepartment of Civil Engineering B.Tech-3 Semester SyllabusTenzing tamangNo ratings yet

- DIV 16 Electrical Labor1Document43 pagesDIV 16 Electrical Labor1Anila SadasivanNo ratings yet

- Design Computation For 12m Double Lane Bridge TgirderDocument50 pagesDesign Computation For 12m Double Lane Bridge TgirderEngineeri TadiyosNo ratings yet

- Sample Bar ChartDocument1 pageSample Bar Chartrheymar diwaNo ratings yet

- PDS - Sika MonoTop-412 MYDocument4 pagesPDS - Sika MonoTop-412 MYNorlizawati YusofNo ratings yet

- Noise Control of Buildings.: Chikodi - 591201 Civil Engineering DepartmentDocument17 pagesNoise Control of Buildings.: Chikodi - 591201 Civil Engineering DepartmentAbhi AppajigolNo ratings yet

- NKGSB-PRS-CL-007-A4-A Fire Water Demand Calculation2 (Autosaved-26-01-20)Document15 pagesNKGSB-PRS-CL-007-A4-A Fire Water Demand Calculation2 (Autosaved-26-01-20)ahmad santoso100% (1)

- 1issue7Document4 pages1issue7Cociorva DanNo ratings yet

- Super Mai A - BOQ Final-RK-BcDocument179 pagesSuper Mai A - BOQ Final-RK-BcRajesh GuptaNo ratings yet

- Modeling Heat Treatment of Steel PartsDocument8 pagesModeling Heat Treatment of Steel PartssakthistoryNo ratings yet

- Disclosure To Promote The Right To Information: IS 4432 (1988) : Case Hardening Steels (MTD 16: Alloy Steels and Forgings)Document15 pagesDisclosure To Promote The Right To Information: IS 4432 (1988) : Case Hardening Steels (MTD 16: Alloy Steels and Forgings)Selvaraji Muthu50% (2)

- Heat Transfer SummaryDocument16 pagesHeat Transfer Summaryanastasios0% (1)

- Lab 1 - GROUP 4Document4 pagesLab 1 - GROUP 4NORHAFINI HAMBALINo ratings yet

- Me1302 LP ADocument3 pagesMe1302 LP ACKDinakarrajNo ratings yet

- Hubbell PDFDocument4 pagesHubbell PDFPuneet GuptaNo ratings yet

- Structural Steel Design: DR - Mu'taz K.M Ass. Prof. in Civil EngineeringDocument16 pagesStructural Steel Design: DR - Mu'taz K.M Ass. Prof. in Civil EngineeringSureshbabu NarayanasamyNo ratings yet

- Shape Memory AlloyDocument20 pagesShape Memory AlloyChandra Sekhar CNo ratings yet

- LIME Perspective by Vaishali Latkar (Compatibility Mode)Document28 pagesLIME Perspective by Vaishali Latkar (Compatibility Mode)Vaishali LatkarNo ratings yet

- Reinforced Concrete Design by Krishna RajuDocument10 pagesReinforced Concrete Design by Krishna RajuncicnsscscNo ratings yet

- FEA Ansys Axisymmetric Skirt ExampleDocument16 pagesFEA Ansys Axisymmetric Skirt Examplejohn_max03No ratings yet

- Fakulti Kejuruteraan Awam Universiti Teknologi Mara Pahang Laboratory ManualDocument6 pagesFakulti Kejuruteraan Awam Universiti Teknologi Mara Pahang Laboratory ManualAMIRUL MUSTAQIM BIN ABDULLAHNo ratings yet

- Flux and Refining Agent InjectionDocument1 pageFlux and Refining Agent InjectionСтанислав ПодольскийNo ratings yet

- Castrol Tribol 800Document2 pagesCastrol Tribol 800Cardoso Malacao0% (1)

- A Company Known For Its Excellence in Heat Transfer SolutionsDocument4 pagesA Company Known For Its Excellence in Heat Transfer SolutionsSaurabh GupteNo ratings yet

Cap Bitucoat

Cap Bitucoat

Uploaded by

Medrar TareqOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cap Bitucoat

Cap Bitucoat

Uploaded by

Medrar TareqCopyright:

Available Formats

CAP BITUCOAT

NON FIBRATED BITUMEN EMULSION BASED PROTECTIVE COATING

DESCRIPTION

CAP BITUCOAT is a ready for use cold TYPICAL PROPERTIES

applied, non fibrated, emulsified bitumen Appearance:

protective coating, specially formulated and Viscous liquid, dark brown in colour, drying to

resistant to sub-soil corrosive salt, fungal black flexible coating.

protection and waterproofing of substrate.

Weight per liter in grams : 1000 + 100.

STANDARDS

CAP BITUCOAT complies with the Flammability : No tendency to flash or ignite.

specifications of ASTM-D 1227 & BS 6949. Toxicity : Non-toxic.

APPLICATIONS

Chemical and water resistance:

Excellent resistance to water vapour, saltwater,

▪ Protective coating for flat, exposed and dilute acids, and alkalis.

pitched roofs as well as kitchens,

bathrooms, and basements. Heat flow resistance:

▪ Damp-proofing of concrete basements, The cured film will not sag or flow under

walls, floors, blockwork walls, etc. service conditions.

▪ Protection of concrete foundations, Shelf life:

footings, retaining walls, etc. above and Minimum 12 months in sealed original

below grade from soil chemicals. containers, under recommended storage

▪ It can serve as a protector on metal conditions.

surfaces that are subjected to corrosion

like metal pipes, steel structural works, COVERAGE

and other metallic surfaces. High built up is possible on account of the

▪ Can be comfortably used as a curing thixotropic consistency of the product. Coverage

membrane, or a primer and sealer for rates vary from 0.4 to 0.6 Kg/m2 depending on

building sub-structures. the type of surface and built up thickness.

ADVANTAGES DIRECTIONS FOR USE

▪ Suitable for use in both dry and damp Surface Preparation:

surfaces. ▪ Concrete surfaces must be clean, sound, and

▪ Easy to apply. free from oil, grease, dirt, dust, and loose

▪ Ready for use; no mixing or heating particles. It is desirable to dampen the surface

required. with water if the concrete or blockwork is

▪ Good weather resistance. very dry.

▪ Does not embrittle at low temperatures. ▪ It is recommended that metal surfaces be

▪ Good resistance to soil acids and salts. wire brushed in order to remove loose rust,

▪ Solvent-free, non-toxic and non-flammable. mill scale, etc. wipe off oil and grease from

▪ Economical in use. the surface with a suitable solvent.

Ver 01.: 01 Sep 2020 Page 1 of 2 Ref No.: ACC/R&D/2009/EBP/113

CAP BITUCOAT

NON FIBRATED BITUMEN EMULSION BASED PROTECTIVE COATING

Method of Application: CLEANING TOOLS

▪ Primer usage is not mandatory but based ▪ Dip brush in clean water before and

on substrate condition if required use during use for ease of application.

Ahlia’s CAP-PRIME as a primer at the ▪ During work break periods place them in

rate of 0.15 to 0.25 Kg/m2 to ensure water to prevent caking up of the bristles.

proper bonding of subsequent coat or ▪ Clean brushes and tools in soap and

CAP BITUCOAT, diluted with water water immediately after use.

may also be used as a primer. ▪ Dried emulsion can be removed with the

▪ CAP BITUCOAT should be thoroughly help of white spirit, petrol, diesel oil etc.

mixed before application. It can be

applied by means of brush, roller, or SAFETY PRECAUTIONS

airless spray. ▪ CAP BITUCOAT is non-flammable and

▪ While the coat is still wet, embed non- hazardous in normal use.

fiberglass mesh into the coat. use the ▪ When the product is wet, it should be

trowel to work the material up and removed from skin by soap and water.

through the mesh until it is completely But when dry, suitable cleaners like

embedded. petrol, diesel, etc. should be used.

▪ Apply minimum of two coats of CAP ▪ Splashes to eyes should be washed

BITUCOAT with a heavily loaded brush immediately with abundant water.

or broom. A thick coat can be laid even ▪ Avoid contact by careful working and

on vertical surfaces, on account of the use barrier cream or gloves.

thixotropic nature of the product.

▪ Each coat must be applied at right angles PACKAGING

to the previous one to obtain proper CAP BITUCOAT is supplied in 15 Kg metal

coverage and uniformity. pails.

▪ The first coat must be fully dry before

the subsequent coat is applied. Normal STORAGE

drying time is between 1 to 4 hours. In ▪ Stored in sealed conventional containers,

high humid and cold weather conditions, protected from extreme weather

this may extend up to 12 hours or more. conditions.

▪ In exposed areas, it is prudent to cover ▪ Stir well before use, if stored for a long

the applied CAP BITUCOAT with a time.

protective screed, in order to avoid direct

exposure to sunlight. The protective

screed will enhance the life of CAP

BITUCOAT treatment.

TECHNICAL SERVICE:

Our Technical Service Department is available at any time to advise you in the correct use of this product or any other Ahlia products.

Note : The information presented herein is based on the best of our knowledge and expertise for which every effort is made to ensure its reliability. Although

all the products are subjected to rigid quality tests and are guaranteed against defective materials and manufacture, no specific guarantee can be extended

because results depend not only on quality but also on other factors beyond our control.

As all Ahlia Technical Data Sheets are updated on a regular basis, it is the user responsibility to collect most recent issue.

Ver 01.: 01 Sep 2020 Page 2 of 2 Ref No.: ACC/R&D/2009/EBP/113

You might also like

- BS en 295-3 1991 PDFDocument30 pagesBS en 295-3 1991 PDFKc FungNo ratings yet

- Powerproof: One Component Polyurethane Dispersion Waterproofing MembraneDocument2 pagesPowerproof: One Component Polyurethane Dispersion Waterproofing MembraneFritz Natividad67% (3)

- Productivity Rate Labor EqptDocument16 pagesProductivity Rate Labor EqptZelalem Mengistu0% (1)

- Brown - Introduction To Thermal Analysis. Techniques and Applications PDFDocument267 pagesBrown - Introduction To Thermal Analysis. Techniques and Applications PDFSávio MendesNo ratings yet

- Capcoat E: N F B EDocument2 pagesCapcoat E: N F B EEng-Medrar AlkateryNo ratings yet

- Sikatop - 107 Sealid 221102 105735Document4 pagesSikatop - 107 Sealid 221102 105735Andre SitumeangNo ratings yet

- Sikatop 107 Seal - Pds en PDFDocument3 pagesSikatop 107 Seal - Pds en PDFMarthinus Tonny PangemananNo ratings yet

- Sikatop 107 Seal Pds enDocument3 pagesSikatop 107 Seal Pds enadriansyahNo ratings yet

- MasterSeal® 610Document2 pagesMasterSeal® 610awad.aslamhouriNo ratings yet

- Sikagrout® - 295Document3 pagesSikagrout® - 295Ayman ZakariaNo ratings yet

- BC Bitumen CoatingDocument3 pagesBC Bitumen CoatingSyerifaizal Hj. MustaphaNo ratings yet

- Sikatop®-144 Id: Product Data SheetDocument3 pagesSikatop®-144 Id: Product Data SheetBenny RamadanNo ratings yet

- Bitumen DatasheetsDocument3 pagesBitumen Datasheetstaztika putriNo ratings yet

- Dolphin Bitumimous TDS - CompressedDocument2 pagesDolphin Bitumimous TDS - CompressedMohanned KhalidNo ratings yet

- Cicoputty - PDSDocument2 pagesCicoputty - PDSalberto.20126No ratings yet

- AWAZEL WB SubmittalDocument26 pagesAWAZEL WB SubmittalAbdel Mongy AhmedNo ratings yet

- Dry RBV (UAE) : Rubberized Bitumen Emulsion Modified With SBRDocument2 pagesDry RBV (UAE) : Rubberized Bitumen Emulsion Modified With SBRADEE666No ratings yet

- Polycrete FC: Polymer Modified Cementitious Fairing CoatDocument2 pagesPolycrete FC: Polymer Modified Cementitious Fairing Coatmohamed ragabNo ratings yet

- Sikatop 107 Seal Pds enDocument3 pagesSikatop 107 Seal Pds ensahal_akNo ratings yet

- Masterseal 380Document2 pagesMasterseal 380Francois-No ratings yet

- Master EmacoDocument3 pagesMaster EmacoSmookers HeavenNo ratings yet

- Curacoat PDocument2 pagesCuracoat PSivaramkumarNo ratings yet

- MasterSeal 610Document2 pagesMasterSeal 610Gavriel NgNo ratings yet

- TDS Bostik BoscoSeal PUDocument2 pagesTDS Bostik BoscoSeal PUJp riveraNo ratings yet

- Sika Igasol Emulsionba-6510Document3 pagesSika Igasol Emulsionba-6510PETYTH AIMENo ratings yet

- Tikidan Tds - Revestidan IndoorDocument2 pagesTikidan Tds - Revestidan IndoorsandeepNo ratings yet

- Basf Mastertop P 650 TdsDocument2 pagesBasf Mastertop P 650 Tdstorvee otaruNo ratings yet

- Polyurethane - Weberdry - RBE-LDocument2 pagesPolyurethane - Weberdry - RBE-LAbdel Razak Al AsmarNo ratings yet

- Sikaseal - 105Document3 pagesSikaseal - 105Nader ToutounjiNo ratings yet

- Uspro Tds Rev0.1Document2 pagesUspro Tds Rev0.1debojyotihati100% (1)

- Manual Everbuild Blackjack PrimerDocument3 pagesManual Everbuild Blackjack PrimermickNo ratings yet

- Sika® Concrete Crack Fix: Product Data SheetDocument3 pagesSika® Concrete Crack Fix: Product Data SheetHamidreza AraghianNo ratings yet

- Bitukold Data Sheet - ColasDocument1 pageBitukold Data Sheet - ColasRubul AliNo ratings yet

- Sika Roofcoat Pds enDocument3 pagesSika Roofcoat Pds enlailiNo ratings yet

- Cicobond®HS PDSDocument2 pagesCicobond®HS PDSalberto.20126No ratings yet

- Sikatop 130 FlexkeDocument3 pagesSikatop 130 FlexkeNagarajan KumaranNo ratings yet

- Sikatop 599 SealDocument3 pagesSikatop 599 SealVanessa GuerreroNo ratings yet

- Sikagrout®-295 In: Product Data SheetDocument3 pagesSikagrout®-295 In: Product Data SheetBala KathirveluNo ratings yet

- Contite Seal MortarDocument2 pagesContite Seal MortarShanaei MiskinNo ratings yet

- Davco k10 PlusDocument3 pagesDavco k10 PlusTARGET TRADE LINKSNo ratings yet

- Masterseal 588: Description Packaging and ColorsDocument2 pagesMasterseal 588: Description Packaging and ColorsmariaNo ratings yet

- Tds-Unichem AlumcoatDocument3 pagesTds-Unichem AlumcoatAnvesh BondugulaNo ratings yet

- Cicoprime 10 Technical DatasheetDocument2 pagesCicoprime 10 Technical Datasheetalberto.20126No ratings yet

- Sikagard Colour Enhancer-En - (02-2019) - 1Document2 pagesSikagard Colour Enhancer-En - (02-2019) - 1Andrei GheoNo ratings yet

- TDS Weberdry RoofDocument2 pagesTDS Weberdry RoofMahendra Singh BudhathokiNo ratings yet

- SikaTop Seal-107 PDFDocument4 pagesSikaTop Seal-107 PDFDan BermasNo ratings yet

- Sikarep: Multi-Purpose Patching and Repair Mortar Technical Data SheetDocument4 pagesSikarep: Multi-Purpose Patching and Repair Mortar Technical Data SheetjodemodeNo ratings yet

- Sikatop®-107 Seal KH: Product Data SheetDocument4 pagesSikatop®-107 Seal KH: Product Data SheetReab SimanthNo ratings yet

- Alpha Dry Adhesive Tds 843706Document2 pagesAlpha Dry Adhesive Tds 843706aruncg2No ratings yet

- Sikafloor - 957 SSDDocument3 pagesSikafloor - 957 SSDRodo Samuel SitorusNo ratings yet

- Dlc-Grout C100: General Purpose, High Strength, Non-Shrink Cementitious GroutDocument4 pagesDlc-Grout C100: General Purpose, High Strength, Non-Shrink Cementitious Grout4919404No ratings yet

- sHOTPATCH 10 v3 PDFDocument2 pagessHOTPATCH 10 v3 PDFAnkita Baban GavadeNo ratings yet

- Shalitex Primer: DescriptionDocument2 pagesShalitex Primer: DescriptionRight Solutions Waterproofing ServicesNo ratings yet

- Primer TC PDFDocument3 pagesPrimer TC PDFFrancois-No ratings yet

- DK11 SlurryDocument2 pagesDK11 SlurryRon Jovi GarciaNo ratings yet

- Plyroute MSDDocument2 pagesPlyroute MSDMuhammad hussainNo ratings yet

- Manual Everbuild Evercryl One Coat 15341Document3 pagesManual Everbuild Evercryl One Coat 15341scribd2162No ratings yet

- Dura Grout: A.B.E. Construction ChemicalsDocument3 pagesDura Grout: A.B.E. Construction ChemicalsVirah Sammy ChandraNo ratings yet

- Cleverproof - 400 BT 2KDocument2 pagesCleverproof - 400 BT 2KAarif TanwarNo ratings yet

- WPM 300 TDSDocument2 pagesWPM 300 TDSPetrus PaulusNo ratings yet

- Aquashield BXDocument2 pagesAquashield BXmk779900mkNo ratings yet

- SikaMonoTop 615SD en MY (11 2018) 1 1Document3 pagesSikaMonoTop 615SD en MY (11 2018) 1 1chanqiming51No ratings yet

- Epoxy Steel Primer: KG KGDocument1 pageEpoxy Steel Primer: KG KGMedrar TareqNo ratings yet

- Polywed Supercoat 500: Technical Properties ApplicationDocument2 pagesPolywed Supercoat 500: Technical Properties ApplicationMedrar TareqNo ratings yet

- Oxide Primer: Instruction For Use Product InformationDocument1 pageOxide Primer: Instruction For Use Product InformationMedrar TareqNo ratings yet

- Cap Hydroseal2Document2 pagesCap Hydroseal2Medrar TareqNo ratings yet

- Capgrout GPDocument2 pagesCapgrout GPMedrar TareqNo ratings yet

- Cap Dryshake HardenerDocument2 pagesCap Dryshake HardenerMedrar TareqNo ratings yet

- Ac 500Document2 pagesAc 500Medrar TareqNo ratings yet

- Jalil 2020 IOP Conf. Ser. Mater. Sci. Eng. 737 012078Document11 pagesJalil 2020 IOP Conf. Ser. Mater. Sci. Eng. 737 012078Kliment RadoevNo ratings yet

- Aci 318 Code Provisions For Deflection Control of Two-Way Concrete SlabsDocument81 pagesAci 318 Code Provisions For Deflection Control of Two-Way Concrete SlabslabunasNo ratings yet

- Deck Design GuideDocument63 pagesDeck Design GuideLê Ngọc-HàNo ratings yet

- Department of Civil Engineering B.Tech-3 Semester SyllabusDocument10 pagesDepartment of Civil Engineering B.Tech-3 Semester SyllabusTenzing tamangNo ratings yet

- DIV 16 Electrical Labor1Document43 pagesDIV 16 Electrical Labor1Anila SadasivanNo ratings yet

- Design Computation For 12m Double Lane Bridge TgirderDocument50 pagesDesign Computation For 12m Double Lane Bridge TgirderEngineeri TadiyosNo ratings yet

- Sample Bar ChartDocument1 pageSample Bar Chartrheymar diwaNo ratings yet

- PDS - Sika MonoTop-412 MYDocument4 pagesPDS - Sika MonoTop-412 MYNorlizawati YusofNo ratings yet

- Noise Control of Buildings.: Chikodi - 591201 Civil Engineering DepartmentDocument17 pagesNoise Control of Buildings.: Chikodi - 591201 Civil Engineering DepartmentAbhi AppajigolNo ratings yet

- NKGSB-PRS-CL-007-A4-A Fire Water Demand Calculation2 (Autosaved-26-01-20)Document15 pagesNKGSB-PRS-CL-007-A4-A Fire Water Demand Calculation2 (Autosaved-26-01-20)ahmad santoso100% (1)

- 1issue7Document4 pages1issue7Cociorva DanNo ratings yet

- Super Mai A - BOQ Final-RK-BcDocument179 pagesSuper Mai A - BOQ Final-RK-BcRajesh GuptaNo ratings yet

- Modeling Heat Treatment of Steel PartsDocument8 pagesModeling Heat Treatment of Steel PartssakthistoryNo ratings yet

- Disclosure To Promote The Right To Information: IS 4432 (1988) : Case Hardening Steels (MTD 16: Alloy Steels and Forgings)Document15 pagesDisclosure To Promote The Right To Information: IS 4432 (1988) : Case Hardening Steels (MTD 16: Alloy Steels and Forgings)Selvaraji Muthu50% (2)

- Heat Transfer SummaryDocument16 pagesHeat Transfer Summaryanastasios0% (1)

- Lab 1 - GROUP 4Document4 pagesLab 1 - GROUP 4NORHAFINI HAMBALINo ratings yet

- Me1302 LP ADocument3 pagesMe1302 LP ACKDinakarrajNo ratings yet

- Hubbell PDFDocument4 pagesHubbell PDFPuneet GuptaNo ratings yet

- Structural Steel Design: DR - Mu'taz K.M Ass. Prof. in Civil EngineeringDocument16 pagesStructural Steel Design: DR - Mu'taz K.M Ass. Prof. in Civil EngineeringSureshbabu NarayanasamyNo ratings yet

- Shape Memory AlloyDocument20 pagesShape Memory AlloyChandra Sekhar CNo ratings yet

- LIME Perspective by Vaishali Latkar (Compatibility Mode)Document28 pagesLIME Perspective by Vaishali Latkar (Compatibility Mode)Vaishali LatkarNo ratings yet

- Reinforced Concrete Design by Krishna RajuDocument10 pagesReinforced Concrete Design by Krishna RajuncicnsscscNo ratings yet

- FEA Ansys Axisymmetric Skirt ExampleDocument16 pagesFEA Ansys Axisymmetric Skirt Examplejohn_max03No ratings yet

- Fakulti Kejuruteraan Awam Universiti Teknologi Mara Pahang Laboratory ManualDocument6 pagesFakulti Kejuruteraan Awam Universiti Teknologi Mara Pahang Laboratory ManualAMIRUL MUSTAQIM BIN ABDULLAHNo ratings yet

- Flux and Refining Agent InjectionDocument1 pageFlux and Refining Agent InjectionСтанислав ПодольскийNo ratings yet

- Castrol Tribol 800Document2 pagesCastrol Tribol 800Cardoso Malacao0% (1)

- A Company Known For Its Excellence in Heat Transfer SolutionsDocument4 pagesA Company Known For Its Excellence in Heat Transfer SolutionsSaurabh GupteNo ratings yet