Professional Documents

Culture Documents

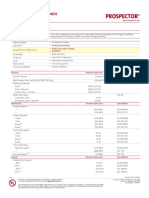

Classification 14009

Classification 14009

Uploaded by

Sayyid AbulkhairOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Classification 14009

Classification 14009

Uploaded by

Sayyid AbulkhairCopyright:

Available Formats

Transparent Transparent Transparent Transparent Transparent Transparent Transparent Transparent

Medical, High chemical resista

Test Method IS High rigidity Middle impact High impact Chemical resistant High chemical resistant Medical, Chemical resistant Scratch resistant

Property Test Condition Units nt

O

920 555 900 352 930 355 950 X01 950 X02 950 ME1 950 ME2 910 X01

>MABS< >MABS< >MABS< >MABS< >MABS< >MABS< >MABS< >MABS<

Physical property

Density 23℃ ISO 1183 kg/m 3 1090 1080 1080 1090 1090 1090 1090 1100

Specific Gravity ASTM D792 - 1.09 1.08 1.08 1.09 1.09 1.09 1.09 1.1

Mechanical property

Tensile strength 23℃ ISO 527-1,2 MPa 54 48 45 50 53 50 53 57

Tensile strength ASTM D638 MPa 48 41 40 43 43

Tensile elongation at Break ASTM D638 % 20 40 40 20 20

Elongation at Break 23℃ ISO 527-1,2 % 17 15 16 14 13 14 13 13

Flexural Strength 23℃ ISO 178 MPa 77 66 64 71 74 71 74 85

Flexural Strength ASTM D790 MPa 74 63 61 67 67

Flexural Modulus 23℃/50% RH ISO 178 MPa 2260 1870 1830 2180 2340 2180 2340 2630

Flexural Modulus ASTM D790 MPa 2160 1810 1810 2100 2100

Rockwell Hardness 23℃ ISO 2039-2 R Scale 115 108 102 110 110 110 110

Rockwell Hardness 23℃/50% RH ASTM D785 Rスケール 115 108 102 110 110

C harpy Im pact Strength(V-notc

23℃ ISO 179 kJ/m 2 9 12 13 14 12 14 12 6

hed)

Ball Pressure Tem p./0.1m m Vica

℃ 90〜90 90〜90 85〜85 80〜85 80〜85 85〜90

t Softening Tem p.

Izod Im pact Strength(V-notched

23℃ 12.7m m ASTM D256 J/m 108 137 147 170 170

)

Izod Im pact Strength(V-notched

23℃ 3.2m m ASTM D256 J/m 108 157 186 180 180

)

Heat property

Heat Deflection Tem p High Load 1.80MPa ISO 75-1,2 ℃ 77 76 74 75 75 75 75 78

Heat Deflection Tem p(Unanneal

6.4m m /1.82MPa ASTM D648 ℃ 83 81 80 79 79

ed)High Load

rank/thickne

Flam m ability UL94 HB HB HB HB HB HB HB HB

ss m m t

Molding property

Mold shrinkage 23℃/50% RH Toray Method % 0.4-0.6 0.4-0.6 0.4-0.6 0.4-0.6 0.4-0.6 0.4-0.6 0.4-0.6 0.4-0.6

Melt Flow Rate 220℃/98N ISO 1133 g/10m in 21 18 23 18 7 18 7 28

Optical property

23℃/50% RH 3m

Total Light Transm ission ISO 13468 % 88 86 85 86 86 86 86 87

m thickness

23℃/50% RH 3m

Haze ISO 14782 % 2 2 3 3 3 3 3 3

m thickness

These values are typical data for this product under specific test

conditions and not intended for use as limiting specifications.

COPYRIGHT © TORAY INDUSTRIES,INC

Transparent

Test Method IS High scratch resistant

Property Test Condition Units

O 912 X01

>MABS<

Physical property

Density 23℃ ISO 1183 kg/m 3 1100

Specific Gravity ASTM D792 - 1.1

Mechanical property

Tensile strength 23℃ ISO 527-1,2 MPa 56

Elongation at Break 23℃ ISO 527-1,2 % 12

Flexural Strength 23℃ ISO 178 MPa 83

Flexural Modulus 23℃/50% RH ISO 178 MPa 2630

C harpy Im pact Strength(V-notc

23℃ ISO 179 kJ/m 2 6

hed)

Ball Pressure Tem p./0.1m m Vica

℃ 85〜90

t Softening Tem p.

Heat property

Heat Deflection Tem p High Load 1.80MPa ISO 75-1,2 ℃ 78

rank/thickne

Flam m ability UL94 HB

ss m m t

Molding property

Mold shrinkage 23℃/50% RH Toray Method % 0.4-0.6

Melt Flow Rate 220℃/98N ISO 1133 g/10m in 30

Optical property

23℃/50% RH 3m

Total Light Transm ission ISO 13468 % 78

m thickness

23℃/50% RH 3m

Haze ISO 14782 % 16

m thickness

These values are typical data for this product under specific test

conditions and not intended for use as limiting specifications.

COPYRIGHT © TORAY INDUSTRIES,INC

You might also like

- ASA Technical GuideDocument9 pagesASA Technical GuideksharidasNo ratings yet

- Amilan™ CM3006: Technical Data Nylon 66Document3 pagesAmilan™ CM3006: Technical Data Nylon 66hamdany danyNo ratings yet

- CPVC PipesDocument24 pagesCPVC Pipeschaudhary osamaNo ratings yet

- PP GF30 - Hostacom PC072-3 Naturale-2Document2 pagesPP GF30 - Hostacom PC072-3 Naturale-2armando0% (1)

- Properties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVCDocument1 pageProperties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVCsidsaleemNo ratings yet

- Hoja Tecnica ASADocument2 pagesHoja Tecnica ASAFernando AngioliniNo ratings yet

- CALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinDocument3 pagesCALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinmikeybhabaNo ratings yet

- Corys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsDocument1 pageCorys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsVenkadesh PeriathambiNo ratings yet

- Datos Duros Acero 1045Document11 pagesDatos Duros Acero 1045Leobardo Gasca OrtegaNo ratings yet

- PC Calibre Technical DataDocument4 pagesPC Calibre Technical DataMitja GorseNo ratings yet

- Ultraform N2320 003 BK120 Q600Document2 pagesUltraform N2320 003 BK120 Q600JoelNo ratings yet

- Ultramid A3WG7 IsoDocument3 pagesUltramid A3WG7 IsoRiccardoNo ratings yet

- PC-Transparent 144RDocument5 pagesPC-Transparent 144Rsantosh.bhattNo ratings yet

- 202-Trinseo Calibre Megarad 2081-15 TDSDocument3 pages202-Trinseo Calibre Megarad 2081-15 TDSobeckoneNo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- Kapton HN Data SheetDocument5 pagesKapton HN Data Sheet谢朋亨No ratings yet

- Estane GP - 85AEDocument2 pagesEstane GP - 85AERonaldo CamargoNo ratings yet

- TDS Conbextra EP160 Saudi ArabiaDocument4 pagesTDS Conbextra EP160 Saudi ArabiajasonNo ratings yet

- 2.2.Tds Astm-Abs Lgchem Hi121Document2 pages2.2.Tds Astm-Abs Lgchem Hi121Wilda Sania MtNo ratings yet

- YEE70G30HSLNCDocument2 pagesYEE70G30HSLNCRanjan GnanaoliNo ratings yet

- Eva - RenewsysDocument1 pageEva - RenewsysShashwata ChattopadhyayNo ratings yet

- ASA LI970: Description ApplicationDocument4 pagesASA LI970: Description ApplicationRonal Deiby Cadavid PinzonNo ratings yet

- Victrex PEEK 450FE20: Conditions Test Method Units Typical ValueDocument2 pagesVictrex PEEK 450FE20: Conditions Test Method Units Typical ValueRohan KulkarniNo ratings yet

- E Isoplast 302EZ ETPDocument1 pageE Isoplast 302EZ ETPaldozenNo ratings yet

- Conbextra EP150: Constructive SolutionsDocument4 pagesConbextra EP150: Constructive SolutionsSHAIK ASIMUDDINNo ratings yet

- Technical Data Sheet - Rilsanclear - G350 (Polyamide PA 12)Document2 pagesTechnical Data Sheet - Rilsanclear - G350 (Polyamide PA 12)Alan TsaiNo ratings yet

- Estane GP 72Db Tpu: Advancing MaterialsDocument2 pagesEstane GP 72Db Tpu: Advancing MaterialsDanielNo ratings yet

- Datasheet Cawiton PR13675 - 002Document1 pageDatasheet Cawiton PR13675 - 002Fred HahnNo ratings yet

- Materialdatasheet 80 NBR 709 6Document3 pagesMaterialdatasheet 80 NBR 709 6Miguel ContrerasNo ratings yet

- Total 1540Document1 pageTotal 1540sercanworkNo ratings yet

- ULTEM™ AUT230 Resin: SABIC Innovative PlasticsDocument4 pagesULTEM™ AUT230 Resin: SABIC Innovative PlasticsLeandro LacerdaNo ratings yet

- MaterialData - 56973 2Document2 pagesMaterialData - 56973 2red_beastNo ratings yet

- Isoplast 300 ETP: Advancing MaterialsDocument2 pagesIsoplast 300 ETP: Advancing MaterialsDanielNo ratings yet

- Radipol A45 TDSDocument1 pageRadipol A45 TDSxy2zjgNo ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- Abs-Er460 EngDocument2 pagesAbs-Er460 Engjdstore99No ratings yet

- RX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourDocument1 pageRX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourEetu SatosalmiNo ratings yet

- Kopla Pa6 KNG1015Document3 pagesKopla Pa6 KNG1015agungNo ratings yet

- Technical Characteristics 2020 ENDocument1 pageTechnical Characteristics 2020 ENezzularabNo ratings yet

- Datasheet Cawiton PR13615 - 001Document1 pageDatasheet Cawiton PR13615 - 001Fred HahnNo ratings yet

- Desmopan 3059D - en - 00898365 00000542 20011347Document2 pagesDesmopan 3059D - en - 00898365 00000542 20011347sosal salvadosNo ratings yet

- Datasheet Cawiton PR13665 - 002 PDFDocument1 pageDatasheet Cawiton PR13665 - 002 PDFFred HahnNo ratings yet

- TDS ASTM LM915 Eng 210923Document2 pagesTDS ASTM LM915 Eng 210923PrashaNo ratings yet

- PermaStat 600 UVDocument2 pagesPermaStat 600 UVPhung LucNo ratings yet

- ABS LG HI21H. Rev.01Document2 pagesABS LG HI21H. Rev.01Ivan TimarevNo ratings yet

- Datasheet Cawiton PR13610 - 002Document1 pageDatasheet Cawiton PR13610 - 002Fred HahnNo ratings yet

- Data Sheet - Mirafi® HPa (200 613-td-05-15)Document1 pageData Sheet - Mirafi® HPa (200 613-td-05-15)khairul umamNo ratings yet

- Rogers - Unknown - RO4400 Series BondplyDocument4 pagesRogers - Unknown - RO4400 Series BondplyHadi SaeidiManeshNo ratings yet

- SABIC® PC Resin PC0703R - AsiaDocument4 pagesSABIC® PC Resin PC0703R - AsiaLong Trịnh ĐìnhNo ratings yet

- Victrex - Peek Data SheetDocument2 pagesVictrex - Peek Data SheetM J VoraNo ratings yet

- 01.03.03.101 Spesifikasi-BPM HDPE SmoothDocument1 page01.03.03.101 Spesifikasi-BPM HDPE SmoothRezky BaskoroNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Dow Corning 791 Silicone Weatherproofing Sealant: Product InformationDocument4 pagesDow Corning 791 Silicone Weatherproofing Sealant: Product InformationРоман СередаNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- Tds - Macgrid BiaxialDocument1 pageTds - Macgrid BiaxialLiliana Ribeiro100% (2)

- Abs - Terluran GP22Document2 pagesAbs - Terluran GP22armandoNo ratings yet

- Pps DatasheetDocument3 pagesPps Datasheetawdhesh ChaudharyNo ratings yet

- AccesoriosDocument28 pagesAccesoriosSayyid AbulkhairNo ratings yet

- Chi Mei Polylac PA 709S ABS ExtrusionDocument2 pagesChi Mei Polylac PA 709S ABS ExtrusionSayyid AbulkhairNo ratings yet

- Model YutingDocument2 pagesModel YutingSayyid AbulkhairNo ratings yet

- C Mac Video LaryngoscopesDocument20 pagesC Mac Video LaryngoscopesSayyid AbulkhairNo ratings yet

- What Is Mold ClampDocument13 pagesWhat Is Mold ClampSayyid AbulkhairNo ratings yet

- Tormek Diamond Wheels Make Sharpening Cleaner, Quicker, Easier and AccurateDocument8 pagesTormek Diamond Wheels Make Sharpening Cleaner, Quicker, Easier and AccurateSayyid AbulkhairNo ratings yet

- 02-Firecel 100 9 Sr-114eDocument1 page02-Firecel 100 9 Sr-114eBrendan StackNo ratings yet

- Paint NotesDocument25 pagesPaint NotesVarun100% (7)

- Normalizing Temperature and Time Effect On Micro Structure and Change in Mechanical Properties of Forged Steel Billet For Axle ProductionDocument3 pagesNormalizing Temperature and Time Effect On Micro Structure and Change in Mechanical Properties of Forged Steel Billet For Axle ProductionAnonymous izrFWiQNo ratings yet

- Kesoram Industries Limited: Cement DivisionDocument10 pagesKesoram Industries Limited: Cement DivisionSuryasai Rednam100% (1)

- D.A.V Public School: Hudco BhilaiDocument12 pagesD.A.V Public School: Hudco BhilaiAbhinandan raiNo ratings yet

- KBR-Economic Bottom of The Barrel Processing To Minimize Fuel Oil Production PDFDocument5 pagesKBR-Economic Bottom of The Barrel Processing To Minimize Fuel Oil Production PDFsantiagoNo ratings yet

- Musi 2005 Ti-5553Document26 pagesMusi 2005 Ti-5553Léo CampanelliNo ratings yet

- Unit 3 Other Lasting Operations: StructureDocument8 pagesUnit 3 Other Lasting Operations: StructureFDDI FDP 2019-23 ChennaiNo ratings yet

- Compendio ElectrocromicosDocument72 pagesCompendio ElectrocromicosJesica Ortiz GarcíaNo ratings yet

- TS012 Wet Gas Metering SamplingDocument4 pagesTS012 Wet Gas Metering SamplingSai Rakesh Varma VadapallyNo ratings yet

- Soft Eye ApplicationsDocument8 pagesSoft Eye ApplicationsGustavo MariduenaNo ratings yet

- ICorr CED CT06 ApplicationOfIntumescentCoatings Issue1 PDFDocument17 pagesICorr CED CT06 ApplicationOfIntumescentCoatings Issue1 PDFJoe Gaffney100% (1)

- Tool Wear and Cutting Fluid LatheDocument17 pagesTool Wear and Cutting Fluid LatheGnanakumar GanesanNo ratings yet

- Hollow Core Slabs in New Widths: Nordimpianti System SRL, 66100 Chieti (CH), ItalyDocument2 pagesHollow Core Slabs in New Widths: Nordimpianti System SRL, 66100 Chieti (CH), ItalySk Prabhu ReddyNo ratings yet

- Article - Calculation of Pitting Resistance Equivalent Numbers (PREN)Document3 pagesArticle - Calculation of Pitting Resistance Equivalent Numbers (PREN)eugenio.gutenbertNo ratings yet

- Colloids Shape and Size and Prep NotesDocument12 pagesColloids Shape and Size and Prep NotesNavnath HatvateNo ratings yet

- Qualitative Analysis Cations and AnionsDocument6 pagesQualitative Analysis Cations and AnionsKemoy FrancisNo ratings yet

- Egger Pumpes and Valves OverviewDocument25 pagesEgger Pumpes and Valves Overviewmanny casiquinNo ratings yet

- Dow CorningDocument12 pagesDow CorningTamara HamiltonNo ratings yet

- Distillate Hydrotreating 19Document1 pageDistillate Hydrotreating 19Annu RawatNo ratings yet

- Single-Fired Ceramic Wall Tile Manufacture: by Dr. Agustin Escardino Benlloch (Spain)Document30 pagesSingle-Fired Ceramic Wall Tile Manufacture: by Dr. Agustin Escardino Benlloch (Spain)map vitcoNo ratings yet

- Adhesive Systems Used in The European Pa PDFDocument14 pagesAdhesive Systems Used in The European Pa PDFRahul Rana100% (1)

- CH 05Document30 pagesCH 05Ariq Rama NurvirgianNo ratings yet

- Basement Stair-Case Typical Floor Stair-Case: Section B-B' Section B-B'Document1 pageBasement Stair-Case Typical Floor Stair-Case: Section B-B' Section B-B'Bhavya PatelNo ratings yet

- Winsem2020-21 Mee4005 TH Vl2020210501802 Reference Material I 20-May-2021 l36-g1 Tg1-W - Magnetron SputteringDocument31 pagesWinsem2020-21 Mee4005 TH Vl2020210501802 Reference Material I 20-May-2021 l36-g1 Tg1-W - Magnetron SputteringRishav RayNo ratings yet

- Group Four ProposalDocument27 pagesGroup Four ProposalILIAS PROKONo ratings yet

- Karakteristik Sifat Mekanik, Ketahanan Api Dan Pembakaran, Dan Morfologi Nanokomposit Campuran PVC Dan LdpeDocument8 pagesKarakteristik Sifat Mekanik, Ketahanan Api Dan Pembakaran, Dan Morfologi Nanokomposit Campuran PVC Dan LdpesuviyantoNo ratings yet

- Phenodur PR 263 70bDocument2 pagesPhenodur PR 263 70bsidneidecarvalhoNo ratings yet

- Carbon NanomaterialDocument4 pagesCarbon NanomaterialAshish Dev (B21MT009)No ratings yet

- List Proyek TunnelDocument8 pagesList Proyek Tunneliniuntuk utubeNo ratings yet