Professional Documents

Culture Documents

SOP For Endotoxin Challenge Test

SOP For Endotoxin Challenge Test

Uploaded by

knbiolabsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOP For Endotoxin Challenge Test

SOP For Endotoxin Challenge Test

Uploaded by

knbiolabsCopyright:

Available Formats

PHARMA SCHOLARS

MICROBIOLOGY DEPARTMENT

STANDARD OPERATING PROCEDURE

Restricted Circulation

Department: Quality Control

TITLE: ENDOTOXIN CHALLENGE TEST

SOP No. testing areas Revision No.

Effective Date Supersedes No.

Review Date Page No. 1 of 12

1.0 OBJECTIVE :

To lay down a procedure for Endotoxin Challenge Test.

2.0 SCOPE:

This SOP is applicable for Endotoxin Challenge Test in Microbiology Lab of Quality Control

Department of ……………………...

3.0 RESPONSIBILITY:

3.1 Officer/Executive – QC (Microbiology)

4.0 ACCOUNTABILITY:

4.1 Head - QC

5.0 DEFINITION:

The Endotoxin Challenge Vial (ECV) is used in the validation of dry heat depyrogenation cycles. The

ability of a particular oven / Tunnel cycle to destroy / inactivate endotoxin is measured by comparing

the endotoxin level in baked ECVs vs unbaked control ECVs.

6.0 PROCEDURE:

--- Prepared By Checked By Approved By

Officer/Executive Department Head Head Quality Assurance

Name

Signature

Date

FORMAT No.: …………………………..

PHARMA SCHOLARS

MICROBIOLOGY DEPARTMENT

STANDARD OPERATING PROCEDURE

Restricted Circulation

Department: Quality Control

TITLE: ENDOTOXIN CHALLENGE TEST

SOP No. testing areas Revision No.

Effective Date Supersedes No.

Review Date Page No. 2 of 12

6.1 MATERIAL & INSTRUMENTS :

6.1.1 Limulus Amebocyte Lysate Reagent

6.1.2 Endotoxin Indicator Vial (100000 EU/ml))

6.1.3 LAL Reagent Water

6.1.4 Ampoules or Vial according to requirement

6.1.5 Depyrogenated Dilution Tubes (13×100 mm)

6.1.6 Depyrogenated Assay Tubes (10×75 mm)

6.1.7 Micropipette with Pyrogen free tip (20-200 µl)

6.1.8 Micropipette with Pyrogen free tip (100-1000 µl)

6.1.9 Vortex Mixer

6.1.10 Heating Block

6.2 PREPARATION OF CHALLENGE VIALS :

6.2.1 Reconstitute the Challenge Vial of Endotoxin (12,50,000 EU/VIAL) with 5 ml LRW to yield 2,50,000

EU/ml) and vortex according to manufacturer”s instructions.

6.2.2 Transfer whole 5 ml content of Challenge Vial (2,50,000 EU/ml) in to 20 ml vial and make up the

volume 12.5 ml with LRW according to factor (1:2.5) and get the Challenge Vial of 1,00000 EU/ml

(Challenge Indicator).

6.2.3 Transfer 0.1 ml aliquot in to ampoules or vials used for Challenge Test (10000 EU/Vial).

6.2.4 Dry the ampoules or vials in Laminar Air Flow for overnight . Each ampoule or vial now contains

10000 EU/Vial. Mark the above prepared Ampoules/Vials as 1 to 10 numbers.

6.2.5 Keep at least 1 Ampoule/Vial as positive control (do not expose through Oven / Tunnel).

6.2.6 Mark the remaining ampoules/vials as NPC.

--- Prepared By Checked By Approved By

Officer/Executive Department Head Head Quality Assurance

Name

Signature

Date

FORMAT No.: …………………………..

PHARMA SCHOLARS

MICROBIOLOGY DEPARTMENT

STANDARD OPERATING PROCEDURE

Restricted Circulation

Department: Quality Control

TITLE: ENDOTOXIN CHALLENGE TEST

SOP No. testing areas Revision No.

Effective Date Supersedes No.

Review Date Page No. 3 of 12

6.2.7 Expose these Ampoules/Vial to appropriate location in DHS/Tunnel as per its typical Depyrogenation

Cycle.

6.3 DILUTION OF POSITIVE CONTROL AMPOULE/VIAL:

6.3.1 Reconstitute the Ampoules/Vials with 1 ml LRW and vortex vigorously for 15 minutes and each

subsequent dilution for 2-4 minutes.

6.3.2 Now the concentration of Endotoxin in the PPC will be 10000 EU/ml.

6.3.3 Prepare 1:20 dilution of the 10000 EU/ml to obtain 500 EU/ml.

6.3.4 Prepare 1:20 dilution of the 500 EU/ml to obtain 25 EU/ml.

6.3.5 Prepare 1:25 dilution of the 25 EU/ml to obtain 01 EU/ml.

6.3.6 From the above 1 EU/ml preparation, prepare a two fold dilution series up to 2λ, λ, λ/2, λ/4, where λ =

Labelled Lysate Sensitivity, λ = 0.125 EU/ml.

DILUTION TABLE

S.No. ENDOTOXIN LRW ENDOTOXIN CONCENTRATION (EU/ML)

1. 10000 EU/Vial 1 ml 10000 EU/ml

2. 0.1 ml of 10000 EU/ml 1.9 ml 500 EU/ml

3. 0.1 ml of 500 EU/ml 1.9 ml 25 EU/ml

4. 0.1 ml of 25 EU/ml 2.4 ml 01 EU/ml (8 λ)

5. 1 ml of 01 EU/ml 1 ml 0.5 EU ml (4 λ)

6. 1 ml of 0.5 EU/ml 1 ml 0.25 EU ml (2 λ)

7. 1 ml of 0.25 EU/ml 1 ml 0.125 EU ml (λ)

--- Prepared By Checked By Approved By

Officer/Executive Department Head Head Quality Assurance

Name

Signature

Date

FORMAT No.: …………………………..

PHARMA SCHOLARS

MICROBIOLOGY DEPARTMENT

STANDARD OPERATING PROCEDURE

Restricted Circulation

Department: Quality Control

TITLE: ENDOTOXIN CHALLENGE TEST

SOP No. testing areas Revision No.

Effective Date Supersedes No.

Review Date Page No. 4 of 12

8. 1 ml of 0.125 EU/ml 1 ml 0..0625 EU ml (λ/2)

9. 1 ml of 0.0625 EU/ml 1 ml 0.0325 EU ml (λ/4)

6.4 DILUTION AND TEST OF NPC AMPOULES/VIAL:

6.4.1 It is assumed that three log reduction is achieved after exposure of ampoules / vials in oven /Tunnel,

the Endotoxin concentration in the vial is 10 EU/Vial now.

6.4.2 Reconstitute each ampoules/Vials with 1 ml LRW and vortex vigorously for 15 minutes and the

Endotoxin concentration in the each ampoule or vial is 10 EU/ml.

6.4.3 Take 0.1 ml from above each vials or ampoules of 10 EU/ml in assay tubes as duplicate and add 0.1

ml Lysate which have the potency 0.125 EU/ml.

DILUTION TABLE

S.No. ENDOTOXIN LYSATE LRW ENDOTOXIN CONCENTRATION

(EU/ML)

1. 10 EU/Vial or Ampoule - 1 ml 10 EU/ml

Assumed

2. 0.1 ml of 10 EU/Vial 0.1 ml - 01 EU/ml

6.5 LAL TEST PROCEDURE :

6.5.1 Test the two fold dilution series prepared from the positive controls ampoules / vial in duplicate.

6.5.2 Test the 10 EU/ml dilutions prepared from each of exposed ampoules / Vial.

6.5.3 Test should be carried out in Clean depyrogenated 10×75 mm assay tubes only.

--- Prepared By Checked By Approved By

Officer/Executive Department Head Head Quality Assurance

Name

Signature

Date

FORMAT No.: …………………………..

PHARMA SCHOLARS

MICROBIOLOGY DEPARTMENT

STANDARD OPERATING PROCEDURE

Restricted Circulation

Department: Quality Control

TITLE: ENDOTOXIN CHALLENGE TEST

SOP No. testing areas Revision No.

Effective Date Supersedes No.

Review Date Page No. 5 of 12

6.5.4 Protocol for Positive Control :

S.No. Dilutions CSE Dilution Used LRW Lysate in µl No. of Replicates

1. 2λ 100 µl of 2λ - 100 µl 2

2. λ 100 µl of λ - 100 µl 2

3. λ/2 100 µl of λ/2 - 100 µl 2

4. λ/4 100 µl of λ/4 - 100 µl 2

5. Negative Water - 100 µl 100 µl 2

Control (NWC)

6.5.5 Protocol for Negative Product Control (Challenged Ampoules/Vial):

Ampoule Dilutions Endotoxin Indicator Lysate in µl No. of Replicates

No. Dilution (01 EU/ml)

1. NPC 100 µl 100 µl 2

2. NPC 100 µl 100 µl 2

3. NPC 100 µl 100 µl 2

4. NPC 100 µl 100 µl 2

5. NPC 100 µl 100 µl 2

6. NPC 100 µl 100 µl 2

7. NPC 100 µl 100 µl 2

8. NPC 100 µl 100 µl 2

--- Prepared By Checked By Approved By

Officer/Executive Department Head Head Quality Assurance

Name

Signature

Date

FORMAT No.: …………………………..

PHARMA SCHOLARS

MICROBIOLOGY DEPARTMENT

STANDARD OPERATING PROCEDURE

Restricted Circulation

Department: Quality Control

TITLE: ENDOTOXIN CHALLENGE TEST

SOP No. testing areas Revision No.

Effective Date Supersedes No.

Review Date Page No. 6 of 12

9. NPC 100 µl 100 µl 2

6.6 CALCULATION:

6.6.1 FORMULA:

Endotoxin Concentration = Lysate sensitivity × Reconstitued Volume × Dilution

For Unbaked (Positive Control) Vials = 0.125 EU/ml × 1 ml/Vial × 10,000 = 1250 EU/ml

For Baked (Heat Treated) Vials = 0.125 EU/ml × 1 ml/Vial × 1 = 0.125 EU/ml

Calculate the minimum log reduction as follows :

Minimum Log Reduction = Log Endotoxin Concentration of the Unbaked Control – Log Endotoxin

Concentration of the Baked Vials.

OR

Minimum Log Reduction = Log value of recovered Endotoxin from positive control – Log value of

recovered sample from heat treated sample.

6.7 INTERPRETATION OF RESULTS / ACCEPTANCE CRITERIA :

6.7.1 Test results are valid of recovery of Endotoxin in non exposed vials is with in a two fold dilution of

the labeled claim.

6.7.2 The depyrogenation cycle is considered as successfully validated if there is more than 3 log reduction

is achieved in challenge Endotoxin vials exposed in to Oven/ Tunnel at specified place. Heat Exposed

Vials.

6.7.3 For a valid Depyrogenation cycle, the PPC must be positive and NPC’s must be negative indicating a

greater than 3 log reduction of pyroburden.

6.7.4 Record the “ Endotoxin Challenge Test Record in Annexure –I.

--- Prepared By Checked By Approved By

Officer/Executive Department Head Head Quality Assurance

Name

Signature

Date

FORMAT No.: …………………………..

PHARMA SCHOLARS

MICROBIOLOGY DEPARTMENT

STANDARD OPERATING PROCEDURE

Restricted Circulation

Department: Quality Control

TITLE: ENDOTOXIN CHALLENGE TEST

SOP No. testing areas Revision No.

Effective Date Supersedes No.

Review Date Page No. 7 of 12

7.0 ABBREVIATION:

SOP Standard Operating Procedure

No. Number

QA Quality Assurance

QC Quality Control

QM QC-Microbiology

Ltd. Limited

GPT Growth Promotion Test

LAF Laminar Air Flow

°C Degree Celsius

ml Milliliter

NLT Not Less Than

PPC Positive Product Control

NPC Negative Product Control

LRW LAL Reagent Water

EU Endotoxin Unit

ml Mililitre

µl Micron litre

λ Sensitivity of the Lysate

--- Prepared By Checked By Approved By

Officer/Executive Department Head Head Quality Assurance

Name

Signature

Date

FORMAT No.: …………………………..

PHARMA SCHOLARS

MICROBIOLOGY DEPARTMENT

STANDARD OPERATING PROCEDURE

Restricted Circulation

Department: Quality Control

TITLE: ENDOTOXIN CHALLENGE TEST

SOP No. testing areas Revision No.

Effective Date Supersedes No.

Review Date Page No. 8 of 12

8.0 ANNEXUREURE :

Annexure No. Title of Annexure Format No.

Annexure - I Endotoxin Challenge Test Report F01-00

9.0 DISTRIBUTION :

• Master Copy Quality Assurance Department

• Controlled Copy No. 01 Quality Assurance

• Controlled Copy No. 02 Quality Control (Microbiology)

10.0 REFERENCES :

• IH

11.0 REVISION HISTORY :

Revision No. Change Control Details of Reason of Effective Done By

No. Changes Changes Date

00 Not Applicable Not Applicable New SOP

--- Prepared By Checked By Approved By

Officer/Executive Department Head Head Quality Assurance

Name

Signature

Date

FORMAT No.: …………………………..

PHARMA SCHOLARS

MICROBIOLOGY DEPARTMENT

STANDARD OPERATING PROCEDURE

Restricted Circulation

Department: Quality Control

TITLE: ENDOTOXIN CHALLENGE TEST

SOP No. testing areas Revision No.

Effective Date Supersedes No.

Review Date Page No. 9 of 12

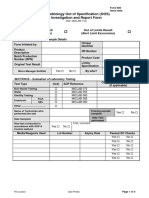

ANNEXURE-I

PHARMA SCHOLARS

MICROBIOLOGY DEPARTMENT

ENDOTOXIN CHALLENGE TEST REPORT

Date of Vial Exposure No. of Exposed Vial

Date of Testing Date of Release

Tunnel / Oven Location Tunnel / Oven ID No.

Performed By Date of Analysis

Shift BET Kit Manufacturer

Heating Block Temperature 37°C ± 1°C Incubation Time 60 Minutes ± 2 Minutes

Incubation Started Date Incubation Completed

at

REAGENT DETAILS :

REAGENT DETAILS LIMULUS CONTROL LAL REAGENT

AMOEBOCYTES STANDARD WATER (LRW)

LYSATE (LAL) ENDOTOXIN (CSE)

Lot No.

Expiry Date

Sensitivity/Potency

Date of Reconstitution/Opening

Use Before

Manufacturer

--- Prepared By Checked By Approved By

Officer/Executive Department Head Head Quality Assurance

Name

Signature

Date

FORMAT No.: …………………………..

PHARMA SCHOLARS

MICROBIOLOGY DEPARTMENT

STANDARD OPERATING PROCEDURE

Restricted Circulation

Department: Quality Control

TITLE: ENDOTOXIN CHALLENGE TEST

SOP No. testing areas Revision No.

Effective Date Supersedes No.

Review Date Page No. 10 of 12

DILUTION PREPARATION FOR HEAT TREATED VIAL (10 EU/VIAL ASSUMED):

Test Endotoxin

S.No. Test LRW Lysate

Dilution Concentration

- - 10 EU/Vial or Ampoule Assumed 1 ml - 10 EU/ml

1. - 0.1 ml of 10 EU/ml - 0.1 ml 01 EU/ml

DILUTION PREPARATION FOR POSITIVE CONTROL VIAL ( 10,000 EU/VIAL) :

Endotoxin

S.No. Test Dilution Test LRW

Concentration

- - 10,000 EU/Vial or Ampoule 1 ml 10,000 EU/ml

1. 1:10 0.1 ml of 10,000 EU/ml 0.9 ml 500 EU/ml

2. 1:10 0.1 ml of 500 EU/ml 0.9 ml 25 EU/ml

3. 1:25 0.1 ml of 25 EU/ml 2.4 ml 01 EU/ml (8 λ)

4. 1:2 1 ml of 01 EU/ml 1 ml 0.5 EU ml (4 λ)

5. 1:2 1 ml of 0.5 EU/ml 1 ml 0.25 EU ml (2 λ)

6. 1:2 1 ml of 0.25 EU/ml 1 ml 0.125 EU ml (λ)

7. 1:2 1 ml of 0.125 EU/ml 1 ml 0.0625 EU ml (λ/2)

8. 1:2 1 ml of 0.0625 EU/ml 1 ml 0.0325 EU ml (λ/4)

--- Prepared By Checked By Approved By

Officer/Executive Department Head Head Quality Assurance

Name

Signature

Date

FORMAT No.: …………………………..

PHARMA SCHOLARS

MICROBIOLOGY DEPARTMENT

STANDARD OPERATING PROCEDURE

Restricted Circulation

Department: Quality Control

TITLE: ENDOTOXIN CHALLENGE TEST

SOP No. testing areas Revision No.

Effective Date Supersedes No.

Review Date Page No. 11 of 12

PREPARATION OF TEST SOLUTION:

Solution Tube No. Product Quantity LRW LAL Reagent Total Volume

01 100 µl - 100 µl 200 µl

NPC

02 100 µl - 100 µl 200 µl

01 - 100 µl 100 µl 200 µl

NWC

02 - 100 µl 100 µl 200 µl

OBSERVATION:

RESULT OF NEGATIVE PRODUCT CONTROL & NEGATIVE WATER CONTROL:

Observation Vial No.

- Tube No.

1 2 3 4 5 6 7 8 9

01

NPC

02

01

NWC

02

--- Prepared By Checked By Approved By

Officer/Executive Department Head Head Quality Assurance

Name

Signature

Date

FORMAT No.: …………………………..

PHARMA SCHOLARS

MICROBIOLOGY DEPARTMENT

STANDARD OPERATING PROCEDURE

Restricted Circulation

Department: Quality Control

TITLE: ENDOTOXIN CHALLENGE TEST

SOP No. testing areas Revision No.

Effective Date Supersedes No.

Review Date Page No. 12 of 12

RESULTS OF POSITIVE CONTROL:

Endotoxin Dilution Negative Water

Tube No.

2λ λ λ/2 λ/4 Control

01

02

+ve : Gel formation -ve : No Gel formation

Calculate the minimum log reduction as follows :

Minimum Log Reduction = Log Endotoxin Concentration of the Unbaked Control – Log Endotoxin

Concentration of the Baked Vials.

OR

Minimum Log Reduction = Log value of recovered Endotoxin from positive control – Log value of

recovered sample from heat treated sample.

Endotoxin Concentration =

Minimum Log Reduction =

Remark: The depyrogenation cycle of Oven/Tunnel complies / does not comply of three log reduction for

Endotoxin Challenge Test.

Microbiologist: Checked By:

Sign & Date: Sign & Date

FORMAT No.:……………….. Page X of Y

--- Prepared By Checked By Approved By

Officer/Executive Department Head Head Quality Assurance

Name

Signature

Date

FORMAT No.: …………………………..

You might also like

- Sterility Test Method ValidationDocument6 pagesSterility Test Method Validationpuneetogupta100% (7)

- SOP. Suitability TestDocument2 pagesSOP. Suitability TestBernardo50% (2)

- Operational Qualification GL ReactorDocument3 pagesOperational Qualification GL Reactorjokish100% (2)

- URS Air SamplerDocument6 pagesURS Air SamplerHưng Lữ Nguyễn Phúc100% (2)

- Assessment 3 - HIT172 - 2023Document5 pagesAssessment 3 - HIT172 - 2023F&B ManagerNo ratings yet

- Geology NotesDocument8 pagesGeology NotesLily QuiNo ratings yet

- Hold Time Study of 70% IpaDocument5 pagesHold Time Study of 70% IpaAshok Lenka100% (5)

- Disinfectant Validation ProtocolDocument4 pagesDisinfectant Validation ProtocolAngel Cvetanov100% (2)

- Performance Qualification Protocol For Water For Injection (WFI) System - Pharmaceutical GuidelinesDocument3 pagesPerformance Qualification Protocol For Water For Injection (WFI) System - Pharmaceutical GuidelinesJayesh PatidarNo ratings yet

- HPLC Calibration FormatDocument6 pagesHPLC Calibration Formatasit_m100% (1)

- Microbial Limit Test SOPDocument31 pagesMicrobial Limit Test SOPDipika Sunil Patel100% (5)

- SOPMS31 Validation of Laminar Air FlowDocument2 pagesSOPMS31 Validation of Laminar Air FlowRahul Patil83% (6)

- Chlorhexidine Gluconate Scrub Solution - ProtocolDocument16 pagesChlorhexidine Gluconate Scrub Solution - ProtocolMy bookNo ratings yet

- 215-Operation and Calibration of Dissolution Apparatus (VDA-8D) New NewDocument4 pages215-Operation and Calibration of Dissolution Apparatus (VDA-8D) New NewDeepak ChaudharyNo ratings yet

- Sop For Cleaning and Calibration of AutoclaveDocument3 pagesSop For Cleaning and Calibration of AutoclavePrince Moni100% (2)

- Title: Cleaning Validation Report For - ToDocument41 pagesTitle: Cleaning Validation Report For - TocpkakopeNo ratings yet

- Hold Time Study Sample Protocol PDFDocument4 pagesHold Time Study Sample Protocol PDFElena Trofin50% (2)

- cGMP Current Good Manufacturing Practices for PharmaceuticalsFrom EverandcGMP Current Good Manufacturing Practices for PharmaceuticalsRating: 1 out of 5 stars1/5 (2)

- Subject Assignment Resit 1: Learning Strategies: General InformationDocument6 pagesSubject Assignment Resit 1: Learning Strategies: General InformationCarmen Cristina Ramos Bustillo100% (1)

- Oerlikon Compact PowerDocument79 pagesOerlikon Compact Powerincim100% (2)

- 08 SOP Tatal Microbial CountDocument5 pages08 SOP Tatal Microbial CountNoor JavedNo ratings yet

- Bacterial Endotoxin Test (BET or LAL Test) Method Validation - Pharmaceutical GuidelinesDocument3 pagesBacterial Endotoxin Test (BET or LAL Test) Method Validation - Pharmaceutical GuidelinesASHOK KUMAR LENKA100% (2)

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersFrom EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersNo ratings yet

- Standard Operating Procedure (Sop) Collecting Swab or Rinse Samples For Chemical and Microbiological AnalysisDocument11 pagesStandard Operating Procedure (Sop) Collecting Swab or Rinse Samples For Chemical and Microbiological AnalysisAbuNo ratings yet

- MLT Validation ProtocolDocument10 pagesMLT Validation ProtocolRambo75% (4)

- 42 Traces of TeepolDocument3 pages42 Traces of Teepolmefro0% (1)

- Cleaning Validation of Sampling ToolsDocument13 pagesCleaning Validation of Sampling Toolsnagendra100% (1)

- Analyst Qualification (Modified)Document6 pagesAnalyst Qualification (Modified)vasant ugale75% (4)

- CV Protocol-Coated TabletsDocument22 pagesCV Protocol-Coated Tabletsqaheadjml007No ratings yet

- Procedure For Environmental Monitoring by Settle Plate MethodDocument2 pagesProcedure For Environmental Monitoring by Settle Plate Methodejazmaqsood100% (1)

- Nystatin Oral Suspension AMVDocument33 pagesNystatin Oral Suspension AMVOm PandeyNo ratings yet

- List of QC SopDocument3 pagesList of QC SopPrince Moni100% (1)

- Sucralfate Oral SuspensionDocument17 pagesSucralfate Oral SuspensionOm PandeyNo ratings yet

- Dynamic Pass Box-PqDocument5 pagesDynamic Pass Box-PqjaimurugeshNo ratings yet

- Sop For Analytical Method Validqation and VerificationDocument7 pagesSop For Analytical Method Validqation and Verificationvasant ugale100% (3)

- SOP For Procurement of CultureDocument5 pagesSOP For Procurement of Culturegreen solution100% (2)

- DHS ValidationDocument7 pagesDHS Validationmuna82dasNo ratings yet

- Protocol Jacketed MFG Tank LV02Document7 pagesProtocol Jacketed MFG Tank LV02pooja aswal100% (3)

- Performance Qualification Protocol FOR Automatic Capsule Filling MachineDocument13 pagesPerformance Qualification Protocol FOR Automatic Capsule Filling Machinemehrdarou.qaNo ratings yet

- Air SamplerDocument42 pagesAir SamplerKuldeepNo ratings yet

- Coa of Purified WaterDocument5 pagesCoa of Purified WaterRavi Yadav100% (1)

- 9.1 Design Qualification Protocol For Dynamic Pass BoxDocument10 pages9.1 Design Qualification Protocol For Dynamic Pass BoxKeval Patel100% (1)

- SOP For Cleaning and Sterilization of Glass Ware Used in Microbiology Lab.Document3 pagesSOP For Cleaning and Sterilization of Glass Ware Used in Microbiology Lab.Bejoy Karim100% (1)

- Microbial Limit Test Validation ProtocolDocument12 pagesMicrobial Limit Test Validation ProtocolMubarak Patel100% (1)

- Operation, Cleaning and Monitoring of Dynamic Pass Box.Document2 pagesOperation, Cleaning and Monitoring of Dynamic Pass Box.RainMan75No ratings yet

- Analytical Method Validation Protocol For Pharmaceuticals - Pharmaceutical GuidelinesDocument7 pagesAnalytical Method Validation Protocol For Pharmaceuticals - Pharmaceutical GuidelinesMSL IndiaNo ratings yet

- MICLAB 150 Initial Investigation of Out of Specification (OOS) Results in Microbiological LaboratoryDocument11 pagesMICLAB 150 Initial Investigation of Out of Specification (OOS) Results in Microbiological Laboratoryspp100% (1)

- Microbial Limit Test Validation ProtocolDocument12 pagesMicrobial Limit Test Validation ProtocolMubarak Patel100% (2)

- Ezetimibe VPGQC14061 00 YaDocument16 pagesEzetimibe VPGQC14061 00 YaDany RockNo ratings yet

- Qualification of Compressed Air ProtocolDocument18 pagesQualification of Compressed Air ProtocolBRIJENDRA KUMAR SINGH100% (2)

- SOP For Preparation and Handling of Working StandardsDocument5 pagesSOP For Preparation and Handling of Working StandardsSolomon100% (2)

- Validation of Dynamic Pass BoxDocument5 pagesValidation of Dynamic Pass BoxMichele Volpe100% (1)

- Procedure For Leak Testing of Strips - BlistersDocument7 pagesProcedure For Leak Testing of Strips - BlistersashishdrNo ratings yet

- Microbiology Out of Specification (OOS) Investigation and Report FormDocument3 pagesMicrobiology Out of Specification (OOS) Investigation and Report FormIra Nurjannah100% (1)

- Hold Time Study ProtocolDocument9 pagesHold Time Study ProtocolMubarak Patel100% (1)

- Autoclave SVP Report 2016Document29 pagesAutoclave SVP Report 2016Rajender Singh100% (1)

- Dynamic Pass BoxDocument3 pagesDynamic Pass BoxMd.Tareque AbdullahNo ratings yet

- Calibration of HPLCDocument12 pagesCalibration of HPLCprashanth50% (6)

- SOP For Bacterial Endotoxin (LAL) TestDocument3 pagesSOP For Bacterial Endotoxin (LAL) TestKranti yadavNo ratings yet

- Temperature Mapping Protocol: Lincoln Parenteral LTDDocument7 pagesTemperature Mapping Protocol: Lincoln Parenteral LTDRajender Singh100% (1)

- RM-Method Validation ProtocolDocument12 pagesRM-Method Validation ProtocolShagorShagorNo ratings yet

- Cleaning Validation Report TEMPLATEDocument9 pagesCleaning Validation Report TEMPLATEnatavceNo ratings yet

- MICLAB 105 SampleDocument7 pagesMICLAB 105 SampleFarzana HossainNo ratings yet

- M - R - EPG - Triclabendazole - Run No #1 - 16-Jul-2021 - 15-44-50Document3 pagesM - R - EPG - Triclabendazole - Run No #1 - 16-Jul-2021 - 15-44-50knbiolabsNo ratings yet

- Tartaric Acid (AGA240004)-2Document1 pageTartaric Acid (AGA240004)-2knbiolabsNo ratings yet

- SOP For Microbiological Good Laboratory PracticesDocument10 pagesSOP For Microbiological Good Laboratory PracticesknbiolabsNo ratings yet

- Nutr Comp of SMPDocument1 pageNutr Comp of SMPknbiolabsNo ratings yet

- SOP For Operation Calibration and Maintenance of Horizontal AutoclaveDocument10 pagesSOP For Operation Calibration and Maintenance of Horizontal AutoclaveknbiolabsNo ratings yet

- Method DetailsDocument1 pageMethod DetailsknbiolabsNo ratings yet

- What Is Data Integrity and ALCOA PlusDocument1 pageWhat Is Data Integrity and ALCOA PlusknbiolabsNo ratings yet

- Application NewDocument2 pagesApplication NewknbiolabsNo ratings yet

- CAA Reg NumbersDocument1 pageCAA Reg NumbersknbiolabsNo ratings yet

- BAMN08 GuideMilkReplDocument4 pagesBAMN08 GuideMilkReplknbiolabsNo ratings yet

- Calf ManagementDocument7 pagesCalf ManagementknbiolabsNo ratings yet

- Application RenewelDocument1 pageApplication RenewelknbiolabsNo ratings yet

- BAA-835 Product Sheet - Akkermansia Muciniphila Derrien Et Al.Document6 pagesBAA-835 Product Sheet - Akkermansia Muciniphila Derrien Et Al.knbiolabsNo ratings yet

- Stack Monitoring KitDocument53 pagesStack Monitoring KitknbiolabsNo ratings yet

- 3 22EM02P3 Handling and Analysis InstrucionsDocument4 pages3 22EM02P3 Handling and Analysis InstrucionsknbiolabsNo ratings yet

- Serendipita Indica (ATCC: Product SheetDocument2 pagesSerendipita Indica (ATCC: Product SheetknbiolabsNo ratings yet

- MI For N410 RE Formulation - Trial 1Document6 pagesMI For N410 RE Formulation - Trial 1knbiolabsNo ratings yet

- US20170267625A1Document6 pagesUS20170267625A1knbiolabsNo ratings yet

- 2 22EM02P3 Result Submission SheetDocument1 page2 22EM02P3 Result Submission SheetknbiolabsNo ratings yet

- CollagenDocument1 pageCollagenknbiolabsNo ratings yet

- Good Chromatography PracticesDocument23 pagesGood Chromatography PracticesknbiolabsNo ratings yet

- Report No:KNB/CHEM/LAB/20/49: Standy Pouch BagDocument2 pagesReport No:KNB/CHEM/LAB/20/49: Standy Pouch BagknbiolabsNo ratings yet

- 1 22EM02P3 PT Item Receipt Ack L0Document2 pages1 22EM02P3 PT Item Receipt Ack L0knbiolabsNo ratings yet

- Tamsulosin Hydrochloride: Official September 1, 2016Document2 pagesTamsulosin Hydrochloride: Official September 1, 2016knbiolabsNo ratings yet

- Sugarcane Organic KIT PracticeDocument4 pagesSugarcane Organic KIT PracticeknbiolabsNo ratings yet

- Vishva Maru, Et AlDocument7 pagesVishva Maru, Et AlknbiolabsNo ratings yet

- Different Formulations of TVDocument8 pagesDifferent Formulations of TVknbiolabsNo ratings yet

- Banana Fibre Extraction by Mycogenic Pectinase Enzyme (S) - An Eco-Friendly ApproachDocument10 pagesBanana Fibre Extraction by Mycogenic Pectinase Enzyme (S) - An Eco-Friendly ApproachknbiolabsNo ratings yet

- Forced Degradation Analysis of Omeprazole Using CORTECS 2.7 M ColumnsDocument5 pagesForced Degradation Analysis of Omeprazole Using CORTECS 2.7 M ColumnsknbiolabsNo ratings yet

- Total Carbohydrates Protocol Ebru Dulekgurgen UIUC'04Document4 pagesTotal Carbohydrates Protocol Ebru Dulekgurgen UIUC'04knbiolabsNo ratings yet

- Vpsa O2 Systems Brochure ML IND0032Document8 pagesVpsa O2 Systems Brochure ML IND0032kalaiNo ratings yet

- BHIR121 102 Bussiness Comm Assignment 1Document7 pagesBHIR121 102 Bussiness Comm Assignment 1nncptp7nsbNo ratings yet

- Standard GCER Pour Petit DiamètreDocument85 pagesStandard GCER Pour Petit DiamètreAyoub EnnamiNo ratings yet

- Andrew GroveDocument16 pagesAndrew GroveArslanNo ratings yet

- Ficha Tecnica Inverter Mini SplitDocument1 pageFicha Tecnica Inverter Mini SplitpabloabelgilsotoNo ratings yet

- Mental HealthDocument24 pagesMental Healthnitin pareekNo ratings yet

- Phoenix Contact PT 2-PES-230AC-STDocument6 pagesPhoenix Contact PT 2-PES-230AC-STblitz301No ratings yet

- Dan-Fuel Rod Heat ConductionDocument7 pagesDan-Fuel Rod Heat ConductionMahmoud EidNo ratings yet

- WPS - 016Document11 pagesWPS - 016MAT-LIONNo ratings yet

- A Detailed 4ADocument5 pagesA Detailed 4ASarah Baylon50% (4)

- Nov 2001 p1Document15 pagesNov 2001 p1Wojtek BłażejNo ratings yet

- WhitePaper AVEVA PredictiveAnalyticsPower 22-04Document6 pagesWhitePaper AVEVA PredictiveAnalyticsPower 22-04matiasnNo ratings yet

- Rele Doble Polo Doble TiroDocument3 pagesRele Doble Polo Doble Tiroの選択 ウィルNo ratings yet

- Analysis of Urban Heat Island IntensityDocument14 pagesAnalysis of Urban Heat Island IntensityItishree RanaNo ratings yet

- Assignment No. 2 MTH 432A: Introduction To Sampling Theory 2021Document1 pageAssignment No. 2 MTH 432A: Introduction To Sampling Theory 2021Krishna Pratap MallNo ratings yet

- CCS D5293Document9 pagesCCS D5293Sofia Fasolo CunhaNo ratings yet

- ACP Employability WorkshopDocument12 pagesACP Employability Workshoplalit saraswatNo ratings yet

- Is 805Document38 pagesIs 805Sse SteelNo ratings yet

- Chapter 7Document6 pagesChapter 7Glace AbellanaNo ratings yet

- Ainscow, Farrell y Tweddle IJIE - 00 Developing Policies For Inclusive EducationDocument19 pagesAinscow, Farrell y Tweddle IJIE - 00 Developing Policies For Inclusive EducationMatías Reviriego RomeroNo ratings yet

- 10002NB01510001Document12 pages10002NB01510001manoj6189No ratings yet

- 2012 KCSE Physics Paper 3Document5 pages2012 KCSE Physics Paper 3lixus mwangiNo ratings yet

- Air Entrainment - 02Document16 pagesAir Entrainment - 02ThejaswiniNo ratings yet

- DM G+12 & Unlimited Test QuestionDocument19 pagesDM G+12 & Unlimited Test Questionmajd el chami100% (1)

- Understanding Feyerabend On GalileoDocument5 pagesUnderstanding Feyerabend On Galileorustycarmelina108No ratings yet

- Best Rosin Press of 2020 PDFDocument4 pagesBest Rosin Press of 2020 PDFdannie gaoNo ratings yet