Professional Documents

Culture Documents

HDFlowPro FINAL NOV21 Web

HDFlowPro FINAL NOV21 Web

Uploaded by

Juan AcostaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HDFlowPro FINAL NOV21 Web

HDFlowPro FINAL NOV21 Web

Uploaded by

Juan AcostaCopyright:

Available Formats

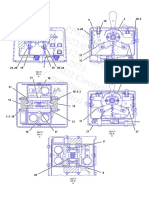

HEAVY DUTY

BRING ON YOUR MOST DEMANDING APPLICATIONS

CIRCUMFERENTIAL PISTON PROCESS PUMPS - HEAVY DUTY SERIES

THE MOST ROBUST PROBLEM-SOLVING PUMP IN THE INDUSTRY

The Heavy Duty Series pumps are resistant to abrasives and air entrainment, can withstand high and variable viscosities, and

can run dry without damage. The HD Series is rated to 450 PSI differential pressure, outperforming most other rotary positive

displacement pumps. This is a true workhorse known to last 30 years in the field!

Isolated Fluid Chamber

Keeps process fluid away from Single Lobe Impellers

primary bearing support for

Maximum strength for high

shafts, maximizing life and

pressure requirements and

pressure capability

minimal fluid shear

External Timing Gears

Prevents any metal-to-metal

contact in the fluid chamber

High Strength Shafts

17-4 PH shafts are standard, offering

high torque capability, corrosion

resistance, and can be hard coated for External Bearing Support

maximum life in abrasive applications

Allows pump to run dry

without damage

OTHER FEATURES & BENEFITS

Heavy-Duty Performance Customized Options Engineered Sealing Options

• Tutriding: hardening process • Standard PTFE/graphite packing

• Pass solids up to 1 1/4"

for maximum life in abrasive • Food-grade packing (pure PTFE)

• Flow rate up to 600 GPM applications

(136 M3/HR) • A variety of engineered packing

• A variety of flanges to satisfy solutions and configurations,

• Differential pressure up to any requirements including Wedgee packing

450 PSI (31 BAR)

• Special clearances to meet a • Cartridge lip seals for leak-free

• Viscosities up to 4,400,000 CST variety of temperature and fluid performance and dry run conditions

• Temperatures up to shear requirements

• A variety of single or double

550°F (290°C) • Special construction for mechanical seal options,

• Self-priming up to 14 feet high temperature including slurry seal

• Bolt-on heating/cooling jackets

for enhanced process control

12500 S. PULASKI ROAD, ALSIP, IL 60803, USA

P: 1.708.389.2500 • F: 1.708.388.0869

TUTHILLPUMP.COM

HEAVY-DUTY DESIGN FOR THE MOST DEMANDING APPLICATIONS

The HD Series can handle it all: slurries, high-viscosity liquids, suspended solids, concentrated acids, chemicals,

high-temperature liquids, sludge, resins, sewage and scum, paints, polymers, plastics, pharmaceuticals, foods,

and shear‑sensitive fluids. Heavy-duty construction provides longer life in the toughest pumping applications.

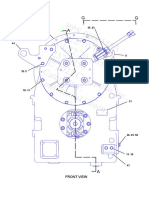

Single Lobe Impeller Design

• Maximum strength for high viscosity and high pressure capability

HD DESIGN

• Long sealing length on impeller arc for maximum life in

HD with bearing

support on both abrasive applications

sides of impellers • Allows large solids to pass through undamaged

• Sharp leading edge can shear softer materials to prevent lock up

External Bearing Support

COMPETITORS • Heavy-duty, grease-lubricated double-row ball bearings support radial

Cantilevered load as well as axial positioning of impellers

designs result in

shaft deflection • Oil-lubricated roller bearings provide maximum radial load support

• Constant diameter shaft (no steps or stress risers) provides maximum

strength and minimal deflection

SPECIFICATIONS

MAXIMUM MAXIMUM

MODEL FLOW RATE

DIFFERENTIAL PRESSURE SPEED

WEIGHT STANDARD MATERIALS OF CONSTRUCTION

Housing:

GPM M3/HR PSI BAR RPM LBS KG Ductile Iron, 316 Stainless Steel

Housing Bearing: DU, Bronze, or Carbon

70A 52 12 450 31.0 350 280 127

Faceplate: Ductile Iron, 316 Stainless Steel

120A 105 24 450 31.0 350 300 136 Faceplate Bearing: Outboard Ball Bearing

Impellers: Ductile Iron, 316 Stainless Steel

330 265 60 450 31.0 350 550 249

Shafts: 17-4 Stainless Steel

600 520 118 450 31.0 350 900 408 Gear Case: Gray Iron

CAUTION: The fluid being pumped must always be specified. Applications above 200 PSI

(13.8 BAR), 350ºF (177ºC), or 200 RPM must be reviewed by factory to ensure proper

pump selection

HD120A HD330 HD600

BIRKDALE CLOSE, MANNERS INDUSTRIAL ESTATE • ILKESTON, DERBYSHIRE DE7 8YA UK

P: 44.0.115.932.5226

TUTHILLPUMP.COM

DIFFERENTIAL PRESSURE UP TO 450 PSI

RUN DRY

CAPABILITY

YOUR BEST PUMPING PROBLEM SOLVER!

INDUSTRIES AND APPLICATIONS

• Adhesive & Sealant • Energy & Power • Resins, Paints, & Coatings

• Chemical Processing • Filled Asphalt • Soaps & Surfactants

• Confectionery • Food & Beverage • Pulp & Paper

• Construction Material • Meat Processing • Water & Wastewater

ALSIP

12500 South Pulaski Road

Alsip, Illinois 60803 USA

P: 708.389.2500

ILKESTON ATEX

Birkdale Close

Manners Industrial Estate

Ilkeston, Derbyshire DE7 8YA UK

P: 44.0.115.932.5226

You might also like

- KOmatsu P&H-trc-series-dipperDocument2 pagesKOmatsu P&H-trc-series-dipperhidrastar123No ratings yet

- Bluebird Cooling SystemDocument66 pagesBluebird Cooling SystemJuan Acosta100% (1)

- DVMX. Between-Bearings, Multistage, Axially Split Pump. API-610,10th Edition ISO M A R E L L IDocument6 pagesDVMX. Between-Bearings, Multistage, Axially Split Pump. API-610,10th Edition ISO M A R E L L Imiguel hernandezNo ratings yet

- Hitachi EX700 BrochureDocument21 pagesHitachi EX700 BrochureJuan Acosta100% (1)

- BIM Guidelines and StandardsDocument11 pagesBIM Guidelines and Standardstempmail16753570No ratings yet

- Moyno Mono 2000 Series Pump Flyer ImperialDocument2 pagesMoyno Mono 2000 Series Pump Flyer ImperialRoger GracieNo ratings yet

- 04 IR 0922 004 EN GlobalGear BrochureDocument4 pages04 IR 0922 004 EN GlobalGear BrochureSerge Páez BenítezNo ratings yet

- Lit Slurry DataDocument8 pagesLit Slurry DataThariqNo ratings yet

- CATALOGO-Bombas WarrenDocument4 pagesCATALOGO-Bombas Warrenjlrllfn81No ratings yet

- IR-0922-004 EN - GlobalGearBrochureDocument4 pagesIR-0922-004 EN - GlobalGearBrochureLeonardo Diego Avila HuaringaNo ratings yet

- 0901d19680904f39 PDF Preview MediumDocument1 page0901d19680904f39 PDF Preview MediumAgoenNo ratings yet

- Pipeline Mixer: Continuous Flow In-Line High Shear MixerDocument4 pagesPipeline Mixer: Continuous Flow In-Line High Shear MixerglizamabNo ratings yet

- MBN High Pressure Stage Casing Pump E00657Document6 pagesMBN High Pressure Stage Casing Pump E00657MustafaNo ratings yet

- Data Sheets Metaltite Metal Seated Ball Valves Data Sheet KTM en en 5196424Document12 pagesData Sheets Metaltite Metal Seated Ball Valves Data Sheet KTM en en 5196424molinachNo ratings yet

- Rod Bar BrochureDocument8 pagesRod Bar BrochureartunianluisNo ratings yet

- SMD Axially Split Casing, Double Suction PumpDocument8 pagesSMD Axially Split Casing, Double Suction PumpdonestebNo ratings yet

- Slurrymax Pump: Split Casing Design For Multiple ApplicationsDocument8 pagesSlurrymax Pump: Split Casing Design For Multiple Applicationssergio.manuel ovandoNo ratings yet

- Slurrymax Camur Pompasi 3 PDFDocument8 pagesSlurrymax Camur Pompasi 3 PDFTecnologia Fabricación MetalmecanicaNo ratings yet

- PHWRDocument6 pagesPHWRMahmoud SaiedNo ratings yet

- Warren Pumps Jaguar 2200 Series 沥青泵选型Document4 pagesWarren Pumps Jaguar 2200 Series 沥青泵选型Ana PaolaNo ratings yet

- Esco Cable Shovel SpecificationsDocument72 pagesEsco Cable Shovel SpecificationssebaNo ratings yet

- SMD Axially Split Casing, Double Suction PumpDocument8 pagesSMD Axially Split Casing, Double Suction PumpSyamil Dzulfida100% (1)

- Scotch Yoke Design: Olga/Olgas Hydraulic ActuatorsDocument48 pagesScotch Yoke Design: Olga/Olgas Hydraulic ActuatorsZack OsNo ratings yet

- Bombas Centrifugas Modelo SRLDocument12 pagesBombas Centrifugas Modelo SRLRenzo VictorNo ratings yet

- Goulds - ICO I-Frame SeriesDocument16 pagesGoulds - ICO I-Frame SeriesAlexNo ratings yet

- HX HN Compressors Brochure 2015 0318 LRDocument20 pagesHX HN Compressors Brochure 2015 0318 LRAlbert Paco GoytiaNo ratings yet

- FR Series: Specification SheetDocument3 pagesFR Series: Specification SheetandrymartNo ratings yet

- Mobilair M270: Portable CompressorsDocument2 pagesMobilair M270: Portable CompressorsivarrojasNo ratings yet

- Everything You Need To Keep On RollingDocument8 pagesEverything You Need To Keep On RollingAlexander GoezNo ratings yet

- MC High Pressure Stage Casing Pump E10026Document6 pagesMC High Pressure Stage Casing Pump E10026Deepak PandeyNo ratings yet

- AlemiteDocument20 pagesAlemitealaa889No ratings yet

- Figure 603 Angle Isolation ValveDocument12 pagesFigure 603 Angle Isolation ValveMetropolitan IndustriesNo ratings yet

- GP - AF - Low 1Document8 pagesGP - AF - Low 1maguilar20No ratings yet

- V4 SUBMERSIBLE PUMPSET - cUuTUtdDocument8 pagesV4 SUBMERSIBLE PUMPSET - cUuTUtdtayadeyadhneshNo ratings yet

- Tapered Equipment: Secoroc Rock Drilling ToolsDocument12 pagesTapered Equipment: Secoroc Rock Drilling Toolsedin saquilNo ratings yet

- Keystone K-Lok: High Performance Butterfly Valves Series 36 and 37Document16 pagesKeystone K-Lok: High Performance Butterfly Valves Series 36 and 37el_apache10No ratings yet

- Isogate WR Series Valves Spec SheetDocument4 pagesIsogate WR Series Valves Spec SheetJonathan RecinosNo ratings yet

- Rexnord Chain TroubleshootingDocument40 pagesRexnord Chain TroubleshootingAneeq RaheemNo ratings yet

- Data Sheets Hilok High Performance Butterfly Valves Keystone en en 5445812Document12 pagesData Sheets Hilok High Performance Butterfly Valves Keystone en en 5445812sonalpanchal7No ratings yet

- CJBrochureDocument16 pagesCJBrochurejcvf1No ratings yet

- 38708-1 BookedDocument24 pages38708-1 BookedJoshwa SimamoraNo ratings yet

- Rolling - Bearings - in - Paper - Machines Otros2Document16 pagesRolling - Bearings - in - Paper - Machines Otros2FreddyNo ratings yet

- Cabillas Convencionales PDFDocument12 pagesCabillas Convencionales PDFgenesisNo ratings yet

- SH 06 UK (May-09) PDFDocument16 pagesSH 06 UK (May-09) PDFhepcomotionNo ratings yet

- Abrasiguard AA Straight Polyurethane Lined Pipe DatasheetDocument3 pagesAbrasiguard AA Straight Polyurethane Lined Pipe DatasheetBeaver Process EquipmentNo ratings yet

- Mobilair M270: Portable CompressorsDocument2 pagesMobilair M270: Portable CompressorsABDELRHMAN SHAMSNo ratings yet

- Product Data Sheet Series 36 37 K Lok High Performance Butterfly Valves Keystone Us en 5196814Document16 pagesProduct Data Sheet Series 36 37 K Lok High Performance Butterfly Valves Keystone Us en 5196814paivagmNo ratings yet

- Datasheet Flygt 2201 390sh 50hz A4 High En-UsDocument2 pagesDatasheet Flygt 2201 390sh 50hz A4 High En-Usjuan riderNo ratings yet

- Vanessa Basic DatasheetDocument20 pagesVanessa Basic DatasheetM Azri ZulkipliNo ratings yet

- Isogate WR Valves Spec Sheet 202009Document4 pagesIsogate WR Valves Spec Sheet 202009Brayan Oscar Pacora JuroNo ratings yet

- ENG-MKT41 - Roller Cone Drill Bit Brochure - Distribution FileDocument8 pagesENG-MKT41 - Roller Cone Drill Bit Brochure - Distribution FileMarianNo ratings yet

- SH LoDocument16 pagesSH LohepcomotionNo ratings yet

- Sucker Rods Brochure 851 06Document12 pagesSucker Rods Brochure 851 06Ronald LlerenaNo ratings yet

- V Cuch WeirDocument4 pagesV Cuch Weirelectrico_concepcionNo ratings yet

- Kinshofer Rotator Line Product FeaturesDocument5 pagesKinshofer Rotator Line Product FeaturesHOryshorNo ratings yet

- Torishima CDM200 1400Document6 pagesTorishima CDM200 1400Peterson TsaoNo ratings yet

- PEDJ0193-04 FINAL - Low ResDocument16 pagesPEDJ0193-04 FINAL - Low ResCarlos Indigoyen LimaymantaNo ratings yet

- Quick Disconnect Couplings & Hydraulic ValvesDocument14 pagesQuick Disconnect Couplings & Hydraulic ValvesLto 750No ratings yet

- Bnr/Ber Robust Series: High-Speed Precision Angular Contact Ball Bearings For Machine Tool SpindlesDocument16 pagesBnr/Ber Robust Series: High-Speed Precision Angular Contact Ball Bearings For Machine Tool SpindlesMEPRO Chiriac C.No ratings yet

- T 720 PG 189-190 PDFDocument2 pagesT 720 PG 189-190 PDFJossimar PerezNo ratings yet

- 0634 BIR54C 91001897 SpecDocument1 page0634 BIR54C 91001897 Speckevin salasNo ratings yet

- Goulds API 3600 i-FRAME: API BB3 Between-Bearing, Axially Split, Multistage PumpDocument12 pagesGoulds API 3600 i-FRAME: API BB3 Between-Bearing, Axially Split, Multistage PumpJean Peak100% (1)

- Sepulveda ProForma Order# 1044329Document2 pagesSepulveda ProForma Order# 1044329Juan AcostaNo ratings yet

- Harness D9RDocument8 pagesHarness D9RJuan AcostaNo ratings yet

- CB534D JoystickDocument2 pagesCB534D JoystickJuan AcostaNo ratings yet

- D9R BombaDocument2 pagesD9R BombaJuan AcostaNo ratings yet

- Swing Drive 330LDocument2 pagesSwing Drive 330LJuan AcostaNo ratings yet

- Tapa Fusibles CB534D EAA165Document2 pagesTapa Fusibles CB534D EAA165Juan AcostaNo ratings yet

- D9R Head Cylinder SensorsDocument2 pagesD9R Head Cylinder SensorsJuan AcostaNo ratings yet

- 980G Hydro-Electrical ControlDocument3 pages980G Hydro-Electrical ControlJuan AcostaNo ratings yet

- 140H Console HarnessDocument2 pages140H Console HarnessJuan AcostaNo ratings yet

- 966H TransmissionDocument4 pages966H TransmissionJuan AcostaNo ratings yet

- Gomaco GT3400 Smart Cylinder CableDocument2 pagesGomaco GT3400 Smart Cylinder CableJuan AcostaNo ratings yet

- Twin Disc PartsDocument22 pagesTwin Disc PartsJuan AcostaNo ratings yet

- M Motors (Cat Ref KPMUK Dated Sept 05) PDFDocument35 pagesM Motors (Cat Ref KPMUK Dated Sept 05) PDFJuan Acosta100% (1)

- 3600NG04 Gomaco Curb & GutterDocument26 pages3600NG04 Gomaco Curb & GutterJuan AcostaNo ratings yet

- ADP-020B User Manual - ADM PDFDocument47 pagesADP-020B User Manual - ADM PDFJuan AcostaNo ratings yet

- Whitehall Versalette - 41" WideDocument2 pagesWhitehall Versalette - 41" Widecvl1983No ratings yet

- A. True: B.FalseDocument4 pagesA. True: B.FalseSnigdha YadavNo ratings yet

- CE Board Nov 2020 - RCD - Set 16Document1 pageCE Board Nov 2020 - RCD - Set 16Dale MalazzabNo ratings yet

- Post Installed RebarsDocument41 pagesPost Installed RebarsGaurav ChobeNo ratings yet

- 11kV Transmission Line Material - ListDocument1 page11kV Transmission Line Material - ListS Rao CheepuriNo ratings yet

- Ed 03 (EN)Document38 pagesEd 03 (EN)Mesafint kassieNo ratings yet

- Tai3 FDP PDFDocument2 pagesTai3 FDP PDFbathinsreenivasNo ratings yet

- The Effect of Delaminations On Local Buckling in Wind Turbine BladesDocument11 pagesThe Effect of Delaminations On Local Buckling in Wind Turbine BladesVinaasha BalakrishnanNo ratings yet

- Metro Rail Design Criteria Section 08 Mechanical Rev 1 051812 PDFDocument60 pagesMetro Rail Design Criteria Section 08 Mechanical Rev 1 051812 PDFJoydipto BoseNo ratings yet

- AS3600 Punching - PS1Document1 pageAS3600 Punching - PS1Yugatheeran ThavaratnasingamNo ratings yet

- Mix Design - M 20Document5 pagesMix Design - M 20Vijay Jamadar0% (1)

- NOMAD Micro HouseDocument16 pagesNOMAD Micro HouseMilanStojanovicNo ratings yet

- Structural Anaylsis-IDocument5 pagesStructural Anaylsis-IPiyush BhandariNo ratings yet

- 3.3 Water - Tube BoilersDocument153 pages3.3 Water - Tube BoilerstespakNo ratings yet

- Archicad Tutorial RoofDocument14 pagesArchicad Tutorial Roofmuthuricollins771No ratings yet

- Test Grease ConductorDocument22 pagesTest Grease ConductorGirinda BayuNo ratings yet

- C749-13 Standard Test Method For Tensile Stress-Strain of Carbon and GraphiteDocument12 pagesC749-13 Standard Test Method For Tensile Stress-Strain of Carbon and Graphiteastewayb_964354182No ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSathish Kumar SelvarajNo ratings yet

- ABAQUS Tutorial: Dr. Ahmed ElkadyDocument6 pagesABAQUS Tutorial: Dr. Ahmed ElkadyHuseinNo ratings yet

- Appendix 1 - Guidance On Timber Frame WallsDocument5 pagesAppendix 1 - Guidance On Timber Frame WallsIsabel BarrosNo ratings yet

- Canopy Glass Thickness PDFDocument1 pageCanopy Glass Thickness PDFRufus ChengNo ratings yet

- Explanatory Note To The Project of A Commercial Building Floor PlanDocument5 pagesExplanatory Note To The Project of A Commercial Building Floor PlanJanina MatanguihanNo ratings yet

- Experimental Study On Strength Behaviour of Plastic Sand BricksDocument4 pagesExperimental Study On Strength Behaviour of Plastic Sand Brickstesfalem kiros100% (1)

- 06 CE 015 - Shear and Torsion - v2 - StuDocument30 pages06 CE 015 - Shear and Torsion - v2 - StuRalp GumilingNo ratings yet

- Denver 3Document43 pagesDenver 3Maswiyat IftekharNo ratings yet

- Alia AUF610 Portable FlowmeterDocument4 pagesAlia AUF610 Portable FlowmeterRexCrazyMindNo ratings yet

- En Iso 13370Document92 pagesEn Iso 13370Mihai Strimbu100% (2)

- V404-COASTAR ESTATES VILLA - A (Final)Document41 pagesV404-COASTAR ESTATES VILLA - A (Final)hat1630No ratings yet

- Nozzles: Reference: Chapter 10 in Eastop Et Al BookDocument12 pagesNozzles: Reference: Chapter 10 in Eastop Et Al BookAnonymous j642lUpl3No ratings yet